Transcription

NOTICE CONCERNING COPYRIGHTRESTRICTIONSThis document may contain copyrighted materials. These materials havebeen made available for use in research, teaching, and private study, butmay not be used for any commercial purpose. Users may not otherwisecopy, reproduce, retransmit, distribute, publish, commercially exploit orotherwise transfer any material.The copyright law of the United States (Title 17, United States Code)governs the making of photocopies or other reproductions of copyrightedmaterial.Under certain conditions specified in the law, libraries and archives areauthorized to furnish a photocopy or other reproduction. One of thesespecific conditions is that the photocopy or reproduction is not to be "usedfor any purpose other than private study, scholarship, or research." If auser makes a request for, or later uses, a photocopy or reproduction forpurposes in excess of "fair use," that user may be liable for copyrightinfringement.This institution reserves the right to refuse to accept a copying order if, inits judgment, fulfillment of the order would involve violation of copyrightlaw.

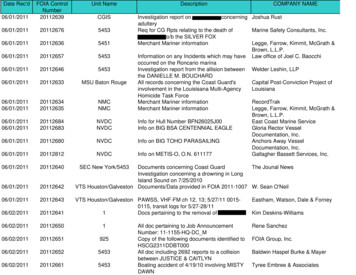

A COST-EFFECTIVE TREATMENT SYSTEM FOR THE(6,ABSTRACTf t h e r i s i n g costs f o r f oa t i o n t h a t such f u e l s are exhaustible,increasing a t t e n t i o n has been focused on theearth's heat as a source f energy. I t has beenestimated t h a t geothermal resources i n the UnitedStates alone could produc 140,000 megawatts o fpower over a l i f e expectancy o f 30 years,. This i sthe equivalent o f 140 nuclear generHowever, there are unsolved problew i t h u t i l i z i n g geothermal brines tRecent t e s t work conducted a t t h e Imperial .Valley,C a l i f o r n i a , provides a s o l u t i o n t o one o f thesemajor problems.A treatment system haswhich spent geothermal brines from a flash-tanheat-extraction p l a n t are s t a b i l i z e d t o permitr e i n j e c t i o n of t h e t r e a t e d b r i n e while maintainingthe i n t e g r i t y o f the w e l l s over an extended period.This treatment system i s both c o s t - e f f e c t i v e andenvironmentally sound. I t incorpolowing unit-process operat0Reconstituting the m idissolved from the;geothermal s t r a t a format i o n s i n a Reactor-Clarifitact precipitation reactioPolishing o f the c l a r i f i eg r a v i t y dual -media f i1t e rBrine from Magmamax #1 now feedsa four-stage f l a s h heat-extraction p l a n t a t theGeothermal Loop Experimental F a c i l i ty, operated bythe San Diego Gas & E l e c t r i c Company and theDepartment o f Energy. Spent b r i n e from the f l a s hsystem i s transported by pipe1i n e approximately5,000 f e e t t o Magmamax #3 well, and i n j e c t e d backi n t o the formation.t o f injection i sThe spent b r i n esupersaturated w i t h respect t o heavy metals ands i l i c a (Table 1), whose p r e c i p i t a t i o n , along w i t hplugglng o f the s t r a t a w i t h d i s c r e t e suspendeds o l i d s i n the brine, has adversely a f f e c t e d t h ei n t e g r i t y o f the i n j e c t i o n well. The v i a b i l i t y ofthe complete p r o j e c t i s i n jeopardy unless coste f f e c t i v e methods can be devised t o s t a b i l i z e thespent b r i n e before i n j e c t i o nTable 1.Chemical analysis o f spent geothermalb r i n e treated i n p i l o t p l a n t reactor-.Sodi umPotass iumCal c i umChlorideIrondisposal.INTRODUCTION'46Salton Sea Known Geothermal Resource Area i nImperial Valley, C a l i f o r n i a , t o demonstrate thev i a b i 1ity o f converting the underlying geothermalbrines t o energy. The p r o j e c t includes f o u r wellsd r i l l e d by Imperial Magma. Two o f the wells,Magmamax #1 and Woolsey #1, are production wells;Total Dissolved SolidspH - ,Temperature range53,27610,25922,414134,48327268520753 1129293-177'228,4485.618O0F-2OO0F82OC- 93OC

