Transcription

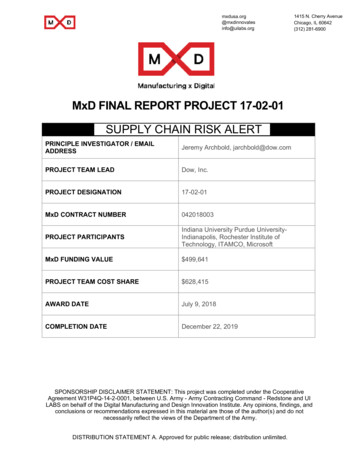

mxdusa.org@mxdinnovatesinfo@uilabs.org1415 N. Cherry AvenueChicago, IL 60642(312) 281-6900MxD FINAL REPORT PROJECT 17-02-01SUPPLY CHAIN RISK ALERTPRINCIPLE INVESTIGATOR / EMAILADDRESSJeremy Archbold, jarchbold@dow.comPROJECT TEAM LEADDow, Inc.PROJECT DESIGNATION17-02-01MxD CONTRACT NUMBER042018003PROJECT PARTICIPANTSIndiana University Purdue UniversityIndianapolis, Rochester Institute ofTechnology, ITAMCO, MicrosoftMxD FUNDING VALUE 499,641PROJECT TEAM COST SHARE 628,415AWARD DATEJuly 9, 2018COMPLETION DATEDecember 22, 2019SPONSORSHIP DISCLAIMER STATEMENT: This project was completed under the CooperativeAgreement W31P4Q-14-2-0001, between U.S. Army - Army Contracting Command - Redstone and UILABS on behalf of the Digital Manufacturing and Design Innovation Institute. Any opinions, findings, andconclusions or recommendations expressed in this material are those of the author(s) and do notnecessarily reflect the views of the Department of the Army.DISTRIBUTION STATEMENT A. Approved for public release; distribution unlimited.

mxdusa.org@mxdinnovatesinfo@uilabs.org1415 N. Cherry AvenueChicago, IL 60642(312) 281-6900TABLE OF CONTENTSEXECUTIVE SUMMARY . 3Project Deliverables . 4PROJECT REVIEW . 4Use Cases & Problem Statement. 4Scope & Objectives. 5Planned Benefits . 6Technical Approach . 7Results .15System Overview .16System Requirements.18System Architecture .19High-Level System Architecture .21Features & Attributes .21Target Users & Modes of Operation .24Software Development/Design Documentation .25Discussion & Analysis .26Industry Impact .26Key Performance Indicators & Metrics .27Accessing the Technology .31Presentations .31Lessons Learned .32Conclusions & Future Work.33Next Steps .33Transition Plan .35APPENDICES .37Appendix A: Definitions .37Appendix B: Demos and Presentations .38Appendix C: Validation & Testing .38Appendix D: User Resources .39Final Project Report January 29, 20202

mxdusa.org@mxdinnovatesinfo@uilabs.org1415 N. Cherry AvenueChicago, IL 60642(312) 281-6900EXECUTIVE SUMMARYThe purpose of this report is to document MxD Project 17-02-01 and share the deliverables,technical approach, results, discussion, analysis, and conclusions. This project worked toimprove and further automate the Supply Chain Event Management (SCEM) process bycreating a framework to digitize, integrate, and automate the information pipeline and actionworkflow as well as offer recommendations based on prior mitigation actions. The primary usecase is integration within a supply chain including an event management team, logistics teams,business decision makers, and customer service representatives, where event mitigationactions can be determined using support data, tracked for cycle-time and where the output canbe utilized to make faster informed decisions in similar situations in the future.Work on this project was split into modules that perform independent actions and when linked,deliver the desired results. The modules are: Predictive Transit: This module provides the shipment planner with an estimated transittime for future shipments based on source, destination, planned shipment date, producttype, weather, and event data.Risk Assessment: This module provides a graphical user interface to allow a user todocument current or future events and automatically compute a risk score for individualshipments in the affected area.Mitigation Planning: This module automatically sends a communication (text/SMS oremail) to subscribed decision makers when a relevant shipment has been promotedfrom the Risk Assessment module. The communication gives them an overview of theshipment and the event impacting it. The user can enter mitigation information that isthen recorded, storing the knowledge. After enough mitigation decisions are collected, amachine learning method can be trained to then automate recommended actions.SIMBA Chain Communications: This module integrates relevant data from differentmodules using a blockchain ledger and sends automated notifications to targetedindividuals when risk thresholds are met.Performance Analytics: This module is a data enablement SQL table with the Azureframework with direct connection to a dashboard that calculates and displays KeyPerformance Indicators (KPIs) which are derived from the various modules. It providesaggregated data and an easy access point for monitoring and decision making.The above modules were tested using Dow historical shipment data in the same form that datawould be expected when being deployed for full use in daily operation. In addition to the abovemodules, this project delivered: technical demonstrations, a report on existing technology,documentation and user guides for the modules, a commercialization plan report, MxD technicaldeliverable acceptance checklists, a half day seminar, and this report.This project delivered the expected functionality but was limited by a lack of a live productionenvironment that would have allowed for a more complete demonstration of the mitigationplanning module recommender system. The further exploration of a future pilot will be part ofDow’s next steps activities.MxD members can access all the software on the MxD membership portal according to themembership agreement post-project. SIMBA Chain offers commercial Smart Contract as aService (SCaaS) software for blockchain integration. The mitigation planning module andperformance analytics modules are deployed as examples only and may be deployed using anypreferred dashboard or web tools. The predictive Transit module requires least two years ofhistorical shipment data .Final Project Report January 29, 20203

