Transcription

Flange Insulation KitsManufacturers and distributors of sealing and jointing materials.

The CompanyNovus Sealing manufactures and supplies a variety of highOver the years we have enhanced our technical facilities to developquality products designed for fluid sealing applications in themore new products and provide guidance and training programmesindustrial and manufacturing sectors. Our company ethos isfor some of the world’s largest chemical and petrochemical plants.to provide honesty, reliability and a high level of service andWe have a dedicated Research & Development team who ensuredependability through all aspects of our business, adding valuehigh quality technical support for all our products.to our products and ensuring we sustain a competitive edge.We constantly look to provide a balanced mix of quality sealing and jointing products with a professional friendly service.Flange Insulation KitsNovus Flange Insulation Kits are typically used onoffshore installations, seawater environments, chemical installations, oil refinery pipelines where galvaniccorrosion protection and electrical insulation isrequired.Novus Flange Insulation Kits are designed for electricalflange insulation. They are used as an insulator betweendissimilar metal flanges or to electrically isolate sectionsof pipework in cathodic protection systems, preventingthe flow of electrostatic charge along the pipelines.Kit ContentsNovus Sealing supply three standard types of FlangeInsulation Kits; designed to suit either raised face, flatfaced or ring grooved flange assemblies.Each kit comprises electrically insulating flangegasket plus the following components :One phenolic/mylar/GRE sleeve per boltTwo laminated phenolic/mylar/GREwashers per bolt

Two plated steel washers per boltNovus Flange Insulation KitType F - Inner Bolt Circle (IBC) GasketInside Bolt Circle insulation kit utilises a centralgasket which locates within the bolts.The outer diameter of the gasket fits tightly intoplace assuring a well centered position.1/8” thick plated steel washerThe illustration clearly shows how the oppositeflanges are totally insulated from each other.Full length insulating sleeveFor use on full face and raised face flanges.1/8” thick insulating washerInner Bolt Circle1/8” thick insulating washer1/8” thick plated steel washerNovus Flange Insulation KitType E - Full FaceFull Face insulation kits are suitable for flat faceand raised face flanges.This assembly minimises the ingress of conductive foreign matter between the portions of theflanges outside the raised faces and reduces therisk of bridging.The illustration clearly shows how the oppositeflanges are totally insulated from each other.1/8” thick plated steel washer1/8” thick insulating washerFull length insulating sleeveFull Face gasket1/8” thick insulating washer1/8” thick plated steel washerFor use on full face and raised face flanges.Novus Flange Insulation KitType D-RTJRing type joint insulation kits comprise of an ovalinsulating ring type joint gasket and are suitable forstandard RTJ flanges.The illustration clearly shows how the opposingflanges are totally insulated from each other.1/8” thick plated steel washerFor use on standard Ring Type Joint Flanges.Full length insulating sleeve1/8” thick insulating washerInsulating oval Ring Type Joint1/8” thick insulating washer1/8” thick plated steel washer

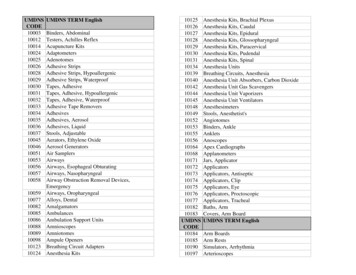

Insulating Gasket nuous OperatingTemperature.ºCGasket MaterialsDescriptionDielectricStrengthVPMNeoprene Faced PhenolicNeoprene coated Phenolic500107Novus 34Premium grade fibre to BS7531 Grade X120*220*Uniflon 50Modified PTFE reinforced with glass microspheres380*260*Uniflon 51Modified PTFE reinforced with Silica430*260*Uniflon 53Modified PTFE reinforced with Barium Sulphate450*260*Pikotec PGEGRE Grade G10 & G11 core with O ring seals750/500140(G10) / 177 (G11)Pikotec VCSGRE laminated bonded to stainless steel core withspring energised seals Grade 10* and G11*750/500140 (G10) / 177 (G11)*The operating temperature of thesematerials are related to their thickness. Thinner materials offer better temperature resistance than thicker grades.Pikotek PGE is a low pressure service gasket designed to give operators an alternative to phenolic based insulating gaskets.With the range of sealing elements provided the PGE is rated for most if not allHydrocarbon and water service applications.The unique offset design of the seal groovescreates a barrier, preventing any migrationof the fluid and or gas. The PGE gasketprovides a maintenance free, flange isolationand corrosion migration prevention solution.PhenolicNovus 34Uniflon 50Uniflon 51Uniflon 53Pikotek VCS has been designed to operate invery critical service applications. The gasketis suitable for use in Full Face, IBC and RTJflanges. It has universally acclaimed excellent dielectric properties and superior sealingcharacteristics. The gasket is suitable for allpressure ratings including API 15,000 psi.Pikotek is the registered trade mark ofour associate suppliers for PGE and VCSspecificationmaterials.Pikotek PGEPikotek VCS

