Transcription

Heavy DutyAir ConditioningService Manual1

Safety Precautions & WarningsServicing Refrigerant Systems1. Always wear the proper protective eyewear and clothing before working on anyrefrigeration system. Remember, refrigerant in the air conditioning system canreach pressures of over 500 PSI – if one of those lines bursts while you’reworking on the system, it can cause serious injury. If refrigerant gets in your eye,it can freeze your eyeball, causing permanent damage or blindness.2. Always wear work gloves whenever you’re working with condensers orevaporators. The aluminum edges are sharp, and can cause serious cuts.3. Always stay clear of the belts and fan blade, and be careful revving the engine ona car with a flex fan – damaged blades have been known to come flying offwithout a moment’s warning.4. Always use a DOT-approved tank for storing used and recycled refrigerants.Look for the Department of Transportation stamp: DOT 4BW or DOT 4BA.5. Always provide plenty of ventilation when using any electrical testing, recycling orrecovery equipment. Avoid breathing any refrigerant vapor, lubricant vapor ormist. Exposure to these (particularly PAG oil mist) may irritate your eyes, noseand throat.6. Always follow the instructions for your recycling equipment; failure to follow thosedirections could end up causing personal injury or damaging your equipment.Never perform any maintenance or service on your recycling equipment while theunit is plugged in (unless directed to do so) or without first consulting withauthorized service personnel. Removing internal fittings and filters can releasepressurized refrigerant. Use care and always wear appropriate safety wear.7. Never use compressed air to leak test or pressure test an R-134a system or R134a service equipment. Under certain conditions, pressurized mixtures of R134a and air can be combustible. Always follow the proper procedures toprevent any safety hazards. In addition, shop air injects moisture into thesystem, and a pressure surge could damage the evaporator.8. Microprocessors and computers are susceptible to damage from electrostaticdischarge. Always use a static strap when working with these components, andalways take the necessary precautions to prevent damage to electroniccomponents.9. Most A/C service manuals indicate that R-12 turns into deadly phosgene gaswhen burned. Recent studies have shown that, while burning R-12 doesn’tchange it into phosgene gas, it does break down into carbonyl fluoride (COF2),carbonyl chlorofluoride (COCIF) with traces of free chlorine (CI2). And, whilebreathing these byproducts isn’t as deadly as breathing phosgene gas, it still canbe very harmful. In large enough concentrations, these byproducts can displaceenough oxygen to cause asphyxiation.10. To prevent cross contamination between refrigerants, verify that the A/C systemhas the correct label and unique service fittings designed for the refrigerant beingused. If you’re ever in doubt, check the system with a refrigerant identifier.2

THEORY OF OPERATIONChapter 1Table of ContentsTheory of Operation:Heat TransferChange of StateLatent HeatBoiling Temperature/Pressure RelationshipR12 vs R134aRefrigerant Boiling Point/Pressure RelationshipBasic Air Conditioning System1-13

THEORY OF OPERATIONHeat TransferHow does an air conditioner make the air feel cooler?To understand how an air conditioner works, first we have to look at some of thephysical principles involved. Let’s begin with heat and heat transfer:Everything you see, touch, taste, smell or hear has a certain amount of heat. Heat isenergy, and everything you’ll run into has some heat. The only exception is at absolutezero, or -460o F. Since you aren’t likely to run into anything quite that cold, let’s assumethat every object has a certain amount of heat.When talking about heat transfer, there really isn’t any such thing as “cold” – sure, an icecube may feel cold to the touch, but actually it just has less heat than your hand that’swhy it feels cold. It’s hard to think of an ice cube having heat, but that’s actually thecase.Now, just for a minute or so, hold the ice cube in your hand. What happens? To beginwith, the ice cube begins to melt. Another thing you’ll notice is your hand gets colder.And wetter. What does all that tell us?That tells us the heat is transferring from your hand to the ice cube. This examplemakes it obvious because the greater the difference in temperature, the faster the heattransfer.1-24

