Transcription

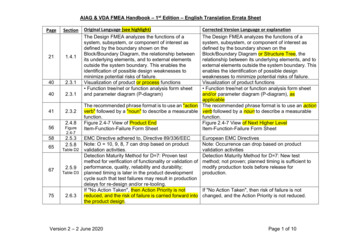

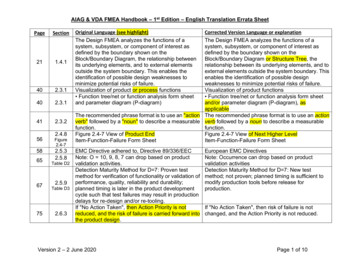

AIAG & VDA FMEA Handbook – 1st Edition – English Translation Errata re2.4-7586567752.4.82.5.32.5.8Table D22.5.9Table D32.6.3Original Language (see highlight)The Design FMEA analyzes the functions of asystem, subsystem, or component of interest asdefined by the boundary shown on theBlock/Boundary Diagram, the relationship betweenits underlying elements, and to external elementsoutside the system boundary. This enables theidentification of possible design weaknesses tominimize potential risks of failure.Visualization of product or process functions Function tree/net or function analysis form sheetand parameter diagram (P-diagram)Corrected Version Language or explanationThe Design FMEA analyzes the functions of asystem, subsystem, or component of interest asdefined by the boundary shown on theBlock/Boundary Diagram or Structure Tree, therelationship between its underlying elements, and toexternal elements outside the system boundary. Thisenables the identification of possible designweaknesses to minimize potential risks of failure.Visualization of product functions Function tree/net or function analysis form sheetand/or parameter diagram (P-diagram), asapplicableThe recommended phrase format is to use an "action The recommended phrase format is to use an actionverb" followed by a "noun" to describe a measurable verb followed by a noun to describe a measurablefunction.function.Figure 2.4-7 View of Product EndFigure 2.4-7 View of Next Higher LevelItem-Function-Failure Form SheetItem-Function-Failure Form SheetEMC Directive adhered to, Directive 89/336/EECNote: O 10, 9, 8, 7 can drop based on productvalidation activities.Detection Maturity Method for D 7: Proven testmethod for verification of functionality or validation ofperformance, quality, reliability and durability;planned timing is later in the product developmentcycle such that test failures may result in productiondelays for re-design and/or re-tooling.If "No Action Taken", then Action Priority is notreduced, and the risk of failure is carried forward intothe product design.Version 2 – 2 June 2020European EMC DirectivesNote: Occurrence can drop based on productvalidation activitiesDetection Maturity Method for D 7: New testmethod; not proven; planned timing is sufficient tomodify production tools before release forproduction.If "No Action Taken", then risk of failure is notchanged, and the Action Priority is not reduced.Page 1 of 10

AIAG & VDA FMEA Handbook – 1st Edition – English Translation Errata gure3.1-1Original Language (see highlight)Answers to these questions and others defined bythe company help create the list of DFMEA projectsneeded. The PFMEA project list assures consistentdirection, commitment and focus.Planning and Preparation: All Processes LevelCorrected Version Language or explanationAnswers to these questions and others defined bythe company help create the list of PFMEA projectsneeded. The PFMEA project list assures consistentdirection, commitment and focus.Planning and Preparation: All Processes LevelMaintenanceOP 40 Work Instruction (Part Replacement)MaintenanceOP 40 Work Instruction (Machine PartReplacement)Planning and Preparation: Department LevelsPlanning and Preparation: Department LevelsMaintenanceOP 40 Work Instruction (Part Replacement)Structure Analysis: Process Structure814M ElementsOperatorGreasing DeviceGreaseEnvironMent(.)OperatorPress MachineSintered Bearing3.1.2Figure3.1-1.823.1.3A plan for the execution of the PFMEA should bedeveloped once the DFMEA project isknown .The DFMEA activities (7-Step process)should be incorporated into the overall project plan.Version 2 – 2 June 2020MaintenanceOP 40 Work Instruction (Machine PartReplacement)Structure Analysis: Process Structure4M ElementsMan (Operator)Machine (Greasing Device)Material (Grease)EnvironMent (Cleanliness)OperatorPress MachineSintered BearingCleanlinessA plan for the execution of the PFMEA should bedeveloped once the PFMEA project isknown .The PFMEA activities (7-Step process)should be incorporated into the overall project plan.Page 2 of 10