mxdusa.org@mxdinnovatesinfo@uilabs.org1415 N. Cherry AvenueChicago, IL 60642(312) 281-6900PROJECT DELIVERABLESThe following list includes all deliverables created through this project. These deliverables willbe referenced throughout this report and should be accessible on the MxD membership portal inaccordance with the rights defined by the Membership Agreement. Specific deliverable typesinclude, but are not limited to, the following items.Table 1: Project Deliverables#DELIVERABLE NAME1Report on ExistingTechnology 11.13.19DESCRIPTIONHigh-level overview of existing technologies thatwere evaluated for project integrationFORMAT OF DELIVERY.docx2MxD Project FinalPresentation FINAL.pptxComplete final presentation slide deck.pptx3Mitigation Planning ModuleSource code for Web UI, APIs source code forpulls/pushes from SQL, example SQL structure4Predictive Transit ModuleAdmin UI, User UI, ML algorithms source code,Executables, example input and output tables,APIs source code for an SQL backend database.5Risk Assessment Module6ITAMCO-SIMBACommunications Module7Performance AnalyticsModule8Implementation Guide SIMBA Chain IntegrationJupyter notebook w/ source code and UI,executables, example input and output tablesstructure, APIs source code for pulls/pushes fromSQL, example SQL structureContains installation instructions for an instanceSIMBA Chain’s Smart Contract as a Service(SCaaS) Azure Environment.Sample dashboard and list of demonstrated andrecommended KPIs. Azure SQL data structure(reference Mitigation module architecture)Contains developer guide for creating SIMBAChain’s Smart Contract as a Service (SCaaS)clients.Folder with readme,licensing.txt,documentation and zipfolders with project filesFolder with readme,licensing.txt,documentation and zipfolders with project filesFolder with installation anduser guide .docx files9Overall SystemArchitectureThis shows the overall architecture of thetechnology deliverables10PresentationsCollection of presentation and demonstrationsfrom throughout the project duration, including therecording of the final presentation.Word document.pbix and .xlsxWord document, Pythonand .NET softwareexamples, LICENCE.txtand README.md.pdf.pdf, .pptx, and .mp4 filesPROJECT REVIEWThis section includes use cases and a problem statement for the project, the scope andobjectives, and planned benefits.Use Cases & Problem StatementThe project aims to address the impact of external events on outbound logistics, an impactwhich is not currently addressed by Supply Chain Event Management (SCEM) systems. Thisgap includes:Final Project Report January 29, 20204

