Transcription

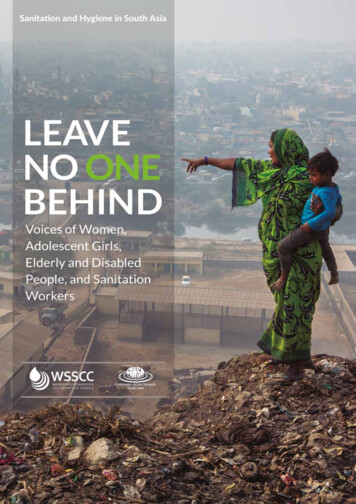

Sustainable SanitationPracticeIssue 9, 10/2011 Digesting Faeces at HouseholdLevel - Experience From a “ModelTourism Village” In South India Biogas Systems in Lesotho: aneffective way to generate energywhile sanitizing wastewater er Moroccan conditionsBiogas SystemsSustainable Sanitation Practice1partner of:Issue 9/2011

Impressumpublished by / Medieninhaber, Herausgeber und VerlegerEcoSan ClubSchopenhauerstr. 15/8A-1180 ViennaAustriawww.ecosan.atEditors / RedaktionElke Müllegger, Günter Langergraber, Markus Lechner EcoSan ClubJournal Manager / Journal ManagementFritz KleemannContact / Kontaktssp@ecosan.atDisclaimer / HaftungsausschlussThe content of the articles does not necessarily reflect the views of EcoSan Club or the editors and should not beacted upon without independent consideration and professional advice. EcoSan Club and the editors will not acceptresponsibility for any loss or damage suffered by any person acting or refraining from acting upon any materialcontained in this publication.Die in den Artikeln vertretenen Standpunkte entsprechen nicht notwendigerweise der Haltung und Ansichten des EcoSan Clubs oder desRedaktionsteams. Der praktischen Anwendung dargestellter Inhalte muss eine unabhängige Begutachtung und professionelle Beratungvorausgehen. EcoSan Club und das Redaktionsteam haften in keiner Weise für Schäden (Sachschaden oder Personenschaden), die durch dieAnwendung, oder Nichtanwendung der in dieser Publikation vermittelten Inhalte, entstehen.Reproduction / ReproduktionPermission is granted for reproduction of this material, in whole or part, for education, scientific or developmentrelated purposes except those involving commercial sale, provided that full citation of the source is given. Coverphoto excluded.Die Reproduktion, Übernahme und Nutzung der Inhalte von SSP, vollständig oder teilweise, für Bildungszwecke, für die Wissenschaft und imZusammenhang mit Entwicklung ist unter Voraussetzung der vollständigen Quellenangabe gestattet und erwünscht. Titelbild ausgenommen.Aim and Scope / Offenlegung der Blattlinie gemäß § 25, Abs. 4 MediengesetzSustainable Sanitation Practice (SSP) aims to make available high quality information on practical experiences withsustainable sanitation systems. For SSP a sanitation system is sustainable when it is not only economically viable,socially acceptable and technically and institutionally appropriate, but it should also protect the environment and thenatural resources. SSP is therefore fully in line with SuSanA, the Sustainable Sanitation Alliance (www.susana.org). SSP targets people that are interested in sustainable sanitation systems and the practical approach to it. Articles arepublished after blind review only. Sustainable Sanitation Practice is published quarterly. It is available for free onwww.ecosan.at/ssp.Sustainable Sanitation Practice (SSP) hat zum Ziel praxisrelevante Information in hoher Qualität im Zusammenhang mit „sustainable sanitation“bereit zu stellen. „sustainable“ also nachhaltig ist ein Sanitärsystem für SSP wenn es wirtschaftlich machbar, soziokulturell akzeptiert, technisch alsauch institutionell angemessen ist und die Umwelt und deren Ressourcen schützt. Diese Ansicht harmoniert mit SuSanA, the Sustainable SanitationAlliance (www.susana.org). SSP richtet sich an Personen, die sich für die praktische Umsetzung von „sustainable sanitation“ interessieren. Artikelwerden nur nach einer Begutachtung veröffentlicht. Sustainable Sanitation Practice erschient vierteljährlich, kostenlos unter: www.ecosan.at/ssp.Information on the publisher / Offenlegung gemäß § 25 MediengesetzPublisher: EcoSan Club, Schopenhauerstr. 15/8, A-1180 Vienna, Austria chairperson: Günter Langergraber website:http://www.ecosan.at/ scope: EcoSan Club was funded as a non profit association in 2002 by a group of peopleactive in research and development as well as planning and consultancy in the field of sanitation. The underlying aimis the realisation of ecological concepts to close material cycles in settlements.Medieninhaber: EcoSan Club, Schopenhauerstr. 15/8, A-1180 Vienna, Austria Obmann: Günter Langergraber Gegenstand des Vereins: DerEcoSan Club wurde 2002 als gemeinnütziger Verein von einer Gruppe von Personen gegründet, die in Forschung, Entwicklung, Planung undBeratung in der Siedlungshygiene - Sammlung, Behandlung oder Beseitigung flüssiger und fester Abfälle aus Siedlungen - tätig waren und sind. DasZiel des EcoSan Clubs ist die Umsetzung kreislauforientierter Siedlungshygienekonzepte (EcoSan Konzepte) zu fördern, um einen Beitrag zum Schutzder Umwelt zu leisten.Cover Photo / Titelbild TED LesothoSustainable Sanitation Practice2Issue 9/2011

