Transcription

Volumetric Measurementin the LaboratoryLearning the basics – how to work with volumetric instruments.

IntroductionVolumetric measurement plays a central role in the laboratory. Theuser has to determine the degree of accuracy required for eachmeasurement. Based on this, he can choose the appropriate volumetric instrument.Reliable measurements require the use of precision instruments andtheir proper handling. To provide a better understanding of volumetric instruments and their operation, this booklet explains the mostimportant terms for their classification and handling, and illustratesthem by using BRAND laboratory equipment as examples.The brochure 'Information on Volumetric Measurement' is designedto give the reader a quick overview of volumetric instruments. It isnot intended to replace the safety instructions or operating manualsof the liquid handling instruments described.Please do not hesitate to contact us if you have any further questions.BRAND GMBH CO KGP.O. Box 11 5597861 Wertheim/Main · GermanyTelephone: 49 93 42 808-0Fax: 49 9342 808-98000E-Mail:info@brand.deInternet:www.brand.de BRAND GMBH CO KG · All rights reserved

ContentsVolumetric Instruments – an Overview . 5Manufacture of Glass Volumetric Instruments . 6From raw material to finished precision instrument6Identification of volumetric instruments8Accuracy classification of volumetric instruments9Working with Volumetric Instruments . 10Meniscus of a liquid10Delivery and waiting times11Pipettes, general12Handling of pipettes13Handling of volumetric flasks15Handling of graduated and mixing cylinders15Handling of burettes16Handling of density bottles17Working with pipetting aids18Working with Liquid Handling Instruments . 21Dispensing with bottletop dispensers22Titrating with bottletop burettes24Pipetting with air-interface pipettes25Pipetting with positive-displacement pipettes29Dispensing with repetitive pipettes30Accuracy Defined . 32Monitoring of Measuring Instruments . 33Procedure for volumetric testing34Calibration software36Calibration service36Conformity and Calibration Certificates . 37BLAUBRAND USP volumetric instruments . 38IVD Directive . 39Quality Management . 40Cleaning of Laboratory Equipment . 41Safety Information . 43

Volumetric Instruments – an OverviewVolumetric Instruments – an OverviewVolumetric instruments glass/plasticsThe volumetric measurement of liquids is a routineoperation in the laboratory. Therefore, volumetricinstruments, such as volumetric flasks, bulb pipettes,graduated pipettes, graduated cylinders and burettesare standard equipment. They can be made fromglass or plastic. Suppliers offer volumetric instrumentsin varying qualities. Graduated beakers, beakers,Erlenmeyer flasks, dropping funnels and the like arenot volumetric instruments! They are not preciselycalibrated, and the scale serves only as an approximate guide. A selection of volumetric instruments byVolumetric flasksBRAND is illustrated here:Bulb and graduatedpipetteGraduatedcylinderBuretteLiquid handling instrumentsTo meet the ever growing demands on volumetricmeasuring in the lab, such as testing in series,new devices are constantly being developed, e.g.,for dispensing, pipetting and titrating. Usually, theinstruments designed by different manufacturersfor a particular purpose are more or less similar infunctional principle. However, major differences areapparent when the focus is on constructional detailsand design. This selection of liquid handling instruments by BRAND illustrates the range of instruBottletop dispenserBottletop dispenserBottletop buretteSingle-channelair interface pipettesMultichannelair interface pipettesPositive displacementpipettewww.brand.dements available:Repetitive pipette,manualRepetitive pipette,electronic5

