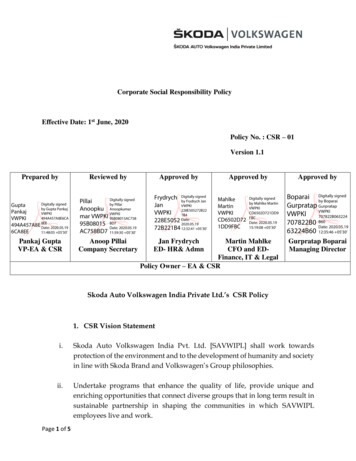

Transcription

PowerFloorLow Rise Residential& CommercialFloor SystemDESIGN AND INSTALLATION GUIDENEW ZEALAND

ContentsIntroduction31. Design and selection details6–H ow to use this design andInstallation Guide6– System components8– Design considerations10– Architectural Specification112. System performance– System properties13– Building regulations15– Joist span tables163. Installation detailThis Design Guide has beenprepared as a source of informationto provide general guidance toconsultants – and in no way replacesthe services of the professionalconsultant and relevant engineersdesigning the project.It is the responsibility of thearchitectural designer andengineering parties to ensurethat the details in this Design andInstallation Guide are appropriatefor the intended application.The recommendations of this guideare formulated along the lines ofgood building practice, but arenot intended to be an exhaustivestatement of all relevant data.21321– Hebel PowerFloor installation sequence21– Construction details22– Hebel PowerFloor panel fixing details26– Control joint details28– Construction Details29– Multi-Level Construction details31– Hold-down/bracing wall details32– Penetrations & notching details33– Wet area detail33– Balcony & staircase details34– Floor covering installation36– Tile installation36– Vinyl installation36– Timber installation374. Handling, storage and responsibility38– Delivery and storage38– Tools and equipment for construction39– Panel installation40– Panel handling41Appendices42– Appendix A. Hebel PowerFloorpanel material properties42– Appendix B. Estimating Hebel PowerFloor43

Better floorsare constructed withHebel PowerFloorHebel is an Autoclaved AeratedConcrete (AAC) available as blocksand lightweight steel reinforcedconcrete panels. Hebel has been usedin Europe for over 70 years and herein New Zealand for over 20 years.Hebel reduces your total cost to build.Hebel is a unique high performance masonry systemthat is easy to install and speeds up construction time.The Hebel system can be installed without bricklayersand reduces the requirement for skilled trades-peopleon site. Whether you choose to install it yourself usingexisting trades or have it supplied and installed byreadily available and experienced crews you will behappy with the cost savings.Hebel Powerfloor. A high-performancelightweight concrete flooring systemHebel PowerFloor is a lightweight concrete flooringsystem ideal for installation over timber or steel joists.This system provides a superior floor solution with thequalities and feel of a concrete floor at a significantlyreduced cost.Unlike concrete, Hebel PowerFloor does not needpropping or curing and is ready for application of floorfinishes within 24hours.Hebel. Supreme comfort, solid and quietThe Hebel PowerFloor system reduces airbornenoise such as foot-fall from upper floors making fora quieter home. This is especially important giventhe trend away from carpet to hard flooring surfacessuch as timber and tiles. Hebel PowerFloor alsoeliminates squeaking that is often the case withparticle board and timber board flooring.PowerFloor boasts superior thermal performance(particularly for suspended floors on sloping sites)and assists in achieving thermal ratings that result inreduced heating and cooling costs.Made and distributed by CSRHebel is manufactured in Australia to the highestquality standards and our warranty is backed by CSR,one of Australia’s oldest companies, for your peaceof mind. Hebel is distributed in New Zealand by CSRHebel, a division of CSR Building Products (NZ) Ltd,a wholly owned subsidiary of CSR in Australia. Oursystems have been developed in New Zealand tomeet local requirements so you can rely on NewZealand and Australian expertise and stock holdings.Hebel PowerFloor panels are reinforced withcorrosion-protected steel mesh and they featuretongue and grooved edges which fit snuggly togetherto form a strong, solid and smooth floor suitable forjust about any floor covering.Hebel PowerFloor can be easily installed by existing onsite tradesmen such as carpenters and is unaffected bywet or changing weather during installation.3