I n December 1977, personnel o f ImperialMagma and Envirotech Corporation met t o discussmethods o f t r e a t i n g the spent b r i n e t o produce anon-scaling l i q u i d s u i t a b l e f o r w e l l i n j e c t i o n .A t t h a t time, i t was conceived t h a t autop r e c i p i t a t i o n o f minerals i n the spent b r i n e couldbe achieved i n a s o l i d s contact c l a r i f i e r , producing an e f f l u e n t o f stable saturated l e v e l s o fs i l i c a and heavy metals.Accordingly, a p i l o t p l a n t Reactor-Clarifier,furnished by Envirotech Corporation t o ImperialMagma, was i n s t a l l e d adjacent t o Magmamax ,#3i n j e c t i o n w e l l and operated continuously 24 hours,per day, 7 days per week from February 28, 1978t o A p r i l 12, 1978, c o n s t i t u t i n g the f i r s t phase o ft e s t work.0- Upflow r a t e- Reaction-well r e t e n t i o n time- Solids concentration i n reaction well.0Measure the s i l i c a and t u r b i d i t y concentrat i o n s o f the e f f l u e n t from various designso f Reactor-Clarifiers.0Measure the q u a n t i t i e s o f s o l i d s p r e c i p i t a t e di n and discharged from t h e Reactor-Clarifier.0Determine the thickening and dewatering chara c t e r i s t i c s o f sludge produced, and the bestdewatering equipment t o use.0Correlate a l l data c o l l e c t e d to:Determine design c r i t e r i a f o r the ReactorC l a r i f i e r t h a t would most e f f i c i e n t l y produce stable saturated l e v e l s o f s i l i c a i nthe e f f l u e n t .Establish c r i t e r i a f o r p o l i s h i n g the ReactorC1a r i f i e r e f f l u e n t .REACTOR-CLARIFIERThe fundamental component o f the spent geothermal b r i n e treatment system i s the EnvirotechReactor-Clarifier, which i s a tank o f 8'0" diameterx 10'6" sidewater depth. A l l external surfaces areinsulated t o minimize heat l o s s o f the spent brine.Area o f the c l a r i f i c a t i o n zone i s 37.7 square feet.The u n i t operates on the p r i n c i p l e o f s o l i d s contact c l a r i f i c a t i o n . Large volumes o f sludge(10 t o 15 times the volume o f feed) are r e c i r c u l a t e d i n t e r n a l l y through a d r a f t tubeJimpellerarrangement t o a r e a c t i o n well. Previously prec i p i t a t e d sludge r e c i r c u l a t e d i n t h i s manner comesi n intimate contact w i t h the feedstream i n thereaction well. DrOVidinQ seed n u c l e i on which d i s solved s o l i d s - i n the feedstream p r e c i p i t a t e underc o n t r o l l e d conditions o f temperature, r e a c t i o ntime, and s o l i d s concentration.The r e s u l t a n t l i q u i d / s o l i d mixture flows fromthe reaction w e l l i n t o the c l a r i f i c a t i o n compartment, where l i q u i d and s o l i d s are separated bygravity. Treated l i q u i d overflows i n t o c o l l e c t i o nlaunders a t t h e upper surface o f the u n i t . Rakearms move the s e t t l e d sludge t o a thickening conea t the bottom center o f the tank, where thethickened sludge i s discharged by g r a v i t y o rpumps.The r e s u l t s o f t h i s t e s t work have l e d t o acontract f o r a 55'0"-diameter Envirotech ReactorC l a r i f i e r having 2,375 f e e t o f t o t a l surface area,able t o t r e a t the t o t a l flow o f spent b r i n e from a10-MW, two-stage, f l a s h heat-extraction demonstrat i o n plant.Determine design c r i t e r i a o f the ReactorC l a r i f i e r f o r s i z i n g on a commercial scale,including:--- quirements.Determine sludge handling and disposal r e - Estimate order o f magnitude costsf o r spentb r i n e treatment and sludge handling anddisposal f o r a 55 MW geothermal energy plant.PILOT PLANT TEST RESULTSSummaryAverage t e s t data from the p i l o t plant,presentedi n F i g 1ol,;ws: are sumarized f o r odesign criteriais0No chemicals are required i n the treatmento f spent geothermal brines.0Upflow Reactor-Clarifier Rate 0.72 G P M / f t 2 .0Solids Concentration i n Reaction Well 2.5%.0Reaction Time i n Reaction Well 17 minutes.0E f f l u e n t Q u a l i t y a t Design C r i t e r i a- S i l i c a - 172 ppm- T u r b i d i t y - 15 NTU (44 ppm s.s.)DESIGN EXPERIMENT0The f i r s t - s t a g e t e s t program was designed t odevelop a v i a b l e and c o s t - e f f e c t i v e system f o rt r e a t i n g spent geothermal b r i n e and f o r handlingand disposing o f sludges produced i n the treatment.The objectives o f the design experiment weret o:0Test t h e o r i g i n a l concept o f auto-precipitationo f minerals i n the spent brine.Sludge Produced:1.7 1b/day per GPM-0 Sludge Characteristics:- From Reactor-Clarifiers- From Thickener: 4.5% s o l i d sLj