EditorialDuring the last years a number of biogas systems have been installed as part of sanitation systems. Issue 9 of SustainableSanitation Practice (SSP) on „Biogas systems“ shows successful examples. The first paper presents results from a study in Kerala, India, for digesters on a household level. The second paper shows the results of a long-term implementation program for biogas systems in Lesotho. The third paper presents first results of a digester constructed in a small village in Morocco.As EcoSan Club will celebrate its 10 year anniversary in 2012, the thematic topic of the next issue will be „10 Years EcoSanClub“ (SSP issue 10, January 2012).Information on further issues planned is available from the journal homepage (www.ecosan.at/ssp). As always we wouldlike to encourage readers and potential contributors for further issues to suggest possible contributions and topics ofhigh interest to the SSP editorial office (ssp@ecosan.at). Also, we would like to invite you to contact the editorial office ifyou volunteer to act as a reviewer for the journal.SSP is available online from the journal homepage at the EcoSan Club website (www.ecosan.at/SSP) for free. We alsoinvite you to visit SSP on facebook ith best regards,Günter Langergraber, Markus Lechner, Elke MülleggerEcoSan Club Austria (www.ecosan.at/ssp)Contentͳͳ Digesting Faeces at Household Level - Experience From a“Model Tourism Village” In South India . 4ͳͳ Biogas Systems in Lesotho: an effective way to generateenergy while sanitizing wastewater . 10ͳͳ Evaluation of formulas to calculate biogas productionunder Moroccan conditions . 18Sustainable Sanitation Practice3Issue 9/2011

Digesting Faeces at Household Level Experience From a “Model Tourism Village”In South IndiaAnalysis of household scale faeces treatment by anaerobic digestion in SouthernIndia shows some critical factors which must be overcome if sustainability andscaling up is expected.Authors: Christian Zurbrügg, Yvonne Vögeli, Nicolas EstoppeyAbstractThe scope of the study was to assess the strengths and weaknesses of existing household level biogas systemstreating toilet waste as well as organic kitchen waste. The biogas systems studied had been implemented onKumbalangi Island in South India within the framework of a Tourism Development Project to improve sanitaryconditions. The assessment comprised a technical monitoring of two selected facilities over a period of two monthsas well as a household level users survey. Results reveal that the systems are working quite satisfactorily andare generating enough biogas to cook the main dishes of a family along with replacing most of the traditionalcooking fuel. The treatment efficiency of the organic pollution is as good as to be expected from biogas systems.However, the effluent does not match the legal requirements for use without any restrictions as organic fertilizeror for discharge into surface water bodies without any further treatment. The current investment costs are high assubsidies formerly provided are not available anymore. This severely limits the potential of wide spread replication.Introductionthe villagers, wander around the village, fish andgo canoeing is promoted. The government of Indiadeclared it a “model fisheries and tourism village” ofIndia and supported the development with respectivefunding.Kumbalangi is an island-village surrounded bybackwaters and paddy fields on the outskirts ofCochin city of Kerala State in South India. The Keralabackwaters are a series of brackish lagoons and lakeslying parallel to the coast and include five large lakeslinked by canals, both manmade and natural, fed by 38rivers, and extending virtually half the length of Keralastate. In a unique initiative to transform the tiny islandof