Transcription

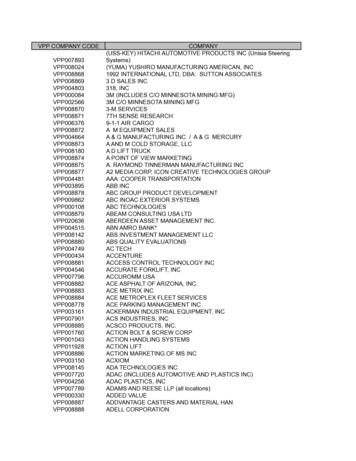

Company Name: Westside ProduceCompany Number: 8737Audit Number: 37575SQFI Audit ReportI. Company InformationCompany NameWestside ProduceAddress 1P.O. Box 7 785 12th StreetAddress 2Click here to enter text.CityFirebaughCountryUnited StatesSQF PractitionerGarrett PatricioFood SectorCategories25. Fresh Produce Wholesaling and DistributionModules AuditedModule 2 (Level 3); Module 12Certified ProductsMelons (Cantaloupe & Honeydew)ConfidentialStatePhone #EmailCACompany #8737Zip Code93622(559) 659-3025garrett@westsideproduce.comPage 1

Company Name: Westside ProduceCompany Number: 8737Audit Number: 37575II.Certification BodyCertifying BodySCS Global ServicesAddress 12000 Powell St.Address 2Suite 600CityEmeryvilleCountryUnited StatesAccreditation BodyIII.ANSICB #StatePhone #CAZip 21Audit ScheduleCertification TypeRecertificationStart Date7/27/2017Scope ofCertificationProduction Process: receiving, cold storage, and distribution. Exclusions: none.ConfidentialLevelEnd DateLevel 37/28/2017Page 2

Company Name: Westside ProduceCompany Number: 8737Audit Number: 37575IV.Audit TeamFirst NameLast NameHeenaPatelPerson #Role9290Lead AuditorAdd Team MemberV.Audit DurationActual Start DateHours Spent atFacilityVI.7/27/201715Actual End Date7/28/2017Hours Spent WritingReport3Certification DecisionCertificate DecisionDateAudit ScoreCertification #Re-certification DateSurveillance AuditDue Date9/6/201792Certificate Issue DateAudit Rating9/6/2017Good87378/15/2018Click here to enter a date.Expiration Date10/29/2018Certification DecisionCertifiedCalculate DatesConfidentialPage 3

Company Name: Westside ProduceCompany Number: 8737Audit Number: 7.12.5.7.2Description2.2.2.2 Records (M)2.5.1.3 ResponsibilityFrequency and Methods2.5.7.1 Internal Audits (M)2.5.7.2 Internal Audits (M)Primary ResponseMinorMinorMinorMinorEvidenceFor the month of July 2017,(i) some records for‘ Forklift Truck Operator Daily/Weekly Checklist’ did not have entries, such as dates.(ii) Some records for ‘Forklift Truck Operator Daily/Weekly Checklist’ did not haveimmediate Supervisor’s review signature and the review date.(iii) Work repair records did not have immediate Supervisor’s review signature and thereview date.(iv) Tunnel temperature tracking records do not have immediate Supervisor’s reviewsignature and the review date.(v) Initial of the person who verifies chemical concentrations is not documented in theChemical Inventory/pH/Concentration records.(vi) Chemical Inventory/pH/Concentration records did not include dates and reviewsignatures.Some records are not reviewed by the SQFP on a scheduled basis:(i) Forklift Truck Operator Daily/Weekly Checklist.(ii) Work order repairs.(iii) Tunnel temperature tracking.Internal Audit on SQF Systems was conducted by the SQFP for year 2017. However,module 12 used for the internal audits did not have any results documented on theoutcome of the audit.There were no records on the internal audit training for the SQFP and the personnel whoconducts in-house GMP inspections.2.9.1.12.9.1.1 TrainingRequirementsMinorSanitation person used to take concentration of the Sodium Hypochlorite was not trainedadequately. Wrong chemical strip was used to take the concentration.12.2.5.312.2.5.3 Dust, Fly and VerminProofingMinorThe external door, located by trap # 22, in the cooler was not self-closing.12.2.7.212.2.7.2 Premises andEquipment MaintenanceMinorHygiene and sanitation clearance is not recorded after any repairs are conducted on theequipment, located near the product storage and handling areas.12.2.11.612.2.11.6 Cleaning andSanitationMinorInventory is not conducted on household cleaners (detergents and sanitizers).ConfidentialPage 4