In Ppm15 NTU Turbidity2? GPM,Tzszis o l i d s concentration held i n the reaction well.As shown i n Fig. 2, a stable s o l u b i l i t y l e v e l o f172 ppm S i O n i s achieved when the s o l i d s concentrat i o n i n the reaction w e l l approaches 2.5% s o l i d sby weight. Further increases above t h e designconcentration range do not markedly improve s i l i c ao f a Reactor-Clarifier i s depenn the s e t t l i n g rates o f p r e c i p i t a t e d s o l i d si n the u n i t . It cannot be operated a t an upflowt e r than the s e t t l i n g r a t e o f the p r e c i p i ids; otherwise, c l a r i f i c a t i o n would n o tn accordance w i t h the Kynch theory, s o l i d si n hindered s e t t l i n g e x h i b i t s e t t l i n g v e l o c i t i e sinversely proportional t o the sol i d s concentrationi n the zone through which they s e t t l e . This i sv e r i f i d i n Fig. 2. Upflow r a t e s as h i g h as 1.33G P M / f t can be maintained i n t h e Reactor-Clarifierwhen r e l a t i v e l y low sol i d s concentrations i n thereaction w e l l are h e l d a t approximately 1.2% s o l i d sby weight. As these concentrations are increased,upflow r a t e s must be reduced accordingly; down, f o rexample, t o a measured low o f 0.62 GPM/ft2 a t as o l i d s concentration o f 2.63%.5I n achieving a c o s t - e f f e c t i v e process, theres t s a compromise between the continuous product i o n o f stable saturated e f f l u e n t from the ReactorC l a r i f i e r and the maximum permissible upflow r a t ei n the u n i t . Test data show t h a t an optimums o l i d s concentration o f 2.5% by weight can bemaintained i n the reaction w e l l while p e r m i t t i n ga maximum design upflow r a t e o f 0.72 GPM/ft2 t oproduce the desired stable saturated e f f l u e n t of172 ppm Si02.1.6