Kumbalangi, to attract tourism and enhance localincome opportunities, the „Kumbalangi IntegratedTourism Village Project” set on re-establishing asustainable approach for the management of localecological resources such as fish and mangroves. Lowimpact tourism, where tourists live and dine withWithin the same initiative, one goal is to improvethe hygienic situation on Kumbalangi Island. To date,“hanging toilets” and other unimproved toilet facilitiesare still frequently being used which discharge excretaand wastewater directly into surface waters thuspolluting the backwaters (Figure 1 and Figure 2). Theidyllic landscape is also threatened by a lack of solidwaste management services. Waste is dumped all over,burnt in the garden or thrown into the backwaters.Key messages: the reactor design is for one household, connected to the toilet effluent whereby kitchen waste can also be added the reactor is designed as floating dome type, constructed with cement and fibreglass reinforced plastic materials the input material consists of toilet waste and organic waste from the kitchen the average daily biogas production is 590 l and replaces a large part of the traditional cooking fuel the effluent exiting the reactor is not further treated and is used as fertilizer in the gardens or discharged into thebackwaters, although based on the quality characteristics this would not be allowed. the current high investment costs to construct and install such a system make it unaffordable for most familiesSustainable Sanitation Practice4Issue 9/2011

Household biogas digesters for faecesFigure 1: Hanging toiletsFigure 2: Toilet discharging into thebackwatersIn order to reduce the environmental problems andhealth hazards of inhabitants, caused by the lack ofappropriate sanitation infrastructure and municipalsolid waste management, the local Kerala based NGOBIOTECH assisted the community with the endeavourto improve 150 toilets linking them to biogas digestersas well as setting up 650 digesters for food waste fromkitchens. Main objective, besides reducing environmentaldegradation of the backwaters, was to hereby generatebiogas for cooking, as well as produce organic fertilizerfor the families and their gardens.discussions with the family operating the biogas plantto obtain an idea on how the owners and users operatethe facility and to engage with them on clarifying theobjectives of the study and designing specific proceduresfor data collection. The study tried to limit its influenceon usual practice, nevertheless one has to assume thatthe influence of having a researcher on site regularly mayin fact influence normal practice of the family. The biogasplant was monitored during an 8 week period regardingthe following aspects: Analysis of feedstock in terms of mass andcharacteristics Analysis of effluent in terms of volume andcomposition Measurement of gas production and gascompositionIn collaboration with BIOTECH, Eawag/Sandec conductedan assessment of the currently implemented householdscale biogas plants in 2010 to evaluate the strengthsand weaknesses and establish recommendations forimprovement. The assessment comprised a technicalperformance evaluation, economic feasibility and socialacceptance (Estoppey, 2010). As there is a overall generallack of well documented information on the performanceof household biogas systems using faeces and solidwaste in low and middle income countries, the technicalassessment evaluated two reactors; one fed only withorganic solid waste (called: Food Waste Biogas Plant)and the other fed with food waste but also connected tothe toilet (called: Toilet Linked Biogas Plant). Parameterswhich were monitored during the technical assessmentcomprised: gas production, treatment efficiency andeffluent quality.The users were asked to collect their kitchen wastedaily in buckets, separating the solid food waste fromthe organic waste water (waste water that originatesin the kitchen). This waste was then sorted on five daysper week to better characterise the waste amounts andtype. On the two other remaining days, the families wereasked to write down the estimated quantities of whatthey fed into the biogas plant. Those estimations werenot used in the calculations but rather allowed a