Transcription

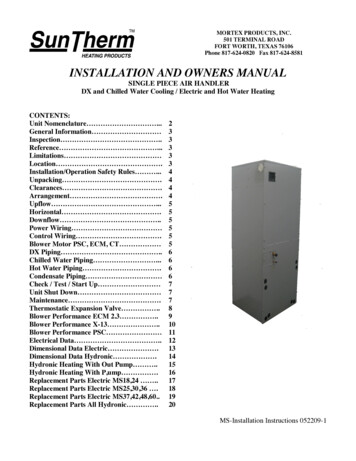

MORTEX PRODUCTS, INC.501 TERMINAL ROADFORT WORTH, TEXAS 76106Phone 817-624-0820 Fax 817-624-8581INSTALLATION AND OWNERS MANUALSINGLE PIECE AIR HANDLERDX and Chilled Water Cooling / Electric and Hot Water HeatingCONTENTS:Unit Nomenclature .General Information Inspection .Reference .Limitations Location .Installation/Operation Safety Rules .Unpacking .Clearances .Arrangement .Upflow .Horizontal .Downflow .Power Wiring Control Wiring .Blower Motor PSC, ECM, CT DX Piping .Chilled Water Piping .Hot Water Piping .Condensate Piping Check / Test / Start Up Unit Shut Down Maintenance .Thermostatic Expansion Valve .Blower Performance ECM 2.3 .Blower Performance X-13 .Blower Performance PSC Electrical Data .Dimensional Data Electric .Dimensional Data Hydronic .Hydronic Heating With Out Pump .Hydronic Heating With P,ump .Replacement Parts Electric MS18,24 .Replacement Parts Electric MS25,30,36 .Replacement Parts Electric MS37,42,48,60.Replacement Parts All Hydronic -Installation Instructions 052209-1

MORTEX PRODUCTS, INC.501 TERMINAL ROADFORT WORTH, TEXAS 76106Phone 817-624-0820 Fax 817-624-8581SINGLE PIECE AIR HANDLER INSTALLATION INSTRUCTIONSDX and Chilled Water Cooling / Electric and Hot Water Series:MS Multi-position Single PieceUS Upflow Single PieceMotor Type:PS Standard PSCVT Variable Speed Constant TorqueVE Variable ECM (Electronic Commutated Motor)Unit Size (Capacity In MBTUH):12 Thru 24 Small Cabinet (42)25 Thru 36 Medium Cabinet (45)37 Thru 60 Large Cabinet (18)OS No Cooling Small Cabinet (42)OM No Cooling Medium Cabinet (42)OL No Cooling Large Cabinet(18)Heating Configuration:00 Cooling OnlyXX Electric Heating Capacity In KW2P 2 Row HW Coil With Pump3P 3 Row HW Coil With Pump4P 4 Row HW Coil With Pump2N 2 Row HW Coil No Pump3N 3 Row HW Coil No Pump4N 4 Row HW Coil No PumpVoltage:A 120v 1 Ph. 50/60 Hz.B 208/230v 1 Ph. 50/60 Hz.Contact Factory For Other Voltage AvailabilityEvaporator Coil Configuration:862T DX Coil Geometry And Metering Device (Refer To Coil Nomenclature)8K2N CW Coil Geometry (Refer To Coil Nomenclature)Option Code:AA Standard Configuration Motor Code Pre-Painted Gray Top & Front, Embossed Galvanized Wrapper Standard Coil 1” InsulationMS-Installation Instructions 052209-2

