Transcription

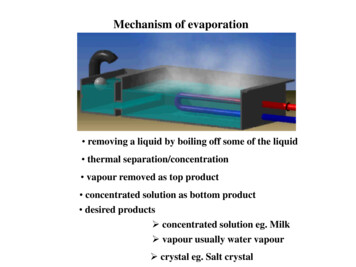

Mechanism of evaporation removing a liquid by boiling off some of the liquid thermal separation/concentration vapour removed as top product concentrated solution as bottom product desired products concentrated solution eg. Milk vapour usually water vapour crystal eg. Salt crystal

Types of evaporators3 Vertical-tube natural circulation evaporator(a) Falling-film evaporator(b) Climbing-film evaporator

(a) Falling-film evaporator(b) Climbing-film evaporator

1. single-effect evaporatorVapour, VT1, yV, HVFeed, FTF, xF, hFP1T1Steam, SCondensate, STS , H STS, hSConcentrated liquid, LT1, xL, hL relatively small capacity cost of steam relatively cheap wasteful as latent heat of vapour is discarded TF Tbp, dilute solution, 1 kg steam 1 kg vapour

Calculation methods for single-effect evaporator (dilute)Vapour, VT1, yV, HVFeed, FTF, xF, hFP1T1Steam, SCondensate, STS , H STS, hSConcentrated liquid, LT1, xL, hL1. Vapour (V) & concentrated liquid (L) flowratesTotal material balance :Solute/solid balance:F L VF(xF) L(xL) (yv 0 as vap has no salt)

Calculation methods for single-effect evaporator (dilute)Vapour, VFeed, FTF, xF, hFT1, yV, HVP1T1Steam, SCondensate, STS, HSTS, hSConcentrated liquid, LT1, xL, hL2. Heat-transfer surface area (A) & no boiling-point rise (BPR) :Energy balance:FhF S(HS – hS) LhL VHVHeat transfer equation: q S UA T UA(TS – T1)whereS(HS – hS) S h cP(T – Tref.)HV latent heat at T1 (T ref. T1)cP of inorganic salt in water cP of water 4.14 kJ/kg.K

Example 8.4-1 (Geankoplis textbook)A continuous single-effect evaporator concentrates 9072kg/h of a 1.0 wt% salt solution entering at 311.0K (37.8oC)to a final concentration of 1.5 wt%. The vapor space of theevaporator is at 101.325 kPa (1.0 atm abs) and the steamsupplied is saturated at 143.3 kPa. The overall coefficient U 1704 W/m2.K. Calculatei)the amounts of vapor and liquid productii) the heat-transfer area required.Assume that, since it is dilute, the solution has the sameboiling point as water.

VExample 8.4-1T1F 9072 kg/hxF 0.01 kg salt/kgTF 311KSP1 101.325 kPaT1SPS 143.3 kPaTsLT1, xL 0.015Vapour (V) & concentrated liquid (L) flowratesTotal material balance :Salt balance:9072 F L VF(xF) L(xL)9072(0.01) L(0.015)L 6048 kg/hSubstituting L 6048 kg/h into eq. (1), V 3024 kg/h(1)

Example 8.4-1V 3024 kg/hT1,HVF 9072 kg/hP1 101.325 kPaxF 0.01 kg salt/kgTF 311KT1SSPS 143.3 kPaTsL 6048 kg/hU 1704 W/m2.KT1, xL 0.015 kg salt/kg ,hLFrom the steam table (A.2-9) at PS 143.3 kPa, TS 110oC ,HS 2691.5 kJ/kg, hS 461.3 kJ/kg, (2691.5 – 461.3) 2230.2 kJ/kgFrom the steam table (A.2-9) at P1 101.325 kPa, T1 100oC ,Hsat. vapour 2676.1 kJ/kg, hliquid 419.04 kJ/kg