crosscheck or unusual quantities of waste. After sampling,the feedstock samples were homogenised with a kitchenblender at the BIOTECH offices for about 30 minutes.Smaller portions of these homogenized samples werethen analysed for Total Solids (TS) and Volatile Solids (VS)at “Cochin University of Science and Technology”.This present paper focuses on the results related tothe toilet linked biogas plant and discusses the resultswith regard to the suitability as a sustainable sanitationoption.MethodsFor estimating toilet waste, the users were asked to noteon a sheet of papers if he/she urinated, defecated ordid both, as well as if he/she used the 4L toilet flush ornot. Once a week, over a period of 24 hours, the familycollected the black water (urine, faeces and flushingUnderstanding the functionality of the biogas plantand assessing key parameters was a challenging task inthe local context. A first period of two weeks entailedSustainable Sanitation Practice5Issue 9/2011

Household biogas digesters for faecesFigure 3: Cross section and top view of a toilet linked biogas plantWhereas the toilet waste is directly flushed into thedigester (using either pour flush or full flush toilets), thefood waste is first cut into small pieces, mixed with waterand then fed into the digester through a separate inlet.The generated biogas is used directly for cooking withoutany gas cleaning step. Merely the condensed water inthe gas pipe is removed regularly. The effluent from thereactor, the digestate, is either used as fertilizer in thegarden, but more often is directly discharged into thebackwaters without any further treatment.water) by connecting the toilet to a 10 litre bucket whichwas emptied regularly into an 80 litre storage tank.This tank then served as sampling point, where afterstrong stirring and mixing 500 ml of liquid was collectedfor analysis. In addition, two samples of black waterwere taken using sterile tubes of 15ml for pathogensmeasurements.To gain information on the economic feasibility and thesocio-cultural aspects of the new sanitation system, ahousehold survey was conducted with 17 owners of atoilet linked biogas plant and 10 owners of a food wastebiogas plant.The total costs of such a biogas system amounts up toaround 600 US . In the past subsidies were granted fromthe Central Government, the Kerala Local Governmentand the Kumbalangi basic unit of administration(Panchayat). The financing system for constructioninvolved the families paying for the cement (100 kg), thebricks (25 normal and 8 cement ones), the excavationof the pit and the cow dung (100 kg) to inoculate thesystem. In total the contribution of a family was around120 US . However, for all biogas systems installed since2010 a new design and new materials were establishedas standard. These are prefabricated portable plantsentirely made of fibreglass reinforced plastic. Althoughthis makes it significantly easier to construct a biogassystems it also makes the system more expensive (about800 US per unit). At the same time the governmentalsubsidies decreased considerably and the costs forinstalling a biogas plant amounts to 600 US per family.This high cost makes the system unaffordable for mostfamilies.Specifications of biogas system and costThe domestic toilet linked biogas plants installed by BIOTECHall have a floating dome design and consist of a digestertank (A), a gasholder drum (B), a food waste inlet (C), a toiletwaste inlet (D), an effluent outlet (E) and a biogas outlet (F).The digester tank with an external diameter of 142 cm ismade of prefabricated reinforced cement concrete (RCC)elements fitted together in an excavated pit. An orthogonalbarrier (a1) of 70 cm height separates the lower part ofthe tank into two compartments in order to increase theretention time of solid particles.The gasholder is made of fibreglass reinforced plastic (FRP).A metallic central rod as axis (a3) serves as a guide frame forthe gasholder and prevents the gasholder from tilting whenthe gasholder is elevated (i.e. full). The water jacket (a2) isa newer development by BIOTECH. It provides water filledguidance groove for the lifting and descending gasholderand avoids contact between digesting material andatmosphere thus also avoiding gas losses. In the stagnantwater of the water jacket a few drops of kerosene are addedto avoid breeding of mosquitoes. In order to increase thegas pressure, a stone of 20 kg is put onto the gasholder (b1).Sustainable Sanitation PracticeResults and DiscussionTechnical performanceThe monitoring of the toilet linked biogas plant (TLBP)showed that the system is working satisfactorilyregarding its technical performance. The systemreceives an average of 3.6 kg waste per day, consistingof faeces and kitchen waste, whereby these are mainly6Issue 9/2011