AIAG & VDA FMEA Handbook – 1st Edition – English Translation Errata SheetPageSection823.1.4833.1.53.2.2Original Language (see highlight)This includes use of a foundation PFMEA (describedin Section 1.3), similar product PFMEA, or productfoundation PFMEA.Corrected Version Language or explanationThis includes use of a foundation PFMEA (describedin Section 1.3), a product family PFMEA, or similarproduct PFMEA.Cross-Functional Team: Team: Team Rosterneeded4M ElementsOperatorGreasing DeviceGreaseEnvironMent(.)OperatorPress MachineSintered Bearing.Refer to Section 3.4-7 Failure Cause for moreinformation about how the 4M approach is used toidentify Failure Causes.Cross-Functional Team: Team Roster neededVisualization of process function4M ElementsMan (Operator)Machine (Greasing Device)Material (Grease)EnvironMent (Cleanliness)OperatorPress MachineSintered BearingCleanlinessRefer to Section 3.4.6 Failure Cause for moreinformation about how the 4M approach is used toidentify Failure Causes.85Figure3.2-2863.2.3883.3.1Visualization of product or process function883.3.2The recommended phrase format is to use an action The recommended phrase format is to use an actionverb followed by a I to describe the measurableverb followed by a noun to describe the measurableprocess function (“DO THIS” “TO THIS”).process function (“DO THIS” “TO THIS”).Version 2 – 2 June 2020Page 3 of 10

AIAG & VDA FMEA Handbook – 1st Edition – English Translation Errata .6108108108108Table P13.5.6Table P13.5.6Table P13.5.6Table P1Original Language (see highlight)For the logical linking of a function and structure,questions are asked as:“What does it do?”How to achieve the product / process requirements –from right to left(Process Item Process Step Process WorkElement)“How?”Why implement the product / process requirements –from left to right(Process Work Element Process Step Process Item) Internal customer (next operation/subsequentoperation/operation tar-gets)Product or Product end user/operatorTest runs according to start-up regulation AV 17/3bS 10: Failure may result in an acute health and/orsafety risk for the manufacturing or assembly workerS 10: Failure may result in an acute health and/orsafety risk for the manufacturing or assembly workerS 8: 100% of production run affected may have tobe scrapped. Failure may result in in-plantregulatory noncompliance or may have a chronichealth and/or safety risk for the manufacturing orassembly worker.S 8: Line shutdown greater than full productionshift; stop shipment possible; field repair orreplacement required (Assembly to End User) otherthan for regulatory noncompliance.Failure may result in in-plant regulatorynoncompliance or may have a chronic health and/orsafety risk for the manufacturing or assembly worker.Version 2 – 2 June 2020Corrected Version Language or explanationFor the logical linking of a function and structure,questions are asked as:“What does it do?”How to achieve the product / process requirements –from right to left(Process Work Element Process Step Process Item)“How?”Why implement the product / process requirements –from left to right(Process Item Process Step Process WorkElement) Internal customer (next operation/subsequentoperation/operation targets)Product end user/vehicle operatorTest runs according to start-up regulationS 10: Failure may result in a health and/or safetyrisk for the manufacturing or assembly workerS 10: Failure may result in a health and/or safetyrisk for the manufacturing or assembly workerS 8: 100% of production run affected may have tobe scrapped.S 8: Line shutdown greater than full productionshift; stop shipment possible; field repair orreplacement required (Assembly to End User) otherthan for regulatory noncompliance.Page 4 of 10

AIAG & VDA FMEA Handbook – 1st Edition – English Translation Errata SheetPage111Section3.5.7Table 14.5.71424.5.7144 /145TableMSR3Original Language (see highlight)MRKJ5038Corrected Version Language or explanationNote: Occurrence can drop based on processvalidation activitiesMRKJ5039If “No Action Taken,” then Action Priority is notIf “No Action Taken,” then the risk of failure is notreduced, and the risk of failure is carried forward into changed and the Action Priority is not reduced.the product.MRKJ5038MRKJ5039Missing header: 4.3.2 FunctionInserted header: 4.3.2 Function (inserted after finalbullet “Basis for the Failure Analysis step”)As an aspect of the Failure Scenario, it is necessary As an aspect of the Failure Scenario, it is necessaryto estimate the magnitude of the Fault Handling Time to estimate the magnitude of the Fault Tolerant TimeInterval (time between the occurrence of the fault,Interval (time between the occurrence of the fault,and the occurrence of the hazard/noncompliantand the occurrence of the hazard/noncompliantFailure Effect).Failure Effect).The Fault Handling Time Interval is the maximumThe Fault Tolerant Time Interval is the minimumtime span of malfunctioning behavior before atime-span of malfunctioning behavior before ahazardous event occurs, if the safety mechanismshazardous event occurs, if the safety mechanismsare not activated.are not activated.The effectiveness of diagnostic monitoring andThe effectiveness of diagnostic monitoring andresponse, the fault monitoring response time, andresponse, the Fault Handling Time Interval, and thethe Fault Tolerant Time Interval need to beFault Tolerant Time Interval need to be determineddetermined prior to rating. Determination of theprior to rating. Determination of the effectiveness ofeffectiveness of diagnostic monitoring is addressed diagnostic monitoring is addressed in detail in ISOin detail in ISO 26262-5:2018 Annex D.26262-5:2018 Annex D.If there is no monitoring control, or if monitoring and If there is no monitoring control, or if monitoring andresponse do not occur within the Fault Handlingresponse do not occur within the Fault Tolerant TimeTime Interval, then Monitoring should be rated asInterval, then Monitoring should be rated as NotNot Effective (M 10).Effective (M 10).Fault Handling Time IntervalFault Tolerant Time IntervalVersion 2 – 2 June 2020Page 5 of 10

