Transcription

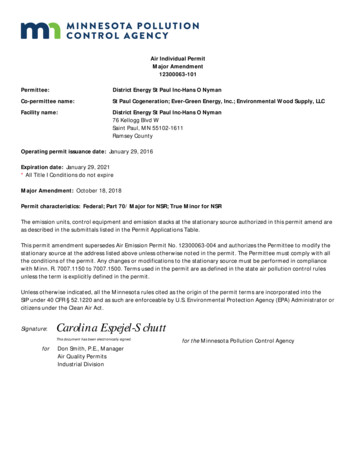

Air Individual PermitMajor Amendment12300063-101Permittee:District Energy St Paul Inc-Hans O NymanCo-permittee name:St Paul Cogeneration; Ever-Green Energy, Inc.; Environmental Wood Supply, LLCFacility name:District Energy St Paul Inc-Hans O Nyman76 Kellogg Blvd WSaint Paul, MN 55102-1611Ramsey CountyOperating permit issuance date: January 29, 2016Expiration date: January 29, 2021* All Title I Conditions do not expireMajor Amendment: October 18, 2018Permit characteristics: Federal; Part 70/ Major for NSR; True Minor for NSRThe emission units, control equipment and emission stacks at the stationary source authorized in this permit amend areas described in the submittals listed in the Permit Applications Table.This permit amendment supersedes Air Emission Permit No. 12300063-004 and authorizes the Permittee to modify thestationary source at the address listed above unless otherwise noted in the permit. The Permittee must comply with allthe conditions of the permit. Any changes or modifications to the stationary source must be performed in compliancewith Minn. R. 7007.1150 to 7007.1500. Terms used in the permit are as defined in the state air pollution control rulesunless the term is explicitly defined in the permit.Unless otherwise indicated, all the Minnesota rules cited as the origin of the permit terms are incorporated into theSIP under 40 CFR § 52.1220 and as such are enforceable by U.S. Environmental Protection Agency (EPA) Administrator orcitizens under the Clean Air Act.Signature:Carolina Espejel-SchuttThis document has been electronically signed.forDon Smith, P.E., ManagerAir Quality PermitsIndustrial Divisionfor the Minnesota Pollution Control Agency

Table of ContentsPage1.2.3.4.5.6.7.Permit applications table . 3Where to send submittals . 4Facility description . 5Summary of subject items . 6Limits and other requirements . 8Submittal/action requirements . 101Appendices . 116Appendix A. Insignificant Activities and General Applicable Requirements. 116Appendix B. Fuel Mixture Procedure for EQUI 11 . 118Appendix C. Sulfur Dioxide Compliance Calculation for Boilers 2, 3, and 4 . 119Appendix D. Environmental Wood Supply PM10 Modeling Parameters . 121Appendix E. PM10 and NOx Modeling Parameters . 123Appendix F. SO2 Modeling Parameters . 124Appendix G. Modeling Parameters used in Significant Impact Analysis for permit #12300063-101 . 125Appendix H. Fugitive Emission Control Plan . 126

Permit issued: October 18, 2018Permit expires: January 21, 201812300063-101Page 3 of 1331. Permit applications tableSubsequent permit applications:Title descriptionApplication receipt dateMajor Amendment4/17/2018 (supplemental informationreceived 8/10/2018)Action number12300063-101

Permit issued: October 18, 2018Permit expires: January 21, 201812300063-101Page 4 of 1332. Where to send submittalsSend submittals that are required to be submitted to the EPA regional office to:Chief Air EnforcementAir and Radiation BranchEPA Region V77 West Jackson BoulevardChicago, Illinois 60604Each submittal must be postmarked or received by the date specified in the applicable Table. Those submittalsrequired by Minn. R. 7007.0100 to 7007.1850 must be certified by a responsible official, defined in Minn. R.7007.0100, subp. 21. Other submittals shall be certified as appropriate if certification is required by an applicablerule or permit condition.Send submittals that are required by the Acid Rain Program to:U.S. Environmental Protection AgencyClean Air Markets Division1200 Pennsylvania Avenue NW (6204N)Washington, D.C. 20460Send any application for a permit or permit amendment to:Fiscal Services – 6th FloorMinnesota Pollution Control Agency520 Lafayette Road NorthSt. Paul, Minnesota 55155-4194Also, where required by an applicable rule or permit condition, send to the Permit Document Coordinator notices of:a.b.c.d.Accumulated insignificant activitiesInstallation of control equipmentReplacement of an emissions unit, andChanges that contravene a permit termUnless another person is identified in the applicable Table, send all other submittals to:AQ Compliance Tracking CoordinatorIndustrial DivisionMinnesota Pollution Control Agency520 Lafayette Road NorthSt. Paul, Minnesota 55155-4194OrEmail a signed and scanned PDF copy to:submitstacktest.pca@state.mn.us(for submittals related to stack testing)AQRoutineReport.PCA@state.mn.us(for other compliance submittals)(See complete email instructions in “Routine Air ReportInstructions Letter” athttp://www.pca.state.mn.us/nwqh472.)