Sludge Handling and DisposalE a r l i e r t e s t work indicated t h a t centrifuges andvacuum drum f i l t e r s could produce a cake nogreater than 50% s o l i d s by weight. A t the sametime, the f i l t r a t e from the f i l t e r press wase s s e n t i a l l y f r e e o f suspended solids, w h i l e thecentrate from the centrifuge contained as muchas 1%s o l i d s by weight. The f i l t r a t e / c e n t r a t emust be returned t o the Reactor-Clarifier. Highsol i d s concentrations i n t h i s r e c i r c u l a t e d streamcould adversely a f f e c t the performance o f t h eReactor-C1 a r i f i e r .Insoluble s o l i d s produced i n the ReactorC l a r i f i e r by auto-precipitation (no a d d i t i o n o fforeign chemicals o r seed material) were c o l l e c t e dfrom the Reactor-Clarifier sludge blowdown andanalyzed. A proximate chemical analysis o f theseinsoluble s o l i d s i s presented i n Table 2. S i l i c o ni s the major constituent o f the t o t a l insolublesol ids, representing approximately 90% by weight,as s i l i c a and possibly other complex s i l i c a t eforms. Heavy metals including iron, strontium,manganese, 1ead, and copper appear t o p r e c i p i t a t eas s u l f i d e and oxide minerals and, perhaps, asother complex forms.Table 2.ITest work t o date has indicated t h a t disposalo f f i l t e r press cake a t 65% s o l i d s i n l i n e d pondsi s the most c o s t - e f f e c t i v e and environmentallysound a l t e r n a t i v e . I t i s possible t h a t metalscould be recovered from the f i l t e r press cake,which o f f e r s some savings i n the o v e r a l l costs o fa spent-brine treatment operation.Proximate chemical analysis o f insolublesol i d s i n Reactor-C1 a r i f i e r sludge.Const ituentWeight-% s o l i d sS i 1 icon as S i(42.82)as Si0291.75S i 0.18Iron0.85CobaltChromiumArsenicCalcium7.92A1 umi num0.02BariumBoron0.02CadmiumRub id i um0.01Sel iniumZinc0.060.63Stront iumCesiumSulfur1.06Total constituents weight:SPENT GEOTHERMAL BRINE TREATMENT SYSTEMPPmS u f f i c i e n t data have been c o l l e c t e d from thephase-one t e s t program t o prove the adequacy ofdesign o f a spent geothermal b r i n e treatment system f o r any given capacity. Test work, however,i s continuing. The f o l l o w i n g t e s t s are planned:9723041885Table 3.273-Phase 2 P i l o t p l a n t operations including aReactor-Clarifier, Gravity Sand/AnthraciteF i 1t e r , S1udge Thickener, and F i 1t e r Presson the same p i l o t scale as reported above ( t obe s t a r t e d approximately J u l y 15, 1978).6Order o f magnitude costs f o r spent b r i n etreatment and sludge handling and d i s posal f o r a 55-MW geothermal generatingstation.ProcessPresentworth( 1,000,000)33Brine treatmentReact ion, C1 a r ification &g r a v i t y f i1t r a tion103.05%----- -----------Notes :1.A l l concentrations greater than 100 ppm areexpressed t o nearest 0.01% s o l i d s by weight.2.Total constituent weights are greater thanloo%, possibly due t o some s i l i c o n being i ncomplex forms other than Si02.b-S1udge hand1i n g &disposalThickening &dewateringDisposal 'The q u a n t i t y o f s o l i d s produced i n the ReactorC l a r i f i e r , as measured by sludge blowdown underoptimum conditions, i s 1.7 lb/day per GPM b r i n efed t o the u n i t .Sub 211.580.7191.6TOTAL26.7------- ---------An Envirotech-Shriver F i l t e r Press was usednear the end o f the first-phase t e s t work t odetermine the dewatering c h a r a c t e r i s t i c

A COST-EFFECTIVE TREATMENT SYSTEM FOR THE (6, ABSTRACT f the rising costs for fo ation that such fuels are exhaustible, increasing attention has been focused on the