Hebel PowerFloor. Better to buildAt the heart of the Hebel systemis the Hebel PowerFloor – a 75mmthick, steel reinforced building panelmade from AAC (Autoclaved AeratedConcrete) supplied in 1800mm &2400mm lengths by 600mm widewith a tongue and groove profile.The unique Hebel attributes arebest summarised with the Hebel‘tick’ below:Lightweight yet solidand tough as concreteBeing a masonry, steel reinforced 75mmthick panel, Hebel PowerFloor is solidand strong. A lightweight concrete floorthat can be easily laid by your normalon-site tradesmen such as carpenters.A comforting thoughtfor a comfortable livingenvironmentHebel’s unique AAC constructionprovides superior insulation qualitiesfor a masonry product. The uniquecombination of thermal resistance along with thermal mass,make building with Hebel a smart choice for meetingNew Zealand’s stringent building regulations.For unit and home owners, the thermal efficiencies of Hebelreduce the reliance on heating and cooling appliances – thecombined effects of using a heater less in winter and fansor air conditioning less in summer and warmer months canhave a big impact on rising energy costs.Faster construction periodHebel PowerFloor is faster to constructthan suspended concrete. No proppingand curing of concrete is required.Typical placement rates of 70m2 per daycan be achieved with follow on tradesstarting after 24 hours.4

with Highly fire resistant for peaceof mind and added securityA sound reason for betteracoustic qualitiesHebel is non-combustible and renownedHebel PowerFloor answers the age oldfor its highly fire resistant properties.issue of sound transfer between floors.The fire rating of the floor systemis determined by the ceiling liningsCreaking timber is a thing of the past asthe tongue and groove solid concrete floor locks together.achieving up to 120/120/120 minutes FRR when firePowerFloor provides superior airborne noise insulationexposure is from the underside (BRANZ FC13639-001).particularly good for foot fall noise when installed withresilient mounts. With home theatres becoming standardin most modern homes, you can enjoy your entertainmentwithout disturbing the rest of the family.Sustainability for a better worldin the long term starts todayHebel delivers a diverse number ofenvironmental benefits over particleboard and concrete. Independent testingshows that overall, Hebel has a 30%lower environmental impact than concrete or brick veneer.Hebel panels use 60% less embodied energy and produces55% less greenhouse emissions compared to concrete orbrick veneer, making it a more sustainable, environmentallyfriendly choice of building material.for all thebest reasonsWith the attributes and benefits shown above this innovativeand versatile masonry product provides confidence thatHebel is ideal for solid floors as detailed throughout theremainder of this Design and Installation Guide.5

1.1 DesignTypical ApplicationsHebel PowerFloor systems detailed in this design and installation guide are joist floor solutions for residential, low risemulti-residential, commercial and industrial construction. The floor applications consist of a Hebel PowerFloor panel connectedto a steel or timber joist system forming a platform floor.Figures 1.1, 1.2, 1.3 show typical applications for Hebel PowerFloor. Contact CSR Technical Services for further details.Fig 1.1 ResidentialSuspended Ground FloorsFig 1.2 ResidentialSuspended First FloorsFig 1.3 Commercial Floors - schools,offices and community centres1.2 How to use thisDesign and Installation GuideSystems Index - Table 1.4Architectural SpecificationThis allows the designer to quickly locate a system thatThis material can be copied for inclusion onto workingcombines the acoustic rating (STC/Rw/Rw Ctr), approximatedrawings or project specifications. This provides a pro-formafloor thickness (excluding joist height), floor covering typelayout with fill in sections to quickly and easily create andand ceiling system requirement.customise project specifications.System Components, SystemProperties & Design ConsiderationsInstallation Diagramsand Fixing InstructionsThese sections provide relevant background informationGeneral design and installation information is provided forto enable designers to plan and select appropriate Hebelthe various systems available. For more detailed informationPowerFloor systems.contact your CSR Hebel representative. For furtherinformation on different joist types and their applications,please contact the joist manufacturer.Hebel PowerFloor System PagesThese pages provide detailed performance information toassist in the selection of an appropriate Hebel PowerFloorsystem for the application under consideration.6