Service RecommendationsThe choice of the insulation gasket isdependant on the application criteria. In addition to temperature, the pressure rating must be taken into consideration before selecting the gasket material.Seating StressSeating StressSeating Stress (20ºC)Gasket )Neoprene Faced Phenolic1530100To achieve an operationally reliable seal, theinsulating gasket should be assembled withinthe seating stress parameters shown here.Novus 3420*40*160*Uniflon 5015*40*135*Uniflon 5120*40*160**Note: For Neoprene faced phenolic gasketsthe bolts should be tightened using a torquewrench only. Hydraulic tensioning is notUniflon 5320*40*160*Pikotec PGE3050160Pikotec VCS3050400recommendedforthesegaskets.Experience has shown that a boltstress of 30,000psi must not be exceeded for Neoprene faced phenolic gaskets.* The seating stresses are dependent on the gasket thickness. Thinner materials offer a lowerminimum seating stress and a higher maximum seating stress than thicker materials.Flange Surface FinishIt is imperative that the flange faces are clean.The recommended surface finish of the flangesis 3.2um (125 RMS) to 6.3um Ra (250 RMS).Low Temperature ServiceInsulations sets which employ elastomericmaterials eg. Neoprene Faced Phenolicgaskets should not be used at temperaturesbelow -40ºC. For these temperatures werecommend the Uniflon range of gaskets orthe Pikotek range fitted with a PTFE seal.Contact our technical department forfurther information.How to order standard Neoprene Phenolic Insulation Kits Flange Insulation Type Size & Pressure rating or Ring Numbereg. Type Eeg. Size 1” Class 300lbs R16Note: This can be abbreviated to Flange Insulation Kit Type E Size 1” Class 300lbsIf gasket material is different this will need to be specified in the event of an order ie: Flange Insulation Type Size & Pressure rating or Ring Numbereg. Type Eeg. Size 1” Class 300lbs Gasket Materialeg. Uniflon 50

Flange Insulation Kits - ASME DimensionsBOLTSSLEEVESWASHERSGASKETSNominal Gasket Class Outside Dia. Outside Dia. Outside Dia. Outside Dia.Inside Inside LengthInsideInsideOutside OutsideNumber SizeSizeLengthRing No.Inside RatingPipeType EType EDia. (inches) (mm)ofof Bolts of Bolts Dia.Type FDia.Type FDia.Dia.Dia.TypeDDiameter Diameter LBSBolts (inches) (mm) (inches) (mm)(inches)(mm)(inches)(mm)(inches) (mms) (inches) 412.70 1.1/16 26.99 9/1612.70 1.5/16 33.34 9/1612.70 1.13/16 46.04 9/1619.05 2.7/16 61.91 13/1619.05 3.1/16 77.79 /25/85/83/43/412.70 1.3/16 30.16 9/1615.88 1.7/16 36.51 11/1615.88 1.15/16 49.21 11/1619.05 2.11/16 68.26 13/1619.05 3.3/16 80.96 2322.231/25/85/87/87/812.70 1.5/16 33.3415.88 1.9/16 39.6915.88 2.1/16 52.3922.23 2.13/16 71.4422.23 3.7/16 8112.7015.8815.8822.2325.401/25/85/87/8112.70 1.7/16 36.51 9/1615.88 1.11/16 42.86 11/1615.88 2.5/16 58.74 11/1622.23 2.15/16 74.61 15/1625.40 3.11/16 93.66 .1/812.70 1.9/16 39.69 9/1619.05 1.13/16 46.04 13/1619.05 2.7/16 61.91 13/1625.40 3.3/16 80.96 1.1/1628.58 4.3/16 106.36 1/815.88 1.15/16 49.21 11/1619.05 2.3/16 55.56 13/1619.05 2.15/16 74.61 13/1625.40 3.15/16 100.01 1.1/1628.58 5.3/16 131.76 /43/47/81.1/81.1/415.88 2.1/16 52.39 11/1619.05 2.7/16 61.91 13/1619.05 3.3/16 80.96 13/1622.23 3.11/16 93.66 15/1628.58 4.7/16 112.71 1.3/1631.75 5.15/16 150.81 83/47/815.8819.0522.232.1/162.9/163.1/1652.39 11/1665.09 13/1677.79 15/1617.4620.6423.811.5/16 33.341.5/16 33.341.3/4 2693.66119.06

Flange Insulation Kits - ASME Dimensions (Continued)GASKETSWASHERSSLEEVESBOLTSNominal Gasket Class Outside Dia. Outside Dia. Outside Dia. Outside Dia.Inside Inside LengthNumber SizeSizeLength Inside Inside Outside OutsideRing No.Inside RatingPipeType EType EDia. (inches) (mm)ofof Bolts of Bolts Dia.Type FDia.Type FDia.Dia.Dia.Type D Bolts (inches) (mm) (inches) (mm)Diameter Diameter LBS(inches)(mm)(inches)(mm)(inches) (mms) (inches) 2850.803/47/811.1/81.3/81.5/8219.05 2.7/16 61.91 13/1622.23 3.7/16 87.31 15/1625.40 4.7/16 112.71 1.1/1628.58 5.1/16 128.59 1.13/1634.93 5.11/16 144.46 1.7/1641.28 7.15/16 201.61 1.11/1650.80 10.11/16 271.46 811.1/81.1/41.3/81.7/8

Insulation Kits; designed to suit either raised face, flat faced or ring grooved flange assemblies. Each kit comprises electrically insulating flange gasket plus the following components : One phenolic/mylar/GRE sleeve per bolt Two laminated phenolic/mylar/GRE washers per bolt Flange Insulation Kits The Company Novus Sealing manufactures and supplies a variety of high quality products designed .