MORTEX PRODUCTS, INC.501 TERMINAL ROADFORT WORTH, TEXAS 76106Phone 817-624-0820 Fax 817-624-8581SINGLE PIECE AIR HANDLER INSTALLATION INSTRUCTIONSDX and Chilled Water Cooling / Electric and Hot Water HeatingGENERAL INFORMATIONThis single piece air handler provides the flexibility forinstallation in any upflow, downflow, or horizontalapplication. These versatile models may be used with orwithout electric or hot water heat. The direct drive 3 speedor optional ECM or CT variable speed motors provide aselection of air volume to match any application.The unit can be positioned for bottom return air in theupflow position, top return air in the downflow positionand end return air in the horizontal position.NOTE: See field installed down flow conversion kitinstallation instructions.INSPECTIONAs soon as a unit is received, it should be inspected forpossible damage during transit. If damage is evident, theextent of the damage should be noted on the carrier’sdelivery receipt. A separate request for inspection by thecarrier’s agent should be made in writing. See localDistributor for more information. Summit Manufacturingassumes no liability for freight damage.Installation of accessories or field conversion should beaccomplished before setting the unit in place or connectionany wiring, electric heat, duct, or piping.REFERENCEThis instruction should be used in conjunction withinstructions supplied with each field installed accessory aswell as outdoor section.Installer should pay particular attention to the words;NOTE, CAUTION, and WARNING.NOTES are intended to clarify or make the installationeasier.A CAUTION identifies procedure which, if not followedcarefully, could result in personal injury, property damageor product damage.A WARNING is given to alert the installer that severpersonal injury, death or equipment damage may result ifinstallation procedures are not handled properly.LIMITATIONSThese units must be wired and installed in accordance withall national and local codes. Voltage limits are as follows.Air mal Oper.Voltage Range104-126187-253LOCATIONLocation is usually predetermined. Check with owner’s ordealer’s installation plans. If location has not beendecided, consider the following in choosing a suitablelocation.1. Select a location with adequate structural support,space for service access, clearance for return andsupply duct connections.NOTE: Service access is generally specified by localcodes.2. Normal operating sound levels may beobjectionable if the air handler is placed directlyover some rooms such as bedrooms, study, etc.3. Precautions should be taken to locate the unit andduct work so that supply air does not short circuitto the return air.4. Select a location that will permit installation ofcondensate drain line to an open drain.NOTE: When the coil is installed in a draw-thruapplication, it is recommended to trap the primary andsecondary drain line. If the secondary drain is not used, itmust be capped.5.6.7.When the evaporator coil is installed in an attic orabove a finished ceiling, an auxiliary drain panshould be provided under the coil as is specifiedby most local building codes.Proper electrical supply must be available.Clearances must also be taken into consideration,and provided for as follows:a. Refrigerant piping and connections arelocated in the front.b. Maintenance and servicing through thefront or access side of the unit with bothsides and rear of unit having zeroclearance.c. Condensate drain lines are connected inthe front (clear of filter).d. When no electric heat is used, the unit aswell as all duct work and plenum aredesigned for zero clearance tocombustible materials.CAUTIONIf electric heat is used, a minimum clearance of 1”Must be maintained on all sides of the supply airDuct and/or plenum continuously for up to 3’MS-Installation Instructions 052209-3