V 3024 kg/hExample 8.4-1100oC, HVF 9072 kg/hP1 101.325 kPaxF 0.01 kg salt/kgT1 100oCSSPS 143.3 kPaTs 110oCTF 311KTS 110oC, 2230.2kJ/kgL 6048 kg/hU 1704 W/m2.K100oC, xL 0.015 kg salt/kg ,hLFrom the steam table (A.2-9) at, T1 100oC ,H 2676.1 kJ/kg, h 419.04 kJ/kgTref 100oC (same as T1),Energy balance:FhF S(HS – hS) LhL VHV9072hF S(2230.2) 6048(hL) 3024(HV)wherehF cPF(TF – Tref.) 4.14(311 – 373) -256.68 kJ/kghL cPL(T1 – Tref) 4.14(100 – 100) 0HV [ (Hsat.vapour) – hliquid] (2676.1 – 419.04) 2257.06 kJ/kg9072(-256.68) S(2230.2) 6048(0) 3024(2257.06)S 4105 kg/h

V 3024 kg/h100oC, HV 2257.06kJ/kgF 9072 kg/hxF 0.01 kg salt/kgTF 311KP1 101.325 kPaT1 100oCS 4105 kg/hSPS 143.3 kPaTs 110oCTS 110oC, 2230.2kJ/kgL 6048 kg/hU 1704 W/m2.KHeat transfer equation:100oC, xL 0.015 kg salt/kg ,hL 0kJ/kgq S UA T UA(TS – T1)q S 4105 kg 2230.2 kJhkg1h3600s 2543 kJ/sA q/[U (TS – T1)]2543.0 x 103 WA (110-100) Km2.K1704 W 149.3 m2

AlternativemethodF 9072 kg/hV 3024 kg/h100oC, HVP1 101.325 kPaxF 0.01 kg salt/kgT1 100oCSSPS 143.3 kPaTs 110oCTF 311KTS 110oC, 2230.2kJ/kgL 6048 kg/hU 1704 W/m2.K100oC, xL 0.015 kg salt/kg ,hLFrom the steam table (A.2-9) at, T1 100oC ,H 2676.1 kJ/kg, h 419.04 kJ/kgTref 0oC (same as steam table),Energy balance:FhF S(HS – hS) LhL VHV9072hF S(2230.2) 6048(419.04) 3024(2676.1)wherehF 159.22 kJ/kg (after interpolation) from steam table (A.2-9)9072(157.32) S(2230.2) 6048(419.04) 3024(2676.1)S 4125 kg/h (compare to 4108 kg/h)

V 3024 kg/h100oC, HV 2676.1kJ/kgF 9072 kg/hP1 101.325 kPaxF 0.01 kg salt/kgTF 311KT1 100oCS 4125 kg/hSPS 143.3 kPaTs 110oCTS 110oC, 2230.2kJ/kgL 6048 kg/hU 1704 W/m2.K100oC, xL 0.015 kg salt/kg ,hL 419.04kJ/kgHeat transfer equation:q S UA T UA(TS – T1)q S 4125 kg 2230.2 kJhkg1h3600s 2555.4 kJ/sA q/[U (TS – T1)]2555.4 x 103 WA (110-100) Km2.K1704 W 150 m2 (compare to 149.3 m2)

Calculation methods for single-effect evaporator(concentrated)Vapour, VFeed, FTF, xF, hFT1, yV, HVP1T1Steam, SCondensate, STS , H STS, hSConcentrated liquid, LT1, xL, hL2. Heat-transfer surface area (A) & with boiling-point rise (BPR) :Energy balance:FhF S(HS – hS) LhL VHVHeat transfer equation: q S UA T UA(TS – T1)whereT1 Tsat. at P1 BPR or from fig. 8.4-2hF and hL from fig. 8.4-3HV Hsat. at P1 1.884(BPR)

Boiling-point rise (BPR) of solutionBoiling-point elevation describes the phenomenonthat the boiling point of a liquid (a solvent) will behigher when another compound is added, meaning thata solution has a higher boiling point than a pure solvent.This happens whenever a non-volatile solute, such as asalt, is added to a pure solvent, such as water.Therefore, the boiling-point elevation means that whena solute is dissolved in a solvent, the boiling point of theresulting solution is higher than that of the pure solvent.