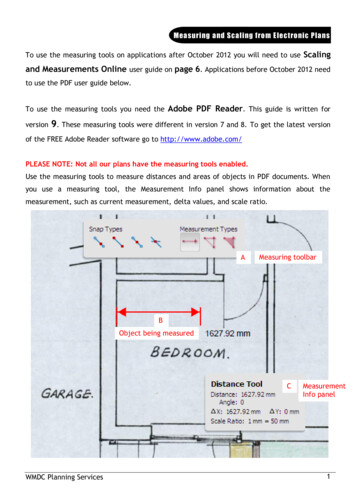

Glass Volumetric Instruments · ManufactureManufacture of Glass Volumetric InstrumentsFrom raw material to finished precision instrumentBlanksTwo types of glass are used for the production of blanks:– soda-lime glass (e.g., AR-GLAS ) for bulb and graduated pipettes– borosilicate glass (typically Borosilicate glass 3.3) for volumetricflasks, graduated cylinders and burettes.These glass types meet the stringent laboratory requirements forchemical and physical resilience.High-quality blanks and strict statistical testing of the requiredquality characteristics are the basis for producing high-qualityvolumetric instruments. For example, thermal stress in the glassblanks must be eliminated by a controlled heating and coolingprocess.This results in optimum mechanical stability, a requirementfor keeping the volume constant despite any subsequenttemperature fluctuations.Therefore, BLAUBRAND andSILBERBRAND volumetricinstruments can be heated upto 250 C in a drying cabinet orsterilizer without any resultingvolume changes.As with all glass instruments,however it should be noted,that uneven heating or suddentemperature changes producethermal stresses, which mayresult in breakage.Therefore:Always place glass instrumentsinto a cold drying cabinet orsterilizer; then heat slowly. Atthe end of the drying or sterilizing period, allow instrumentsto cool off slowly inside theswitched-off drying cabinet orsterilizer. Never heat volumetricinstruments on a hotplate!Blanks for graduated cylindersCalibrationEvery glass volumetric instrument is individually calibrated atBRAND, i.e. the instrument isaccurately filled with a definedquantity of water, and a calibration mark is applied at the lowest point of the meniscus. Inthe case of graduated instruments, two calibration marksare applied.Computer-controlled systemsensure maximum precision in afully automated production line.'Statistical Process Control'(SPC) guarantees production ofvolumetric instruments with thesmallest deviation from nominalcapacity (accuracy) and narrowscatter of individual values(coefficient of variation).Volumetric instruments are either calibrated 'to contain' ('In')or 'to deliver' ('Ex').Calibration 'to contain'(TC, In):Calibration 'to deliver'(TD, Ex):The contained quantity of liquidcorresponds to the capacityprinted on the instrument.These instruments include e.g.,graduated cylinders, volumetricflasks, and capillary pipettes upto 200 µl.The delivered quantity of liquidcorresponds to the capacityprinted on the instrument.The wetting residue remainingin the instrument has alreadybeen taken into account in thecalibration. These instrumentsinclude e.g., graduated andbulb pipettes, and burettes.Reference temperatureThe standard reference temperature, i.e. the temperatureat which volumetric instrumentswill contain or dispense theirvolumes, is 20 C.If the adjustment or calibration is performed at a temperature that deviates from thisstandard, the correspondingmeasurement values must becorrected.Note:Due to the small coefficient ofexpansion of the glass material,the reference temperature is ofminor significance in practicaluse since the measurement deviations resulting from volumeexpansion of the measuring instrument are generally smallerthan the error limit.Calibration of graduated pipettes6info@brand.de