MORTEX PRODUCTS, INC.501 TERMINAL ROADFORT WORTH, TEXAS 76106Phone 817-624-0820 Fax 817-624-8581SINGLE PIECE AIR HANDLER INSTALLATION INSTRUCTIONSDX and Chilled Water Cooling / Electric and Hot Water HeatingINSTALLATION/OPERATION SAFETY RULES:1. Read these rules and instructions carefully.Failure to follow these rules and the installationinstructions could cause a malfunction of the unit,and a possible safety hazard. Keep theseinstructions nearby the unit for future reference.2. While this unit has been designed andmanufactured to comply with National codes, it isthe installer’s responsibility to install this unit tocomply with National codes and/or prevailinglocal codes and regulations. Suntherm assumes noresponsibility for units installed in violation ofany code or regulation.3. Before servicing, allow unit to cool.WARNING:ALWAYSSHUTOFFELECTRICITY WHEN WORKING ON UNIT.This will prevent any electrical shocks or burns.4. Ground the unit to prevent electric shock. Allelectrical wiring should be in accordance with theNational Electric Code.5. Duct work must be installed in accordance withthe standards of the National Fire ProtectionAssociation (NFPA) for the installation of AirConditioning, Warm Air Heating and VentilatingSystems (NFPA 90A and 90B). Duct work innon-conditioned spaces must be insulated toprevent formation of condensate and formaximum efficiency.6. The safety testing agency label appearing on theseunits covers the unit and factory installed coil (ifprovided) only. It does not cover any otherequipment. Exterior surface of cabinet may sweatwhen units is installed in a non-conditioned spacesuch as an attic or garage. Installer must provideprotection such as full size auxiliary drain pan onall units installed in a non-conditioned space toprevent damage from condensation runoff. It isrecommended that units installed in nonconditioned spaces be insulated with 1” thickfiberglass with the vapor barrier on the outside.7. While designed to operate quietly when properlyinstalled, several steps should be taken insure this.Use of isolation pads when mounting unit,flexible duct collars for discharge, and use ofacoustical duct liners are all good installationpractices that promote quite operation.8.Cabinet insulation is rated for R-4.2 (standard).Some jurisdictions require R-6.0 on installationsin a non-conditioned space. Add insulation 1”thick to exterior of unit to comply in thesejurisdictions, putting the vapor barrier on theoutside.WARNING:Hot water can scald. Water heated to a temperaturewhich will satisfy space heating can scald andpermanently injure a person upon contact. Some peopleare more likely to be permanently injured by hot waterthan others. These include the elderly, children, theinfirm, physically or mentally handicapped.Check local, State, and National codes requiring acertain temperature water at the hot water tap. Specialprecautions must be used in addition to using the lowestpossible temperature setting that satisfies your hot waterneeds. A Tempering device such as a mixing valve,should be used at the hot water taps, or water heater.UNPACKING THE UNIT:The unit should be unpacked on receipt and if any damageis found, follow the instructions under “INSPECTION”on page 1.This air handler is completely assembled. (NOTE: Electricheat can be ordered as factory or field installed, if fieldinstalled, refer to the separate installation instructionsprovided with the heat kit.) Only electrical power,thermostat wiring, hot water piping (if applicable) andduct connections are needed for installation. DX coils willalso require refrigerant and condensate drain connections.Some units may have motor supports over the motor shaft.Remove these supports as necessary.MINIMUM CLEARENCES:These units have a 0” minimum clearance to combustiblematerials rating from all cabinet surfaces. The unit shouldbe installed with serviceability clearance of 30” from thefront of the unit. The unit can be services entirely from thefront, including replacing the filter. Be sure to routeprimary and secondary condensate drain piping so as notto obstruct replacement of filter.ARRANGEMENT:Unit is shipped from the factory arranged to be installed ina vertical upflow or horizontal right to left air flowposition (standard) or field convertible to a horizontal leftto right air flow position.MS-Installation Instructions 052209-4