Boiling-point rise (BPR) of solutionConcentrated solution – thermal properties differ from waterDuhring line chart – estimate boiling-point rise for a solution90Figure 8.4-2. Duhring line chart for aqueous solutions of sodium hydroxide

Example 8.4-2 Use of Duhring Chart for BPRAs an example of the use of the chart, the pressure in anevaporator is given as 25.6 kPa (3.72 psia) and a solution of 30%NaOH is being boiled. Determined the boiling temperature ofNaOH solution and the boiling point rise , BPR of the solutionover that of water at the same pressure.Steam table, bpt of water at 25.6 kPa 65.5oC (150oF)From Duhring chart, at 150oF and 30% NaOH, bpt of NaOHsolution is 79.5oC (175oF)BPR (79.5 – 65.6)oC 13.9oC

Boiling-point rise (BPR) of solution17579.5Figure 8.4-2. Duhring line chart for aqueous solutions of sodium hydroxide

Enthapy-concentration chartenthapy chart – Tref. liquid water at 0oC- used together with steam tables92214Figure 8.4-3. Enthapy-concentration chart for the system NaOH-water

Example 8.4-3An evaporator is used to concentrate 4536 kg/h (10,000 Ibm/h)of a 30% solution of NaOH in water entering at 60oC (140oF) toa product of 40% solids. The pressure of the saturated steamused is 172.4 kPa (25 psia) and the pressure in the vapor spaceof the evaporator is 11.7 kPa (1.7 psia). The overall heat-transfercoefficient is 1560 W/m2.K ( 275 btu/h.ft2.oF).Calculate the steam used, the steam economy in kg vaporized/kgsteam used, and the heating surface area in m2.

Calculation methods for single-effect evaporator(concentrated)Vapour, VFeed, FTF, xF, hFT1, yV, HVP1T1Steam, SCondensate, STS , H STS, hSConcentrated liquid, LT1, xL, hL2. Heat-transfer surface area (A) & with boiling-point rise (BPR) :Energy balance:FhF S(HS – hS) LhL VHVHeat transfer equation: q S UA T UA(TS – T1)whereT1 Tsat. at P1 BPR or from fig. 8.4-2hF and hL from fig. 8.4-3HV Hsat. at P1 1.884 (BPR)

Example 8.4-3V T1F 4536 kg/h TF 60oCxF 0.2 kg NaOH/kgSHVP1 11.7 kPaT1SNaOHPS 172.4 kPaTS, hSHSL T1xL 0.5 kg NaOH/kg hLGiven : U 1560 W/m2.KTotal material balance :Solute/solid balance:4536 F L VF(xF) L(xL)4536(0.2) L(0. 5)L 1814 kg/hSubstituting L 1814 kg/h into eq. (1), V 2722 kg/h(1)

V 2722 kg/h T1Example 8.4-3F 4536 kg/h TF 60oCxF 0.2 kg NaOH/kgSPS 172.4 kPaHVP1 11.7 kPaT1NaOHSTS, hSHSL 1814 kg/h T1xL 0.5 kg NaOH/kg hLGiven : U 1560 W/m2.KFrom the steam table (A.2-9) at PS 172.4 kPa, after interpolation,TS 115.6oC ,HS 2699.9 kJ/kg, hS 485.03 kJ/kg, (2699.9 – 485.03) 2214.87 kJ/kgFrom the steam table (A.2-9) at P1 11.7 kPa, after interpolation,Tsat. Tboiling point of water 48.9oC , Hsat. vapour 2590 kJ/kg

Example 8.4-3F 4536 kg/h TF 60oCxF 0.2 kg NaOH/kgSPS 172.4 kPaTS 115.6oC 2214.87 kJ/kgV 2722 kg/h T1HVP1 11.7 kPaTsat 48.9oCT1NaOHSTS, hSL 1814 kg/h T1xL 0.5 kg NaOH/kg hLT1 is obtained from Figure 8.4-2, at 50% NaOH and Tbp water 48.9oC(120oF) T1 193oF (89.5oC)193120