THEORY OF OPERATIONHeat always flows to cold until the temperatures equalBasically, the Second Law of Thermodynamics says: Heat will always flow from awarmer object to a cooler one, until the temperatures become equal.When you held the ice cube in your hand,the heat from your hand began to traveltoward the ice cube. The ice cubeabsorbed heat, causing it to melt. As theheat traveled from your hand, your handbecame colder; slowly, the temperature ofthe ice cube and your hand were trying toequalize. If the ice cube was large enough,and could absorb enough heat, eventuallyyour hand and the ice cube would reach thesame temperature.This drawing shows how heat moves; one ofnature’s laws. Heat always moves from a warm toa cool area – heat flows into the cab in hotweather and flows out in cold weather.That’s the principle behind how an airconditioner cools the air in your machine:by flowing warm air over a coldevaporator, the heat from the air flows tothe cold evaporator, making the air lesshot. The heat from the air flows into theevaporator fins, and from there into thecold refrigerant. The refrigerant carriesthe heat away from the evaporator,cooling the evaporator so it can cool moreair.The evaporator absorbs heat while the condenserreleases heat.1-35

THEORY OF OPERATIONThis picture shows the direction of refrigerant and engine coolant flow in the system.The air conditioner evaporator coil and condenser, and the heater core, are the mainpoints of heat transfer.1-46

THEORY OF OPERATIONChange of StateHeat transfer can force matter to change its stateAll matter exists in three states: solid, liquid andgas. That’s an important point to remember whenlooking at how an air conditioner works.Remember what happened to your hand whenyou held onto the ice cube? Your hand becamecolder, but it also became wetter – the transfer ofheat caused the ice cube to change its state froma solid to a liquid that is, from ice to water.That’s one change that heat transfer can cause, butthere’s another change that we’re going to beconcerned with: the change in state when water goesfrom liquid to gas.By applying enough heat, we can force an object tochange its state, from a solid to a liquid to a gas.The same is true in reverse: by removing enoughheat, we can force an object to change states from agas to a liquid to a solid.You’re familiar with that change: if you continue toapply heat to water, eventually it begins to boil andturn to steam. But there’s more going on thanmeets the eye.Latent HeatIt takes more heat to change water to steam than to boil waterTo understand the heat necessary to force water to change states, we need to be able tomeasure the heat that water absorbs. Fortunately, someone already defined that for us.A British Thermal Unit, or BTU, is the amount of heat necessary to raise one pound ofwater one degree on the Fahrenheit scale at sea level. In other words, to increase thetemperature of one pound of water from 100oF to 212oF (38oC to 100oC), you have toapply 112 BTUs of heat to the water. This is called “Sensible Heat” – as you apply heat,the temperature increases. But that still isn’t enough heat to change that pound of waterfrom a liquid to a gas. You’d have to apply an additional 970 BTUs of heat to changethat pound of water into a pound of steam.1-57

THEORY OF OPERATIONoHeat needed to convert one pound zero degree ice to one pound 212 degree steamThe point to remember here is even though you added 970 BTUs to the water, the watertemperature never went over 212oF (100oC). That 970 BTUs was the energy necessaryto change the state of the water from a liquid to a gas (vapor). The extra heat beingabsorbed is known as “The Latent Heat of Evaporation,” or Latent Heat.What about changing back from a vapor to a liquid? The principle’s the same, but theheat flows in the opposite direction. For steam to change states back to a liquid, it mustrelease 970 BTUs of heat. At this point, as long as the liquid doesn’t release any moreheat, the water will still be 212oF (100oC). The transfer of 970 BTUs simply allowed thewater to condense back from a gas (vapor) to a liquid. This is “The Latent Heat ofCondensation.”The Merriam-Webster Dictionary defines latent as: “Present, but not visible or active.”The additional heat required for water to change states is present, but since the watertemperature doesn’t change, we say the heat is latent.What all that means is a substance can absorb or release a lot of heat, without actuallychanging temperature itself, while changing states from a liquid to a gas, or from a gasto a liquid. As you’ll soon see, these principles explain how the refrigerant in an airconditioning system can absorb and carry off heat.But before we dive into the operation of a basic air conditioning system, there’s onemore set of rules we need to examine: the rules that define the relationship betweenpressure and boiling temperature.1-68