Company Name: Westside ProduceCompany Number: 8737Audit Number: 37575VIII.Root Cause Analysis (To be completed by ption2.2.2.2 Records (M)2.5.1.3 ResponsibilityFrequency and Methods2.5.7.1 Internal Audits (M)2.5.7.2 Internal Audits (M)Primary ResponseRoot CauseMinorOversight from SQFP.MinorOversight from SQFP.MinorOversight from SQFP.MinorOnly VP was trained and the SQFP was not provided with training.2.9.1.12.9.1.1 TrainingRequirementsMinorSQFP was not aware of taking correct and proper way of taking concentration levels forboth Sodium Hypochlorite and Enviro Bac 2.12.2.5.312.2.5.3 Dust, Fly and VerminProofingMinorHinges got rusted and became hard from lack of use.12.2.7.212.2.7.2 Premises andEquipment MaintenanceMinorOversight from SQFP.12.2.11.612.2.11.6 Cleaning andSanitationMinorOversight from SQFP.IX.Corrective ActionsClausePrimaryResponseCorrective Action(Supplier)Created a food safety managementdaily/weekly/monthly/checklist.Created a checklist that will be checked on adaily/weekly/monthly basis.Verification of Closeout(Certification Body)RequiredCompletion DateClose Out(CB)2.2.2.2MinorApproved and Closed Out (HP).8/27/20178/24/20172.5.1.3MinorApproved and Closed Out (HP).8/27/20178/24/20172.5.7.1MinorCompleted module 12.Approved and Closed Out (HP).8/27/20178/24/20172.5.7.2MinorThe VP provided training on internal audit.Approved and Closed Out (HP).8/27/20178/24/20172.9.1.1MinorOrdered correct strips and concentration wasverified.Approved and Closed Out (HP).8/27/20178/24/2017ConfidentialPage 5

Company Name: Westside ProduceCompany Number: 8737Audit Number: 3757512.2.5.3MinorThe door was fixed.Approved and Closed Out (HP).8/27/20178/24/201712.2.7.2MinorWork repair form was updated.Approved and Closed Out (HP).8/27/20178/24/201712.2.11.6MinorTook inventory of chemicals and amount ofeach chemical.Approved and Closed Out (HP).8/27/20178/24/2017Populate Stats From Sections(Requires Enabled Macros)ConfidentialPage 6

Company Name: Westside ProduceCompany Number: 8737Audit Number: 37575Audit StatementHeaderItemEvidenceOpening MeetingPeople Present at the Opening Meeting (Please list names and roles inthe following format Name: Role separated by comas)Closing MeetingPeople Present at the Closing Meeting (Please list names and roles inthe following format Name: Role separated by comas)Garrett Patricio: Vice President/SQFP, Rosa Meza: SQFPractitioner.Facility DescriptionAuditor Description of Facility (Please provide facility descriptioninclude # of employees, size, production schedule, general layout, andany additional pertinent detailsThe site started the operation in 1993. The site is 45,000 sq.feet. The operation is seasonal. The shed is in operation fromJune till end of October. There are about 18 to 20 workersemployed by the company during the season. The melons(honeydew and cantaloupes) are field packed and received at thefacility. Products are inspected for quality on a random basisduring when received. The receiving area is partially enclosed andcovered by a roof. Products on pallets are transported to thecooler and cooled via forced air cooling system to remove fieldheat. Products are stored in the cooler at 40F prior todistribution. Approved growers contract Westside Produce tohandle, store, distribution and sell to final customers. Customersare responsible for the distribution/transportation of product andsend their trucks for shipping.AuditorRecommendationAuditor RecommendationProceed with certification once corrective actions are accepted.ConfidentialGarrett Patricio: Vice President/SQFP, Rosa Meza: SQFPractitioner.Page 7

Company Name: Westside ProduceCompany Number: 8737Audit Number: 375752.1.1 Management .1.1 ManagementPolicy (M)Senior management shall prepare and implement a policy statementthat outlines as a minimum: the organization's commitment to supplysafe food; the methods used to comply with its customer andregulatory requirements and continually improve its food safety andquality management system; and the organization's commitment toestablish and review food safety and quality and quality objectives.CompliantClick here to enter text.2.1.1.2 ManagementPolicy (M)The policy statement shall be: signed by senior management; madeavailable in language understood by all staff; and displayed in aprominent position and effectively communicated to all staffCompliantClick here to enter text.2.1.1 Management Policy SummaryThe policy statement was prepared by the senior management. The policy was reviewed and it outlines the organization's commitment to supply safe quality food, themethods used to comply with its customer and regulatory requirements, continually improve its food safety management system, and the organization's commitmentto establish and review food safety and quality objectives. The policy statement is signed by the President. The Facility Manager and SQFP were interviewed and theywere able to describe the content of the statement. The policy statement in English and Spanish is displayed on the employee bulletin board in the employee breakroom. In addition, the policy statement is included in the annual refresher training.ConfidentialPage 8

