Transcription

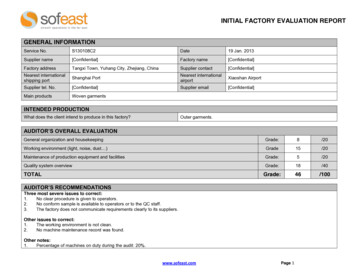

INITIAL FACTORY EVALUATION REPORTGENERAL INFORMATIONService No.S130108C2Date19 Jan. 2013Supplier name[Confidential]Factory name[Confidential]Factory addressTangxi Town, Yuhang City, Zhejiang, ChinaSupplier contact[Confidential]Nearest internationalshipping portShanghai PortNearest internationalairportXiaoshan AirportSupplier tel. No.[Confidential]Supplier email[Confidential]Main productsWoven garmentsINTENDED PRODUCTIONWhat does the client intend to produce in this factory?Outer garments.AUDITOR’S OVERALL EVALUATIONGeneral organization and housekeepingGrade:8/20Working environment (light, noise, dust )Grade15/20Maintenance of production equipment and facilitiesGrade:5/20Quality system overviewGrade:18/40Grade:46/100TOTALAUDITOR’S RECOMMENDATIONSThree most severe issues to correct:1.No clear procedure is given to operators.2.No conform sample is available to operators or to the QC staff.3.The factory does not communicate requirements clearly to its suppliers.Other issues to correct:1.The working environment is not clean.2.No machine maintenance record was found.Other notes:1.Percentage of machines on duty during the audit: 20%.www.sofeast.comPage 1

INITIAL FACTORY EVALUATION REPORT2.The factory does not have an export license.A. FACTORY PROFILEDate of establishment13 Oct. 1994Certificate No:Business licenseHangzhou Jiexheng GarmentFactoryGrace WangAnnual turnover for the past3 years:NoIs the factory part of a group?Issuing date:Expiration date:13 Oct. 199412 Oct. 2024Export sales turnover onlyTotal sales turnover20128 Million USD8 Million USD20118.6 Million USD8.6 Million USD20008.5 Million USD8.5 Million USDB. MAJOR CUSTOMERSCustomer nameCustomercountryBrand under whichproducts were soldType(s) of productLast year totalquantityPercentage of total factoryproductionJC PENNEYAmericaJC PENNEYWomen garments500,000 pcs50%MANGOSpainMANGOWomen garments150,000 pcs15%ZARASpainZARAWomen garments100,000 pcs10%BVAustraliaEVENTSWomen garments10,000 pcs3%C. NUMBER OF EMPLOYEESTotalemployeesManagement &administrationProductionQualitycontrolDesign &printingTotal kingengineersOther(logistics,canteen )2503020020653521www.sofeast.comPage 2

INITIAL FACTORY EVALUATION REPORTD. WORKING TIMEOperating hoursNo. of hours / shiftNo. of shifts per dayNo. of shifts per weekNo. of days off / monthMax overtime / month8 hours815924E. LEAD TIMES (for an average order, for the client’s intended production, according to the factory)Peak production monthsSlow production monthsOctober to FebruaryMarch to SeptemberNo. of days from reception ofPO to reception of allmaterials & componentsNo. of days needed for themanufacturing processes30-45 days60-90 daysSize of average order(used for estimate)2,000 to 5,000 pcsMain components / materials for the client’s intended productionComponent / materialSourcing area (province, country)Lead time to receive after orderingCottonZhejiang & Jiangsu Province30 daysSilkZhejiang & Jiangsu Province30 daysPolyesterZhejiang & Jiangsu Province35-40 daysZipper & Button & LabelsZhejiang7-10 daysF. PROCESS STEPSProcess stepName of process stepNumber of machines (total)Number of operators7 cutting machines41Fabric cutting2Sewing80 sewing machines283Button12 machines64Iron7 Irons55Final inspection-46Tagging & trimming10 Swift guns67Packing1 metal detector & 1 strapping machine8www.sofeast.comPage 3

INITIAL FACTORY EVALUATION REPORTDetails of process steps on 1 line on duty (from components to packing)Notes for auditor: Please choose a line that makes the products closest to the client’s product.Process step 1Fabric cuttingMachine nameNo. of machinesNo. of workersDaily capacityCutting machine221,000-1,500 setswww.sofeast.comPage 4

INITIAL FACTORY EVALUATION REPORTProcess step 2SewingMachine nameNo. of machinesNo. of workersDaily capacitySewing machine187About 120 pcsProcess step 3Button attachingMachine nameNo. of machinesNo. of workersDaily capacityButton sewing machine126About 1,500 pcswww.sofeast.comPage 5