Glass Volumetric Instruments · ManufactureSilk-screeningScreening inksCalibration is followed bysilk-screen printing of marksand inscriptions. BRAND usesstretchable screen stencils forall graduated pipettes, burettes,graduated cylinders, and mixing cylinders. These stencilscan be stretched to match thecalibration marks accurately, sothat the measuring precision ismaintained for all intermediatevolumes.BRAND uses quality inks manufactured especially for glass volumetric instruments:Blue enamel:White enamel:Amber diffusion stain:High contrast, optimumcombination of resistance andlegibility. Blue enamel is usedfor BLAUBRAND volumetricinstruments (class A/AS).White enamel is used forSILBERBRAND volumetricinstruments (class B).Diffuses into the glass surface and can only be removedby abrasion. It is used forvolumetric instruments that areexposed to especially aggressive cleaning conditions. Anamber diffusion dye is usedfor BLAUBRAND ETERNAvolumetric instruments (classA/AS) as well as for SILBERBRAND ETERNA volumetricinstruments (class B).Pipettes are additionally markedwith 'color-code' rings at theirupper end, which make it easierto identify similar pipette sizesclearly. The ISO 1769 industrystandard defines color-codingfor different nominal volumes.Automatic silk-screening of volumetric flasksFiringQuality assuranceFiring or annealing thescreened ink is the last step onthe way from the blank to thefinished volumetric instrument.A carefully controlled annealing process, along with thespecially produced quality inks,is a prerequisite for durablegraduations. This involves agradual heating and cooling ofthe volumetric instruments. Depending on the type of glass,temperatures of 400 to 550 Care reached in this process.Quality assurance is implemented at BRAND throughongoing testing during production and statistical testing in thefinal inspection. (For detailedinformation, see page 39.)Silk-screened graduated cylinders before firingFor more information about glassvolumetric instruments see the videoon our Youtube channelmylabBRAND:BLAUBRAND – the right line involumetric measurementwww.brand.de7

Glass Volumetric Instruments · ManufactureIdentification of volumetric instrumentsDE-M, followed bybatch numberExample:BLAUBRAND bulb pipetteManufacturerDesignation of the standardBRAND trademark forvolumetric instrumentsclass A/ASCountry of originReference temperature (20 C),waiting time (5 sec.),calibration (TD, Ex to deliver)Nominal volumeError limitClass 'A', the highestquality grade,'S' for swift deliveryVolume unitThe labeling below must be printedThe following information mayon every volumetric instrument:also be added:n Nominal capacitylCountry of originn Unit symbol: ml or cm³lError limitn Calibration temperature: 20 ClManufacurer's trademark(here: BLAUBRAND )n Class: A, AS, AW or BlStandard, e.g., ISO 648n Waiting time (if necessary):in the format 'Ex 5 s'lBatch numbern Calibration: Ex or Inn Manufacturer’s name or logon Volumetric flasks and graduated cylinders: glass material8info@brand.de

Glass Volumetric Instruments · ManufactureAccuracy classificationVolumetric instruments are generally available in two accuracy classes:Class A/AS/AWVolumetric instruments of class A and AS have identical error limits as established by DIN EN ISO. These are generally implemented only in glass volumetric instruments. Exceptions are BRANDplastic volumetric flasks made from PFA and PMP and plasticgraduated cylinders made from PMP, which are designed to meetthe highest requirements and likewise correspond to class A.Measuring flasks with wide neck are marked with class AW andhave a higher error limit compared with class A measuring flasks.For class AS volumetric instruments, calibrated to deliver (TD, Ex),the additional 'S' means swift delivery.Class AS volumetric instruments have become quite well established. The risk of clogging is low in pipettes and burettes witha larger tip opening. The delivery behavior of various liquids iscompensated by observing the defined waiting time (see 'Deliveryand waiting times' on page 11).Class A/AS/AW Always stands for thehighest-grade accuracy 'S' stands for swift delivery(pipettes and burettes) Only classes A/AS/AWhave DE-M marking Graduation:The long graduation marksextend over at least 90%of the tube perimeter or arepresent as ring markings.Class BVolumetric instruments of class B are available in glass or plastic.Class B instruments generally have twice the error limits of classA/AS.Examples of BRAND class B plastic volumetric instruments arevolumetric flasks and graduated cylinders made of PMP or PP,as well as bulb and graduated pipettes made of PP.For class B measuring instruments calibrated to deliver (TD, Ex),no waiting time is specified.Class B Generally twice the errorlimits of class A/AS Graduation:The long graduation marksextend about 20 - 40% ofthe tube perimeter.The choice of volumetricinstruments – glass or plastic?There is no all-round materialto meet every single requirement in the laboratory. Thedecision to use glass or plastic is guided by the application,product design and after considering the specific propertiesof the materials and economic aspects. Volumetric instruments of plastic excel by theirhigh resistance to breakageand low weight. PP, PMP andPFA are proven materials.www.brand.deThe accuracy of bulb pipettes,graduated pipettes, volumetricflasks, and graduated cylindersmade from PP corresponds tothat of class B error limits.PMP and PFA are also used formeasuring instruments that correspond to class A error limits,e.g., volumetric flasks (PMP/PFA) and graduated cylinders(PMP). Due to its higher purity,PFA is preferably used in traceanalysis applications.Graduated cylinder made ofPMP, class A9

