Transcription

t)'1'fJJ8t. ( AI(& "lU.S. ENVIRONMENTAL PROTECTION AGENCYPR(f(i--:1' VESSEL SAFETY MANUALOFFICE OF ADMINISTRATION AND RESOURCES MANAGEMENTSAFETY. HEALTH AND ENVIRONMENTAL MANAGEMENT DIVISIONWASHINGTON, DCAPRIL 2012

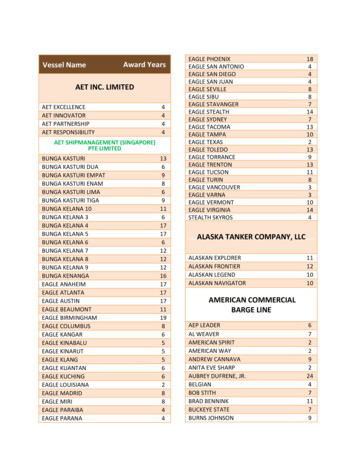

FOREWORDThis manual sets forth minimum acceptable requirements for the safety and occupational healthof all individuals (crew, scientific staff and passengers) who embark on U.S. EnvironmentalProtection Agency (EPA) vessels of any size. EPA vessels currently range in size from theOcean Survey Vessel Bold (224 feet) and Great Lakes Research Vessel Lake Guardian (180feet), down to 14-foot aluminum skiffs powered by small outboard engines, canoes andinflatables. Accordingly, this manual addresses the entire spectrum of EPA vessel sizes, poweredand unpowered. EPA vessels may be operated under contract or charter, by professionallyqualified EPA crew, or, in the case of small craft, by EPA scientific staff on an intermittent basis.To achieve the EPA goal of minimizing risk to anyone who embarks on an EPA vessel, allconcerned shall read and understand the requirements of this manual.EPA vessels are public vessels of the United States. It is EPA’s intent to maintain compliancewith those existing standards and codes of marine safety (which appear in Title 46 of the Code ofFederal Regulations) deemed necessary to achieve the EPA risk management objective. To thatend, this manual sets forth the minimum requirements that must be met to attain EPA’s marinehealth and safety objectives.All aspects of “good marine practice” cannot be set forth in statutes, regulations or standards.Accordingly, the absence of a written requirement for a specific issue should not be interpretedas meaning that the issue has a lower importance or priority. Vessel captains/masters andoperators of small craft should emphasize to all personnel that health and safety are considered tobe paramount at all times onboard EPA vessels.EPA Class C vessels’ contractor crews are subject to the Safety of Life at Sea InternationalSafety Management Code. This manual provides the top-tier policy for implementing this coderequirement.In addition to safety requirements, this manual also includes general security requirements for allEPA vessels.The EPA's Safety, Health and Environmental Management Division welcomes any suggestionsfor improving this manual. Please contact us at SHEMD-at-Your-Service@epa.gov to provideyour feedback.Revision dated April 2012i

TABLE OF CONTENTS1.INTRODUCTION. 1-11.1Scope and Policy . 1-11.2Background and Authority . 1-11.3Program Applicability. 1-11.4EPA Auditing and Self-Assessment Programs. 1-21.5Environmental Management System (EMS) and Stewardship . 1-21.6Principles of a Safety and Health Management System (SHMS) . 1-31.7Changes . 1-32.PROGRAM ADMINISTRATION. 2-12.1Goals and Objectives . 2-12.2Roles and Responsibilities. 2-13.CLASSES OF EPA VESSELS . 3-13.1Background. 3-13.2Vessel Classifications. 3-13.3Vessel Types. 3-54.LAWS AND REGULATIONS. 4-14.1Involved Organizations . 4-15.MANNING . 5-15.1Background. 5-15.2Licensed Personnel . 5-15.3Makeup of Crew . 5-15.4Scientific Personnel Limitations – All EPA Class Vessels . 5-25.5Captain/Master of the Vessel. 5-35.6Chief Scientist. 5-35.7Vessel Organization – Class C Vessels. 5-36.GENERAL MARINE ENGINEERING AND ONBOARD SAFETYREQUIREMENTS . 6-16.1Background. 6-16.2Standards . 6-16.3Marine Engineering Details. 6-26.4Exhaust Uptake and Vent Control . 6-26.5Electrical Engineering Details . 6-36.6Structural Standards and Alterations. 6-36.7Stability . 6-46.8Ground Tackle . 6-56.9Inspection . 6-56.10 Oxygen and Acetylene Cylinders . 6-56.11 Scientific Equipment . 6-76.12 Watertight Integrity. 6-8Revision dated April 2012ii

