Transcription

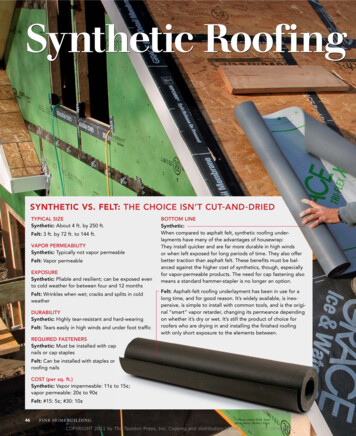

Synthetic RoofingSYNTHETIC VS. FELT: THE CHOICE ISN’T CUT- AND - DRIEDTYPICAL SIZESynthetic: About 4 ft. by 250 ft.Felt: 3 ft. by 72 ft. to 144 ft.VAPOR PERMEABILITYSynthetic: Typically not vapor permeableFelt: Vapor permeableEXPOSURESynthetic: Pliable and resilient; can be exposed evento cold weather for between four and 12 monthsFelt: Wrinkles when wet; cracks and splits in coldweatherDURABILITYSynthetic: Highly tear-resistant and hard-wearingFelt: Tears easily in high winds and under foot trafficBOTTOM LINESynthetic:When compared to asphalt felt, synthetic roofing underlayments have many of the advantages of housewrap:They install quicker and are far more durable in high windsor when left exposed for long periods of time. They also offerbetter traction than asphalt felt. These benefits must be balanced against the higher cost of synthetics, though, especiallyfor vapor-permeable products. The need for cap fastening alsomeans a standard hammer-stapler is no longer an option.Felt: Asphalt-felt roofing underlayment has been in use for along time, and for good reason. It’s widely available, is inexpensive, is simple to install with common tools, and is the original “smart” vapor retarder, changing its permeance dependingon whether it’s dry or wet. It’s still the product of choice forroofers who are drying in and installing the finished roofingwith only short exposure to the elements between.REQUIRED FASTENERSSynthetic: Must be installed with capnails or cap staplesFelt: Can be installed with staples orroofing nailsCOST (per sq. ft.)Synthetic: Vapor impermeable: 11 to 15 ;vapor permeable: 20 to 90 Felt: #15: 5 ; #30: 10 46FINE HOMEBUILDINGPhoto: Justin Fink. Insetphoto above: Rodney Diaz.COPYRIGHT 2011 by The Taunton Press, Inc. Copying and distribution of this article is not permitted.

UnderlaymentsThese materials aretougher than felt,but do they performas well?BY MARTIN HOLLADAYAmilestone in any construction projectis drying in, usually defined as theday the roof sheathing is covered withunderlayment. Building codesrequire the installation of asphalt felt forseveral reasons: Underlayment keeps thesheathing dry until the roofing is installed,it provides some protection against leaks incase wind-driven rain gets past the roofing,and it provides a slight improvement in aroof’s fire resistance.For years, roofers chose between basic #15or heavier #30 asphalt felt, which are commodity products sold under many brandnames. Both types of felt are made fromrecycled corrugated paper mixed with sawdust; to provide water resistance, the paper isimpregnated with asphalt. These days, however, roofers also can choose from a varietyof synthetic roofing underlayments: sheetproducts made of laminated polypropyleneor polyethylene plastic.Synthetic roofing underlayments look andfeel similar to housewrap. Unlike housewrap, though, most synthetic roofing underlayments are vapor barriers, so they shouldn’tbe used on unventilated roofs (sidebar p. 49).These plastic underlayments also offerhigher resistance to UV radiation, bettertraction for roofers, and more square footageof coverage at a lower weight. They are not,however, intended or approved to replacepeel-and-stick membranes in areas prone toice dams.Traditional felt still competeswith newer syntheticsAlthough synthetic roofing underlaymentshave several advantages over asphalt felt,www.finehomebuilding.comOCTOBER/NOVEMBER 2011COPYRIGHT 2011 by The Taunton Press, Inc. Copying and distribution of this article is not permitted.47