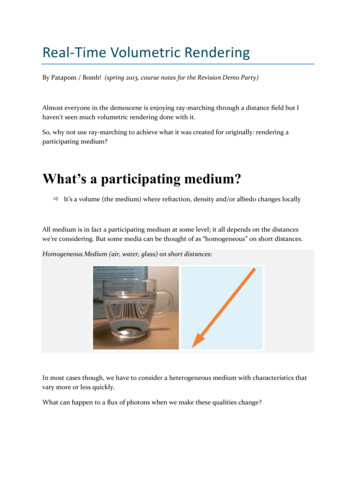

Volumetric Instruments of Glass · Measuring the VolumeWorking with Volumetric InstrumentsThe liquid meniscusThe term meniscus describes acurvature in the surface of theliquid.The meniscus may be curvingupwards or downwards. Thecurvature develops as a function of the interplay betweenthe adhesion and cohesionforces.If the liquid molecules areattracted more strongly bythe glass wall (adhesion) thanby their own kind (cohesion),the meniscus is curved downwards, or concave; the edgeof the liquid surface is slightlyraised. This is the case, e.g.,with aqueous solutions.If the diameter of a pipette isnarrow enough – as with capillary pipettes – the adhesionforce is strong enough to pullup not only the edge but alsothe entire liquid level (capillaryeffect).If the cohesion force of a fluidis stronger than the adhesionforce of the glass wall, anupwardly curved (convex) meniscus is formed. This happenswith mercury, for example.Meniscus settingCorrect meniscus setting is a prerequisite for accurate volumetric measurement.Important note:Concave meniscus in agraduated pipette.Convex meniscus in agraduated pipette.Appearance of the meniscusat the Schellbach stripe in aburette.In the case of a concave meniscus, the volume has to beread at the lowest point of theliquid level. The lowest point ofthe meniscus has to touch theupper edge of the graduationmark.In the case of a convex meniscus, the volume has to beread at the highest point of theliquid level. The highest pointof the meniscus has to touchthe lower edge of the graduation mark.The Schellbach stripe is anarrow blue band at the centerof a white stripe. Schellbachstripes are imprinted on theback of volumetric instrumentsto improve readability.The refraction of light causestwo arrow points to appearat the meniscus. The readingpoint is where the two arrowsmeet.The temperature of the liquidand the environment duringuse are important. While theexpansion of a glass volumetricinstrument is negligible, theexpansion of the liquid at different temperatures must betaken into account. To minimizevolume errors as much aspossible, the volumes of allthe liquids in contact with oneanother should be measuredat a common (prevailing daily)temperature. Especially in thepreparation of standard solutions, for example, the pipettingof the samples and the titrationshould be done at the sametemperature to the extent possible. Significant temperaturedifferences between the measuring instrument and the liquidshould likewise be avoided.Reading the meniscusFor parallax-free adjustment ofthe meniscus, the volumetricinstrument is held upright andthe observer’s eye must be atthe same height as the meniscus. In this position the ringmark will appear as a line.The meniscus will appear darker and more easily readable infront of a light background ifa piece of dark paper is heldbehind the instrument immediately beneath the ring mark orgraduation mark.10Ring mark /graduationmarkMeniscusinfo@brand.de