Example 8.4-3V 2722 kg/h T1 89.5oCHVF 4536 kg/h TF 60oCP1 11.7 kPaxF 0.2 kg NaOH/kgSPS 172.4 kPaT1 89.5oC(Tsat. 48.9oC)HSxL 0.5 kg NaOH/kg hL217hF at 60oC(140oF) & 20% NaOH fromfigure 8.4-3, hF 92 btu/Ibm (214 kJ/kg)89.5oC(193oF)hL atfrom figure 8.4-3,& 50% NaOH hL 217 btu/Ibm (505 kJ/kg)TS, hSNaOHL 1814 kg/h T1 89.5oCGiven : U 1560 W/m2.KBPR T1- Tsat (89.5 – 48.9)oC 40.6oCTref. 0oC (same figure 8.4-3),S92

Example 8.4-3V 2722 kg/h T1 89.5oCF 4536 kg/h hF 214 kJ/kgxF 0.2 kg NaOH/kgSTS 115.6oC 2214.87 kJ/kgHVP1 11.7 kPaT1 89.5oC(Tsat. 48.9oC)STS, hSNaOHL 1814 kg/h hL 505 kJ/kgxL 0.5 kg NaOH/kg hLGiven : U 1560 W/m2.KBPR T1- Tsat (89.5 – 48.9)oC 40.6oCTsat. 48.9oC , Hsat. vapour 2590 kJ/kgEnergy balance:FhF S(HS – hS) LhL VHV4536(214) S(2214.87) 1814(505) 2722HVHV 2590 1.884(40.6) 2667 kJ/kg4536(214) S(2214.87) 1814(505) 2722(2667)S 3255 kg/h

Example 8.4-3V 2722 kg/h T1 89.5oCF 4536 kg/h hF 214 kJ/kgxF 0.2 kg NaOH/kgS 3255 kg/hHV 2667 kJ/kgP1 11.7 kPaT1 89.5oCNaOHTS 115.6oC 2214.87 kJ/kgGiven : U 1560STS, hSL 1814 kg/h hL 505 kJ/kgxL 0.5 kg NaOH/kg hLW/m2.KHeat transfer equation:q S UA T UA(TS – T1)q S 3255 kg 2214.87 kJ1hhkg3600s2002 x 103 WA (115.6-89.5) Km2.K1560 WSteam economy V/S 2722/3255 0.836 2002 kJ/s 49.2 m2 1: not economical 1: more economical

1. forward-feed multiple-effect evaporator fresh feed to 1st stage/effect conc. prod. from 1st effect to 2nd effect vapour from 1st effect as heating medium for 2nd effect co-current flow TF Tbp, dilute solution, 1 kg steam 3 kg vapour feed is hot heat-sensitive final product

2. backward-feed multiple-effect evaporator fresh feed enter last stage/effect conc. prod. from3st effect to 2nd effect vapour from 1st effect as heating medium for 2nd effect counter-current flow liquid pumps in each effect (P1 › P2 › P3) cold feed as less liquid needs to be heated highly viscous conc. prod. as higher temp. reduce viscosity

3. parallel-feed multiple-effect evaporatorV1 , T1feed, TF(1)T1FV2 , T2V3 , T3(2)(3)T2Fto vacuumcondenserT3steam, TsTS1L1, T1TS2L2 , T2TS3L3 T3 fresh feed and withdrawal conc. prod. at each effect vapour from 1st effect as heating medium for 2nd effect almost saturated feed solid crystals as product

Triple-effect forward feed evaporatorsAssumptions: latent heat of condensing steam latent heat of vapour areas in all effects are equal (A1 A2 A3) q1 U1A1 T1 q1 S S 1 T1 TS1-T1 T1 T1/U11/U1 1/U2 1/U3 T2 TS2-T2 No BPR: T2 T1-T2 No BPR: T TS1-TS4 BPR: T2 T1- BPR1-T2 BPR: T TS1-TS4-(BPR1 BPR2 BPR3)

Procedure for Triple-effect forward feed evaporatorsDetermine:1. T3 & BPR32. L3 & V1 V2 V3. Assume V1 V2 V33. L1,L2,x1 & x24. BPR1 & BPR25. T, T1, T2 & T3. Readjust if necessary6. T1, TS1, T2, TS2, T3 & TS37. cP, enthalpies, L1, L2,V1 ,V2 ,V3 & S8. Compare ans. from step7 with ans. from steps 2 & 3. If errors 10%, redo step 3.9. If errors 10%, calculate q1, q2 , q3 , A1, A2, A3 & Aave. If errors 10%, revise Ts.