Permit issued: October 18, 2018Permit expires: January 21, 201812300063-101Page 5 of 1333. Facility descriptionThe District Energy St Paul Inc-Hans O Nyman (Facility) is located at 76 Kellogg Boulevard W in Saint Paul, RamseyCounty, Minnesota.District Energy St. Paul (the facility) provides heating and cooling services to downtown St. Paul and adjacent areas.The facility has seven boilers that produce hot water (Boilers 5 and 6) or steam (Boilers 1 through 4 and 7) forheating and electrical generation. Boilers 1, 4, 5, and 6 combust natural gas and distillate fuel oil. Boilers 2 and 3combust coal, biomass, and natural gas. Boiler 7 combusts biomass and natural gas. The facility also has severalemission sources such as wood and coal receiving, and ash handling and storage that qualify as insignificant sources.District Heating Development Company d/b/a District Energy St. Paul, Inc. (District Energy) is a majority owner ofEver-Green Energy, LLC (formerly Market Street Energy Company, LLC), and District Cooling St. Paul, Inc. is a minorityowner. Ever-Green Energy, LLC manages operations at District Energy. Boiler 7 is a combined heat and power (CHP)boiler and is owned by St. Paul Cogeneration. St. Paul Cogeneration is jointly owned by Ever-Green Energy, LLC andDTE St. Paul LLC. St. Paul Cogeneration has a 20-year Power Purchase Agreement for the sale of electricity generatedby the CHP boiler to District Energy.Environmental Wood Supply, LLC (EWS) is owned by Ever-Green Energy, Inc. EWS and District Energy are considereda single source under Prevention of Significant Deterioration (PSD) regulations. EWS is located approximately 3 milessouth of the District Energy St. Paul facility and supplies clean cellulosic biomass to the District Energy St. Paulfacility.The main pollutants of concern at the facility are the products of combustion: particulate matter (PM), particulatematter 10 microns (PM10), particulate matter 2.5 microns (PM2.5), sulfur dioxide (SO2), nitrogen oxides (NOx),carbon monoxide (CO), volatile organic carbon (VOC), carbon dioxide equivalents (CO2e), and Hazardous AirPollutants (HAPs). Particulate Matter from Boilers 2 and 3 is controlled by multiple cyclones. Particulate matter fromcoal ash storage is controlled by a medium-efficiency centrifugal collector and a fabric filter. NOx emissions fromBoiler 7 are controlled by selective non-catalytic reduction (SNCR) with urea injection, and particulate matter fromBoiler 7 is controlled by a high-efficiency centrifugal collector and an electrostatic precipitator (ESP).With this permit action, District Energy will be authorized to replace the existing burners in Boilers 2 and 3 withburners capable of burning natural gas, distillate fuel oil, and biodiesel. When this conversion is complete, DistrictEnergy will no longer receive, handle, or combust coal at their facility. At that time, the multiple cyclones controllingBoiler No. 2 and 3, the coal ash silo and associated controls, will be decommissioned in-place or removed from thefacility. District Energy expects to continue burning coal through the 2018/2019 winter season and expect to beginthe transition to burning primarily natural gas in Boilers 2 and 3 in time for the 2019/2020 season. Regardless ofexpectations, the permit is written with no set date required to cease coal combustion and the facility may continueto comply with their current requirements as long as they choose. A number of requirements will no longer applyonce coal burning has ceased and are indicated as such in the permit.