STEP 1. Scan the ‘System Index’ for systems with the appropriate floor covering for the intended application.STEP 2. Determine the acoustic and thermal performance requirements by contacting the appropriateproject engineer.STEP 3. Turn to the selected system page and select ceiling system that provides appropriateperformance (FRR/STC/IIC/Rw/Rw Ctr/Lnw C1/R-Value).STEP 4. Determine the structural requirements of the floor (live load & dead load) by contacting the appropriateengineer or architect.STEP 5. Determine joist type, size and spacing from the joist span tables in section 2.3 of this guide or from theproject engineer as appropriate.Table 1.4 System index for CSR Hebel PowerFloor SystemsHebel PowerFloorSystem DescriptionFloorCovering TypeSystem No.SystemDetailsPage No.Hebel 1474Hebel 1475Hebel 147622Hebel 1478Hebel 1479Hebel 148125 I nexpensive floor witha hard surface andhigh level of thermalperformance.Hebel 1486Hebel 1487Hebel 149123 Attractive solidtimber finish with ahigh level of thermalperformance.Hebel 1494Hebel 1495Hebel 150124Applications& Benefits Carpeted floor witha high level thermal Medium duty underlay performance. CarpetDesign and selection detailsSelecting a system 8mmCeramic tiles R igid floor system,with good thermalperformance. Suitable Waterproof membranefor wet or dry areas.(not requiredin dry areas) Flexible adhesive Vinyl sheet floorcovering Masonite underlay 19mm T&Ghardwoodflooring 70 x 35mm timberbattensNote: Resilient mounts will help reduce footfall noise when using hard surface coverings such as tiles.7

1.3 System ComponentsThese components are compatible withtimber and steel joists.Timber & SteelSupport SystemsHebel PowerFloor PanelTimber or steel floor framing can be used to support theFloor CoveringHebel PowerFloor panels. The allowable spacing of thejoists is 300mm, 450mm or 600mm (maximum). The joists,Proprietary Ceiling Systembearers and other supports shall be sized in accordance withHebel Adhesivethe project engineer recommendations. For selection ofFuller Max Bond solid timber joists refer also to section 2.3. Where steel joist framing are used it must be ensured that the PowerFloorFasteners & Fixingspanels are provided with uniform and complete bearing ontoCaulkingeach steel joist.CSR Building Products Limited, guarantees only the productsthat are manufactured by CSR Hebel, not the components,products or services supplied by others.Hebel PowerFloor PanelThe Hebel PowerFloor panel is available in a stock length ofNote: When determining floor joist or supporting framingdesign, the designer should allow at least 42kg/m2 forthe self-weight of the Hebel PowerFloor panel under inservice conditions (panel weight at 10% moisture content).Consideration may also need to be given to the self-weightduring construction which is likely to be approx. 51kg/m2 (panelweight at 30% moisture content). A minimum joist flange widthof 45mm is required.1800mm x 600mm width or 2400mm x 600mm width, withProprietary Ceiling Systemsa mass of up to 56kg/panel. Where necessary, panels can beThe underside of Hebel PowerFloor can be lined withcut on-site using a circular saw with diamond tipped cuttingproprietary ceiling systems. These ceiling systems consistblade. The minimum recommended width of a cut panel isof combinations of components, such as furring channel,270mm wide and 600mm long.resilient mounts, clips, suspended steel framing, insulation,The panels are screw fixed and bonded to all floor joistsand plasterboard.including at panel butt joints. Panel butt joints must occur overThe most common combinations are detailed in the tablestructural framing support. For further information on fixingbelow with relevant FRR'S achieved.Hebel PowerFloor panels, please refer to relevant constructiondetails outlined in this guide.Fig 1.5 Hebel PowerFloor Panel Cross Section600mm75mmFloor CoveringsA range of floor coverings can be installed over the HebelPowerFloor panels, such as, direct stick tiles, carpet andunderlay, topping slab and tiles, timber (floating or onbattens) and vinyl over masonite.8