1415 N. Cherry AvenueChicago, IL 60642(312) 281-6900Sensing and providing advance warning of events (such as major weather or socialpolitical events) that would impact schedules or transit,Objectively assessing the risk associated with an event and shipment pairing,Proactively mitigating risk impact in an expedited and more data informed manner, andRecording what mitigation actions are successful for future knowledge and modelling.The primary use case can be described from the point of view of a customer servicerepresentative (CSR) or shipment owner: As a CSR, I want to proactively address the riskassociated with my shipment due to an unexpected event so that I can mitigate the costassociated with a delayed shipment and minimize the negative customer experience impact.Currently, delayed shipments impacted by events are often reacted to after the fact or as theimpact is happening. This leads to scenarios when a CSR is notified of a delay just as thecustomer is just finding out as well. In the case of events with longer lead times, such as ahurricane, there is some proactive work that can be in a “war room” style of group mitigationactivity. What this kind of reaction typically fails to do is track and record what actions weretaken and how effective they were, so some individuals come away with firsthand experiencebut there are no records or stored knowledge to use the next time a similar event occurs.Another use case from the point of view of a CSR: As a CSR, I want to have a recommendationfor how to mitigate the risk associated with a shipment so that I can keep the shipment onschedule using proven best practices.Scope & ObjectivesThe core objectives are to deliver a more systematic monitoring capability and betterassessment of risk exposure, as well as a means by which mitigation decisions can be mademore accurately and rapidly, so as to create a more positive customer experience andemployee experience. The scope selected needs to ensure that this can be demonstratedeffectively.Dow is a very large global manufacturing company that does business in about 160 countries.Modes of Transportation (MOTs) include Air, Deep Sea, Inland Waterways, Pipeline, PostalService, Rail, Road and Sea. Across these primary MOTs, there are more than a couple dozenvarious shipment types that help move hundreds of thousands of shipments. Setting realisticexpectations for what could be tackled in this project, while covering sufficient complexity,impacted the scope of the work selected and performed on this project. The framework ismodular and extensible so that manufacturers can integrate supply chain solutions suited totheir business needs at desired scale of deployment, regardless of MOTs and shipment volume.Necessarily we limited our project scope for the proof-of-concept shipment selection. We did,however, make a selection that would be perhaps the most impactful and likely most relatable tothe majority of domestic manufacturing partners, as our intended scope was to help cover themost common and frequent shipping types. Shipment data was limited to North American(US/CAN) road and rail outbound shipments being tracked by origin and destination points.While it would have been ideal, we were not able to refine scope to only “real-time shipmentvisibility” data from electronic logging devices (ELDs), as this may have offered enhancedmodeling data points. Two years of historical data wase used for feature selection, training andtesting of the machine learning modules for transit time prediction, and the forward-lookingplanning window was limited to 5 days. Further, the solution was limited to internalFinal Project Report January 29, 20205

mxdusa.org@mxdinnovatesinfo@uilabs.org1415 N. Cherry AvenueChicago, IL 60642(312) 281-6900communications only, but has full potential to incorporate supplier and customercommunications through the framework.Beyond shipment scope, there were additional scoping challenges during the project durationregarding the technology and models considered. Notably the decision to utilize native Azureconnectivity to move and aggregate the module flow and key communications, although theblock chain solution could also perform these tasks if working in a non-integrated environment,and indeed was developed to augment the native Azure capability, as demonstrated. Also, ascope decision was made regarding the mitigation module and the recommender logic. Thedecision came about as we lacked historical decision data in a format that was able to beorganized to train the model. Therefore, we opted to scope out the recommender until such apoint in time when the newly designed mitigation module could capture and store newmitigations decisions for this training. While this was unfortunate, there was not enough timeoriginally scoped for the project for this additional manual data gathering and cleansing activity.Overall the scope was still quite acceptable for the testing and validation of the event and riskmodules and presented a good amount of variability so we could comfortably be assured thatthe solution presented would deliver value. This final project scope represented approximatelya quarter of the total global shipments for Dow in 2019.Planned BenefitsThe planned benefits of the solution are increased customer experience and on-time delivery,and decreased response time, recovery time, and freight and manpower costs associated withdisruptions. These benefits would be expected as soon as the solution is implemented andwould improve over time as it becomes more integrated into work processes.Benefits can be achieved by pursuing an agile and efficient supply chain infrastructure that iswell monitored and maintained to meet, or exceed, customer expectations/needs during supplychain disruption events.The benefit of such a system would allow the shift towards proactivity regarding event impactprediction, risk prioritization, mitigation planning, timely and consistent communications, with arobust system performance monitoring and value measurement capability.Recently, Dow has conducted a comprehensive assessment of the expected value from such asolution and found that it can deliver reductions in disruption incurred freight costs andreductions in disruption related manpower costs with a total value of nearly 5MM over threeyears in the Dow’s Outbound Logistics space for North America. Moreover, Dow’s research intoresponse time latency revealed an important connection between days in transit and cost –primarily through freight cost surges – but also in Manpower costs to manage a disruption. Afaster response means fewer delays, fewer suboptimal shipments, and superior customerservice during a crisis. The proposed solution will reduce freight costs based on a substantialimprovement in response to disruptive events and better prioritization of shipments based onimproved categorization of risks. The scalable, automated approach will also reduce thesignificant manpower costs associated with managing disruptions. Large scale events incur agreater manpower and shipping costs. The goal of the proposed SCEM solution is to ensurethat significant disruptive events are handled as efficiently as possible.Final Project Report January 29, 20206