6.13Onboard Safety Requirements. 6-107.FIRE PROTECTION. 7-17.1Applicability . 7-17.2Responsibilities. 7-17.3Firefighting Responsibilities . 7-17.4Fire Control Plans . 7-77.5Quality Controls. 7-77.6General Fire Prevention Training . 7-107.7Marking of Fire Protection Equipment . 7-117.8Control of Ignition Sources and Combustible Materials. 7-127.9Life Safety Considerations . 7-177.10 Structural Fire Protection . 7-187.11 Fire-Extinguishing Systems. 7-197.12 Precautions for Flooded Space Fire Suppression Systems. 7-227.13 Fire Detection and Alarm Systems . 7-238.MEDICAL AND FIRST AID. 8-18.1Purpose . 8-18.2Specific Requirements . 8-19.LIFESAVING AND SAFETY, COMMUNICATIONS AND POLLUTIONCONTROL EQUIPMENT. 9-19.1Life Saving and Safety Equipment . 9-19.2Communications Equipment . 9-149.3Pollution Control Equipment. 9-1910.VESSEL OPERATIONS, RECORDS, REPORTS, AND EMERGENCYNOTIFICATION. 10-110.1 Introduction . 10-110.2 Station Bills . 10-110.3 Log Books . 10-110.4 Cruise and Float Plans. 10-110.5 Reporting – All EPA Class Vessels . 10-210.6 Weather Reports . 10-310.7 Emergency Crisis and Accident Reporting Requirements. 10-311.SOLAS INTERNATIONAL SAFETY MANAGEMENT (ISM) SYSTEM. 11-111.1 Background. 11-111.2 Applicability . 11-111.3 Safety Management System . 11-111.4 ISM Safety Management Systems Certification and Enforcement . 11-212.HEAVY WEATHER. 12-112.1 Discussion. 12-112.2 EPA Class A Vessel Weather Restriction . 12-112.3 Safety Precautions During Heavy Weather Conditions . 12-1Revision dated April 2012iii

13.VESSEL SECURITY . 13-113.1 Introduction . 13-113.2 Background. 13-113.3 Security Requirements for EPA Vessels . 13-114.CHARTERING NON-EPA-OWNED VESSELS. 14-114.1 Background. 14-114.2 Pre-Charter Evaluation . 14-114.3 Recommended Inspection Checklist for Chartering Non-EPA-OwnedVessels. 14-2APPENDIX A VESSEL SAFETY OVERVIEW. A-1APPENDIX B SEAMANSHIP/DECK AND SCIENCE OPERATIONS.B-1APPENDIX C DEFINITIONS .C-1APPENDIX D EXAMPLE FLOAT PLANS . D-1APPENDIX E INJURY AND ILLNESS FORMS .E-1APPENDIX F EMERGENCY NOTIFICATION CHECKLIST . F-1Revision dated April 2012iv

LIST OF TABLESTable 3-1. Examples of EPA Vessel Classifications . 3-2Table 5-1. EPA Class C Vessel Crews Minimum Merchant Mariner Credential (MMC)Endorsement and Manning . 5-4Table 5-2. EPA Class C Vessel Crew Minimum STCW for Seafarers Endorsements Requiredfor Service Near Coastal and Ocean, in Addition to the MMC Endorsements in Table 5-1Service in Great Lakes or U.S. inland waters is exempt, per 46 CFR 202(5) . 5-6Table 6-1. USCG-Approved Color Legend for Piping Systems . 6-2Table 7-1. Fire Protection Equipment Guidance . 7-9Table 7-2. Minimum Fire Separations . 7-19Table 7-3. Typical Fire Extinguishers. 7-21Table 7-4. Typical Fire Extinguisher Space Locations. 7-21Table 7-5. Minimum Fire Extinguishers for Class A Vessels . 7-22Table 8-1. First Aid Kit Contents . 8-3Table 8-2. Nonprescription Medication Inventory . 8-4Table 8-3. Prescription Medication Inventory. 8-6Table 9-1. Fire Extinguishers for Class A Vessels . 9-13LIST OF FIGURESFigure 7-1. Fire Procedure Template . 7-6Figure 7-2. Welding Permit Template . 7-15Figure 7-3. Hot Work Permit Checklist . 7-16Figure 8-1. Environmental Protection Agency Survey Personnel Data Sheet . 8-8Revision dated April 2012v