AIAG & VDA FMEA Handbook – 1st Edition – English Translation Errata SheetPage147151Original Language (see highlight)Product Effect High 9 - Extremely low - Very low Table AP 2-3 - Reliable – High 1 - LIf "No Action Taken", then Action Priority is not4.6.3reduced and the risk of failure is carried forward intothe product design.Model Year / PlatformA1Section4.5.8159 161All Forms159Form A160Form B163 168A2167167167All FormsCorrected Version Language or explanationProduct Effect High 9 - Extremely low - Very low 2-3 - Reliable 1 - LIf "No Action Taken", then risk of failure is notchanged, and the Action Priority is not reduced.Model Year / ProgramModel Year / PlatformRemove “Filter Code (Optional)” column from Step 6– Optimization on DFMEA Form ARemove “Filter Code (Optional)” column from Step 6– Optimization on DFMEA Form BModel Year / ProgramError in Header alignment:Fixed Header alignment:Error in Header alignment:Fixed Header alignment:Error in Header alignment:Fixed Header alignment:A2Form GA2Form GA2Form GVersion 2 – 2 June 2020Page 6 of 10

AIAG & VDA FMEA Handbook – 1st Edition – English Translation Errata SheetFunction Analysis (Step 3) Item 3:Process Element4M TypeModel Year / PlatformCorrected Version Language or explanationFunction Analysis (Step 3) Item 2:Function of the Process Step and ProductCharacteristic(Quantitative value is optional)Function Analysis (Step 3) Item 3:Function of the Process Work Element and ProcessCharacteristicModel Year / ProgramB1.5DFMEA AP: H, M, L, N/ADFMEA AP: H, M, LB1.6DFMEA AP: H, M, L, N/ADFMEA AP: H, M, LB1.6Status: Open, Decision pending (optional),Implementation pending (optional), Completed,DiscardedStatus: Open, Decision pending (optional),Implementation pending (optional), Completed, NotImplementedRemove “Filter Code (Optional)” column from Step 6– Optimization on DFMEA Form AIt is recommended to list the Severity Rating next toeach of the 3 areas (Your Plant, Ship to plant,Process Item, End User) being considered and usethe highest Rating for the Severity. Rank. One area,such as End User, may not always have the highestSeverity Rating.It is recommended to list the Severity Rating next toeach of the 3 areas (Your Plant, Ship to Plant, EndUser) being considered and use the highest Ratingfor the Severity. One area, such as End User, maynot always have the highest Severity Rating.B2.5PFMEA AP: H, M, L, N/APFMEA AP: H, M, LB2.6PFMEA AP: H, M, L, N/APFMEA AP: H, M, LPageSection168View B168View B169 170All 2.5-1178FigureB2.6-1Original Language (see highlight)Function Analysis (Step 3) Item 2:Process StepStation No. And Name of Focus ElementVersion 2 – 2 June 2020Page 7 of 10

AIAG & VDA FMEA Handbook – 1st Edition – English Translation Errata SheetB3.5Original Language (see highlight)Status: Open, Decision pending (optional),Implementation pending (optional), Completed,DiscardedFMEA-MSR AP: H, M, L, N/ACorrected Version Language or explanationStatus: Open, Decision pending (optional),Implementation pending (optional), Completed, NotImplementedFMEA-MSR AP: H, M, LB3.6FMEA-MSR AP: H, M, L, N/AFMEA-MSR AP: H, M, LB3.6Status: Open, Decision pending (optional),Implementation pending (optional), Completed,DiscardedNote: O 10, 9, 8, 7 can drop based on productvalidation activities.Status: Open, Decision pending (optional),Implementation pending (optional), Completed, NotImplementedNote: Occurrence can drop

The Design FMEA analyzes the functions of a system, subsystem, or component of interest as defined by the boundary shown on the Blo ck/Boundary Diagram, the r elationship between its underlying elements, and to external elements outside the system boundary. This enables the identification of possible design weaknesses to