Hebel flooringCeiling liningJoistsGBFC 301 x 13mm GIB FyrelineTimber joistGBCJ 301 x 13mm GIB FyrelineComposite joistGBSJ 301 x 13mm GIB FyrelineSteel joistHebel PowerfloorGBSC 301 x 13mm GIB FyrelineSuspended gridGBUC 301 x 16mm GIB FyrelineTimber or steel joistGBDFA 30a2 x 13mm standard plasterboardTimber joistGBDFA 30d1 x 13mm GIB Braceline/ NoiselineTimber joistGBFC 451 x 13mm GIB FyrelineTimber joistGBCJ 451 x 13mm GIB FyrelineComposite joistGBSJA 452 x 13mm GIB FyrelineSteel joistGBSCA 452 x 13mm GIB FyrelineSuspended gridGBFC 601 x 16mm GIB FyrelineTimber joistGBCJ 601 x 16mm GIB FyrelineComposite joistGBSJ 601 x 16mm GIB FyrelineSteel joistGBSC 60a2 x 13mm GIB FyrelineSuspended gridGBSC 60b1 x 16mm GIB FyrelineSuspended gridGBUC 602 x 13mm GIB FyrelineTimber or steel joistGBDFA 60b2 x 13mm GIB FyrelineTimber joistGBDFA 60d2 x 13mm GIB FyrelineTimber joistGBDFA 60e2 x 13mm GIB FyrelineTimber joistGBSJA 601 x 16mm and 1 x 13mm GIB FyrelineSteel joistGBSCA 60a1 x 13mm and 1 x 16mm GIB FyrelineSuspended gridGBFC 902 x 16mm GIB FyrelineTimber joistGBSC 901 x 13mm and 1 x 16mm GIB FyrelineSteel joistGBUC 902 x 19mm GIB FyrelineTimber or steel frameGBFC 1202 x 19mm GIB FyrelineTimber or steel frameGBUC 1202 x 19mm GIB FyrelineTimber or steel frameHebel AdhesiveHebel Adhesive (supplied in 20kg bags) is used for gluingthe panels together at all joints. Typically, panel joints are2-3mm thick. Sufficient pressure is to be applied to the jointto ensure full coverage of adhesive in the joint. Adhesive isto be mixed to the proportions as stated on the bag.Construction AdhesiveA 5mm (minimum) bead of Fuller Max Bond constructionadhesive is applied to the top of the joists. Where panelends butt together over a common joist, two beads ofadhesive shall be applied. Ensure the surface is free ofcoatings and loose material that may inhibit bond.FastenersThe correct sized fasteners for the construction of thefloor systems must always be used. Install screws rews for fixing Hebel PowerFloor panels to SteelJoists: 14-10 x 95mm Hex Head Self-tapping Screws orequivalent (no seal required). 14-10 x 135mm Hex HeadSelf-tapping Screws or equivalent (no seal required)for skew fixing where required. These fasteners aresuitable for metal thickness 3mm. Refer to screwmanufacturer’s guidelines.CaulkingHebel PowerFloor requires that all gaps at openings,penetrations and control joints be caulked to provide anairtight floor system that maintains acoustic, thermal,verminand fire resistance performance. All gaps must becarefully and completely filled with an appropriate flexiblepolyurethane sealant, installed in accordance with the sealantmanufacturer’s specifications.shown in the Hebel PowerFloor Panel Fixing DetailsHebel Patchsection of this guide.Minor chips or damage to panels are to be repaired usingScrews for fixing Hebel PowerFloor panels to TimberJoists: 14-10 x 100mm MP Bugle Head Batten Screwsor equivalent. 14-10 x 125mm Hex Head Screws orequivalent for skew fixing where required.Design and selection detailsGIB System referenceHebel Patch. Hebel Patch is available in 10kg bags.Hebel anti-corrosion protection paintReinforcement exposed when panels are cut shall becoated with a liberal application of Hebel anti-corrosionprotection paint.9