Permit issued: October 18, 2018Permit expires: January 21, 201812300063-101Page 6 of 1334. Summary of subject itemsSI ID:DescriptionTFAC 1: District EnergySt Paul Inc-Hans ONymanACTV 3: All AI'sCOMG 1: ControlEquipment for Boiler 7Relationshi Related SI ID:p TypeDescriptionCOMG 2: MultipleCycloneshasmembersCOMG 3: WoodHandling - EWShasmembersCOMG 4: NESHAPDDDDD CommonRequirementshasmembersCOMG 5: ContinuousEmission Monitors(State)hasmembersCOMG 6: NESHAPDDDDD Gas 1 Boilerwith CurtailmentCOMG 7: Boilers 1, 5,and 6COMG 8: Boilers 2, 3,and 4hasmembersCOMG 9: ContinuousEmission Monitors(NSPS)hasmembersEQUI 1: Boiler 2ismonitoredbyEQUI 1: Boiler 2EQUI 1: Boiler 2ismonitoredbyismonitoredbysends toEQUI 1: Boiler 2isEQUI 1: Boiler 2SI ID:DescriptionEQUI 2: Boiler 3hasmembershasmembershasmembersEQUI 11, TREA3, TREA 4,TREA 14EQUI 1, EQUI2, TREA 5,TREA 6FUGI 1, FUGI2, FUGI 3,FUGI 4, FUGI 5EQUI 1, EQUI2, EQUI 11,EQUI 14, EQUI19, EQUI 20,EQUI 21EQUI 1, EQUI2, EQUI 3,EQUI 4, EQUI9, EQUI 11,EQUI 14, STRU5EQUI 14, EQUI19, EQUI 20,EQUI 21EQUI 19, EQUI20, EQUI 21EQUI 1, EQUI2, EQUI 14,STRU 5EQUI 5, EQUI6, EQUI 7,EQUI 11, STRU5EQUI 31:TeledyneOpacityMonitorEQUI 3: SulfurDioxideEQUI 4:Diluent CO2MonitorSTRU 5: Boilers2, 3, 4, and 7TREA 5:EQUI 2: Boiler 3EQUI 2: Boiler 3EQUI 2: Boiler 3EQUI 2: Boiler 3Relationship redbysends toiscontrolledbyEQUI 3: Sulfur DioxideEQUI 4: Diluent CO2MonitorEQUI 5: NOx MonitorEQUI 6: Diluent CO2MonitorEQUI 7: SO2 MonitorEQUI 8: Opacity monitorEQUI 9: NOx Monitor forAmmoniaEQUI 11: Boiler 7ismonitoredbyEQUI 11: Boiler 7ismonitoredbyEQUI 11: Boiler 7ismonitoredbyEQUI 11: Boiler 7ismonitoredbyEQUI 11: Boiler 7ismonitoredbyEQUI 11: Boiler 7ismonitoredbyEQUI 11: Boiler 7ismonitoredbyEQUI 11: Boiler 7isRelated SI ID:DescriptionMulticlone woFly Ash ReinjEQUI 31:TeledyneOpacityMonitorEQUI 3: SulfurDioxideEQUI 4:Diluent CO2MonitorSTRU 5: Boilers2, 3, 4, and 7TREA 6:Multiclone woFly Ash ReinjEQUI 28:OxygenanalyzerEQUI 29: FlowMonitorEQUI 30:Teledyne COMonitorEQUI 5: NOxMonitorEQUI 6:Diluent CO2MonitorEQUI 7: SO2MonitorEQUI 8:OpacitymonitorEQUI 9: NOx