Household biogas digesters for faecesFigure 4: Treatment efficiency of TLBP plantrice leftovers. Interestingly, the owner of the monitoredfacility also collects kitchen waste from three otherfamilies to increase the gas production. The liquid wasteadded to the reactor amounts to an average of 36.5 litresper day. Half of this liquid waste is flushing water withoutany or very little organic content and the rest is urine andgreywater from the cooking of rice.concentration of E. Coli and total Coliforms with theWHO-guidelines for “safe use of wastewater, excretaand greywater” (WHO, 2006) would only allow forrestricted irrigation. Thus the families should be carefuland only use the effluent on crops that are cookedbefore consumption. In addition, contact with mouthor wounds have to be avoided and hands must bewashed after contact. Furthermore the effluent shouldbe applied directly on the soil as close to the roots aspossible and not be sprayed over the crops. Appropriateuse includes irrigation of banana and coconut trees.The high amount of flushing water in the TLBP leadsto a very low concentration of volatile fatty acids of 82mg/l and a low organic loading rate of 0.58 kgVS/m3.Nevertheless the average hydraulic retention time is 37days which corresponds to the range as recommendedin literature. The treatment efficiency of the plant can beregarded as good showing a high reduction in total solids(TS), volatile solids (VS) and chemical oxygen demand(COD) (Figure 4). Of the generated biogas the methanecontent was always stable at around 60%. The averagedaily biogas production of 690 litres is sufficient to cookthe main dishes of a family. The pH remains stable at 6.9and thus is in the optimal range for anaerobic digestionwhich lies between 6.7 - 7.5. The temperature insidethe digester was stable at around 29 C , which is slightlybelow the optimum of 32-42 C for mesophilic conditions(Deublein and Steinhauser, 2008).A household survey revealed that several familiesdischarge the effluent directly into the backwaters(Figure 5). Given the environmental standards fordischarge of environmental pollutants by the Ministryof Environment & Forests (Government of India) andthe measured values for CODtot and Ntot of the effluent,it is obvious that the environmental standards areexceeded and an additional treatment step would beneeded (e.g. filter bed) to further reduce the organicload of the effluent before safe discharge.Quality of effluentThe effluent from the biogas plant (i.e. the digestate)is very high in water content as most solid parts aredecomposed during digestion. The nutrient content inthe effluent shows nitrogen values of Ntot 871 mgN/l,potassium of Ktot 766 mgK/l and phosphorus of Ptot 61 mgP/l. However, it is difficult to evaluate its qualityas a liquid fertilizer as this depends very much on theplants where the fertilizer is applied.Figure 5: Biogas plant discharging directlyinto the backwatersThe reduction in pathogen content was foundto be very high, but nevertheless comparing theSustainable Sanitation Practice7Issue 9/2011

