Transcription

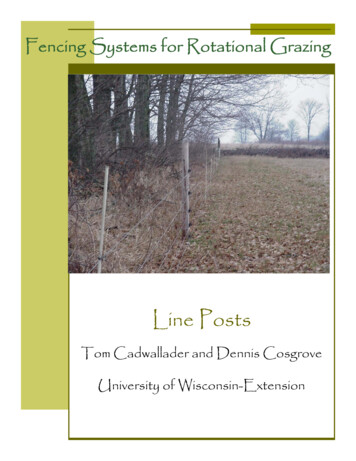

Fencing Systems for Rotational GrazingLine PostsLine PostsTom Cadwallader and Dennis CosgroveUniversity of Wisconsin-Extension1

The Line PostsOnce the ends and corners are putinto place its time to put in the postsbetween them that keep wires offthat ground and apart. As we talkline posts its important to note thathigh-tensile wire fences do not needto physically constrain animals. Theyare wires intended to reliably delivera shock to animals in order to keepthem where you want them. Otherthan the end and corner posts, therest of the fence should be able totake a shock and spring back intoplace. This means that the posts canbe flexible and the wires shouldnever be fixed tightly to them.To put on line posts there arebasically four steps; lining them up,putting in posts that can handlechanges in elevation and wherethere are long distances betweenends and corners, setting distancesbetween posts and installing them. Lining up the posts: There are afew different ways to line up fenceposts. One of course is to havesomeone stand at the end of thefence and call out when posts are inline. It will definitely work but it doeshave its limitations the farther awayyou get from each other. The easiestway is to stretch one of the hightensile wires and use it as a guide.Simply temporarily mark a few spotsalong the fence so that when thewire is moved out of the way to puta post in it can be put back in place.Using a high-tensile wire that isslightly tightened will also help in thenext step, deciding where to putposts that hold the fence downwhen going through a low spot orup when going over a rise. Putting in posts that can handle adrastic change in elevation: Whenhigh-tensile wire fences aretightened up they can easily pull apost of the ground when goingthrough a low spot or drive them inwhen going over a hill. In a low spotit is usually necessary to install a postwith some kind of deadman asdiscussed previously. Since the postisn’t being asked to provide muchhorizontal support a 4-inch topwood post will work just fine.Backfilling would be the same asdescribed in section 2 on settingposts. At the top of a rise wherethere will be downward pressure,just using a 4-inch wooden postwould be adequate The line posts: There are lots ofdifferent options for line posts inhigh-tensile electric fences. Each hasits own advantages anddisadvantages in both installationand maintenance. It is also commonto use the different types of posts onthe same fence depending on whatthe post is being asked to do. We’llonly go through a few of the morecommon ones.Wood: There is nothing wrong withwood for line posts .Their bigadvantage is they are reliable andstrong. Their downside of course istheir purchase and installation cost.Most treated wood posts aren’t verygood insulators so that means theadditional expense of usinginsulators to the hot wires. But if the2

posts are available, reasonably pricedand you have a post driver available,wood can be a good choice.Another possible option is to use awood post in combination withother types of line posts as shown inFigure 1.Figure 1. Wooden Posts Eucalyptus: Eucalyptus is a verydense wood that resists decay(Figure 2). The importers of theseposts claim that they have goodelectrical insulating value but there isno research to support this claim,especially in areas of high rainfall.They are relatively expensive andthey can be broken.Figure 2 InsultimberSteel: Steel T-posts will definitelywork but they have some majordisadvantages. The first being thecost. Although the post itself mightbe even be free they aren’t cheap toinstall because all of the wires needto be insulated. Because its steel itsan excellent conductor and shortingout is real problem. If you are goingto use a steel T-post make sure to usean insulator that can be securelyfastened to the fenceFiberglass: Fiberglass posts are oneof the most popular types of postsused for line posts in high-tensileelectric fences. A few of theirdisadvantages are cost, availabilityand splintering with age. From acost standpoint the better qualityfiberglass posts can cost more than a3-4 inch top wood post anddefinitely more than a steel t-post.But when you consider they are selfinsulating, what you spend on thepost you might make up for in savingon insulator costs. As far asavailability goes, not all fencesuppliers handle the same kind ofposts, and even those that do alwayscontinue to market them. Thesplintering is caused by thefiberglass’s susceptibility to UV light.Over time fiberglass posts canbreakdown and loss some of theirstrength. They can also start tosplinter, which makes them tough towork with, and the breakdown inthe fibers can cause them to carrysmall amount of electricity, reducingtheir insulating value. Good qualityfiberglass posts are treated to resistbreakdown. Below are just a few ofthe fiberglass posts that arecommonly available: Coated fiberglass with predrilledholes: Figure 3 shows a fiberglasspost that is UV stabilized and has aprotective coating put on it so it3