Permit Issued: [month day, year]Permit Expires: [month day, year]SI ID:DescriptionEQUI 11: Boiler 7Relationship Typemonitoredbysends toEQUI 11: Boiler 7iscontrolledbyEQUI 11: Boiler 7iscontrolledbyEQUI 11: Boiler 7iscontrolledbyEQUI 12: Coal Ash Silosends toEQUI 12: Coal Ash SiloiscontrolledbyEQUI 12: Coal Ash SiloiscontrolledbyEQUI 14: Boiler 4ismonitoredbyEQUI 14: Boiler 4EQUI 14: Boiler 4ismonitoredbyismonitoredbysends toEQUI 19: Boiler 1sends toEQUI 20: Boiler 5sends toEQUI 21: Boiler 6sends toEQUI 14: Boiler 4EQUI 28: OxygenanalyzerEQUI 29: Flow Monitor12300063-101Page 7 of 133Related SI ID:DescriptionMonitor forAmmoniaSTRU 5: Boilers2, 3, 4, and 7TREA 14:SelectiveNoncatalyticReduction forNOXTREA 3:CentrifugalCollector High EfficiencyTREA 4:ElectrostaticPrecipitator High EfficiencySTRU 8: CoalAsh SiloTREA 7:CentrifugalCollector MediumEfficiencyTREA 8: FabricFilter - LowTemperature,i.e., T 180Degrees FEQUI 31:TeledyneOpacityMonitorEQUI 3: SulfurDioxideEQUI 4:Diluent CO2MonitorSTRU 5: Boilers2, 3, 4, and 7STRU 6: Boiler1STRU 7: Boilers5 and 6STRU 7: Boilers5 and 6SI ID:DescriptionEQUI 30: Teledyne COMonitorEQUI 31: TeledyneOpacity MonitorFUGI 1: Unpaved RoadsDelivery and Haul TrucksFUGI 2: Wood Chip PileFUGI 3: Unpaved RoadsFront-end LoadersFUGI 4: Wood ChipLoadingFUGI 5: Wood GrindersSTRU 5: Boilers 2, 3, 4,and 7STRU 6: Boiler 1STRU 7: Boilers 5 and 6STRU 8: Coal Ash SiloTREA 3: CentrifugalCollector - HighEfficiencyTREA 4: ElectrostaticPrecipitator - HighEfficiencyTREA 5: Multiclone woFly Ash ReinjTREA 6: Multiclone woFly Ash ReinjTREA 7: CentrifugalCollector - MediumEfficiencyTREA 8: Fabric Filter Low Temperature, i.e.,T 180 Degrees FTREA 14: SelectiveNoncatalytic Reductionfor NOXTREA 14: SelectiveNoncatalytic Reductionfor NOXRelationshi Related SI ID:p TypeDescriptionisTREA 8: Fabriccontrolled Filter - Lowin series by Temperature,i.e., T 180Degrees FisTREA 3:controlled Centrifugalin series by Collector High EfficiencyisTREA 4:controlled Electrostaticin series by Precipitator High Efficiency

Permit issued: [month day, year]Permit expires: [month day, year]12300063-101Page 8 of 1335. Limits and other requirementsSubject ItemSec.SI.ReqtSI des:SI descTFAC 112300063District Energy StPaul Inc-Hans ONymanRequirement & Citation5.1.1Permit Appendices: This permit contains appendices as listed in thepermit Table of Contents. The Permittee shall comply with allrequirements contained in Appendices:A. Insignificant Activities and General Applicable Requirements,B. Fuel Mixture Procedure for EQUI 11,C. Sulfur Dioxide Compliance Calculation for Boilers 2, 3, and 4, andH. Fugitive Emission Control Plan.Modeling parameters in Appendices D (Environmental Wood SupplyPM10 Modeling Parameters), E (PM10 and NOx ModelingParameters), F (SO2 Modeling Parameters), and G (ModelingParameters used in Significant Impact Analysis for permit12300063-101) are included for reference only as describedelsewhere in this permit. [Minn. R. 7007.0800, subp. 2]5.1.2PERMIT SHIELD: Subject to the limitations in Minn. R. 7007.1800,compliance with the conditions of this permit shall be deemedcompliance with the specific provision of the applicablerequirement identified in the permit as the basis of each condition.Subject to the limitations of Minn. R. 7007.1800 and 7017.0100,subp. 2, notwithstanding the conditions of this permit specifyingcompliance practices for applicable requirements, any person(including the Permittee) may also use other credible evidence toestablish compliance or noncompliance with applicablerequirements.This permit shall not alter or affect the liability of the Permittee forany violation of applicable requirements prior to or at the time ofpermit issuance. [Minn. R. 7007.1800(A)(2)]5.1.3Access areas, road, parking facilities: No person shall cause orpermit the use of access areas surrounding coal stockpiles and useof all active truck haul roads and parking facilities which are locatedwithin a coal handling facility whose coal throughput by truck is lessthan 200,000 tons per year unless such areas and roads are treatedwith water, oils, or chemical agents. This requirement will no longerapply when the facility is no longer a coal handling facility. [Minn. R.7011.1105(A)(2)]5.1.4Coal loading stations: Control fugitive particulate emissions fromthe loading of trucks, haulers, and railcars by dust suppressionmethods so that emissions from such sources are minimized. Thisrequirement will no longer apply when the facility is no longer acoal handling facility. [Minn. R. 7011.1105(B)]5.1.5Truck and hauler unloading stations: Control fugitive particulateemissions from the unloading of trucks or haulers by dustsuppression methods so that emissions from such sources areminimized. This requirement will no longer apply when the facility isno longer a coal handling facility. [Minn. R. 7011.1105(C)]