mxdusa.org@mxdinnovatesinfo@uilabs.org1415 N. Cherry AvenueChicago, IL 60642(312) 281-6900TECHNICAL APPROACHThis section outlines the functionalities of each module (i.e., Predictive Transit, RiskAssessment, Mitigation Planning, and SIMBA Chain, Performance Analytics modules).There is also a strong emphasis on the integration of the modules, as while they can eachfunction independently, much of the end-to-end value comes from an integrated solution acrossthe connected modules.The way our project team approached this was by putting a strong focus on our Use Cases, andassuming the personas of our key users. By doing so we could better understand how what wewere building would be utilized in a production environment. As an example, a CSR would notwant to see various types of communications for all events when triggered, so creating a systemthat could consistently deliver only the required details in a timely and organized manner waskey. The CSR also would like to have control over the event alerts they see, so having aflexible subscription capability was key technical objective.Likewise, a business decision maker who has been alerted of an event that is of meaningful risklevel would always be interested in reviewing decision support data, and thus would appreciatehaving that readily available. This happens to be a huge bottleneck as reporting access/skillcan be restricted and is also a time-consuming activity. The technical approach was to pre-pullthe multiple data sources periodically and aggregate within our system so it would be ready andavailable when needed, and then could be integrated into the mitigation module for direct reviewby the business decision maker, enabling much better and faster data driven decisions.The data we included encompasses all the possible sources that are utilized today. These areresources that the business ‘wants’ to consider and utilize, but due to access and timing issues,they often would not spend the time to acquire and join/merge the support data with theimpacted shipments. So in Dow’s case, the data was available, but was not utilized due toaccessibility, but our technical approach for an integrated framework and data aggregationsolved that problem.Final Project Report January 29, 20207

mxdusa.org@mxdinnovatesinfo@uilabs.org1415 N. Cherry AvenueChicago, IL 60642(312) 281-6900Predictive TransitThe predictive transit module works on aTwitter DataCount of tweets for each keywords:route by route basis, training a model usingroad, event, accident, traffic.historical shipment data and validatingWeatherMaximum and minimumagainst more current data. A route is definedDatatemperature, maximum andaccording to a source/destination zip codes.minimum rain, Maximum andThe route is geofenced and historicalminimum snowweather and events on that route areSupplierDataShipment dateextracted. A model is trained using threeShipment type (e.g., full truck load,groups of historical data: supplier shipmentspartial truck load, tank truck)data, weather data, and social event dataDelivery priorityrelated to traffic. Once a model is trained forDelivery itema given route, it can be used to estimate thetransit time for a future shipment on theCarrier identificationsame route. The estimated transit time fromDangerous good indicator (Yes/No)the model and the baseline transit timeLoading point for the shipmentestablished by the shipment planner arecompared and presented to the RiskTable 1 Model input features.Assessment module for review and analysis.In the future the estimated transit timederived from Predictive Transit module canbe used to establish realistic event-adjusted reference transit time during shipment planning.In order to construct a model for a given route, the supplier data is complemented with twoexternal datasets: social media and weather. The former is extracted from Twitter and thelatter from NOAA . These two sources were selected because they provide publicly availablehistorical data. The combination of the three datasets constitute the input features of theproposed model which are listed in Table 1.In order to generate the data needed for each model, several steps are performed. The first stepconverts the source/destination zip codes into a sequence of geocodes and geofences alongthe route. Each geofence has a radius and a centre represented by a longitude and a latitude.This conversion is performed only once for each route by using geocoding and geofencingapplications such as Geocode and OSRM , respectively. Tweets are then retrieved by usinga date, a geofence from the route and a set of query keywords. The keywords are road, event,accident, and traffic. These query keywords were selected based on an examination of severaltweets. For instance, contexts such as “road congestion” and “road construction” wereaggregated under the keyword “road” because of the co-occurrence of the underlying terms.Once the above extraction is completed, duplicate tweets are deleted, and the total number oftweets that mention each keyword are summed. The frequency of occurrence of each keywordis used as an input feature to the model (Table 1). We opted for this approach in order to limitthe computational complexity of the model given that a supplier may have in excess of athousand routes where each route corresponds to a model.In order to extract weather data, weather stations along each route are identified according totheir proximity to the centers of the geofences. Daily minimum and maximum values are thenextracted for temperature, rain and snow (Table 1). These values are aggregated along theroute to create overall minimum and maximum daily values.Finally, the supplier data include the shipment date. The remaining features in this group arecategorical and include the shipment type (e.g., full truck load or partial truck load), the deliveryFinal Project Report January 29, 20208