THEORY OF OPERATIONBoiling Temperature/Pressure RelationshipBoiling temperature directly affected by pressure changesUntil now we’ve made a lot of blanketstatements about the boiling temperatureof water. We said it boils at 212oF, or100oC. That’s true but only at sea level.If you set up camp at the top of amountain, say, 5000 feet elevations, you’dfind that water boils at a lowertemperature. That’s because atmosphericpressure’s lower at 5000 feet than it is atsea level.The converse is also true: If you set upcamp in Death Valley, you’d find waterboils at a higher temperature than 212oF (100oC).Death Valley is below sea level, so atmosphericpressure’s higher than at sea level.Now, granted, the temperature difference we’retalking about isn’t very much – maybe a coupledegrees no more. Butthe pressure differencesaren’t all that great either.You’re only talking abouta couple of poundsdifference in atmosphericpressure between DeathValley and Mount St.Helens.The pressure radiator cap seals the cooling system at theinlet on top of the radiator. Caps are pressure rated tomatch cooling system design. Each pound of pressure onthe cooling system raises the boiling point of coolant threedegrees Fahrenheit, so the pressure cap extends thecooling system operating range above the normal boilingpoint. The cap pressure valve opens when operatingpressures are high. Coolant can flow through the heatercore regardless of thermostat position.But inside an airconditioning system we’llbe working with pressuredifferences ranging froma high of 350 PSI (2400kPa), down to as little as30” vacuum. At 30”vacuum, water boils atless than -100F (-23oC)!So far we’ve looked atthe principles of heattransfer as they apply to water, but these principlesremain the same for all condensable fluids. To workin an air conditioning system, we need a fluid withboiling temperatures and pressures that are moremanageable than water’s.ooWater doesn’t necessarily boil at 212 F, or 100 C pressure affects boiling temperature. By increasingsystem pressure, boiling temperature increases.1-79

THEORY OF OPERATIONRefrigerant Boiling Point/Pressure RelationshipPressure changes affect the refrigerant temperature and boiling point That’s how an air conditioning systemworks: The low side of the systemmaintains a fairly constant pressuredesigned to keep the evaporatortemperature at about 32oF (0oC). Since therefrigerant is at its boiling temperature, itshould take on heat and boil, changing stateinto a vapor.On the system’s high side, the processreverses – pressures rise well over 100 PSI(690 kPa), increasing the refrigerant’stemperature and its boiling point. In fact, atthese pressures, the refrigerant temperaturewould be higher than outside air – the refrigerantwould like to change back into a liquid.Latent heat is the heat required to make aliquid at a certain pressure turn into a vapor atthat pressure. The saturation temperaturechanges with the pressure of the refrigerant.But it can’t. Not yet, anyway – not until it gets ridof the heat it absorbed earlier when it changed states to become a vapor. Until it gets ridof that additional heat, it will remain a vapor. The additional heat keeping the refrigerantfrom changing back into a liquid is called “superheat.” To condenser back into a liquid, ithas to release that superheat.That’s easy – remember, when the refrigerant pressure increased, so did its temperature– well above the ambient air temperature. The “superheated” refrigerant passes throughthe condenser and has no problem releasing its heat to the outside air, enabling it tocondense back into a liquid.These principles of temperature, pressure, boiling point and heat transfer are what allowan air conditioning system to work.1-810

