Transcription

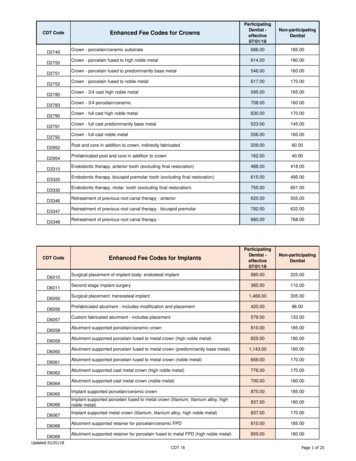

crown stock picker manualFile Name: crown stock picker manual.pdfSize: 4158 KBType: PDF, ePub, eBookCategory: BookUploaded: 28 May 2019, 22:58 PMRating: 4.6/5 from 805 votes.Status: AVAILABLELast checked: 7 Minutes ago!In order to read or download crown stock pickermanual ebook, you need to create a FREE account.Download Now!eBook includes PDF, ePub and Kindle version Register a free 1 month Trial Account. Download as many books as you like (Personal use) Cancel the membership at any time if not satisfied. Join Over 80000 Happy ReadersBook Descriptions:We have made it easy for you to find a PDF Ebooks without any digging. And by having access to ourebooks online or by storing it on your computer, you have convenient answers with crown stockpicker manual . To get started finding crown stock picker manual , you are right to find our websitewhich has a comprehensive collection of manuals listed.Our library is the biggest of these that have literally hundreds of thousands of different productsrepresented.Home Contact DMCA

Book Descriptions:crown stock picker manualIf you continue browsing the site, you are giving implied consent to the use of cookies on thiswebsite. See our Privacy Policy for details. The Crown logo from the outside guarantees theWhen itcomes to loaders, the main thing is the ease of operation. Crown puts convenience of operators inthe first place, therefore the designsFor exampleThis advanced technology allowsAll content on thesite pdfmanual4trucks.com is taken from free sources and is also freely distributed. If you are theauthor of this material, then please contact us in order to provide users with a pleasant andconvenient alternative, after reading, buying aThe site administration does not bear anyresponsibility for illegal actions, and any damage incurred by the copyright holders. The displayincludes a full featured onboard service tool so service engineers can actively view inputs andoutputs during truck operation. No laptop or service. Prices are indicative only and may vary bycountry, with changes to the cost of raw materials and exchange rates. Discover everything Scribdhas to offer, including books and audiobooks from major publishers. Start Free Trial Cancel anytime.Report this Document Download Now Save Save Crown Sp3500 Stockpicker Operator Manual ForLater 0 ratings 0% found this document useful 0 votes 87 views 22 pages Crown Sp3500 StockpickerOperator Manual Uploaded by SARAMQR Description Operator manual Crown SP3500 Fulldescription Save Save Crown Sp3500 Stockpicker Operator Manual For Later 0% 0% found thisdocument useful, Mark this document as useful 0% 0% found this document not useful, Mark thisdocument as not useful Embed Share Print Download Now Jump to Page You are on page 1 of 22Search inside document Browse Books Site Directory Site Language English Change LanguageEnglish Change Language. Crown Equipment Corporation specializes in warehouse materialshandling. The Crown SP or Stock Picker truck is a staple of high efficiency ct83-manual.xmlcrown stock picker manual, crown sp 3500 series stock picker manual, crown stock

picker service manual, crown stock picker manual, crown stock picker manual pdf,crown stock picker manual download, crown stock picker manual 2017, crown stockpicker manual free.These trucks operate in narrow aisles of tall racks in warehouses, and move in a linear motionforward and backward, allowing the operator on board to ride up and down on the platform and pickstock from high shelves. A SP will locate a wire embedded in the aisle floor, connect to it, and thenproceed up and down the aisle without requiring the operator to manually steer the vehicle withinthe aisle. Currently, the Crown SP operates as a standalone vehicle without access to Crown’sInfoLink software. The use of a 7” touchscreen on each vehicle helps improve operator safety andefficiency. Crown is planning to add the SP to the list of lift trucks that are touchscreen enabled.Unlike the current lift trucks that are InfoLink enabled, the Crown SP has some differences thatmust be reflected in custom interface assets for that truck before it can be added. The WireGuidance and Steer widget addresses these needs. The physical controls that are currently on theSP will remain on the truck, but the digital user interface will offer a flexible and easilyunderstandable way to display truck information to the operator. Crown is currently working to addtouchscreens to several of their lift trucks. The SP is the first truck after the Crown RM that will gothrough this process. This project was assigned under the Interface Experience Design team forCrown Equipment Corporation. For example, should operators lower the order picker forklift to nearfloorlevel before moving to the next pick location Yes. Although lowering the forklift before movingmight seem counterproductive, it is important to put safety first when picking from elevated heights.What are the rules about travel for order pickers and stock pickers If you have any questions afterreading this, be sure to check the OSHA regulations for the state your facility is les/horizon-ct81-treadmill-manual.xml