MORTEX PRODUCTS, INC.501 TERMINAL ROADFORT WORTH, TEXAS 76106Phone 817-624-0820 Fax 817-624-8581SINGLE PIECE AIR HANDLER INSTALLATION INSTRUCTIONSDX and Chilled Water Cooling / Electric and Hot Water HeatingUPFLOW APPLICATION:In an upflow installation the discharge outlet is at the top.Care should be taken to insure unit is level to permitproper condensate drainage. Normal upflow installationwill be in a closet or basement. If installed in a closet, thecloset should have a platform framed in, with an openingat the top of the platform centered in the closet. Connectthe supply air outlet to a plenum. Install return air grillesfrom outside the closet to space below the platform.Platform must be at least 12” above the floor. If installedin a basement, run supply and return duct work inaccordance with local codes.HORIZONTAL APPLICATION:Horizontal applications will normally be used in an attic orcrawl space. This type of installation requires a return airduct be attached to the unit inlet. The opposite end of thereturn air duct is attached to a return air filter grille throughthe ceiling or wall. Remove air filter from unit if filtergrille is used. The unit is shipped in right to leftconfiguration. For left to right applications (beforeconnecting drains, refrigerant or water piping) remove coiland doors and move horizontal pan to right side. Reinstallcoil and doors.DOWNFLOW APPLICATION:Contact distributor for proper downflow conversion kit.Hydronic heat units cannot be used in the down flowposition.CAUTION:It is mandatory to use an emergency auxiliary drain panwith any coil or air handler installed in an attic or abovea finished ceiling.ELECTRICAL WIRING:Refer to the unit nameplate for specific electrical data.CAUTION:Disconnect power at main fuse or circuit breakerdistribution panel before wiring unit to prevent shock orfire hazard.POWER WIRING:Unit is suitable for use with copper conductors. Tighten allwire connectors. Take care not to damage heater ceramicinsulators on electric heat models. For correct field wiresize see unit nameplate and field wiring table insideelectrical compartment door. Use 75 C minimum wire inunit wiring compartment. Units larger than 10 KW willrequire multiple sets of power conductors.NOTE: See unit for complete wiring diagram located onblower housing.CONTROL WIRING:Field connections to the low voltage leads are made usingappropriate field supplied wiring connectors. Consultinstallation instructions provided with accessory items forspecific information on control wiring. Use 18 AWGminimum copper conductors for control wiring up to 50’between units. 16 AWG control conductors arerecommended for lengths between 50’ and 100’. Class 2wiring is acceptable. Take care not to short control leads,transformer burnout could result. Some manufacturer’soutdoor units are equipped with a 24 volt controltransformer. If this type of outdoor unit is used with thisair handler, use a thermostat with isolating contacts toprevent inter-connection of two separate Class 2 circuits.Set thermostat heat anticipator at 0.15 amps for units12KW or smaller, set at .30 amps for 15 KW and larger.BLOWER MOTOR:CONSTANT SPEED MOTOR:Two factory selected motor speed leads are connected tothe blower relay to provide automatic speed change forheating and cooling airflow volumes. The pre-selectedmotor speeds would normally not have to be changed inthe field. All models contain a blower time delay relay(TDR 10-30 seconds) that delays the blower turning onand off when the thermostat calls for “Fan Only” or“Cooling”. The TDR improves energy efficiency.VARIABLE SPEED MOTORS:Electronic commutated and constant torque motors arefactory programmed and cannot be re-programmed in thefield. ECM motors have (4) jumper settings, and CTmotors have (5) speed taps. Refer to blower performancedata located in the SunTherm Technical Guide forselection of jumper or tap settings that best fits thisapplication.NOTE: All 208/230 volt motors are factory programmedfor “0” second fan “ON” delay for use with electric heat.Motor must energize with electric heat. All 115 voltmotors are factory programmed for “30” second fan “ON”delay for use with hydronic heat.MS-Installation Instructions 052209-5