Volumetric Instruments of Glass · Measuring the VolumeDelivery and waiting timesIn volumetric instruments for liquid delivery (calibrated to deliver, TD, Ex), the volume delivered isalways smaller than the volume contained in the measuring instrument. This is caused be the fact,that a certain amount of liquid remains as a film on the inner surface of the instrument. The volumeof this liquid film depends on the delivery time and should be taken into account when calibrating themeasuring instrument.Possible volume errors:The volume delivered from a pipette or burette becomes smaller if the tip is broken off (shorter delivery time), or increases if the tip is not clean and the liquid outflow is impeded (longer delivery time).Likewise, the volume increases if the residual liquid in the tip after pipetting is blown out by mistake.(for the proper handling of pipettes, see page 13.)Delivery timeWaiting timeThe delivery time is defined asthe period of time required forthe free fall of the meniscus(discharge of water due togravity) from the upper volumemark to reach the lower volumemark or the tip. This is connected with the defined waitingtime for class AS volumetricinstruments.The waiting time begins whenthe meniscus comes to rest atthe lower volume mark or in thetip. During the waiting time,residual liquid continues to flowdown from the glass wall.Waiting time for class AS:The established waiting time of5 s for class AS bulb andgraduated pipettes is the timeafter which the meniscus visiblycomes to rest in the tip, andbefore the tip can be removedfrom the inner surface of thereceiving vessel.The waiting time of 5 s must beindicated on the pipette by themanufacturer (see page 8).Examples of delivery and waiting timesfor different classes(25 ml bulb pipette)Class AS (DE-M marking)Delivery time 15 - 20 sec. Waiting time 5 sec.Class A (DE-M marking)Delivery time 25 - 50 sec. (no waiting time)Class BDelivery time 10 - 50 sec. (no waiting time)www.brand.de11

Glass Volumetric Instruments · HandlingWorking with Volumetric InstrumentsPipettes, generalPipettes are volumetric instruments for measuring volumes of liquid and are generally calibrated'to deliver'. During the manufacturing process, they are individually volumetrically calibrated andprovided with one or more calibration marks.We distinguish between bulb and graduated pipettes (calibrated to deliver, TD, Ex) and disposablemicropipettes up to 200 µl (calibrated to contain, TC, In).Bulb pipettesGraduated pipettes Calibration:Class AS: 'Ex 5 s'Class B: 'Ex' Calibration:Class AS: 'Ex 5 s'Class B: 'Ex' Generally higher measurement accuracy than graduated pipettes Scaling permits the readingof partial volumes Types of graduated pipettes: Bulb pipette models:Type 2 – nominal volume attop, total deliveryalso for partialvolumesType 1 – nominal volume atbottom, partial delivery for all volumesType 3 – nominal volumeat bottom, totaldelivery only for thenominal volumeThe most important model isthe bulb pipette with 1 mark(total delivery).Less common is the modelwith 2 marks (partial delivery).Bulb pipettes are also calledsingle volume pipettes.Bulb pipette with1 mark12Graduated pipette,type 2, nominal volumeat the topCapillary pipettese.g., BLAUBRAND intraMarkCapillary pipettese.g., BLAUBRAND intraEnd Calibrated to contain (TC, In) Calibrated to contain (TC, In) One ring mark No ring mark Volume limited by one endand the ring mark Volume limited by both ends(end-to-end capillaries)info@brand.de