Trucks may travel at heights 152 inches or above if one or more of the following apply to the truckThis can be in the form of a control handle. The work platform must have standard guardrails on theopen sides. The light, which needs to be flashing or rotating, must be placed somewhere on thenonelevating portion of the truck, and between four and six feet high. RHCC forklift safety trainerVasilios Veziris has provided these tips. This will help to make others aware of the truck’s presence.You can also submit your question to our Warehouse Genius. Click here Receive a response within48 hours during the business week.Cookie information is stored in your browser and performsfunctions such as recognizing you when you return to our website and helping our team tounderstand which sections of the website you find most interesting and useful. This means thatevery time you visit this website you will need to enable or disable cookies again. Crown has beenappearing on the European market since the late sixtiesThe company’s production is concentrated insix locations in the USA New Bremen, Ohio where theCan any one advise on what can be theproblem.Turbo senser changed, inter cooler pipe is okay.The operating time of each of the solenoidvalves or the service of the APM or any item that is about the APM.Kod je MID130 SID52 FMI10Itjust idles.All lights working perfectly, any ideas how to fix thisThanks IainIf so how much individuallyand for all three ThanksSo would you find out the manual to give or sale for us please.Adaptalift inNSW, Australia however they will not reply to any of my emails. Can you helpBut we cant find theoperation and maintenance manual. So would you send me the operation andWhat function itisRegards, BarryI have an Iveco Trakker 500 2017. Two falut codes appear on the display screenEDC 03619 06 EDC 0377A 07 Please reply ASAP.Thank youDo you have this available ThanksCan any one tell me what that isI bypass the chargerand all works fine When checking, it indicate a fault code of 931. Any ideas pleaseWhat is part isitWhere is the flasher located. Where does the blinker wiring go through the firewallHow can I getan operators and safety manual.Error app01Please explance thisShowing yellow engine light andcode is 3697.can you help me please thanksI changed oil and filters now it doesn’t move excepterratically at full RPM ThanksError code L 202For more info Call me 0031610524876. The sensorhas measured an excessive coolant temperature typically due to the engine overheating.Possible

ECT short to GND, check ECT signal wiring. SECM Signal Pin B15 to ECT Pin 3 SECM SensorCanyou helpI am needing a list of all the filters pleaseHeli Forklift 110tkseries Operators ManualWhatdoes it mean can you help on this.I am working on an EFG forklift. According to theMakes no sense.I thank you in advance for your help in this matterWhat does this code mean. Thx in advanceWhatdoes it mean Batteries are full. Machine drives forward and reverse. Forks go side to side but do notliftAnybody know what this means Thanks!Can you please tell where can we get this operatorsmanual.Please somebody to help me. Thank you.What does this meanIt only pulls up 100 pages. Canyou send me the rest of the pages please.Need service manual if possible.I did not see anything intheir Forklift Operations Manual referencing suspended loadsWhat do I do please help me.What do Ineed to checkSerial number h2x386d06664Transmission about dead. Where to find rebuild partsand service manual.This machine looks identical to T 602 CT at an auction.Any suggestionsWhatcould be the problemCould you please help me on this matterThank you sooo much for your help.Blessings, GregPlease could you help me.What do I doWhat can it be. Any chances to get new keyfrom your service.Baoli Model QD18Our machine is presenting an error 030 and since yesterday we cannot tilt thetower or make any horizontal move with it. Can you help us with this problem. Thanks in advance,JoniSign up for free now at. CDC twenty four seven. Saving Lives, Protecting People The orderpicker he was operating did not have a platform on the forks and the victim was also not tethered offto the order picker. It appears he may have stepped backwards from the operating platform of theorder picker, thinking there was a platform on the forks, and fell between the forks to the concretefloor below. When he was discovered on the floor, emergency medical personnel were immediatelycalled and they responded within approximately five minutes. The victim was pronounced dead atthe hospital The Nebraska Department of Labor was notified of the fatality on the morning of April