mxdusa.org@mxdinnovatesinfo@uilabs.org1415 N. Cherry AvenueChicago, IL 60642(312) 281-6900priority which represents the priority level given to the shipment, the delivery item whichrepresents the product being delivered, the carrier assigned to the shipment, a dangerous goodindicator that identifies whether or not the product being delivered falls under the category ofhazardous materials, and the loading point assigned to the shipment.Using the above data, a machine learning model is developed for each route. This modelconsists of an ensemble of classifiers that are trained using a set of shipments and tested usinga different set of shipments. Each classifier uses support vector machine (SVM) with radialbasis function kernel. For the purpose of this study, the training shipments span a two yearperiod and the validation was performed on shipments spanning a period of 6 months in 2019.This selection of training and testing shipments guarantees the separation between training andtesting datasets. Moreover, it aligns with the aim of this application which is to use historicalshipment data in order to estimate the transit time for future shipments.The number of classifiers for each route is determined based on the range of the transit time.The transit time is measured in number of days where a transit time equal to 0 corresponds tothe same day delivery, a transit time of 1 day corresponds to the next day delivery, etc. Foreach route, a valid range (i.e., minimum, maximum) for the transit time is defined from thehistorical supplier shipment data. For each value in the transit time range a classifier isdeveloped. For example, if a given route has a transit time range from 0 days to 2 days, anensemble of three different SVM classifiers are developed. The goal of the first classifier is toidentify the shipments that have a transit time of 0 days. Similarly, the goal of the second andthird classifiers is to identify the shipments that have a transit time of 1 and 2 days, respectively.The result of the classifiers are then combined to estimate the transit time for any shipmentusing the one-versus-all approach.Risk AssessmentThe Risk Assessment module considers a subjective assessment of likelihood (SAL) (manualdecision from the SCEM team), a shipment priority score (based on business unit weights andcustomer variables), and transit information from the previous module to create a risk score foreach shipment impacted by an event (source or destination is within the event geofence). If thisrisk score is above a set determined level, the shipment/event is promoted forward for review inthe Mitigation Planning module.The shipment priority score (SPS) is computed using critical customer variables weighted by thespecific business group. Each business unit can customize the weights to best reflect theirspecific internal processes. The weights are internally normalized to permit user friendly unitsand different scales for different customer variables, while maintaining desired relativeimportance of the customer variables. The SPS is then combined with the SAL and nonlinearlymapped to produce the risk score, as illustrated in the figure below.Final Project Report January 29, 20209

mxdusa.org@mxdinnovatesinfo@uilabs.org1415 N. Cherry AvenueChicago, IL 60642(312) 281-6900Figure .This process is integrated with the manufacturer’s database which provides data on shipments,customer variables, and business unit groups. Additionally, there is a connection to the PTM.The delayed shipment identified by the PTM are displayed per SCEM analyst's request, byoverlaying markers on the map of previously identified shipments on a day. When an event issubmitted by the event manager, the system records the event data into the manufacturer’sdatabase which contains several tables, described in the stand alone document on the RAmodule (RA Module Final Documentation.docx). In total, the module employs eleven internaltables for storing the data and model parameters. The RA module notifies SIMBA chain, whichin turn creates immutable records of events containing at-risk shipments that are above aprescribed risk threshold. The resulting records from an event creation using the RA module arecurrently used by the manufacturer to trigger emails about the at-risk shipments to businessgroup managers for mitigation options.Mitigation PlanningMaking timely and informed mitigation decision around your impacted shipments is a criticalopportunity for nearly all manufactures. Of course, the initial challenge is coming to know aboutwhat events are occurring (event module), and of those many events which are actually hittingyour shipments in an impactful way (risk module), and only then can we know that action isrequired to perhaps alter the course the impacted shipment via mitigation planning.The Mitigation Planning module will proactively notify decision makers when they have impactedshipments and collect their mitigation decision feedback, including final mitigation actions,primary decision factor that influenced the decision (used to modify future risk assessmentweighting), cost to serve data (disruption incurred freight and manpower costs), and atimestamp to measure time to recover metrics. These are collected through a web form that issent to subscribed users for a business, customer, location, route or other criterion. Thewebform currently provides relevant supporting customer data by querying the reportingFinal Project Report January 29, 202010

mxdusa.org@mxdinnovatesinfo@uilabs.org1415 N. Cherry AvenueChicago, IL 60642(312) 281-6900database an

SIMBA Chain Integration Contains developer guide for creating SIMBA Chain's Smart Contract as a Service (SCaaS) clients. Word document, Python and .NET software examples, LICENCE.txt and README.md . 9 . Overall System Architecture This shows the overall architecture of the technology deliverables .pdf . 10