THEORY OF OPERATION11

HOW HVAC WORKSCab EnvironmentUnderstanding the three ways heat moves helps you consider allthe heat sources that an air conditioner contends with. Conduction is when heat is transferred through a solidsuch as the metal fins of an evaporator. Convection is when a colder gas displaces a warmer gascausing them to move around and circulate. Radiant heat is when the sun’s rays hit a solid surfacecausing it to heat up.Truck cabs and off-road machinery cabs are hard to heat and cool. They have largeglass areas and are not always well insulated. Hot and cold weather directly affectthe temperature inside the cab. This means that any air conditioner system must havethe capacity to do a lot of heating and cooling.The purpose of an AC system is to keep the driver comfortable (which sometimesseems to be an impossibility). Most people feel comfortable in the 70 F to 80 F range.Because truck drivers and heavy duty vehicle operators are in their cabs for longperiods of time, the cab temperature is very important for their comfort.For example, understanding radiant heat will help you considerhow the sun places an additional load on an air conditioner.The ideal cab environment has a modest humidity level and should reach andremain at a temperature of 70 F to 80 F within several minutes of operation. Mostair conditioners cycle on and off by the action of a thermostat or a low pressureswitch. This switch cycles the compressor clutch and regulates the evaporator coretemperature. This cycling action maintains a comfortable temperature range for thedriver and any passengers.PAGE 412

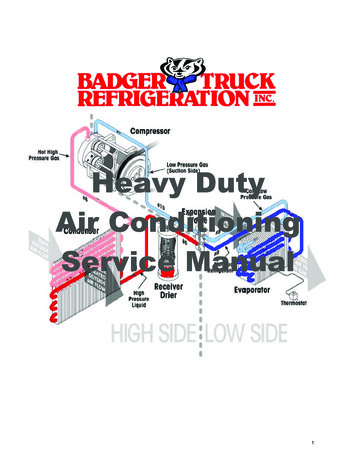

HOW HVAC WORKSIntroduction to A/C OperationExpansionValve SystemAC Systems are much like a mother, who uses a sponge to soakup milk from a spilled glass. She soaks it up and then wrings themilk out of the sponge and into the sink. Similarly, an AC systemsoaks up heat in the cab using evaporation and then squeezesthe heat into the outside air using condensation. Let’s take acloser look.Air conditioners have two basic layouts: the expansionvalve system and the accumulator system. Red Dotprimarily uses the expansion valve system.With five basic componentsAccumulatorSystem1. Expansion device: A restriction in the liquid line of thesystem, purposely designed to cause a pressure drop.2. Evaporator: A device that removes heat from the cab air byexchanging it into boiling refrigerant.3. Compressor: Provides the mechanical energy to moverefrigerant and manipulate pressures. This is the heart ofthe system.4. Condenser: Designed to exchange heat from the refrigerantto the outside air. Similar to the evaporator.5. Drier Filter Device: A storage container for extrarefrigerant that usually contains a drying agent calleddesiccant and a filter to screen out contaminants.PAGE 913

HOW HVAC WORKSExpansion Valve Systemorsserp SImoC -30 P300PSI17Cold#10 HoGasLow Prseeou esss St ureateRMWA T AIRELINLCOOTORIA C ABTHEThermostEvaporatorat#8M HosRef eterederiGasgerane tStaousteExpaValnsionveseHo re#10PressuatetLoweous SSide)sGa ction(Suese surHoh Pres8# Hig te) ta00 eous S2(tsoaH GCondensseHo#6 quidLi teStarive receRe Drier#Hig 6 HoshLiquPresseid ure135State LCOOSIDETOU FLOWAIRTEDHEASIDETOU FLOWAIRLOW SIDE HIGH SIDEPAGE 1014

HOW HVAC WORKSAccumulator SystemseHosure01s# Pre atetLoweous SSide)sanG ctio(Susosermp SICor3000P17-3seHo )#8t (200s sureHo h Pre StateHig eousGasLOW SIDECold#10 HoGasLow Prseeou esss St ureateOrificHig Tu eh-P bemRMWA T AIRELINuAccseHo re#6Pressueh atHig uid StiL q 35 1Liqu ressid ureLowto theSideLCOOTORAI CABTHEEvaporatorThermosttoraluPSIHIGH SIDECondensLCOOSIDETUO FLOWAIRerTEDHEASIDEOUTFLOWAIRatPAGE 1115