1.4 Design ConsiderationsAcousticsRecommended locations for control joints are:Placement of insulation in the ceiling cavity can enhance theTypically at a max. spacing of 6000mm.sound insulation performance of a floor/ceiling system.Over lines of support for the joists. Refer to Fig 3.10.A carpet/underlay floor covering incorporated with HebelLocated at changes in joist orientation.PowerFloor will provide the best impact sound resistance.For hard surface floor coverings, we suggest using a floatingWet Area Floor Constructionfloor and/or an independent ceiling system, incorporatingAll wet areas require a waterproof membrane layer over theresilient mounts or resilient furring channels.Hebel PowerFloor panel. Waterproofing membranes shallFor ceilings that incorporate resilient mounts or resilient furringbe nominated by the designer or specifier, and installed inchannels, flanking sound paths through adjacent walls areaccordance with manufacturer’s recommendations.common, especially in timber framed buildings. To maintainSTC/Rw/Rw Ctr and IIC and Lnw C1 ratings, the wall liningsServiceability Behaviourmay also need to be resiliently mounted. For multi-tenancyThe deflection limits of the floor are governed by thebuildings, providing a control joint at the party wall junctionswill break a flanking path and maintain acoustic amenity.Alternative FramingAlternative support framing systems including steel, andcomposite steel/timber joists, laminated timber joists, andtrussed plywood web joists may be used without reducingthe system FRR rating for a fire source ‘from above’. Thedesign of joists shall allow for temperature effects. Alternativesupport framing systems may affect acoustic performance,and advice from an acoustic consultant is recommended.Penetration RestrictionsPenetrations may be required to accommodate services, suchas waste pipe-work, water pipe-work, and air conditioningductwork, etc. Hebel PowerFloor can accommodate an 80mmmaximum circular penetration without a reduction in structuraladopted joist size. As a guide, the following typical deflectionlimits provide acceptable behaviour and dynamic response:Dead Load (DL): span/300 or 12.5mm max.Live Load (LL): span/360 or 9mm max.DL & LL: span/400.Dynamic Response: 2mm max. under a 1kN point load.Note: The designer should select appropriate deflectionlimits to suit individual projects.Concentrated LoadsFor concentrated loadings, such as a loadbearing wall or pointloads, the designer should ensure additional joists or blockingare provided beneath the wall or bearing plate. This willreduce the localised bearing stress. Bearing stress in the AACshall be limited to 1.0MPa.performance. Multiple penetrations in the same panel are toBracingbe in a straight line, parallel to the long edge of the panel.For bracing walls parallel to joists, a joist shall be positionedFor large or clustered multiple penetrations, additional joistsbeneath the wall. For bracing walls perpendicular to joists,or bridging should be included for support of the panel in thisblocking shall be positioned beneath the wall. Blockingarea. Refer to the ‘Penetration & Notching Details’ section ofshall have a minimum width of 45mm. Bearing stress in thethis guide. All penetrations are a potential source for waterAAC shall be limited to 1.0MPa. Hebel PowerFloor is notingress or air leaks, and should be sealed with an appropriateconsidered to provide a horizontal diagram bracing capacity.flexible fire rated sealant or proprietary collar.Should such capacity be required a separate bracing systemwill need to be used - refer to the project engineer.Control Joint LayoutControl joints are a necessary part of Hebel PowerFloor.Panel SupportControl joints provide a region in which to relieve stress dueAll Hebel PowerFloor panels are to start and finish overto movement of the structural system, and to control thea joist or support framing. Where panel joints bear ontolocation where movement can occur without a detrimentala common joist the panel ends must not be cut i.e use aeffect on the floor finish.factory produced panel end.10