LIST OF ACRONYMSAAAssistant AdministratorABable seamanABSAmerican Bureau of ShippingABYCAmerican Boat and Yacht CouncilAEDautomated external defibrillatorAIHAAmerican Industrial Hygiene AssociationAISAutomatic Identification SystemANSIAmerican National Standards InstituteARPAAutomatic Radar Plotting AidASHRAEAmerican Society of Heating, Refrigerating, and Air-Conditioning Engineersbhpbrake horsepowerCFRCode of Federal RegulationsCHMChemical Hygiene ManagerCHPChemical Hygiene PlanCO2carbon dioxideCOLREGInternational Regulations for Preventing Collisions at SeaCPRcardiopulmonary resuscitationDOTDepartment of TransportationDPADesignated Person AshoreDSCDigital Selective CallingEEBAemergency escape breathing apparatusEMSEnvironmental Management SystemEOexecutive orderEPAU.S. Environmental Protection AgencyEPIRBEmergency Position Indicating Radio BeaconGMmetacentric heightGMDSSGlobal Marine Distress Safety SystemGPSGlobal Positioning SystemGTgross tonnageRevision dated April 2012vi

H2Shydrogen sulfideHAZMAThazardous materialsHFhigh frequencyHPhorsepowerIAPPInternational Air Pollution PreventionIEEEInstitute of Electrical and Electronic EngineersIMOInternational Maritime OrganizationINMARSATInternational Maritime Satellite SystemISMInternational Safety ManagementJHAjob hazard analysisLOTOlockout/tagoutMARPOLInternational Convention for the Prevention of Pollution from ShipsMARSECMaritime SecurityMED-EVACmedical evacuationMFmedium frequencyMMCMerchant Mariner CredentialMMSIMaritime Mobile Service IdentityMOBman overboardMSDMarine Sanitation DevicesMSDSMaterial Safety Data SheetNAVTEXNavigation TelexNECNational Electrical CodeNFPANational Fire Protection AssociationNIOSHNational Institute for Occupational Safety and HealthNOAANational Oceanic and Atmospheric AdministrationNOxnitrogen oxideNRCNational Research CouncilNTASNational Terrorism Advisory SystemNVICNavigation and Vessel Inspection CircularsOAOffice of AdministrationOARMOffice of Administration and Resources ManagementRevision dated April 2012vii

OSHAOccupational Safety and Health Administration (U.S. Department of Labor)PFDpersonal flotation devicePMLpersonal marker lightPPMparts per millionPPOBPolicy, Programs, and Oversight BranchQA/QCquality assurance/quality controlQMEDQualified Member Engineering DepartmentRARegional AdministratorRCCRescue Coordination CenterRCRAResource Conservation and Recovery ActRFradio frequencySCBAself-contained breathing apparatusSEESenior Environmental EmploymentSHEMsafety, health and environmental managementSHEMDSafety, Health and Environmental Management DivisionSHEMPSafety, Health and Environmental Management ProgramS.H.I.P.Seafarers’ Health Improvement ProgramSHMSSafety and Health Management SystemSOLASInternational Convention for the Safety of Life at SeaSOPstandard operating procedureSTCWStandards of Training Certification and WatchkeepingTPAThermal Protective AidTWICTransportation Workers Identification CredentialULUnderwriters LaboratoriesUNOLSUniversity – National Oceanographic Laboratory SystemUSCUnited States CodeUSCGUnited States Coast GuardVCHPVessel Chemical Hygiene PlanVHFvery high frequencyVMOVessel Management OfficialVSOVessel Security OfficerRevision dated April 2012viii