INITIAL FACTORY EVALUATION REPORTProcess step 4IroningMachine nameNo. of machinesNo. of workersDaily capacityIron75About 1,500 pcsProcess step 5Final inspectionMachine nameNo. of machinesNo. of workersDaily capacityN/AN/A4About 1,500 pcswww.sofeast.comPage 6

INITIAL FACTORY EVALUATION REPORTProcess step 6Tagging & trimmingMachine nameNo. of machinesNo. of workersDaily capacityNeedles and scissorsN/A6About 1,500 pcsProcess step 7PackingMachine nameNo. of machinesNo. of workersDaily capacityPacker & metal detection tester1 packer, 1 metal detection tester8About 1,500 pcswww.sofeast.comPage 7

INITIAL FACTORY EVALUATION REPORTNotes from auditor:- Percentage of machines on duty during the audit: 20 %- For ironing, button attaching and packing: no process running at time of audit. Factory claimed these workers were home due toabsence of work that day.- Some machines were not kept clean and were not maintained in good condition.AUDITOR’S EVALUATIONGeneral organization and housekeepingGrade:8/20Working environment (light, noise, dust )Grade15/20Maintenance of production equipment and facilitiesGrade:5/20Grade:28/60TOTALG. QUALITY SYSTEM OVERVIEWNotes for auditor: Please choose a line that makes the products closest to the client’s product.CheckpointsComments and evaluations from auditorDoes the factory communicate requirements to its suppliers on its POs (orother documents)? Are requirements clearly listed?No, the factory does not communicate requirements clearly.The factory said they just call suppliers to arrange deliveries, and theycommunicate requirement on the phone.Are incoming QC (IQC) results recorded in a formal report / registry?Yes, IQC results are recorded in reports. See below.www.sofeast.comPage 8

INITIAL FACTORY EVALUATION REPORTIncoming QC recordIncoming QC recordIncoming QC recordAre clear procedures given to each operator, for each job / task (including the No clear procedure is given to each operator.QC staff)?Order details (see below) were given to line leaders and to QC employees.Order details given to line leader & QC employeesNo conform sample is available to operators.Are conform samples available to workers in production and QC areas?No conform sample is available to QC employees.Are in-process QC (IPQC) results recorded in a formal report / registry?In-process QC recordYes, IPQC results are recorded in reports. See below.In-process QC recordwww.sofeast.comIn-process QC recordPage 9

INITIAL FACTORY EVALUATION REPORTIn-process QC under wayIn-process QC under wayDoes Final QC (FQC) occur before packing is completed?Final QC under wayIn-process QC under wayFQC takes place before packing is completed.FQC under wayDefective products areaWhat proportion of products is checked during FQC?100% of pieces are inspected, according to factory.Are there QC staff solely dedicated to FQC? How many?Do they only do QC, or also a finishing operation at the same time?There are 4 QC employees solely dedicated to IPQC.There are 4 QC employees solely dedicated to FQC.They do QC and threads trimming.www.sofeast.comPage 10

INITIAL FACTORY EVALUATION REPORTFinal QC under wayAre FQC results recorded in a formal report / registry?FQC result recordFinal QC under wayFinal QC areaYes, FQC results are recorded.FQC result recordFQC result recordEVALUATION FROM AUDITORQuality system overviewGrade:www.sofeast.comPage 1118/40

INITIAL FACTORY EVALUATION REPORTH. OBSERVATION OF FACILITIESGate of the factoryFactory overviewFactory overviewReceptionOfficeOfficewww.sofeast.comPage 12

INITIAL FACTORY EVALUATION utting linewww.sofeast.comPage 13

INITIAL FACTORY EVALUATION REPORTIroning lineSewing lineSewing lineSewing lineLabelingFabric storagewww.sofeast.comPage 14

INITIAL FACTORY EVALUATION REPORTMaterials & accessories in stockMaterials & accessories in stockMaterials & accessories in stock--Semi-finished products storageSemi-finished products storagewww.sofeast.com--Page 15

INITIAL FACTORY EVALUATION REPORTI. PHOTOS OF IMPORTANT DOCUMENTSBusiness licenseTax licenseOrganization code license***Note: Note that the actual report you will receive will go into the same level of detail but might be different in format.www.sofeast.comPage 16

No conform sample is available to operators or to the QC staff. 3. The factory does not communicate requirements clearly to its suppliers. Other issues to correct: 1. The working environment is not clean. 2. No machine maintenance record was found. Other notes: 1. Percentage of machines on duty during the audit: 20%. INITIAL FACTORY EVALUATION REPORT Page www.sofeast.com 2 2. The factory does .