MORTEX PRODUCTS, INC.501 TERMINAL ROADFORT WORTH, TEXAS 76106Phone 817-624-0820 Fax 817-624-8581SINGLE PIECE AIR HANDLER INSTALLATION INSTRUCTIONSDX and Chilled Water Cooling / Electric and Hot Water HeatingPIPING:DX REFRIGERANT PIPING:Air handlers with DX type evaporator coils require liquidand suction piping sized in accordance with condensingunit manufacturer’s recommendations. The evaporatorcoils have sweat copper connections. Refrigerant linesshould be soldered with silver solder or other hightemperature brazing alloy. The suction must be insulatedfor satisfactory operation. An oil trap must be installed inall vertical suction risers. An additional oil trap must beinstalled every 15’ for risers over 15’ in height. If thecondensing unit is located over the evaporator coil, an“inverted” oil trap must be installed at the top of thesuction riser. Horizontal suction line runs should be sloped1” every 20’ toward the condensing unit. The manufacturerrecommends that dry nitrogen be flowed through therefrigerant lines during the soldering operation. Liquid lineis capped. NOTE: Pressure drop in liquid must not exceed30 psi or erratic operation and thermostatic expansiondamage will occur.CHILLED WATER PIPING:All piping must be supported independent of coils toprevent vibration and stress on coil headers. Swing jointsor flexible fittings must be provided to absorb expansionand contraction strains. Rigid piping reduces theeffectiveness of vibration isolators.Water piping should always be connected so that theentering water is on the leaving side of the coil. Coils mustbe adequately vented in order to prevent air binding. Unitsare provided with manual air vents mounted through themanifold panel.HOT WATER PIPING:If a residential water heater is used for space heating water,do not exceed a distance of 70’ between the air handler andthe water heater. The water heater should be the quickrecovery type. Air handler and water heater must belocated indoors and not subject to freezing temperatures.WARNING:Air handler must be located so that if any connectionsshould leak, water will not cause damage to the adjacentarea. When such locations can’t be avoided, a suitabledrain pan should be installed under the air handler, notover 1-1/2” deep, with minimum length and width at least2” greater than the air handler dimensions andconnected to an adequate drain. Under no circumstancesis the manufacturer to be held libel for any water damagein connection with this air handler.HOT WATER PIPING: Continued).Total piping should not exceed 140’. All piping should be¾” copper or approved PVC. It is recommended that thewater shut-off valve for the water heater be located closeto the water heater. Isolation valves are alsorecommended.It is recommended that any devices installed, which couldcreate a closed system, have a by-pass and/or the systemhave an expansion tank to relieve the pressure built up bythermal expansion in the water system.WARNING:Toxic chemicals such as used for treatment of boilers ornon-potable water heating appliances shall never beintroduced into a potable water space heating system.WARNING:When the system required water at temperatures higherthan required for other uses, a means such as a mixingvalve shall be installed to temper the water for those usesin order to reduce the scald hazard potential.After piping has been installed, allow the system to fillwith water and check connections for leaks. To insurecomplete filling of the system, follow start-up procedure.CONDENSATE DRAIN PIPING:The air handler “A” coil drain pan has two ¾” NPTfemale primary and two secondary connections (left orright hand). Horizontal pan has two ¾” NPT female, oneprimary and one secondary. Piping from each fitting usedis to have 1-1/2 minimum trap and each run in such amanner as to provide enough slope for adequate drainageto a visible area. Do not pipe these two fittings togetherinto a common drain. Cap unused connection.PVCPIPETypical Condensate TrapsAIR FILTER:A clean, appropriately sized filter must be used or systemdamage will occur. Filters are not supplied with this airhandler, a field installed filter accessory is available.MS-Installation Instructions 052209-6

MORTEX PRODUCTS, INC.501 TERMINAL ROADFORT WORTH, TEXAS 76106Phone 817-624-0820 Fax 817-624-8581SINGLE PIECE AIR HANDLER INSTALLATION INSTRUCTIONSDX and Chilled Water Cooling / Electric and Hot Water HeatingCHECK TEST AND START UP:UNITS WITH ELECTRIC HEAT:The unit should be tested after the system has beencompletely installed to determine proper operation. Unit isequipped with heater time delay controls. All heatingelements should turn on within one minute.NOTE:Circuit breakers are equipped with a visual “visi-trip” redflag indicator. If red indicator shows that circuit breakerhas tripped, this indicated that a problem exists in yoursystem which should be corrected before resettingbreaker.UNITS WITH HOT WATER HEATING:SYSTEM SHUT-DOWN:For short periods of time during freezing temperatures ifthe system is to be left unused, to prevent freezing of theair handler and piping, do the following. Do not turn thesystem off, and the air handlers thermostat left on the heatsetting. If the water heater and air handler must be shutdown for extended periods, a qualified service technicianshould insure that the air handler and coil are completelydrained of waterPERIODIC MAINTENANCE:The filter must be changed monthly to permit properairflow for safe and efficient operation. All othermaintenance should be performed by a licensedtechnician.NOTE:Heating system should not be switched on until system isfilled and hot water coil vented.1.2.3.4.5.6.Fill and pressurize the water heater and airhandler.The water heater should be started.Vent air from the water tank by opening a hotwater spigot.Vent and flush the supply and return lines byattaching a hose to the volume purge valve andrunning purge water to a safe location. Runapproximately 5 gallons of water at a high flowrate to purge.Energize the unit by switching on the line voltagesource and the thermostat. The fan and pumpshould start simultaneously. The water coil shouldbecome warm after a few minutes of operation.Units are rated at temperatures of 130 -180 F.Set water source temperature at designtemperature and take proper safeguards for waterusage at supply points as per local codes andsafety considerations.MS-Installation Instructions 052209-7