HOW HVAC WORKSLow-Side OperationSince the low side has a very low pressure, the refrigerant canbegin to boil off into a gas. When the refrigerant changes fromliquid to gas it gathers heat from the cab air. The pressuredifference is created by an expansion device.Pressure-Temperature DropThere are two types of expansion device is the component thatbegins the evaporation process:1. Thermostatic Expansion Valve (TXV) (left)2. Orifice Tube (right)The expansion device creates a pressure drop by restricting theflow of refrigerant around the system. Slowing down the flow ofrefrigerant causes the compressor to partially evacuate one sideof the system. This low pressure void is called the “Suction side”or the “Low side” of the system.Orifice TubeExpansion ValveValve DiaphragmInternal Equalization PassageDischarge from EvaporatorWhen Operating Pin pushes ball seat,refrigerant bleeds into EvaporatorOutlet to EvaporatorlowFure ratorssPreEvapowLo romwFlofeurssPre ratorwLo vapoto EThe refrigerant inside of an air-conditioner is essentially a “heat sponge.” It verylowFure rssPre ressowLo ompto ClowFure rssre ensoPdhHig ConmfroOutLow PressureFlow toEvaporatorOrifice Tube(Small tube)O-RingOutlet to CompressorSealed Sensing BulbOperating PinInlet from Receiver DrierHigh Pressure LiquidMetering OrificeValve SpringHigh PressureFlow fromCondensorsimilar to taking a dry sponge and dunking it into a bucket of water. As the waterfills the sponge, the sponge expands and becomes heavy with water. Then, when youwant to remove the water, you simply squeeze the sponge with your hands and thewater comes out.PAGE 1216

HOW HVAC WORKSExpansion CoolingLow-Side OperationCold refrigerant absorbs heat from the cab air while therefrigerant circulates inside the evaporator coil. Heat from thecab air passes through the metal of the evaporator and cause therefrigerant to expand by boiling off into a vapor. This boiling ispossible because refrigerants used in AC systems have a boilingpoint of about one pound per square inch per 1 F. For example,the boiling point of refrigerant is approximately 20 F at 20psi. As the refrigerant expands by boiling into a vapor, it takesmassive amounts of heat with it. 3. Expansion valve"(TXV)8 &5 */ "*3Refrigerantmist issprayed intoevaporatorHeated gas runs thruTXV to help valvemeter flowGas goes on to thecompressorDense,hot high pressureliquid hits restriction-08 4*%&0- 0 50"*3 "#5)&Refrigerantboils into vapor,collecting heatfrom cab air)*() 4*%&Refrigerantis forced thruorifice intolow-pressurevoidEvaporatorThermostatAn air conditioner uses similar principles. It uses refrigerant like a sponge to soak upheat (just like a sponge soaks up water). When the refrigerant enters into the thermalexpansion valve (TXV) it is essentially a dry sponge. When it passes through the smallorifice of the TXV it sprays into the evaporator. As the refrigerant heats up in theevaporator, it expands collecting large amounts of heat, like a sponge expands withwater.PAGE 1317

HOW HVAC WORKSHigh-Side OperationSo far, we have learned that the low pressures attract heat intothe system by expanding refrigerant. The part of the systemthat rejects heat into the outside air is known as the high side.It rejects heat by condensing hot vapor into warm liquid andthrough this process, squeezes heat out of the system. Heatrejection is accomplished using very high pressures (up to 350psi) and large volumes of air.1Piston on DownstrokeLow pressure coming in. Ondownstroke piston sucksrefrigerant gas through openvalve.COMPRESSION HEATINGRemember that raising the refrigerant pressure is necessary tobegin the process of rejecting heat into the outside air.On its downstroke (#1 at right), the compressor piston collectsthe expanded refrigerant inside the compressor. On its up-stroke(#2) the piston forces the refrigerant molecules closer together.The refrigerant vapor is raised in pressure, temperature andboiling point before being forced out of the valve plate assembly.The temperature of the vapor is normally two and a half timeshigher than the temperature of the outside air. Since heat alwaysflows from hot to cold, the refrigerant must be much hotter thanthe outside air to be able to move heat out of the system.2Piston on UpstrokeHigh pressure going out.On upstroke the valveis forced open and hotrefrigerant gas is forcedinto high side of system.PAGE 1418