Household biogas digesters for faecesRegarding the use of biogas which derives from faecesfor cooking, only one family had objections. Theodorous effluent however was of major concern; anissue which was not raised with families only feedingkitchen waste into their digester.Economic feasibilityWith the change in materials used for the biogasreactor and the decrease in governmental subsidies,the investment costs of a biogas reactor for a familyamounts to approximately 600 US . This is a significantincrease compared to a cost per family of 120 US when the initiative could still benefit from subsidiesand cheaper material design. The amount of 600US corresponds to about five monthly salaries of anaverage labourer on Kumbalangi. Costs for operationand maintenance however are comparatively low,the system proves to be very robust and low inmaintenance. About 3 US per year have to be investedto replace broken pieces (stove knob, valve lever ongas holder).The majority of families are pleased with the amountsof biogas they can obtain on a daily basis. All use anadditional cooking fuel when they want to cook fasteror when they need a second stove.User knowledge of operation and maintenanceinstructions were lacking. None of the familiesinterviewed were aware of the recommendedmaximum daily load or on the recommended dilutionof the feedstock. Only half of the users were awarethat they shouldn’t use chemicals to clean the toilets.Despite of these difficulties and challenges, all biogasplants were working well and the gas production wassatisfactory.In terms of financial benefits, the generated biogas cansubstitute traditional cooking fuel, mostly firewoodand liquefied petroleum gas (LPG). The savings fromreplacing firewood and LPG with biogas accountfor about 40 US per year. The 690 l/d of biogas areenough to cook for approximately 3h and 15min perday and thus allows preparation of the main dishes.The families however can not completely rely solely onbiogas as they will still need a second stove for cooking.ConclusionsIn principle biogas sanitation systems for thehousehold level could be an appropriate sanitationtechnology. Main benefit is the production of biogaswhich is easily available for cooking and replaces aconsiderable amount of traditional cooking fuel. Theco-treatment with other organic household wasteis highly recommended in order to increase the gasproduction. The survey showed a high satisfaction ofthe users and little objection to using the biogas fromfaeces as cooking fuel. Furthermore, the low operationand maintenance efforts required makes the systemattractive as also waste handling is simple and doesnot require any direct human contact with the toiletwaste.The payback period of the new design with its currentsubsidy system compared to the old design andsubsidies increased from 3 years to 15 years, takinginto account savings in replacing other fuels. Costs ofprevious kitchen or toilet waste management are notconsidered, as most families used to dispose of theirwaste in the streets and used to defecate into thebackwaters. The environmental benefits as a result ofthe new sanitation system and replacement of the oldunacceptable situation were not quantified.However two major challenges still must beresearched and improved if such a technology was tobe implemented at wide scale in the region.The economic feasibility of the system is thusrather weak. Hence widespread replication andimplementation is only possible if the investmentcosts can be reduced considerably. Mass production,cheaper materials, higher subsidies or other incentivesystems could be options to reduce investment costs.Else, using the current design, biogas plants will onlybe affordable to wealthy families.1. The study showed clearly that the quality of theeffluent is not sufficient for use as fertilizer withoutrestrictions or even for discharge into water bodiesand that a post-treatment step is needed. Basically,the same technologies as for wastewater can beconsidered. In the context of decentralized biogassystems in low and middle-income countries, thiscan for example be an anaerobic baffled reactor witha subsequent planted horizontal or vertical filter(Borda, 2009, Tilley et al, 2008, Morel and Diener,2006).2. Current investment costs for a biogas reactor, ofthe type that is disseminated in the region, arefar too high for an average family on KumbalangiIsland. With the current subsidy system and thecurrent design and construction cost, the paybackrate is 15 years. Additional technical measuresfor effluent treatment would even increase theSocial aspectsA household survey showed that the acceptance ofthe biogas systems is in general very good and mostfamilies that have one would recommend it to others.The improved waste management and the productionof biogas were mentioned as the main advantages.The smell of the effluent (when using toilet waste),not enough biogas, slower cooking with biogas andthe difficult access and design of the toilet facilities(steep and unsafe stairs) were mentioned as maindisadvantages.Sustainable Sanitation Practice8Issue 9/2011