Glass Volumetric Instruments · HandlingHandling of pipettesPipettes calibrated 'to deliver' ('TD, Ex')Proper pipetting with bulb pipettes with 1 mark (here: nominal volume 25 ml)and graduated pipettes type 2, class AS (here: partial volume 3 ml)Utility: pipetting aid (see page 18)FillingBulb pipette1 mark1. Fill the pipette with a pipetting aid to approx. 5 mmabove the selected graduation mark.2. Remove any liquid remainingon the outside of the tip ofthe pipette with a tissue.Type 2Type 1Type alvolumeat the topzero pointat the topzero pointat the topSet meniscus2 timesSet meniscus2 timesSet meniscus1 time3. Set the meniscus.4. Wipe off any drop of liquidadhering to the tip.Delivering5. Hold the pipette vertically.Deliver the liquid with thetip of the pipette in contactwith the inner surface of theinclined receiving vessel.6. When the meniscus comesto a rest in the tip, the waiting time of 5 s begins (classAS only).Type 1 and type 37. After the waiting time,draw the pipette tip upwardsalong the inner wall througha distance of about 10 mmto remove residual liquid.Set meniscus1 timeNote:The residual liquid still leftin the tip has already beentaken into account duringcalibration and must not bedischarged into the vessel,such as by blowing out.When using type 1 or type 3graduated pipettes (zero pointat top), the meniscus must1.) first be set at the zero pointand then the liquid be runout to slightly above thedesired partial volume.2.) After a waiting time of 5 s,the meniscus should be seta second time.Working with type 2 graduatedpipettes is significantly quickerand simpler. With type 1 andtype 3 pipettes there is a riskthat with the always necessary second meniscus settingtoo much liquid is released,and that the sample needsto be prepared again (as alsowith bulb pipettes that have2 marks).Fill pipettewww.brand.deWipe offSet meniscusDeliver13

Glass Volumetric Instruments · HandlingHandling of pipettesPipettes calibrated 'to contain' (TC, In)Correct pipetting with capillary pipettesUtility: pipetting aid (see page 18)Capillary pipettes are pipettes with a very narrow internal diameter. They are filled either with apipetting aid, or automatically by capillary action. After emptying, the capillary pipette must berinsed repeatedly with the diluting medium.Filling Aspirate liquid accurately tothe desired mark. Hold the pipette horizontallyand carefully wipe off with atissue.Delivering To empty capillaries blowout the liquid with a pipetting aid, and rinse two tothree times with the dilutingmedium (required due tocalibration 'to contain').Fill capillaryWipe offDeliver End-to-end capillaries areoften placed directly in thedilution solution and washedout by shaking.Pipette holder withend-to-end-capillaries14info@brand.de

Glass Volumetric Instruments · HandlingHandling of volumetric flasksVolumetric flasks, class A andB, are calibrated to contain(TC, In), and are mainly usedfor the preparation of highlyaccurate dilutions and standardsolutions.Modern analytical methodsrequire small-capacity volumetric flasks. Small-sized conventional volumetric flasks (up toapprox. 50 ml) tend to tip overeasily due to their high centerof gravity and their small basearea. Trapezoidal volumetricflasks are much more stable.Their center of gravity is lower,and their base area is morethan twice as large comparedto the equivalent standardflasks.How to prepare a standard solution with a volumetric flask:1. Insert the precisely weighed amount of substance, or rinse in astandard solution concentrate.2. Fill the flask with distilled water to about half. Swirl the flask todissolve and mix the contents thoroughly.3. Top up the flask with distilled water to just below the ring mark.4. Top up the remaining volume, using a wash bottle or pipette,until the meniscus is exactly at the ring mark. Important: meniscus must be read at eye level. The wall of the flask must notbe wetted above the mark.5. Close the flask and shake upside down to mix contents.Handling of graduated and mixing cylindersGraduated cylinders:Handling:Mixing cylindersGraduated cylinders, class Aand B, are measuring instruments that are calibrated tocontain (TC, In), i.e. they indicate the exact volume taken up. Fill with liquid.The mixing cylinder is calibrated to contain (TC, In), justas the graduated cylinder. Theyare additionally supplied with aground glass joint and stopper. Set the meniscus to therequired mark (read at eyelevel!) The wall of the cylindermust not be wetted abovethe mark. The indicated volume is theamount of liquid contained.Note:In the laboratory, graduatedcylinders are frequently usedjust like measuring instrumentsthat are calibrated to deliver(TD, Ex).Measurements with watershowed that the dispensedvolume is reduced by approximately the amount of the errorlimit of the graduated cylinderdue to the residue amount fromwetting. Prerequisite: The liquidis slowly dispensed in one portion, and to finish delivery ofthe liquid the cylinder is held atan incline for a further 30 s.www.brand.deMixing cylinders can be used inthe preparation of standard solutions and dilutions, the sameas volumetric flasks. After portions of variousliquids have been measuredout, these can then bemixed by shaking directly inthe mixing cylinder.Note:When two liquids are mixed, avolume change may occur.15