Company Name: Westside ProduceCompany Number: 8737Audit Number: 375752.1.2 Management dence2.1.2.1 ManagementResponsibility (M)The organizational reporting structure describing those who haveresponsibility for food safety and quality and their interrelationshipshall be defined and communicated within the organization.CompliantClick here to enter text.2.1.2.2 ManagementResponsibility (M)The senior management shall make provision to ensure fundamentalfood safety and quality and quality practices are adopted andmaintained.CompliantClick here to enter text.2.1.2.3 ManagementResponsibility (M)The senior management shall ensure adequate resources are availableto achieve food safety and quality objectives and support thedevelopment, implementation, maintenance and ongoing improvementof the SQF System.CompliantClick here to enter text.2.1.2.4 ManagementResponsibility (M)The senior management shall designate an SQF practitioner for eachsite with responsibility and authority to oversee the development,implementation, review and maintenance of the SQF System, includingfood safety fundamentals outlined in 2.4.2, the food safety planoutlined in 2.4.3, and the food quality plan outlined in 2.4.4; takeappropriate action to ensure the integrity of the SQF System,communicate to relevant personnel all information essential to ensurethe effective implementation and maintenance of the SQF System.CompliantClick here to enter text.2.1.2 Management yResponseEvidencePage 9

Company Name: Westside ProduceCompany Number: 8737Audit Number: 375752.1.2.5 ManagementResponsibility (M)2.1.2.6 ManagementResponsibility (M)2.1.2.7 ManagementResponsibility (M)The SQF practitioner shall be employed by the supplier as a companyemployee on a full-time basis, hold a position of responsibility inrelation to the management of the supplier's SQF System, havecompleted a HACCP-based training course and be competent toimplement and maintain HACCP-based food safety and food qualityplans, have an understanding of the SQF Code level 3 and therequirements to implement and maintain SQF Systems relevant to thesupplier scope of certification.The responsibility for establishing and implementing the training needsof the organization's personnel to ensure they have the requiredcompetencies to carry out those functions affecting products, legality,and safety and quality shall be defined and documented.All staff shall be informed of their responsibility to report food safetyand quality problems to personnel with authority to initiate action.ConfidentialCompliantClick here to enter text.CompliantClick here to enter text.CompliantClick here to enter text.Page 10

Company Name: Westside ProduceCompany Number: 8737Audit Number: 375752.1.2 Management ResponsibilityElement2.1.2.8 ManagementResponsibility (M)2.1.2.9 ManagementResponsibility (M)DescriptionJob descriptions for those responsible for food safety and quality shallbe documented and include provision to cover for the absence of keypersonnel.The senior management shall establish processes to improve theeffectiveness of the SQF System to demonstrate iantClick here to enter text.CompliantClick here to enter text.2.1.2 Management Responsibility SummaryThe senior management has provided sufficient resources to achieve the food safety objectives and to support the on-going maintenance and improvement of theSQF System. The SQF Practitioner was interviewed and according to her, the process has been the same for many years, however adequate resources have beenprovided to maintain the program. The SQF Practitioner (FS Manager) is designated by the organization. The SQF Practitioner has the responsibility and authority tosupport the development, implementation, maintenance, and ongoing improvement of the SQF system.The organizational chart was verified by the senior management and a brief description of job responsibility was documented, which provided a snapshot of howpositions interact and share responsibility for food safety and quality. The Vice President is a SQFP and is assigned to oversee the food safety program as a back-up.The SQF Practitioners are employed by the supplier as company employees on a full-time basis, hold a position of responsibility in relation to the management of thesupplier's SQF System.Training: The SQFP, Rosa Meza has attended a 2 day training class on implementing SQF Systems provided by SCS on March 10-11, 2015. She took a 2 day food safetyawareness training class in May 2013, provided by Western Food Safety Summit. She also attended a 1 day Global GAP training provided by SCS in 2012. The SQFP andFacility Manager took a 2 day HACCP training, provided by SCS on 11/13/12 and 11/14/12. The SQFP took Food Safety Rule training course at Western Food SafetySum

SQFI Audit Report I. Company Information Company Name Westside Produce Company # 8737 Address 1 P.O. Box 7 785 12th Street Address 2 Click here to enter text. City Firebaugh State CA Zip Code 93622 Country United States Phone # (559) 659-3025 SQF Practitioner Garrett Patricio Email garrett@westsideproduce.com Food Sector CategoriesFile Size: 1MBPage Count: 119

![Shareholders’ Agreement of [Company name] company. 1 .](/img/1/startup-founders-sha-sample.jpg)