VSPVessel Security PlanVTSVessel Traffic ServiceRevision dated April 2012ix

1.INTRODUCTION1.1Scope and PolicyScope: This document describes safe vessel specifications and operational procedures asrequired by the U.S. Environmental Protection Agency’s (EPA’s) Vessel Safety Manual. Themanual has been developed with the goal of minimizing risk to all individuals who embark onEPA vessels.Policy: It is EPA policy that the operation of all EPA vessels will be governed in accordancewith the requirements set forth in this manual.1.2Background and AuthorityBackground: The President, through Executive Order (EO) 12196, and the Secretary of Labor,through section 19 of the Occupational Safety and Health Act and Title 29 of the Code ofFederal Regulations (CFR) section 1960, requires that all federal agencies establishcomprehensive safety and health management programs.Authority: In accordance with EPA Order 1440.1, Safety, Health and EnvironmentalManagement Program, the Director of the Safety, Health and Environmental ManagementDivision (SHEMD), under the supervision of the Director of the Office of Administration (OA),is responsible for developing agency occupational safety and health policies, programs,standards, goals and objectives for evaluating the effectiveness of the programs at all operationallevels.SHEMD provides safety and health support for theagency’s National Occupational Safety and Healthprograms to program offices, regional offices andlaboratories. This program and related standards andguidance have been established by the AssistantAdministrator for Administration and ResourcesManagement.The authorities cited in EPA Order 1440.1 pertain to safety and health policies, programs andstandards, including those related to protection from maritime hazards. As such, comprehensiveefforts to minimize employee exposure to accidents and enhance safety awareness onboard EPAvessels, as described in the program, correspond to the intent of EO 12196, the OccupationalSafety and Health Act, the regulations established by other federal agencies, and the mandate forSHEMD.1.3Program ApplicabilityThis program applies to all EPA-owned, operated or leased vessels, from the largest to thesmallest, that are operated on any body of water, foreign or domestic, and all activities conductedby employees and contractors in support of EPA vessel operations on any EPA-occupied orcontrolled vessel.Revision dated April 20121-1

Notes: The term “EPA workers” is occupational in nature and includes full-time, part-time,temporary and permanent EPA federal and contract employees; the crew and staff ofleased vessels; and details to the EPA from other governmental agencies. Students who are assigned to the EPA; enrollees in the EPA’s Senior EnvironmentalEmployment (SEE) Program; and interns and fellows assigned to the EPA may bedesignated as EPA workers by the EPA Vessel Management Official (VMO) or theappropriate designee responsible for the specific vessel. If they are so designated as EPAworkers, they must comply with all applicable requirements of this manual.Based on local conditions and requirements, program offices and regions may wish to establishmore stringent requirements than those set forth in this manual. If this is the case, the provisionsof this program may be supplemented, but not replaced or superseded, by regional and programoffice requirements.1.4EPA Auditing and Self-Assessment ProgramsEPA Class B and C vessels (vessel classifications are defined in section 3.2) must be auditedunder the EPA Auditing Program, which requires that vessels undergo a comprehensive safety,health and environmental management (SHEM) audit every three years. The focus of the audit isto assess compliance with fire protection, health and safety, and environmental requirements andagency policy. EPA Class A vessels that are available will be inspected as part of thelaboratory/office audits. EPA audit policies, authorities, procedures and protocols are provided manuals/shemaudit.htm.EPA regional and program locations are required to perform annual vessel self-assessmentsunder the EPA Self-Assessment Program. This program provides a consistent agencywideprocess for conducting site-specific SHEM-related monitoring in support of continualimprovement in performance and includes the same areas of inquiry as the SHEMD AuditProgram. This program is described more thoroughly in the EPA SHEM Self-AssessmentProgram Guidance and Tools (June 2009) located content/self-assess 508.pdf.1.5Environmental Management System (EMS) and StewardshipThe EPA is responsible for coordinating the implementation of EMS at all designated EPAfacilities, including vessels, in accordance with the requirements of EO 13148. In addition tosupporting EMS implementation, SHEMD is responsible for reviewing the EMS that has beenestablished at each location and for self-declaring its conformance to the EO 13148requirements. Similar to the EPA Audit Program, an external conformance review that includesany vessels must take place every three years. EPA Class A vessels are part of the conformanceaudit with the facility they are associated with, including the staff on these vessels. Additionalinformation about EMS is located environmental/ems/index.htm.Revision dated April 20121-2