MORTEX PRODUCTS, INC.501 TERMINAL ROADFORT WORTH, TEXAS 76106Phone 817-624-0820 Fax 817-624-8581SINGLE PIECE AIR HANDLER INSTALLATION INSTRUCTIONSField Installed Thermal Expansion Valve Kit Non-Bleed.INTRODUCTION:Thermal expansion valve (TXV) can be used on both heatpump and air conditioning applications. All TXV’s have abuilt in check valve making them heat pump capable. Allare externally equalized with non-adjustable superheat andare available with 15% bleed construction. Hard startcapability for outdoor units is not normally required when15% bleed valve is used. The external equalizer lineattached to the TXV has a female flare nut with built inSchrader valve depressor that attaches to the Schradervalve port provided on coils.INSTALLATION STEPS: (Continued).6.a.b.APPLICATION DATA:R72DB0005 (R-22) 15% Bleed 1.5-3.0 tonsR72DB0003 (R-410A)Outlet male Rotalock. Outlet female swivel nut.R72DB0006 (R-22) 15% Bleed 3.0-5.0 tonsR72DB0004 (R-410A)Outlet male Rotalock. Outlet female swivel nut.INSTALLATION NOTES:With reference to the figure at right, the TXV assembly isto be installed between the flowrator distributor and theexisting liquid line attached to the flowrator distributor.c.7.Install the TXV bulb to the suction manifold ofcoil or the suction line using the two bulb clampsfurnished with kit.Bulb should be installed on a horizontal run ofthe manifold if possible. On line less than 7/8”OD the bulb may be installed on top of the line.With 7/8” OD and over, the bulb should beinstalled in a position at about 4 or 8 o’clock.If bulb installation is made on a vertical run, thebulb should be located at least 6 inches from anybend, and on the tubing side opposite the plane ofthe bend. On vertical bulb installations, the bulbshould be positioned with the bulb capillary tubeat the top.The bulb should be insulated using thermalinsulation to protect it from the effect of thesurrounding ambient temperature.After completing installation of TXV (includingequalizer tube), it will be necessary to leak checkthe coil and evacuate the coil through the serviceaccess fittings of liquid and suction line valves.WARNING:Coil is pressurized with nitrogen. Relieve pressure beforeinstalling TXV by depressing Schrader valve on coilmanifold.INSTALLATION STEPS:1. After coil pressure has been relieved, turn thefemale swivel nut counter-clockwise to remove.2. 2. Remove the piston from the flowratordistributor fitting using a small diameter wire orpaper clip. ALWAYS REMOVE PISTON FROMDISTRIBUTOR BODY WHEN TXV ISINSTALLED).3. Attach the TXV by connecting the female swivelnut on TXV outlet to the flowrator distributor(aligning Teflon seal first) and torque swivel nutto 10-30 ft. lbs.4. Attach liquid line with female swivel nut to malerotalock fitting on TXV inlet (Aligning Teflonseal first) and torque swivel nut to 10-30 ft. lbs.5. Remove the cap on Schrader valve port on coilmanifold. Attach equalizer tubing with ¼” femaleflare nut that includes depressor to this maleSchrader port. Torque nut to 10-30 ft. lb.MS-Installation Instructions 052209-8