This specification should be adopted as a guideonly, and shall be superseded by the contractspecifications of the project.* Insert or select appropriate specifications.ScopeLevels of Finish - Floor CoveringPrior to installation of the floor covering, thecontractor shall ensure the installed panels arewithin the tolerances of the project specifications.The contractor shall ensure that all control joints areinstalled as per project specifications, panel jointsThe contractor shall furnish all material andare completely filled with Hebel Adhesive, minorequipment required to satisfactorily complete thechipping damage of the panels shall be patched withinstallation and jointing of Hebel PowerFloor whereHebel Mortar, and all sealants are installed as perindicated in the contract specification.manufacturer’s specifications.MaterialsAll AAC material shall be a Hebel PowerFloor panel asmanufactured by CSR Hebel.Floor coverings shall be installed as permanufacturer’s specifications, unless specifiedotherwise in the contract documentation.All accompanying fixings shall be those supplied byPlasterboard fixingCSR Hebel or approved by the project engineer.All layers shall be fixed to the framing (ie., timberSteel frame components shall be those manufacturedby Rondo Building Services Pty Ltd (or products ofequivalent or better performance).Construction adhesive shall be Fuller Max Bond asmanufactured and supplied by Fuller (or products ofequivalent or better performance).or steel floor joists and/or steel furring channels) asspecified for the relevant ceiling system.CaulkingWhere caulking is indicated in Powerfloor systemsfire rated polyurethane sealant or fire rated backingrod with acoustic rated polyurethane sealant shallAll sealants shall be a polyurethane type with requiredbe used, and installed in accordance with thefire and acoustic ratings, (or products of equivalent ormanufacturer’s recommendations.better performance).Design and selection details1.5 Architectural SpecificationWhere caulking is indicated in wet areas, aAll infill materials shall be products manufactured andpolyurethane sealant must be used when caulkingsupplied by CSR Bradford (or products of equivalent*non-fire rated/fire rated wet areas, as indicated,or better performance).and installed in accordance with the manufacturer’srecommendations.ImportantAny variation or substitution of materials or assemblyrequirements, or compromise in assembly may resultin failure under critical conditions.11

2.1 System PropertiesHebel PowerFloorFire Resistance Rating (FRR)Hebel autoclaved aerated concrete (AAC) PowerFloor panelsNew Zealand building regulations express the firegenerally follow the design principles outlined in Australianperformance of building elements with the rating systemStandard AS5146 - Reinforced Autoclave Aerated Concretecalled the Fire Resistance Rating according to the Lifefor strength and serviceability design, with the exception ofRating, Property Rating and Risk Group.cover requirements for durability where corrosion protectioncoatings have been used on the steel reinforcement. Whenused as a flooring material, Hebel PowerFloor meets therequirements of NZBC B1 Structure and meets the 50 yeardurability performance requirement of NZBC B2 Durability.Risk Group (RG) is the classification of a building or Firecellswithin a building according to its intended use and activitiesof the occupants.Firecells are any space including a group of contiguousspaces on the same or different levels within a building,Structural PerformanceHebel PowerFloor systems can support a maximum uniformlydistributed load of 5kPa, or concentrated (point) load 1.8kN overa load area of 350mm2 (with joist at 450mm or 600mm centreswhich are enclosed by any combination of fire separatingwalls, roofs and/or floors.Life Rating (LR) is to be applied to elements of constructionthat allow movement of people from their location in aonly) & 3.9kN over a load area of 10,000mm2 (with joists atbuilding to a safe place.300mm centres). For loads outside this range, please contactProperty Rating (PR) is to be applied to elements ofCSR Hebel.construction that allows for protection of other (i.e adjacent)The designer should specify the magnitude of the gapsproperty.between the Hebel PowerFloor panel and structure. This gapFire Resistance Rating (FRR) is used to describe thewill allow movement to release any confining stresses dueminimum fire resistance required of primary and secondaryto movement of the supporting structure.building elements as determined in the standard test for fireresistance (i.e Fire Test), or in accordance with a specificDiaphragm CapacityHebel PowerFloor 75mm AAC floor panel system is able tocalculation method verified by experimental data fromstandard fire resistance tests (i.e Fire Assessment).achieve diaphragm action to resist in plane shear forces whenThe FRR rating consists of three performance criteria,constructed in accordance with this Design & Installation Guide.structural adequacy/integrity/insulation.The maximum ultimate in-plane shear force that can be appliedThe fire performance of Hebel PowerFloor system isto the floor structure 4 kN/m. The minimum floor panel sizeshould be 3.6m x 1.8m. Panels assumed to be continuous withHebel adhesive between panels. Determination of the loadvalue(s) remains the responsibility of the project design engineer.DurabilityWhere Hebel PowerFloor is installed in a multi-residential/commercial application, the PowerFloor panels must besuitably protected against trafficability during construction tomaintain the long term durability and integrity of the panels. Itis the responsibility of the builder to provide and maintain suchprotective coverings to the PowerFloor panels until such timethat the finished floor coverings are installed.For application of PowerFloor in commercial projects HebelTechnical Services must be contacted for advising on durabilityand protection of the PowerFloor panels during construction.12determined by the ceiling lining. Page 9 of this guide liststhe FRR of Hebel PowerFloor system with variety of ceilingconfigurations.