asphalt felt remains popular as a roofingunderlayment for several good reasons.While the price of asphalt felt fluctuatessomewhat, it’s still the least expensive option.Builders typically pay about 5 per sq. ft. for#15 felt and 10 per sq. ft. for #30 felt. Synthetic underlayments cost more than twice asmuch as #15 felt—usually between 11 and15 per sq. ft. Vapor-permeable syntheticunderlayments are even more expensive—from 20 to 90 per sq. ft.According to Dyami Plotke, a managerat Roof Services in Islip, N.Y., “For a standard roof assembly, where the felt andasphalt shingles are installed on the sameday, it doesn’t make any difference whatunderlayment you use, so the lower cost ofthe standard felt is a big advantage. Wherethe synthetics outperform felt by a mile is intheir tear resistance. Synthetic underlaymentallows us to bring a building to a watertightcondition just by papering it, without installing the roofing immediately—and it willstay watertight for months. That’s why wealways use synthetic underlayment underspecialty steep-slope products like slate andtile, which are slow to install.”Cap fasteners aren’t optionalAlthough asphalt felt doesn’t seal aroundfasteners as effectively as peel-and-stickmembranes, it is less likely to leak at nailand staple penetrations than a syntheticunderlayment. Synthetic underlaymentpunctured by staples or common roofingnails can, with the help of capillary action,lead to leaks. That’s why plastic-cap nails orstaples, which help to seal penetrations, area must when installing synthetic underlayments. Cap fasteners can be installed with acompatible pneumatic tool or, in the case ofcap nails, manually.Some roofers also have reported that synthetic underlayments allow more wickingat laps than asphalt felt. For areas that needsealing—including vulnerable laps—usecaulk rather than the traditional black roofing cement.Exposure limits and warrantiesIn their technical-data sheets, manufacturersof synthetic roofing underlayment list maximum time limits, ranging from two monthsto 30 months, for exposure to the weather.A word of warning, however: There is littleevidence that 12-month products actuallyperform differently from four-month or six48Features aside, it comes down toNOT-SO-SLIPPERY SLOPEAlthough Grace’s Tri-Flex Xtreme is skid-resistant whendry, its surface is designed to swell slightly so that itbecomes even more tacky when wet.DOESN’T MIND CONSTRUCTION DELAYSMost synthetic underlayments can be left exposed for six monthsand some for 12 months. The woolly, tan-colored Opus RoofBlanket, though, is approved for 30 months of UV exposure.BREATHE EASYRated at 550 perms, Cosella-Dörken’s DeltaFoxx underlayment is by far the most vaporpermeable product in this category, makingit ideal for use over unvented assemblies orunder slate, clay, or tile roofing.FINE HOMEBUILDINGCOPYRIGHT 2011 by The Taunton Press, Inc. Copying and distribution of this article is not permitted.Photo: Rodney Diaz

permeancewww.finehomebuilding.comUnknownVapor permeableVapor impermeableMost synthetic underlayments have permeanceratings under 1 perm, makingthem effective vapor barriers.Because these underlaymentsdon’t allow roof sheathing todry upward, manufacturersrecommend that they be usedonly over ventilated spaces(that is, vented cathedral ceilings or vented attics) that allowdownward drying.Of course, just because anattic is currently vented doesn’tmean it will stay that way. Afew years down the road, ahomeowner might decide toinstall spray polyurethane foamon the underside of the roofsheathing; at that point, thesheathing will no longer beable to dry downward. If thispossibility worries you, stickwith asphalt-felt underlayment.(Asphalt felt is the original“smart” vapor retarder; it hasa permeance of about 5 permswhen dry, but a much higherrating of 60 perms when wet.)Although underlaymentmanufacturers often don’tdistinguish between differenttypes of roofing when makingventilation recommendations,some experts do. Accordingto building scientist JosephLstiburek, “Having a vaporpermeable underlayment is abig deal if you have a tile roofor a cedar-shingle roof—a roofthat is assembled like a ventedrain screen. It’s very beneficialto be able to dry the roof deckupwards. But the permeanceof the underlayment doesn’tmatter when asphalt shinglesare involved.” In other words,if you are installing a type ofroofing that doesn’t allowupward drying, you don’t haveto worry about the permeanceof your underlayment.Lstiburek tempers his advicewith the commonsense observation that underlayment permeance isn’t worth obsessingover. “The permeance of theunderlayment is irrelevant ifeverything blows off the reNemco IndustriesRoofAquaGuard UDLX0.035 perm6 monthsW.R. GraceTri-Flex Xtreme0.04 perm4 monthsPactivGreenGuard0.04 perm6 monthsAlpha Pro TechREX SynFelt0.05 perm6 monthsBerger Building ProductsPro-Master Roof Shield UDL & UDL Plus0.05 perm12 monthsInterWrapTitanium UDL0.05 perm6 monthsRobetexTech Wrap 3000.05 perm6 monthsRobetexTech Wrap UL0.05 perm12 monthsKirsch Building ProductsSharkskin Ultra0.059 perm12 monthsIntertape PolymerNovaSeal0.06 perm6 monthsRobetexTech Wrap 1500.08 perm6 monthsPropex Operating CompanyOpus Roof Blanket0.1 perm30 monthsSDP Advanced Polymer ProductsPalisade0.1 perm6 monthsSystem ComponentsFelTex0.1 perm6 monthsIKORoofGard-SB0.18 perm6 monthsCertainTeedDiamondDeck0.183 perm6 monthsOwens CorningDeck Defense0.23 perm6 monthsPGI-FabreneFabrene UDL and Matrix UL0.8 perm2 monthsAtlas RoofingSummit 1 perm6 monthsDuPontRoofLiner 1 perm6 monthsGAF MaterialsTigerPaw 1 perm6 monthsRosenlew RKWRoofTopGuard II 1 perm6 monthsPerma R ProductsPermaFelt 1 perm6 monthsGAF MaterialsDeck-Armor16 perms6 monthsCosella-DörkenDelta-Maxx Titan28 permsASAPVaproShieldSlopeShield59 perms4 monthsCosella-DörkenVent S120 permsASAPNemco IndustriesRoofAquaGuard BREA146 perms4 monthsCosella-DörkenDelta-Foxx550 permsASAPBerry PlasticsBarricade Dry StepUnknown6 monthsPrimeSource Building ProductsGrip-Rite ShingleLaymentUnknown6 monthsTamkoTam-ShieldUnknown6 monthsTri-Built MaterialsTri-Built High PerformanceUnknown6 months*ASTM E 96, procedure Ahe says. “This vapor-permeanceis arcane stuff, and none of itmatters if you forget to fastenand flash everything properly.”Although most syntheticunderlayments are vapor barriers, there are exceptions.Several manufacturers produceproducts with a vapor permeance that is as high as, or evenhigher than, asphalt felt. Thehigher the permeance, thefaster water vapor can passthrough a material. Any material with a perm rating of 10 orgreater is highly permeable.These products are significantly more expensive thanvapor-impermeable underlayments, so if you want a vaporpermeable product, you mayprefer to stick with asphalt felt.A final note: Although it’sperfectly acceptable to useasphalt felt on the roof andas a water-resistive barrier onwalls, the same isn’t true ofvapor-impermeable syntheticroof underlayments. Theseproducts are not approved foruse on a wall, unless, of course,you’re using one of the vaporpermeable options.OCTOBER/NOVEMBER 2011COPYRIGHT 2011 by The Taunton Press, Inc. Copying and distribution of this article is not permitted.49