MORTEX PRODUCTS, INC.501 TERMINAL ROADFORT WORTH, TEXAS 76106Phone 817-624-0820 Fax 817-624-8581Model NumberNominalTonsMotorHPMSVE18,24Electric1.5 & 2.00.33MSVE18,24Hydronic1.5 & odel NumberNominalTonsMotorHPMSVE18,24Electric1.5 & 2.00.33MSVE18,24Hydronic1.5 & LOWER PERFORMANCE ECM-2.3 MOTOR AIR FLOWVolts 1 Ph.MotorBlowerCFM @CFM @Jumper50/60 1421B12151214240VB10 X 7C898989D865865A12941255B11311104120VH10 X 7C974942D808769A19571919B15761565240VC12 X 9C14951482D14111385A20142007B18561839120VI12 X 9C16511632D14611440CFM 7590973619001547145113721992180616031407CFM 8285370218711517143213381968178815841396CFM 2383165718471487140913111952176115641385BLOWER PERFORMANCE ECM-2.3 MOTOR AMPSVolts 1 Ph.MotorBlowerAMPS @ AMPS @ AMPS @ AMPS @ AMPS @Jumper50/60 .1901.2701.390240VB10 X 3.200120VH10 X 1.600240VC12 X 5.650120VI12 X 290MS-Installation Instructions 052209-9

MORTEX PRODUCTS, INC.501 TERMINAL ROADFORT WORTH, TEXAS 76106Phone 817-624-0820 Fax 817-624-8581Model NumberNominalTonsMotorHPMSVT18,24Electric1.5 & 2.00.33MSVT18,24Hydronic1.5 & odel NumberNominalTonsMotorHPMSVT18,24Electric1.5 & 2.00.33MSVT18,24Hydronic1.5 & LOWER PERFORMANCE X-13 MOTOR AIR FLOWVolts 1 Ph.MotorBlowerMotorCFM @50/60 416932753120VJ9X637854838587418142846240VE10 X 731059411525124717142872120VK10 X 73108241156513131133921467240VF12 X 93155641661520701147921558120VL12 X 9316414178351935CFM 161417491879CFM 59617231764CFM 6701764CFM 6251694BLOWER PERFORMANCE X-13 MOTOR AMPSVolts 1 Ph.MotorBlowerMotorAMPS @ AMPS @ AMPS @ AMPS @ AMPS @50/60 8400.8700.9000.940240VE10 X 102.620120VK10 X 1.000240VF12 X 3.25023.4403.4803.5903.6603.740120VL12 X 27056.8306.5806.2605.9905.710MS-Installation Instructions 052209-10

MORTEX PRODUCTS, INC.501 TERMINAL ROADFORT WORTH, TEXAS 76106Phone 817-624-0820 Fax 817-624-8581Model NumberNominalTonsMotorHPMSPS18,24Electric1.5 & 2.00.33MSPS18,24Hydronic1.5 & odel NumberNominalTonsMotorHPMSPS18,24Electric1.5 & 2.00.33MSPS18,24Hydronic1.5 & LOWER PERFORMANCE PSC MOTOR AIR FLOWVolts 1 Ph.MotorBlowerMotorCFM @50/60 772120SJ9X6Med815High836Low1087240SB10 X 7Med1280High1448Low930120SK10 X 7Med1206High1412Low1462240SC12 X 9Med1756High2092Low1091120SM12 X 9Med1456High2231CFM 21723202910

MORTEX PRODUCTS, INC. 501 TERMINAL ROAD FORT WORTH, TEXAS 76106 Phone 817-624-0820 Fax 817-624-8581 . condensate drain line to an open drain. NOTE: When the coil is installed in a draw-thru application, it is recommended to trap the primary and secondary drain line. If the secondary drain is not used, it