Ps3 9 kPaExampleF 22680 kg/hxF 0.12TF 93oCPs1 170 kPaGiven: BPRoC 0.63 - 3.62x 15x2x2 0.6cp kJ/kg.K 4.19 – 2.93xU1 2271 W/m2.K, U2 1420 W/m2.KAt 9 kPa, T sat3. 43.66oC (from A.2-9 after interpolation)BPR2 0.63 - 3.62(0.6) 15(0.6)2 3.858oC T2 Tsat.3 BPR2 43.66 3.858 47.52oCTotal balance:F (V1 V2) L2 22680 kg/hSolid balance:FxF L2x222680(0.12) L2(0.6) L2 4536 kg/h

F 22680 kg/hxF 0.12TF 93oCPs1 170 kPaTotal balance: 47.52oC22680 (V1 V2) 4536L2 4536 kg/hx2 0.6(V1 V2) 18 144 kg/hAssume V1 V2Effect 1:V1 V2 18 144 /2 9072 kg/hTotal balance:F 22680 V1 L122680 9072 L1L1 13 608 kg/hSolid balance:FxF L1x122680(0.12) 13 608x1Effect 2:Total balance:x1 0.2L1 V2 L213608 9072 4536

V1 9072 kg/hF 22680 kg/hxF 0.12TF 93oCPs1 170 kPaU1 2271 W/m2.KU2 1420 W/m2.KV2 9072 kg/hT s3 43.66oC 47.52oCBPR2 3.858oCL1 13608 kg/hx1 0.2L2 4536 kg/hx2 0.6BPR 0.63 - 3.62x 15x2BPR1 0.63 - 3.62(0.2) 15(0.2)2 0.506oCAt 170 kPa, T s 115oC T TS1-TS3-(BPR1 BPR2) 115 – 43.66 –(3.858 0.506) 66.976oC T1 T1/U11/U1 1/U2 T1 TS1-T1 66.9761/2271 25.767oC1/2271 1/142025.767 115 -T1 T1 89.233oC T2 ΔT-ΔT1 66.976 – 25.767 41.209oC T2 TS2-T241.209 TS2 -47.52 TS2 88.727oC

V1 9072 kg/hF 22680 kg/hxF 0.12TF 93oCPs1 170 kPaGiven: cp (kJ/kg.K) 4.19 – 2.93xV2 9072 kg/hT s3 43.66oC 89.233oC 47.52oCBPR2 3.858oCL1 13608 kg/hx1 0.2TS2 88.727oCL2 4536 kg/hx2 0.6cpF 4.19 – 2.93xF 4.19 – 2.93(0.12) 3.838 kJ/kg.Kcp1 4.19 – 2.93x1 4.19 – 2.93(0.2) 3.604 kJ/kg.Kcp2 4.19 – 2.93x2 4.19 – 2.93(0.6) 2.432 kJ/kg.KTref. 0oC (liquid solution),hF cPF(TF – Tref.) 3.838(93 – 0) 356.97 kJ/kgh1 cP1(T1 – Tref.) 3.604(89.233– 0) 321.6 kJ/kgh2 cP2(T2 – Tref.) 2.432(47.52 – 0) 115.56 kJ/kg

V1 9072 kg/hF 22680 kg/hxF 0.12TF 93oCPs1 170 kPa 89.233oCV2 9072 kg/hT s3 43.66oC

An evaporator is used to concentrate 4536 kg/h (10,000 Ib m /h) of a 30% solution of NaOH oin water entering at 60oC (140 F) to a product of 40% solids. The pressure of the saturated steam used is 172.4 kPa (25 psia) and the pressure in the vapor space of the