Impact Isolation Class (IIC)Sound RatingsThe Impact Isolation Class (IIC) quantifies theFloor systems, consisting of the Hebel PowerFloor andother products, have been laboratory tested to establishtheir sound insulation characteristics. A laboratorytest involves the installation of a system betweentwo massive concrete rooms, which are normallywell isolated from one another, so that only directtransmission is via the system.A steady sound level of various frequencies isgenerated on one side and measurements taken ontransmission of impact sound through a floor/ceilingsystem. The test involves impacting the floor assemblywith a standard tapping machine and measuring thesound level below in the same manner as described forthe airborne sound insulation. Higher numbers indicateless sound is being transmitted. IIC is an Americansystem and is to be being replaced in New Zealand byLn,w, which is the ISO equivalent.Ln,wboth sides. These measurements are made in one/Ln,w is the ISO equivalent of the American IIC system,third octave bands from 100Hz to 5000Hz. For eachbut with the ISO method, lower numbers mean lessspecified frequency, the sound transmission loss issound (better performance). Typically, Ln,w 110 – IIC.calculated. To assist in communication the performanceC1 Adaptation Termis conveniently expressed as a single number called the‘Weighted Sound Reduction Index’ (Rw).Weighted Sound Reduction Index (Rw)System performanceAcoustic ConsiderationsThe rating by Ln,w appears to work well wherecarpets or floating floors are employed on concreteor timber framed floors. With hard floor finishes,Currently, New Zealand building regulations expressparticularly with timber joist floors, the low frequencythe acoustic performance of a building element (orperformance may require further consideration by yoursystem) using the Sound Transmission Class (STC)acoustic consultant.rating. The International Standard Organisationacoustic rating system called the Weighted SoundSound Transmission EstimatesReduction Index (Rw) is essentially identical.Computer models are used to determine soundA correction figure of Ctr is sometimes added totransmission estimates for specific configurations, knownthe Rw value to better quantify the low frequencyas ‘Acoustic Assessments’. The computer model predictsperformance of the building system. This is not usedthe Rw performance expected from the laboratory test onwith STC ratings.the system, with a 96% confidence limit of 2.5 db.Ctr Adaptation TermThe normal rating of Rw more closely defines theacoustic performance for speech frequencies. Wherelow frequency sound insulation performance isimportant, as may be the case with traffic noise ormusic and DVD systems, then a correction factoris applied to the airborne sound rating (Rw) todifferentiate the systems with good sound insulationto these frequencies. The factor is Ctr and it is anegative value. A system with good low frequencyperformance will have a value of say -4; a systemwith poor performance will have a value of say -12.Performance - Laboratory vs Field.When selecting the appropriate Hebel PowerFloorsystem, the designer or specifier must be aware thatthe field performance will nearly always be lowerthan the laboratory Rw values . This is due to thefield conditions, such as flanking paths, air leaks, floorframe construction type and stiffness, etc., whichcan be exacerbated

Hebel PowerFloor systems detailed in this design and installation guide are joist floor solutions for residential, low rise multi-residential, commercial and industrial construction. The floor applications consist of a Hebel PowerFloor panel connected to a steel or timber joist system forming a platform floor.