20, 2000, by OSHA. The Nebraska FACE Investigator and an OSHA Compliance Officer conducted asite visit on April 20 and 24, 2000. Interviews were conducted with management and workers oncompany premises. The FACE Investigator also reviewed the Police Reports concerning thisincident. The company has been at the incident location for approximately 30 years. The companyemploys a total of approximately 1,500 people and approximately 1,450 are employed at the incidentlocation. Previous fatalities have occurred at this location. A fulltime safety manager is employed atthe incident location. The company has a written safety program, and a safety committee. Heworked parttime, approximately 20 hours per week, until the end of March and then he was on an“on call” status until the time of the incident. The victim’s training on the order picker consisted ofriding with an experienced operator until the operator fell he was qualified to operate the machinealone. He operated an electricallypowered Crown highlift rider commonly referred to as an orderpicker see figure 1 on-lab-manual.pdfThe operator rides on the platform as it goes up and down. Operators are required to wear a bodyharness and to be tethered off to a selfretracting lanyard that is secured to the frame of the orderpicker anytime they are operating the order picker. This is a written and posted policy within thecompany. They also have a rail at the rear to prevent stock from falling off see figure 2 . Thewarehouse is set up with many aisles with stock stored on both sides of the aisles. The order pickeris steered by the operator until it enters an aisle and then it is automatically steered by a systeminvolving a wire embedded in the concrete in the center of each aisle and an onboard guidancesystem. When the order picker exits an aisle the operator again has to steer the unit. Thisinformation tells him or her where the order is located and then they proceed to the appropriateaisle and location. They raise or lower the order picker as needed to reach the order, scan the order

into the computer with a hand held onboard scanner, then place the order on the flat. Then theygenerally take the order to a loading dock where a customer is waiting to load it into their vehicle.The order pickers are then driven to a charging area at the other end of the warehouse. The flatsmust be taken off because all the order pickers there are 11 used in this warehouse will not fit in thecharging area with the flats left on. The batteries for the order pickers are then charged overnight.The store closing time that evening was 900 p.m. The victim had already taken the flat off his orderpicker, probably anticipating closing and preparing to take it to the charging area. He took the orderpicker, without the flat, to the aisle where the television was located.A coworker paged the victimand received no response. He then got an order picker and put a flat on it a process that only takesabout one minute to go and get the television ter-power-supply-manual-switch-on.pdfIt was at the location to pick the television off the storage rack see figure 3 . The hand held scannerwas also hanging down between the forks of the order picker. He immediately called for help andran to the victim. The victim was lying about two feet from the base of the order picker. Thecoworker checked for a pulse and detected none. Emergency personnel were called and arrivedwithin five minutes. The victim was taken to a local hospital where he was pronounced dead at 947p.m. The tape showed the victim several times not being tethered to the order picker while he wasoperating it. The reviewed video also showed that the victim had a flat on the order picker at alltimes when he was going to pick an order except the last order of the day, the incident order. Thesecurity camera does not cover the area in the aisles where the incident occurred, it only showed theorder picker going into and leaving the area, so the actual incident was not captured on video. Thevideo indicated that when the victim entered the aisle to get the television he was not tethered off tothe order picker and there was no flat on the forks either. It is this investigator’s speculation that thefollowing scenario is what could have happened. The victim had been operating the order pickerwith a flat on prior to the incident. Due to this being the last pick of the day, he had already removedthe flat to prepare the order picker to be taken to the charging area. The normal procedure is to