Permit Issued: October 18, 2018Permit Expires: January 29, 2021Subject ItemSec.SI.Reqt12300063-101Page 9 of 133SI des:SI descRequirement & Citation5.1.6Clean up all coal spilled on roads or access areas as soon aspracticable using methods that minimize the amount of dustsuspended. This requirement will no longer apply when the facilityis no longer a coal handling facility. [Minn. R. 7011.1105(I)]5.1.7Comply with Fugitive Emission Control Plan: The Permittee shallfollow the actions and recordkeeping specified in the fugitiveemission control plan in Appendix H of this permit. If theCommissioner determines the Permittee is out of compliance withMinn. R. 7011.0150 or the fugitive control plan, then the Permitteemay be required to amend the control plan and/or to install andoperate particulate matter ambient monitors as requested by theCommissioner. [Minn. R. 7007.0100, Minn. R. 7007.0800, subp. 2,Minn. R. 7009.0020, Minn. R. 7011.0150, Minn. Stat. 116.07, subd.4a]5.1.8These requirements apply if a reasonable possibility (RP) as definedin 40 CFR Section 52.21(r)(6)(vi) exists that a proposed project,analyzed using the actual-to-projected-actual (ATPA) test (either byitself or as part of the hybrid test at Section 52.21(a)(2)(iv)(f)) andfound to not be part of a major modification, may result in asignificant emissions increase (SEI). If the ATPA test is not used forthe project, or if there is no RP that the proposed project couldresult in a SEI, these requirements do not apply to that project. ThePermittee is only subject to the Preconstruction Documentationrequirement for a project where a RP occurs only within themeaning of Section 52.21(r)(6)(vi)(b).Even though a particular modification is not subject to New SourceReview (NSR), or where there isn't a RP that a proposed projectcould result in a SEI, a permit amendment, recordkeeping, ornotification may still be required by Minn. R. 7007.1150 7007.1500. [Minn. R. 7007.0800, subp. 2, Title I Condition: 40 CFR52.21(r)(6) and Minn. R. 7007.3000]5.1.9Preconstruction Documentation -- Before beginning actualconstruction on a project, the Permittee shall document thefollowing:1. Project description2. Identification of any emission unit whose emissions of an NSRpollutant could be affected3. Pre-change potential emissions of any affected existing emissionunit, and the projected post-change potential emissions of anyaffected existing or new emission unit.4. A description of the applicability test used to determine that theproject is not a major modification for any regulated NSR pollutant,including the baseline actual emissions, the projected actualemissions, the amount of emissions excluded due to increases notassociated with the modification and that the emission unit couldhave accommodated during the baseline period, an explanation ofwhy the amounts were excluded, and any creditablecontemporaneous increases and decreases that were considered inthe determination.

Permit Issued: October 18, 2018Permit Expires: January 29, 2021Subject ItemSec.SI.Reqt12300063-101Page 10 of 133SI des:SI descRequirement & CitationThe Permittee shall maintain records of this documentation. [Minn.R. 7007.0800, subps. 4-5, Minn. R. 7007.1200, subp. 4, Title ICondition: 40 CFR 52.21(r)(6) and Minn. R. 7007.3000]5.1.10The Permittee shall monitor the actual emissions of any regulatedNSR pollutant that could increase as a result of the project and thatwere analyzed using the ATPA test, and the potential emissions ofany regulated NSR pollutant that could increase as a result of theproject and that were analyzed using potential emissions in thehybrid test. The Permittee shall calculate and maintain a record ofthe sum of the actual and potential (if the hybrid test was used inthe analysis) emissions of the regulated pollutant, in tons per yearon a calendar year basis, for a period of 5 years followingresumption of regular operations after the change, or for a periodof 10 years following resumption of regular operations after thechange if the project increases the design capacity of or potential toemit of any unit associated with the project. [Minn. R. 7007.0800,subps. 4-5, Title I Condition: 40 CFR 52.21(r)(6) and Minn. R.7007.3000]5.1.11Before beginning actual construction of any project which includesany electric utility steam generating unit (EUSGU), the Permitteeshall submit a copy of the preconstruction documentation (items 14 under Preconstruction Documentation, above) to the Agency.[Minn. R. 7007.0800, subps. 4-5, Title I Condition: 40 CFR52.21(r)(6)(ii) and Minn. R. 7007.3000]5.1.12For any project which includes any EUSGU, the Permittee mustsubmit an annual report to the Agency, within 60 days after the endof the calendar year. The report shall contain:a. The name and ID number of the facility, and the name andtelephone number of the facility contact person.b. The quantified annual emissions analyzed using the ATPA test,plus the potential emissions associated with the same projectanalyzed as part of a hybrid test.c. Any other information, such as an explanation as to why thesummed emissions differ from the preconstruction projection, ifthat is the case. [Minn. R. 7007.0800, subps. 4-5, Title I Condition:40 CFR 52.21(r)(6) and Minn. R. 7007.3000]5.1.13For any project which does not include any EUSGU, the Permitteemust submit a report to the Agency if the annual summed (actual,plus potential used in hybrid test) emissions differ from thepreconstruction projection and exceed the baseline actualemissions by a significant amount as listed at 40 CFR Section52.21(b)(23). Such report shall be submitted to the Agency within60 days after the end of the year in which the exceedances occur.The report shall contain:a. The name and ID number of the facility, and the name andtelephone number of the facility contact person.b. The annual emissions (actual, plus potential if any part of theproject was analyzed using the hybrid test) for each pollutant forwhich the preconstruction projection and significant emissions rateis exceeded.