TAILOR THE INSTALLATION TO THE ROOFAsphalt-felt roofing underlayment has specific installation instructions outlined in the code book.To date, there are no such code guidelines for synthetic underlayments, so the installation forthese products is dictated by manufacturers. Below are some of the more generic details, as wellas areas that may differ from brand to brand. Not installing synthetic underlayment according tomanufacturer requirements is a quick way to void the warranty.When drying in, lap underlayment over ridgesand hips. When it comes time to install theridge vents for vented roofs, cut back theunderlayment.Most synthetic underlaymentsare approved for roofs as lowsloped as 3-in-12 providedthat the material is overlappedby about 50%. A betterapproach is to cover lowslopes completely with peeland-stick membrane.To protect againstwind-driven rain, lapunderlayment underthe rake edge.Avoid end laps if possible,but where unavoidable,lap the underlayment atleast 6 in.Peel-and-stick membrane is required ateaves, should be lapped under the dripedge, and must cover the entire overhang.It then must extend up the roof deck atleast 2 ft. past the front wall of the house.month products, so it doesn’t make muchsense to rely on these numbers when selecting a product.Despite the fact that Cosella-Dörken’sunderlayments have an excellent reputation for durability, the company recommends that roofing be installed “as soon aspossible.” Product manager Peter Barrettexplains, “Plastic begins to degrade as soonas it is exposed to UV light. Once degradation starts, it will go on, even when coveredby roofing, since heat and oxidation continueto act on the plastic. Most manufacturers arejust giving a guess on the durability of theirproducts. They’re gambling that nobody willactually uncover them to see how they’re50The underlaymenttypically has referencelines to help determinehorizontal overlaps,usually around 4 in.holding up. Warranties are mostly used asmarketing tools; these numbers are not anexpression of durability.”Which brand should I choose?Most roofers aren’t too picky about whichbrand of synthetic underlayment they use,and in many cases, the options will be dictated by your specific region. “In terms ofperformance, I think that synthetic felt is acommodity product,” says Plotke. Becauseslippery underlayments can be dangerous, the deciding factor for many roofers istraction. According to evaluations made byFine Homebuilding editorial adviser MikeGuertin, the tested underlayments thatshowed the greatest slip resistance in bothwet and dry conditions were TitaniumUDL, RoofLiner, and Tri-Flex Xtreme.Under wet conditions, Sharkskin didn’tperform as well as the top-rated underlayments. This segment of the market is growing quickly, however, and there are well overa dozen products that Mike has not had theopportunity to investigate.To keep track of the product options asthey multiply and to weigh in with yourown product reviews, visit our onlineMaterial Guide at FineHomebuilding.com/materialguide. Martin Holladay is a senior editor.FINE HOMEBUILDINGCOPYRIGHT 2011 by The Taunton Press, Inc. Copying and distribution of this article is not permitted.Drawing: Bob La Pointe

CertainTeed DiamondDeck 0.183 perm 6 months Owens Corning Deck Defense 0.23 perm 6 months PGI-Fabrene Fabrene UDL and Matrix UL 0.8 perm 2 months Atlas Roofing Summit 1 perm 6 months DuPont RoofLiner 1 perm 6 months GAF Materials TigerPaw 1 perm 6 months Rosenlew RKW RoofTopGuard II 1 perm 6 months Vapor permeable