doesn’t splinter over time. Thepredrilled holes allow using longcotter pins attach the wires at avariety of different heights andspacings. The posts that are shownare about a half-inch in diameter andwill provide good lateral strength.Figure 3 Fiberglass post Coated fiberglass with springclips: Figure 4 show a fiberglass postthat is similar to the previousfiberglass post but rather thanhaving the pre-drilled holes andcotter key method of attaching thewire it uses a spring steel clip thatcan be slid up and down the post.The advantage to this system is thepost doesn’t need a bunch holesdrilled in it but the disadvantage is itthe clip is difficult to work with bothputting it on the post and installingthe wire. The springs also have atendency to loosen up over time andeven rust.Figure 4 Fiberglass post with clip Sucker Rod: Sucker rod posts arefiberglass posts that are a byproductof the oil drilling industry. Longfiberglass rods are joined together topull drilling equipment out of theground. When they’ve outlived theirusefulness for the drillers they arevery often cut up into lengths thatcan be used for fence post. Figure 5shows a sucker rod that has hadholes drilled into it for attaching thewires. The diameter of these postrun anywhere from three quarters ofan inch to an inch. Their numberone drawback is they aren’t UVstabilized so the do splinter and inmoist conditions they can carry smallamounts of electricity. They arestrong and at times can be a goodbuy.Figure 5 Sucker RodPVC: Another option is three quarteror one inch, schedule 40 PVCplumbing or conduit pipe. Figure 6shows a three quarter inch schedule40 PVC pipe with a cap on it to keepthe rain out and hole/cotter keycombination for fastening the wires.This particular post is not UVstabilized but it has been in use for 5years even through cold Wisconsinwinters. They are fairly flexible and4

are excellent insulators. They areprobably the least expensive optionavailable. The downside of coursewould be their strength so they maynot be a good option is places wherethere would be a lot of horizontalforces placed on them. They are bestused with more expensive sturdierline posts. Post distances: The spacebetween line posts on a high-tensileelectric fence really depends on theindividual situation. Traditionalphysical barrier fences, such aswoven or barbed wire, usually havethe posts set about every rod, 16.5feet. In these fences the posts areconstantly being called on to holdthe fence up. In high-tensile electricfences the fences are intended to bemore flexible and with the hightensile strength of the wires, as longas the wires don’t sag too muchbetween posts, distance isn’t asimportant. Post spacing can runanywhere from 50 to 100 feet, andeven farther if set posts are used incombination with droppers.Figure 6 PVC post Line post combinations anddroppers: All of the posts that havebeen mentioned have theiradvantages and disadvantages socreating fences that have acombination of posts makes a greatdeal of sense. Placing sturdy andmore expensive posts at criticalplaces and then putting lessexpensive, more flexible posts inbetween can not only reduce thecost of the fence, it can actuallyincrease the life because the fence ismore flexible and capable ofabsorbing different forces. Anothervery common concept is thedropper, which is a post that actuallysits on the ground and just to keepthe wires at the desired height anddistances apart. Fixed post anddropper combinations can be verycost effective.5

probably the least expensive option available. The downside of course would be their strength so they may not be a good option is places where there would be a lot of horizontal forces placed on them. They are best used with more expensive sturdier line posts. Figure 6 PVC post Line post combinations and droppers: All of the posts that have