Permit Issued: October 18, 2018Permit Expires: January 29, 2021Subject ItemSec.SI.Reqt12300063-101Page 11 of 133SI des:SI descRequirement & Citationc. Any other information, such as an explanation as to why thesummed emissions differ from the preconstruction projection.[Minn. R. 7007.0800, subps. 4-5, Title I Condition: 40 CFR 52.21(r)(6)and Minn. R. 7007.3000]5.1.14The Permittee shall comply with National Primary and SecondaryAmbient Air Quality Standards, 40 CFR pt. 50, and the MinnesotaAmbient Air Quality Standards, Minn. R. 7009.0010 to 7009.0090.Compliance shall be demonstrated upon written request by theMPCA. [Minn. R. 7007.0100, subp. 7(A), 7(L), & 7(M), Minn. R.7007.0800, subp. 4, Minn. R. 7007.0800, subps. 1-2, Minn. R.7009.0010-7009.0090, Minn. Stat. 116.07, subd. 4a, Minn. Stat.116.07, subd. 9]5.1.15Circumvention: Do not install or use a device or means thatconceals or dilutes emissions, which would otherwise violate afederal or state air pollution control rule, without reducing the totalamount of pollutant emitted. [Minn. R. 7011.0020]5.1.16Air Pollution Control Equipment: Operate all pollution controlequipment whenever the corresponding process equipment andemission units are operated. [Minn. R. 7007.0800, subp. 16(J),Minn. R. 7007.0800, subp. 2]5.1.17Operation and Maintenance Plan: Retain at the stationary source anoperation and maintenance plan for all air pollution controlequipment. At a minimum, the O & M plan shall identify all airpollution control equipment and control practices and shall includea preventative maintenance program for the equipment andpractices, a description of (the minimum but not necessarily theonly) corrective actions to be taken to restore the equipment andpractices to proper operation to meet applicable permit conditions,a description of the employee training program for properoperation and maintenance of the control equipment and practices,and the records kept to demonstrate plan implementation. [Minn.R. 7007.0800, subp. 14, Minn. R. 7007.0800, subp. 16(J)]5.1.18Operation Changes: In any shutdown, breakdown, or deviation thePermittee shall immediately take all practical steps to modifyoperations to reduce the emission of any regulated air pollutant.The Commissioner may require feasible and practical modificationsin the operation to reduce emissions of air pollutants. No emissionsunits that have an unreasonable shutdown or breakdown frequencyof process or control equipment shall be permitted to operate.[Minn. R. 7019.1000, subp. 4]5.1.19Fugitive Emissions: Do not cause or permit the handling, use,transporting, or storage of any material in a manner which mayallow avoidable amounts of particulate matter to become airborne.Comply with all other requirements listed in Minn. R. 7011.0150.[Minn. R. 7011.0150]5.1.20Noise: The Permittee shall comply with the noise standards setforth in Minn. R. 7030.0010 to 7030.0080 at all times during theoperation of any emission units. This is a state only requirementand is not enforceable by the EPA Administrator or citizens underthe Clean Air Act. [Minn. R. 7030.0010-7030.0080]