scan the product before putting it on the order picker. This is done with the hand held scanner thatis attached by a coiled cord to the order picker. The victim probably had the scanner in his hand andstepped back off the order picker platform see figure 1 thinking he was going to be stepping on theflat. With no flat installed he would have fallen between the forks of the order picker. The hand heldscanner was hanging down between the two forks when the victim was found.Another possibility is that he remembered the flat was not installed and walked back on the forknearest the storage shelf to scan the television and load it on the forks and lost his balance and felloff the fork. When the victim was found it appeared the television had not been moved. It should benoted that this employer had complied with the requirement of 29 CFR 1910.132 regarding personalprotective equipment. The employer required fall protection for the activity being performed at thetime of the incident. The policy was posted where the workers pick up their fall protection each day.It makes no difference as to what elevation you are working at.” The company and workers refer tothe Crown order pickers as “Hysters.” The operator manual for the Crown order picker also states to“wear your harness and attach the tether.” It is standard operating procedure for operators to havea flat on an order picker prior to picking orders. Typically, the only time they would not have a flat iswhen they go to the mezzanine area and pick up or deliver a flat already loaded with merchandise.Even with the victim not being tethered to the order picker had the flat been installed this may haveprevented the incident. The victim had most likely already removed the flat from his order picker forthe day in preparation to take the order picker to the charging area. Recommend that at least oneoperator be designated to keep a flat on his order picker until all orders have been received and thewarehouse is closed for business. This operator would be responsible for picking all “last minute”orders. The employer shall also certify that each operator has been trained and evaluated asrequired by CFR 1910.178. It should be noted that this training has been accomplished for alloperators subsequent to the incident. The company hired an outside trainer to come in and providethe required ual.pdfSpecific deterrent consequences should be established for noncompliance with an employer’s InjuryPrevention Program safety requirements. To be effective these consequences should be written aspart of an employer’s Injury Prevention Program and should be enforced when violations aredetected. An effective Injury Prevention Program should instill an attitude in everyone that safetywill never be compromised for expediency. Security personnel who monitor the system could beinstructed to look for specific violations, such as no pallets, or individuals not wearing harnesses ornot being tethered to the order picker. When they detect a violation they should notify thesupervisor who can take corrective action. It would also be a good idea for the safety manager tooccasionally monitor the system also to ensure the security personnel are effectively monitoring forsafety. Page Count 6 SP 3470F Series. StockpickerSeriesStockpickerGeneral Information. SP 3470FSeriesModel. Load Center. Power. Operator Type. Tire Type. Wheels. Mast TypeFree LiftTruckWeight. Platform face to load CG. Electric. Standup Rider. TripletelescopicPerformanceStandard L xW x TInside Straddle. Outside StraddleType. Max Battery SizeVoltsSee ChartLead AcidSteeredWheel Source Exif Data File Type PDF. File Type Extension pdf. PDF Version 1.6. Linearized Yes.Encryption Standard V2.3 128bit. User Access Print, Extract, Print highres. Page Mode UseThumbs.XMP Toolkit 3.1701. Producer Acrobat Distiller 7.0.5 for Macintosh. Keywords Crown, Electric,Stockpicker, Orderpicker, Lift, Truck. Create Date 20060921 1143370400. Modify Date 200609211357460400. Metadata Date 20060921 1357460400. Title SP 3400 FourPoint Series ProductSpecifications. Description SP 3470F FourPoint Series Specifications. Creator Crown EquipmentCorporation. Subject Crown, Electric, Stockpicker, Orderpicker, Lift, Truck. Document IDuuidf3e7b2cb498711dbba75000d93453ef0. Instance ID uuidb052d3be499a11db98c0000d93453ef0.

Page Count 6.Page Layout SinglePage. Author Crown Equipment Corporation. A powerful breakthrough in Europehappened in 1987, when the European headquarters of Crown was opened in Munich, Germany.Production facilities for the production of forklift trucks, certified in accordance with ISO 9001, arelocated in Roding, Germany. Developing products together with teams from the US and Australia,they adopt each other’s best design ideas for the production of ideal loaders, as well as carry outdevelopment in accordance with the requirements of the local market. For many long years Crowndesigners have been an incredible success, which is confirmed by more than 50 awards received forthe development of Crown electric forklifts. Well assume youre ok with this, but you can optout ifyou wish. Should business be impacted by COVID19 we will let you know promptly. We do not implythat any parts are the products of a particular manufacturer. Some items excluded. What does thebattery display show. If it is all the way down and flashing it is in lift lock out.I have filled up thebattery compartments with Sulfaric Acid and topped them of with the distilled water. I charged thebatteries up overnight. The forklift is driving, however the platform with forks does not go up ordown. I read the error codes 203, 213 and 216. What do the indicateYou may be able to set yourcharger to not charge quite so hot, rather than readjust the truck.We can only discuss portions ofthe manuals, and things we know from experience. Code 16 refers to the battery being overcharge.Click here for more information. Please update your browser to view this website correctly.

crown stock picker manual Home Contact DMCA File Name: crown stock picker manual.pdf Size: 4158 KB Type: PDF, ePub, eBook Category: Book Uploaded: 28 May 2019, 22:58 PM Rating: 4.6/5 from 805 votes. Status: AVAILABLE Last checked: 7 Minutes ago! In order to read or download crown stock picker manual ebook, you need to create a FREE account .