HOW HVAC WORKSHigh-Side OperationSubcoolingThe hot, high pressure vapor makes its next stop at the condensingcoil. The condenser is just like the evaporator – it is a heatexchanger. It looks a little different from the evaporator becauseit is more flat and a little larger (an evaporator must fit underthe dash). Inside the condensing coil, the gas starts its way fromthe top to the bottom, cooling down a little with each pass. Bythe time the refrigerant reaches the lower third of the coil, itcools down enough to change back into a liquid. As a liquid, itcontinues to cool 15-30 F below its boiling point in a process called“subcooling.” Subcooling is an important concept to understandbecause it will tell what is wrong with the high side of the system.The next modules four, five and six will cover Troubleshooting,Inspection and AC Performance with more detail on subcoolingand other topics.Hot high pressure gas fromCompressorTEDEAEH SIDTOU FLOWAIRCondenserWhen the expanded refrigerant enters into the compressor, the mechanical force ofthe piston forces the expanded refrigerant molecules closer together, increasing thepressure (just like when you squeeze a sponge full of water). When the high pressurerefrigerant enters into the condenser, the heat is squeezed out into the outside air.PAGE 1519

Red Dot White PaperRefrigerants for Heavy-dutyA/C Systems20

Red Dot White PaperRefrigerants for Heavy-duty A/C SystemsWhy it’s important to consider a global solution for all vehiclesDriving Toward a Common Alternativeto R-134aLean into the engine compartment of a commercial truck or piece ofoff-highway machinery and, as air-conditioning systems go, you’llWhich is why suppliers to heavy-duty trucks and off-highwaysee a familiar landscape.equipment have been vocal in the debate over what should replaceCompressor? Check. Condenser? Check. Just about everythingR-134a even before regulations for commercial vehicles have beenyou’d find under the hood of a passenger car is in there, just built todrafted.handle a more demanding duty cycle.The European Union’s prohibition on fluorinated greenhouseHow demanding?gases with a global warming potential (GWP) greater than 150The heavy-duty and severe-service mobile A/C market spansapplies only to cars and light commercial vehicles starting in 2011.a mile-wide range of operating conditions, including heavyCurrently, there are no regulatory timetables in North Americaconstruction, mining, forestry, defense, farming, trucking, massor abroad to require low-GWP refrigerants in on- or off-highwaytransit, and fire and rescue. Many of these vehicles operate 24commercial vehicles.hours a day, seven days a week and shut down only for scheduled“What works well in a car in Europe may not provide the bestmaintenance.combination of performance, cost, and reliability for us.”Even the average long-haul tractor-trailer will have its engine“The auto market is where the production volumes are,” Hansenrunning for 21 hours a day, including six to seven hours at idle sosays. “But what works well in a car in Europe may not providethe driver can heat or cool the cab during a rest period. With mostthe best combination of performance, cost, and reliability for ourheavy trucks logging between 100,000 and 125,000 miles a year, thesegment of the industry. Practically speaking there should be onewarranty period on heavy-duty A/C components is longer than thelow-GWP refrigerant that can be used all over the world in manylife of most automobiles.different types of vehicles, including those in heavy-duty and severe-“The big difference between a car and a commercial vehicleservice environments.”is that the owner is counting on that truck or piece of equipmentIn the United States, heavy trucks alone account for 21% ofto help him earn a living,” says Gary Hansen, vice-president andtransportation-related greenhouse gas emissions, behind passengerchief engineer at Red Dot Corp. in Seattle, which designs andcars (33%) and light-duty vehicles (28%). These figures include directmanufactures heavy-duty mobile HVAC systems and components.emissions from fossil fuel combustion as well as HFC emissions fromDowntime isn’t an inconvenience, it’s an expensive loss ofmobile air conditioners.productivity. When you’re working in an open pit mine or have cropsRed Dot has been a leading voice on low-GWP alternativeto harvest, you can’t just pop into the local A/C shop for a repair. Therefrigerants for heavy-duty mobile HVAC systems. In 2007, theidea of shutting down a multi-million-dollar piece of machinery tocompany received the prestigious Climate Protection Award fromreplace a blown compressor is pretty galling.the U.S. Environmental Protection Agency for its research into theviability of HFC-152a.Red Dot Corporation – White Paper2Refrigerants for Heavy-duty A/C Systems21