Permit Issued: October 18, 2018Permit Expires: January 29, 2021Subject ItemSec.SI.Reqt12300063-101Page 12 of 133SI des:SI descRequirement & Citation5.1.21Inspections: The Permittee shall comply with the inspectionprocedures and requirements as found in Minn. R. 7007.0800, subp.9(A). [Minn. R. 7007.0800, subp. 9(A)]5.1.22The Permittee shall comply with the General Conditions listed inMinn. R. 7007.0800, subp. 16. [Minn. R. 7007.0800, subp. 16]5.1.23Performance Testing: Conduct all performance tests in accordancewith Minn. R. ch. 7017 unless otherwise noted in this permit. [Minn.R. ch. 7017]5.1.24Limits set as a result of a performance test (conducted before orafter permit issuance) apply until superseded as stated in theMPCA's Notice of Compliance letter granting preliminary approval.Preliminary approval is based on formal review of a subsequentperformance test on the same unit as specified by Minn. R.7017.2025, subp. 3. The limit is final upon issuance of a permitamendment incorporating the change. [Minn. R. 7017.2025, subp.3]5.1.25Monitoring Equipment Calibration - The Permittee shall either:1. Calibrate or replace required monitoring equipment every 12months; or2. Calibrate at the frequency stated in the manufacturer'sspecifications.For each monitor, the Permittee shall maintain a record of allcalibrations, including the date conducted, and any correctiveaction that resulted. The Permittee shall include the calibrationfrequencies, procedures, and manufacturer's specifications (ifapplicable) in the Operations and Maintenance Plan. Anyrequirements applying to continuous emission monitors are listedseparately in this permit. [Minn. R. 7007.0800, subp. 4(D)]5.1.26Operation of Monitoring Equipment: Unless noted elsewhere in thispermit, monitoring a process or control equipment connected tothat process is not necessary during periods when the process isshutdown, or during checks of the monitoring systems, such ascalibration checks and zero and span adjustments. If monitoringrecords are required, they should reflect any such periods ofprocess shutdown or checks of the monitoring system. [Minn. R.7007.0800, subp. 4(D)]5.1.27Recordkeeping: Retain all records at the stationary source, unlessotherwise specified within this permit, for a period of five (5) yearsfrom the date of monitoring, sample, measurement, or report.Records which must be retained at this location include allcalibration and maintenance records, all original recordings forcontinuous monitoring instrumentation, and copies of all reportsrequired by the permit. Records must conform to the requirementslisted in Minn. R. 7007.0800, subp. 5(A). [Minn. R. 7007.0800, subp.5(C)]5.1.28Recordkeeping: Maintain records describing any insignificantmodifications (as required by Minn. R. 7007.1250, subp. 3) orchanges contravening permit terms (as required by Minn. R.

Permit Issued: October 18, 2018Permit Expires: January 29, 2021Subject ItemSec.SI.Reqt12300063-101Page 13 of 133SI des:SI descRequirement & Citation7007.1350, subp. 2), including records of the emissions resultingfrom those changes. [Minn. R. 7007.0800, subp. 5(B)]5.1.29If the Permittee determines that no permit amendment ornotification is required prior to making a change, the Permitteemust retain records of all calculations required under Minn. R.7007.1200. For expiring permits, these records shall be kept for aperiod of five years from the date the change was made or untilpermit reissuance, whichever is longer. The records shall be kept atthe stationary source for the current calendar year of operation andmay be kept at the stationary source or office of the stationarysource for all other years. The records may be maintained in eitherelectronic or paper format. [Minn. R. 7007.1200, subp. 4]5.1.30Shutdown Notifications: Notify the Commissioner at least 24 hoursin advance of a planned shutdown of any control equipment orprocess equipment if the shutdown would cause any increase in theemissions of any regulated air pollutant. If the owner or operatordoes not have advance knowledge of the shutdown, notificationshall be made to the Commissioner as soo

District Energy St. Paul (the facility) provides heating and cooling services to downtown St. Paul and adjacent areas. The facility has seven boilers that produce hot water (Boilers 5 and 6) or steam (Boilers 1 through 4 and 7) for heating and electrical generation. Boilers 1, 4, 5, and 6 combust natural gas and distillate fuel oil. Boilers 2 and 3