In response to EO 13423, the EPA encourages and recognizes responsible environmentalmanagement across all its facilities, including vessels, through environmental stewardshipreporting. The EO mandates that federal agencies conduct their environmental, transportationand energy-related activities in an environmentally, economically and fiscally sound, integrated,efficient and sustainable manner. Additional information on environmental stewardship islocated at vironmental/stewardship.htm.1.6Principles of a Safety and Health Management System (SHMS)SHMS covers similar characteristics as the EPA EMS Program. For example, the SHMS is basedon the same “Plan-Do-Check-Act” continual improvement cycle as the EMS. An effectiveSHMS is uniquely designed for each organization but consists of six critical elements applyingsafety and health management practices at appropriate and relevant functions and levels of theorganization. These elements include 1) management commitment and planning, 2) employeeinvolvement, 3) safety and health training, 4) work-related hazard/risk analysis, 5) hazardprevention and control, and 6) conformance monitoring, corrective/preventative action andmanagement review. More information on SHMS is located safety/shms.htm.1.7ChangesThis manual will be modified on an as-needed basis as determined by experience, changingoperational requirements and referenced regulations and authorities. The EPA's SHEMDwelcomes any suggestions for improving this manual. Please contact us at SHEMD-at-Your Service@epa.gov to provide your feedback.Revision dated April 20121-3

2.PROGRAM ADMINISTRATION2.1Goals and ObjectivesThis section sets forth the administrative functions that are necessary to effectively manage thesafety, health and environmental programs onboard EPA vessels. The goals of the EPA vesselsafety program include: The strategic goals of the programs provided in the Vessel Safety Manual are toincorporate nationally consistent means and methods for identifying, assessing,recording, eliminating, reducing, controlling and communicating the potential risks anddangers associated with occupational accidents onboard marine vessels. The program’s operational goals also include compliance with applicable federal, stateand local governmental regulations; ongoing incorporation of appropriate elements ofnationally recognized consensus standards; and a continual emphasis on quality and theeffective use of the wide range of the national and international expertise available toEPA.The objectives of the EPA vessel safety program include: Establishing an acceptable level of risk with respect to the operation of EPA vessels byimplementing the components of the Vessel Safety Manual. Working within the current EPA organizational framework and administrative directives. Defining and delegating clear lines of authority and responsibility. Ensuring compliance with applicable domestic and international laws and regulations. Maximizing the contribution and participation of administrative and technical EPA staffat all operating levels in developing, implementing and monitoring the components of theVessel Safety Manual.2.2Roles and ResponsibilitiesAdministratorThe Administrator is overall responsible for establishing and maintaining an effectiveagencywide safety, health and environmental management program (SHEMP), includingmaritime safety.Assistant Administrator (AA) for the OARMThe AA for the OARM is EPA’s designated safety and health official. The AA establishes: Agencywide safety, health and environmental management programs, including those formaritime operations.Revision dated April 20122-1

The national program office to direct the development and implementation of theprograms provided in the Vessel Safety Manual. Essential programs requirements for AAs and Regional Administrators (RAs) to followin implementing and managing their local SHEM programs agencywide.Director of OAThe Director is responsible for ensuring that: Adequate financial and staff resources are allocated for safety, health and environmentalmanagement programs. Program functions are strategically sited within the Office to ensure effectiveimplementation and management. Delegations of authority for each component of the program are issued. Performance standards that parallel and clarify accountability for program performanceare established for Office staff.Director of SHEMDThe Director of SHEMD leads and directs the development and implementation of agencywideSHEMPs, including maritime safety. The Director is authorized to: Formulate the agency’s policies, programs, plans, standards, protocols, goals, objectives,and priorities in accordance with those statutes, regulations and guidelines associatedwith vessel safety. Coordinate implementation activities by safety and health managers and environmentalcompliance coordinators. Develop national SHEM programs to guide implementation within the program officesand regions. Provide technical and managerial consultation services for establishing and maintainingthe vessel safety program agencywide. Develop and maintain administrative support for the vessel safety program. Conduct quality assurance and quality control (QA/QC) activities in order to:o Assure compliance with the program.o Evaluate program effectiveness.o Foster continual program improvement.Revision dated April 20122-2

Collect and synthesize data to document the QA/QC results.Primary responsibility for ensuring the successful national implementation and operation of theseSHEM programs ultimately rests with the AA for Administration and ResourcesManagement. Responsibility for implementation and ongoing effective management of theseprograms rests with the AAs, RAs and SHEMD.RAs and AAsRAs are responsible for: Allocating adequate financial and staff resources for their SHEMP managers, includingfor maritime safety programs provided in the Vessel Safety Manua

Vessel Safety Manual. The manual has been developed with the goal of minimizing risk to all individuals who embark on EPA vessels. Policy: It is EPA policy that the operation of all EPA vessels will be governed in accordance with the requirements set forth in this manual. 1.2 Background and Authority . Background: