Transcription

Food Safety OutreachProgramProject RoundtableFebruary 4, 20212:30-4:00 PM ET

ImportantInformationThankyou for joining us for the FSOP Project RoundtableInformation for today’s program: We are using the Zoom webinar format. Attendees are muted and your video isoff.The chat box has been disabled, please use the Q&A function to submit yourquestions for presenters.Slides with presenter permission will be posted to the Southern Center websiteand linked to the Food Safety Resource Clearinghouse.We are not recording this webinar.Evaluation will be sent to the email you registered with after the program.Questions? Contact Katelynn Stull at k.stull@ufl.edu

FSOP Project Roundtable-February 4, 2021Southern Regional Center for Food Safety Training, Outreach andTechnical Assistance Continuation, and Lead Regional CoordinationCenterKeith R. Schneider, University of Floridakeiths29@ufl.eduUSDA-NIFA

Southern Regional Center for Food Safety Training, Outreach and Technical Assistance Continuation,and Lead Regional Coordination CenterKeith R. Schneider, University of Floridakeiths29@ufl.eduREQUEST FOR APPLICATIONS Food Safety OutreachCompetitive Grants ProgramFUNDING YEAR:APPLICATION DEADLINE:LETTER OF INTENT DEADLINE:AWARD AMOUNT:Fiscal Year 2021April 1, 2021Not RequiredApprox. ntsProgram-RFA-508.pdf

Southern Regional Center for Food Safety Training, Outreach and Technical AssistanceContinuation, and Lead Regional Coordination CenterKeith R. Schneider, University of Floridakeiths29@ufl.eduDevelop a Communication PlanReach out to your Regional Centers for GuidanceNECAFSSCElizabeth NewboldElizabeth.Newbold@uvm.eduKatelynn Stullk.stull@ufl.eduNCRWRCAnirudh Naiganaig@iastate.eduJovana Kovacevicjovana.kovacevic@oregonstate.edu

Southern Regional Center for Food Safety Training, Outreach and Technical AssistanceContinuation, and Lead Regional Coordination CenterKeith R. Schneider, University of Floridakeiths29@ufl.eduWhat Your Regional Centers Needs from You Evaluation is a required component of leading FSOPs. Including an evaluation expert on your team isrecommended. Evaluation should track participation, outputs,knowledge gain, practice change, and success stories (WC092/WC092: Using the TOP Model to MeasureProgram Performance: A Pocket Reference(https://edis.ifas.ufl.edu/wc092))

FSOP Project Roundtable-February 4, 2021Strengthening FSMA Agriculture WaterOutreach and Education for ProduceGrowers in Kansas and MissouriLonda Nwadike,Kansas State University/University of Missourilnwadike@ksu.eduAward 2019-70020-30358, USDA, NIFA

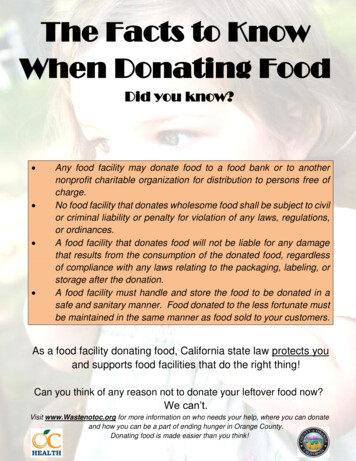

Strengthening FSMA Agriculture Water Outreach and Education forProduce Growers in Kansas and MissouriLonda Nwadike, KSU/MU, lnwadike@ksu.eduUSDA FSOP 2019Problem Statement / Issue Definition:Based on producer water testing conducted in 2016 FSOP- Some growers had very high E. coli levels in their water- Limited knowledge of water testing importance- Needed more training specifically on waterPrevalence of generic Escherichia coli in agriculturalwater4.4% 2.7%48.7% MPN 1/100 mL39.5% MPN 1-126/100 mL4.7% MPN 127-410/100 mL4.4% MPN 411-2419.6/100 mL2.7% MPN 2419.6/ 100 mLN 679 surface, ground, other samples4.7%39.5%48.7%

Strengthening FSMA Agriculture Water Outreach and Educationfor Produce Growers in Kansas and MissouriLonda Nwadike, KSU/MU, lnwadike@ksu.eduUSDA FSOP 2019Approach / Methods:1. Develop and administer survey on grower knowledge and practicesrelated to water quality2. Pilot study- microbial source tracing3. Demonstration systems on treating surface water for post-harvestuse4. Develop grower training materials on ag water5. Provide free microbial water testing to MO and KS produce growers

Strengthening FSMA Agriculture Water Outreach and Educationfor Produce Growers in Kansas and MissouriLonda Nwadike, KSU/MU, lnwadike@ksu.eduUSDA FSOP 2019Results / Outcomes:Obj 1: Survey of MO/KS produce growers still open; results so far:- 36% of respondents tested their water 1x/ year- 38% have never tested their water- 53% use municipal water for post-harvest- 8% use pond water post-harvest- 78% do not treat post-harvest waterObj 2: Started sampling for MST (4 ponds, 1 cistern)Obj 3: Beginning planning for testing sanitizer effectiveness oncistern and pond waterObj 4: Resource development: will translate into key languagesObj 5: Continuing free water testing

College of Agricultural, Consumer and Environmental SciencesBE BOLD. Shape the Future.New Mexico State Universityaces.nmsu.eduOnline Food Safety Training for NM Food ManufacturersExecutive producers:Nancy C. Flores, PhD; Extension Specialist Food TechnologyRebecca Mijares, Karla Y. Lopez, Adetoye AbodunrinGabriela Reyes and Judah SanchezGraphic illustrators: Anastasia Hames and Adrian AguirreSpecial Effects: Michaelyne J. WilkinsonModels: Alberto Galarza, Adetoye Abodunrin, Karla Y. Lopez,Gabriela Reyes and Phil McVann.Educational Consultants: Sharon Bartley PhD; Paul Gutierrez PhDThis work is supported by Extension Family Consumer ScienceDepartment and Grant No.12644511 USDA NIFABE BOLD. Shape the Future.The College of Agricultural, Consumer and Environmental Sciences is an engine for economic and community developmentNew Mexico State Universityin New Mexico, improving the lives of New Mexicans through academic, research, and Extension programs.aces.nmsu.edu

Develop training modules for manufactured foodfacilities in New Mexico. Modify existing materials usingthe Popular Education model for Hispanic and NativeAmerican audiences and for local food processingsystems. Pilot developed materials for target audiencein focus groups for appropriateness for target audienceand then test for online delivery that will certifyfarmer-processor and food manufacturer. Modify asneeded before implementing live online certificationprogram.BE BOLD. Shape the Future.New Mexico State Universityaces.nmsu.edu

Approach for Training ModulesLearning objectives and activities tied to specific levelsof understanding for each moduleLevel 1- Knowledge: List the different types of hair restraints available tofood workers.Level 2- Comprehension: Describe how to properly wear the different types ofhair restraints available to food workers. Explain why food workers must wear hair restraints toensure food safety as well as personal safety. Identify how to properly use hair restraints.Level 3- Application: Demonstrate how to properly use hair restraints.BE BOLD. Shape the Future.New Mexico State Universityaces.nmsu.edu

Program DevelopmentBE BOLD. Shape the Future.New Mexico State Universityaces.nmsu.edu

GMP modules Hair restraints, Disease control, Hand washing Unit ppt narrated presentation Embedded videos Worksheet and key Poster (bilingual) Assessment and keyBE BOLD. Shape the Future.New Mexico State Universityaces.nmsu.edu

ResultsBE BOLD. Shape the Future.New Mexico State Universityaces.nmsu.edu

FSOP Project Roundtable-February 4, 2021Bridging the GAPs: Approaches for TreatingPreharvest Agricultural Water On-FarmFaith Critzer, Washington State Universityfaith.critzer@wsu.eduUSDA, Food Safety Outreach ProgramYour Logo(s)

Bridging the GAPsFaith Critzer, WSU, faith.critzer@wsu.eduUSDA, FSOPProject Need Preharvest water treatment asa strategy identified in thePSR and by some high-riskcommodities Implementation is extremelycomplex without any trainingsupport High likelihood of failureIrrigationFertigationFoliar SpraysCoolingFrostProtection

Bridging the GAPsFaith Critzer, WSU, faith.critzer@wsu.eduUSDA, FSOPApproach Four-part curriculumdeveloped by our team Includes supplementalresources Videos Interactive Test Strip VirtualLab Hands-on activities Hosting both grower trainingsand train-the-trainersModule 1:Agricultural WaterTreatment andFSMAModule 2:Agricultural WaterTreatment ToolsModule 3:Developing Onfarm AgriculturalWater TreatmentProgramsModule 4:ImplementingAgricultural WaterTreatment on theFarm

Bridging the GAPsFaith Critzer, WSU, faith.critzer@wsu.eduUSDA, FSOPOutcomes Three train-the-trainers 79 participants 30 states and Puerto Rico21.7% increase in knowledge Participants leave with all thematerials to deliver any of thecontent to their stakeholders

Bridging the GAPsFaith Critzer, WSU, faith.critzer@wsu.eduUSDA, FSOPOutcomes 125 growers trained January-March 202025.8% increase in knowledge Mean course rating of 4.22 ona 5-point Likert scale

Bridging the GAPsFaith Critzer, WSU, faith.critzer@wsu.eduUSDA, FSOPOutcomesAnimated Videosirrigation.nmsu.edu

Bridging the GAPsFaith Critzer, WSU, faith.critzer@wsu.eduUSDA, FSOPOutcomesTest Strip Appirrigation.nmsu.edu

FSOP Project Roundtable-February 4, 2021Experiential Learning Opportunities for LimitedResource Growers through Mobile Farm Innovationin Mississippi, Alabama, and GeorgiaRebecca Catalena, Alabama Extensionrjc0026@auburn.eduUSDA NIFA, FSOP

Farm Innovation Project in MS, AL, and GARebecca Catalena, Alabama Extension, rjc0026@auburn.eduUSDA NIFA, FSOPProblem Statement / IssueDefinition:The overarching goal ofthe project is to meet thecritical challenges to farmviability faced by sociallydisadvantaged, limitedresource, and minoritygrowers in the region whoare trying to balance foodsafety and conservationconcerns.

Farm Innovation Project in MS, AL, and GARebecca Catalena, Alabama Extension, rjc0026@auburn.eduUSDA NIFA, FSOPApproach / Methods: Design and construct three Mobile Farm Innovation trailers tomeet the learning needs of limited resource growers withsmall acreage. Develop and implement a multimodal and modular trainingprogram that balances food safety and conservation needs. Conduct outreach in Mississippi, Alabama, and Georgia Evaluate the program

Farm Innovation Project in MS, AL, and GARebecca Catalena, Alabama Extension, rjc0026@auburn.eduUSDA NIFA, FSOPResults / Outcomes: One trailer is wrapped inphotographs and text depictingsafe water use, hygienepractices, vegetative buffers,and safe rotational grazing. The inside of the trailer hasbeen modified with cabinets,electrical outlets, andadditional space to holdexperiential learning activities. The second trailer has beenpurchased and internalmodifications are in process.

Farm Innovation Project in MS, AL, and GARebecca Catalena, Alabama Extension, rjc0026@auburn.eduUSDA NIFA, FSOPResults / Outcomes: The Farm Innovationmaterial developmentcommittee created eighteducational fact sheets andfacilitator guides. Handwashing StationCoolBotCold StorageCleaning and SanitizingChoosing a SanitizerWater SamplingGoogle Maps

Farm Innovation Project in MS, AL, and GARebecca Catalena, Alabama Extension, rjc0026@auburn.eduUSDA NIFA, FSOPResults / Outcomes: The Farm Innovation materialdevelopment committeecreated seven educationalScreencasts. Google MapsPSA Required RecordsK-State Exemption WorksheetAlabama Extension FarmingBasics NECAFS Vermont Peer-to-Peer Portal PSA Sanitizer Tool

Farm Innovation Project in MS, AL, and GARebecca Catalena, Alabama Extension, rjc0026@auburn.eduUSDA NIFA, FSOPResults / Outcomes:First pilot took place in Okolona, Mississippion Dec. 5, 2020 with 13 participants.

Farm Innovation Project in MS, AL, and GARebecca Catalena, Alabama Extension, rjc0026@auburn.eduUSDA NIFA, FSOPResults / Outcomes: Participants were askedquestions about theimportance of on-farmhandwashing,maintaining a cold chain,cleaning and sanitizing,having a farm map, andwater testing. After rotating to eachactivity station,participants reported theywere more likely to installon-farm handwashing,install a CoolBot storageunit, make a farm map,and test their water.

Farm Innovation Project in MS, AL, and GARebecca Catalena, Alabama Extension, rjc0026@auburn.eduUSDA NIFA, FSOPCollaboratorsAndrew Williams-Deep South FoodAlliance (TUCCA)E’licia Chaverest-Alabama A&M SmallFarms Research CenterJoshua Dawson-Fort Valley StateUniversityBilly Mitchell-National Farmers UnionKristin Woods, Janice Hall, AmeliaMitchell, & Rebecca Catalena- AlabamaExtensionFarmer Advisory BoardNancy Carnley, Machis TribeCarolyn Jones (MS)Demetrius Milling (GA)Bill Minor (AL)Monica Ponce (GA)Grover Robinson (AL)Ozell White (MS)

FSOP Project Roundtable-February 4, 2021Developing a Handbook of ProduceSafety Standards for BuyersWesley Kline, Rutgers Cooperative Extensionwkline@njaes.rutgers.eduHans Estrin, UVM Extensionhestrin@uvm.eduElizabeth Newbold, UVM Extension, NECAFSElizabeth.Newbold@uvm.eduJennifer Matthews, Rutgers Cooperative Extensionjmatthews@njaes.rutgers.edu

Developing a Handbook of Produce Safety Standards for BuyersProblem Statement/IssueDefinition: Many produce safety standardsand systems to navigate bybuyers and producers. Need regional resources tomake this navigation easier. Need to improve: Produce safety knowledge Communication andalignment among buyersand producers

Collaborative Approach :The need for this Buyers Handbook was guided by aninterdisciplinary, regional project team.

Developing a Handbook of Produce Safety Standards for BuyersWesley Kline, Rutgers Cooperative Extension, Goal is to provide a produce safety online handbook to help buyersnavigate FSMA PSR and audit standards that impact producers inthe Northeast region.Project Phases Include:1. Review and compare all relevant state and federal produce safetystandards (COMPLETE)2. Develop online buyer handbook based on specific produce safetystandards (Version 1 in progress--due in early 2021)3. Extend the project results through education and outreach Slides, fact sheets, social media, existing networks4. Evaluate and assess project and impact Google analytics, surveys, buyer advisory group

Developing a Handbook of Produce Safety Standards for BuyersWesley Kline, Rutgers Cooperative Extension, wkline@njaes.rutgers.eduUSDA-FSOPResults/Outcomes from Buyers Handbook Project:Actual outcome:1. A Buyers Handbook that summarizes relevant Northeast state andfederal produce safety information in one placePlanned outcomes :1. Improved competency, connection and collaboration amongstregional buyers2. Expanded materials used by educational programs that supportknowledge development of regional buyers3. New knowledge, applied by buyers in meaningful and measurableways, increases regional market access for producers.

Buyers Handbook Project Status:Mockup developed with Workgroup Feedback, SiteDevelopment in progress

FSOP Project Roundtable-February 4, 2021IMPROVING ACCESS AND MOTIVATION FORSMALL AND MEDIUM PROCESSORS IN THENORTHEAST TO BE IN COMPLIANCE WITHFSMA’S PC RULEJill FitzsimmonsDepartment of ResourceEconomicsjfitzsim@umass.eduUSDA, FSOP

Improving Access and Motivation for Small and Medium Processors inthe Northeast to be in Compliance with FSMA’s PC RuleJill Fitzsimmons, Department of Resource Economics, jfitzsim@umass.eduUSDA NIFA, FSOPPROBLEM STATEMENTSmall and medium sized processors (SMP) in the Northeastface barriers to implementing FSMA’s Preventive Controls(PC) Rule, including: A lack of accessible resources tailored to their needs, A lack of knowledge regarding how the implementation ofPC will impact their businesses, and Absence of scale-relevant materials that illustrate thepotential financial benefits of compliance

Improving Access and Motivation for Small and Medium Processors inthe Northeast to be in Compliance with FSMA’s PC RuleJill Fitzsimmons, Department of Resource Economics, jfitzsim@umass.eduUSDA NIFA, FSOPAPPROACH1. Provide targeted, scaffoldedtechnical support to SMPs.2. Document five SMPs’journey to implement PCcompliant FSP.3. Use documentation to develop accessible, scaleappropriate motivational mixed-media content toencourage SMPs to implement PC.

Improving Access and Motivation for Small and Medium Processors in theNortheast to be in Compliance with FSMA’s PC RuleJill Fitzsimmons, Department of Resource Economics, jfitzsim@umass.eduUSDA NIFA, FSOPRESULTS: PROVIDE TARGETED,SCAFFOLDED TECHNICAL SUPPORT TOSMPS.5Select Pre/ Post Webinar Changes in opKnowledgePost33-Day PCQIcourse210PC Rule*FSMASteps toImplement*FlowCostsThis work was supported by the Food Safety Outreach Program from theNational Institute of Food and Agriculture, U.S. Department of Agriculture015331-00002. The contents are solely the responsibility of the authors and donot necessarily represent the official views of the USDA or NIFA.

FSOP Project Roundtable-February 4, 2021Food Safety Management Training for Smalland Emerging Food Businesses:Integrating a Food Safety Culture from Concept toCommercializationAmanda J. Kinchla, UMass-Amherstkinchla@umass.eduUSDA, NIFA, Grant 2017-04978, Project accession 1014003Collaborating Team: Nicole Richard,Chris Von Achen, & Lori Pivarnik

Food Safety Management Training for Small and Emerging Food Businesses:Integrating a Food Safety Culture from Concept to CommercializationAmanda Kinchla, UMass-Amherst, kinchla@umass.eduFSOP, USDA-NIFA Grant 2017-04978, Project accession 1014003Problem Statement / Issue Definition: The development of shared-use processingfacilities - challenged with regulation and foodsafety compliance. Increase feasibility of locally and regionallyproduced agricultural products, - provide afocused educational delivery of customizedtraining to food entrepreneurs to understandcritical food safety considerations from conceptto commercialization. Project Goal: To develop and implement asustainable food safety training programcustomized to small and emerging foodbusinesses (SEFB) that will help increase theirknowledge in food safety and enableentrepreneurial success in the marketplace.

Food Safety Management Training for Small and Emerging Food Businesses:Integrating a Food Safety Culture from Concept to CommercializationAmanda Kinchla, UMass-Amherst, Kinchla@umass.eduFSOP, USDA-NIFA Grant 2017-04978, Project accession 1014003Approach / Methods:1. Conduct a needs assessment specific to thefood safety educational and trainingopportunities necessary to support small andemerging food businesses.2. Develop a curriculum and online training tools,field a pilot test and evaluate the food safetyeducational program that addresses the needsspecific to small and emerging food businessesthat will enable FSMA compliance.3. Implement a food safety program specific tosmall and emerging food businesses to enhancefood safety culture

Food Safety Management Training for Small and Emerging Food Businesses:Integrating a Food Safety Culture from Concept to CommercializationAmanda Kinchla, UMass-Amherst, Kinchla@umass.eduFSOP, USDA-NIFA Grant 2017-04978, Project accession 1014003Outputs and Outcomes Outputs JFPT Re: needs assessment Jan (2021)Standardized Curricula (8 modules)2 pilots (27 participants)TTT (23 participants)Hosted 4 programs to date programs(53 participants) OutcomesCurriculum Training modules1. Introduction2. Food Safety Hazards3. Product Development Life Cycle4. Controlling Food Quality and Safety5. Product Labeling6. Food Safety Management7. Hazard Analysis8. Preventive Controls Participants are more prepared toimplement key food safety practicesIncluding: Implementing GMPs, records, TTT curriculumand assessing and controlling food safety Online self-paced training toolhazards Increased awareness of food safety hashelped to improve a food safety culture fortheirreachbusinessout to Amanda Kinchla if you are interested in the nextPleasevirtual Train-the Trainer on April 14th

FSOP Project Roundtable-February 4, 2021Collaborative Food Safety EducationProgram for LouisianaRetail/Manufacturing CrossoverBusinessesWenqing Xu, PhDLouisiana State University AgCenterwenqing.xu@agcenter.lsu.eduUSDA-NIFA, FSOPYour Logo(s)

Collaborative Food Safety Education Program for Louisiana Retail/ManufacturingCrossover BusinessesWenqing Xu, PhD, LSU AgCenter, wenqing.xu@agcenter.lsu.eduUSDA-NIFA, FSOPProblem Statement / Issue Definition:The blending of manufacturers, distributors, and retailers hascontinued to gain momentum. Food businesses now have thefreedom to cross over the traditional boundaries of industrylines. These crossover businesses have their uniquechallenges because it is difficult to know where they fit in theregulations. With the enactment of the Food SafetyModernization Act (FSMA), the increasing complexity ofregulations lead to the confusion of the food business ownersand the challenge for local regulatory agencies. Detailednavigation and customized education are needed forretail/manufacturing crossover business owners as well aslocal regulatory agencies.Include pictures, figures,tables, or graphs of results. Ifapplicable. (Feel free to addmore than 1 image)

Collaborative Food Safety Education Program for Louisiana Retail/ManufacturingCrossover BusinessesWenqing Xu, PhD, LSU AgCenter, wenqing.xu@agcenter.lsu.eduUSDA-NIFA, FSOPApproach / Methods:

Collaborative Food Safety Education Program for LouisianaRetail/Manufacturing Crossover BusinessesWenqing Xu, PhD, LSU AgCenter, wenqing.xu@agcenter.lsu.eduUSDA-NIFA, FSOPResults / Outcomes: Identify the detailed needs for regulatory and crossoverfood businesses in food safety regulation training Organize and evaluate the existing training materials andidentify the gaps. Develop a series of eLearning modules and train-thetrainer curriculum for crossover food businesses and LDHsanitarians, respectively. Conduct the train-the-trainer workshops for LDHsanitarians and implement the eLearning modules forcrossover food businesses.

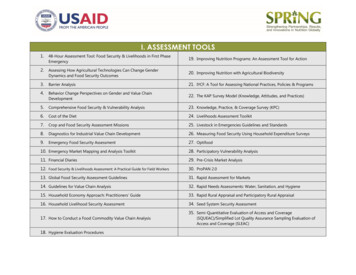

Collaborative Food Safety Education Program for LouisianaRetail/Manufacturing Crossover BusinessesWenqing Xu, PhD, LSU AgCenter, wenqing.xu@agcenter.lsu.eduUSDA-NIFA, FSOPResults / Outcomes: 171 responses were collected Most popular variance processes included reduced oxygen processing (ROP) (40%),using of additives such as vinegar as a method of preservation (21%), and smokingfood as a method of preservation (20%).Specialized ProcessingROP21%40%9%smoking food as a method ofpreservationcuring food10%20%shellfish life support systemwith shellfish offered forhuman consumption

Collaborative Food Safety Education Program for LouisianaRetail/Manufacturing Crossover BusinessesWenqing Xu, PhD, LSU AgCenter, wenqing.xu@agcenter.lsu.eduUSDA-NIFA, FSOPResults / Outcomes: ROP of raw single ingredient (26%), hot smoking (88%), and sushi (25%) ratedthe most popular, within each category, respectively. However, only 15%businesses who perform ROP were considered having sufficient trainings, and13% for smoking foods or sushi. Number of sanitarians who reported “not confident when inspecting” reached 2735%. Food establishments not aware of regulation (35%) and no knowledge andresources to develop the systems to comply (35%) were top two challenges.

Thank you for attending the FSOP ProjectRoundtable!Evaluation will be sent to the email youregistered with.Questions? Contact Katelynn Stull at k.stull@ufl.edu

New Mexico State University aces.nmsu.edu BE BOLD. Shape the Future. New Mexico State University . improving the lives of New Mexicans through academic, research, and Extension programs. Executive producers: Nancy C. Flores, PhD; Extension Specialist Food Technology: Rebecca Mijares, Karla Y. Lopez, Adetoye Abodunrin . Sharon Bartley PhD .