Red Dot White Paperthe operating pressures in a CO2 system, or complicate things with“It makes sense for us to be proactive on the issue and have a voicein the process,” Hansen says. “Otherwise, we may face a mandate toadditional hydraulics or a second A/C system running off anotheruse a refrigerant that doesn’t meet the specific needs of the heavy-engine that’s closer to the cab.”duty market.”Certainly, a CO2 system would require longer operating periods inCO2: Heavy-Duty Concernshigh ambient conditions. The higher the ambient, the less efficient aAn example of such a refrigerant is carbon dioxide (CO2), or R-744,CO2 system becomes compared to R-134a systems. For a heavy truck,which has been promoted as a potential alternative to R-134a. Whilethe increased power demand would compromise fuel economy on theCO2 refrigerant has the benefits of being non-flammable, non-toxic,highway and require higher engine rpm at idle. That would be hardand readily available, the drawbacks of CO2 are amplified in heavy-dutyfor truck owners—who consume more than 50 billion gallons of fuelvehicles.a year and measure consumption in tenths of a mile per gallon—toaccept.A CO2 system is transcritical: the refrigerant operates in one physical“We may need to fine-tune the TXV, or use XH7 desiccant, but thesestate instead of transitioning between a liquid to a gas. High operatingpressures are necessary in order for CO2 refrigerant to pick up and giveare minor changes compared to what CO2 or 152a would require.”off heat. Head pressures can exceed 2,000 psi compared to 275 or 300Finally, there’s an issue of engineering and development costs.psi on a typical R134a system. To handle the pressure and contain theCompressors, heat exchangers—virtually every component wouldrelatively small CO2 molecule within the system, metal hoses and sealshave to be redesigned to handle the higher pressures.“Today, the low-side pressure in our system is 50 psi in thewould be required.evaporator. Well, you’re at 500 psi in the evaporator on a CO2 system,”“Unlike rubber, metal seals don’t tolerate foreign material or slightimperfections. A spec of dirt, a human hair, a scratch—it doesn’tHansen says. “If something lets go at 500 psi, that’s not a trivialtake much to compromise a metal seal,” Hansen says. Because CO2problem.”He says there’s a chasm between what is technically feasible versusmolecules are relatively small (less than half the molar mass of R134a),what a factory can mass produce at a reasonable cost.and in a highly pressurized system, leaking seals could be a problem.“We’ve developed components that we know will last a long timeMetal lines present another challenge. On a commercial truck,most cabs use a supplemental air suspension to cushion the ride. Thisin hot, humid, and dusty environments. To go back to ground zero andisolates the cab from the vibrations and bumps endured by the rest ofengineer new components that would deliver the exact same resultsthe truck. Metal lines are vulnerable to these differential movementsas what our customers expect now would be a monumental task,”between the engine and the cab.Hansen says.The Emergence of HFO-1234yfFurthermore, the physical differences between a Mercedes-Benzand a BMW car—or a minivan and a sedan—aren’t particularly great,Ideally, a substitute for 134a would deliver similar performancewhich makes it easier and more cost-effective for mobile A/C systemwithout requiring a radical redesign of components. HFO-1234yf,suppliers to design their products.developed jointly by Dupont and Honeywell, shows the most promise.Physical DifferencesIt enables vehicle manufacturers around the world to meet EUHeavy-duty vehicles come in a wide range of configurations. In somelow-GWP mandates. While no requirements currently apply to heavy-cases, the cab and engine may not be in close proximity.duty and off-highway equipment, Hansen says

by flowing warm air over a cold evaporator, the heat from the air flows to the cold evaporator, making the air less hot. The heat from the air flows into the evaporator fins, and from there into the cold refrigerant. The refrigerant carries the heat away from the evaporator, cooling the evaporator so it can cool more air.