Household biogas digesters for faecescurrent investment cost making the system surelyunaffordable for most families. Reducing costcontribution by the individual family is an urgentrequirement, be this through subsidies or reductionsof construction costs. Possible solutions could be tolower cost though mass production, to lower theunit cost, or else provide solutions constructed withother materials, such as the older brick built versionsor simple plastic drum type reactors.AcknowledgementsWe would like to express our gratitude to BIOTECH forallowing us to analyse the project and providing all thenecessary support, information and documentation.Moreover, the authors wish to thank the Swiss Agencyfor Development and Cooperation (SDC), the SwissNational Centre of Competence in Research (NCCR)North-South, and the Swiss Federal Institute of AquaticScience and Technology (Eawag) for their supporttowards this research work.ReferencesBorda (2009): Decentralised Wastewater Treatment Systems (DEWATS)and Sanitation in Developing Countries. A Practical Guide. BremenOverseas Research and Development Association. Germany. ISBN:978 1 84380 128 3Deublein, D., Steinhauser, A. (2008): Biogas from waste and renewableresources: an introduction. Wiley-VCH. Weinheim, Germany.Estoppey, N. (2010): Evaluation of small-scale biogas systems for thetreatment of faeces and kitchen waste. Case study Kochi, SouthIndia. Sandec Report, Swiss Federal Institute of Aquatic Science andTechnology (Eawag), Dübendorf, Switzerland.Ministry of Environment and Forest (undated): EnvironmentalStandards - General Standards for discharge of environmentalpollutants. Government of India. Delhi.Morel, A., Diener, S. (2006): Greywater Management in Low andMiddle-Income Countries. Review of different treatment systemsfor households or neighbourhoods. Swiss Federal Institute ofAquatic Science and Technology (Eawag). Dübendorf, Switzerland.Tilley, E., Lüthi, C., Morel, A., Zurbrügg, C., Schertenleib, R. (2008):Compendium of Sanitation Systems and Technologies. SwissFederal Institute of Aquatic Science and Technology (Eawag).Dübendorf, Switzerland.Name: Christian ZurbrüggOrganisation: Swiss Federal Institute ofAquatic Science and TechnologyTown, Country: Zurich, SwitzerlandeMail: zurbrugg@eawag.chWorld Health Organization (2006): WHO guidelines for the safe useof wastewater, excreta and greywater. Volume 4: Excreta andgreywater use in agriculture. 2nd edition, Geneva, Switzerland.Name: Yvonne VögeliOrganisation: Swiss Federal Institute ofAquatic Science and TechnologyTown, Country: Zurich, SwitzerlandeMail: yvonne.voegeli@eawag.chName: Nicolas EstoppeyOrganisation: Swiss Federal Institute ofAquatic Science and TechnologyTown, Country: Zurich, SwitzerlandeMail: Nicolas estoppey@bluewin.chSustainable Sanitation Practice9Issue 9/2011

Biogas Systems in Lesotho: an effective way togenerate energy while sanitizing wastewaterIn Maseru, Lesotho, the Non-Governmental Organization TED constructs biogassystems for decentralized wastewater treatment (BiogasDEWATS) since 2003 inhouseholds, schools, orphanages and military camps, improving food securitythrough the re-use of plant nutrients in the treated water by irrigation.Author: Mantopi MdP Lebofa, Elisabeth M. HubaAbstractThis article describes Biogas as a decentralized wastewater treatment system implemented in Lesotho, where in 2002 agroup of technicians, with strong interest in the link between environmental protection and human well-being, startedto implement household biogas digesters for sanitation purposes in peri-urban settlements of the capital Maseru. Thedemand for the technology is created by problems with overflowing or leaking septic tanks and high-priced drinkingwater commonly used for irrigation. No subsidy is provid

Sustainable Sanitation Practice 2 Issue 9/2011 Iessu ulise / Medieninhaber, Herausgeber und Verleger EcoSan Club Schopenhauerstr. 15/8 A-1180 Vienna Austria www.ecosan.at Eitors / Redaktion ol Dºoo PP U'ºv vP P UD lµ Zv { } v oµ