Glass Volumetric Instruments · HandlingHandling of burettesBurettes are glass volumetric instruments calibrated to deliver(TD, Ex) which are used for titration in volumetric analysis.CalibrationClass AS: 'Ex 30 s'Class B: 'Ex'Note on waiting time:Compared to pipettes, the handling of burettes is different duringpractical use and calibration. Typically, the volume used in a titration is less than the nominal volume, and the standard solution isadded dropwise when close to the color change to avoid overtitration.In practice the time required for this dropwise addition is the sameor even longer than the established waiting time. As a result, it isnot necessary to observe the established waiting time of 30 s withclass AS burettes during practical use.Types of burettes:Handling1. Rinse the burette with the standard solution to be used, andalign burette tube vertically.2. Fill the burette slightly above the zero mark. To prime the stopcock, drain the burette no further than the nominal capacity.3. Refill the burette with titrant free of air bubbles to approx. 5mm above the zero mark.4. Drain liquid to set the zero point accurately. Important: Meniscus must be read at eye level (parallax-free level). Automaticburettes: Fill to approx. 5 mm above the zero mark. This is adjusted automatically after air release.5. Wipe off any drops adhering to the discharge tip.6. Open the stopcock and slowly add titrant tothe sample (containing the indicator). Thedischarge tip must not touch the wall of thevessel. Keep swirling the sample vessel lightly while adding titrant, or place it on a magnetic stirrer.7. Read the discharged volume at eye level.8. Any drops remaining on the tip of the stopcock should be wiped against the vessel walland rinsed down. It is part of the titrated volume.Burette with lateralstopcockAutomatic burette,Pellet patternAutomatic burette, Compact buretteDr. Schilling patternNotes on titration:In addition to burettes, volumetric flasks, bulb pipettes andErlenmeyer flasks are required for titrating. For easiest recognitionof the color change, place the sample vessel on a white surface.Make sure that the solution is completely homogenous. There16must be no cloudiness, flocculation or precipitation present. Thetitration is finished, when the color change is reached. Beforeeach new titration, reset the zero point and start the titration fromthere.info@brand.de

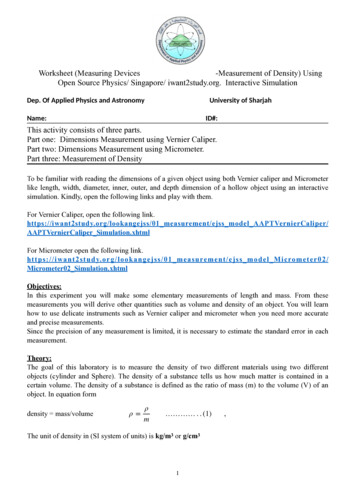

Glass Volumetric Instruments · HandlingHandling of density bottlesDensity bottles are mainly used to determine the density of liquids of moderate viscosity. They are not volumetric instruments, however, they are calibrated 'to contain' as in the case of volumetric flasks.Handling1. Determine the weight of the dry and empty density bottle.2. Fill the density bottle with liquid, avoiding bubbles. The groundneck should be covered to about 1/3.3. In a thermostatic bath, adjust the temperature of the bottle andcontents to 20 C.4. Align the stopper respectively, the thermometer of the densitybottle according to the marking, and insert carefully. The capillary tube fills up and the displaced liquid comes out.5. Carefully dry the outer surfaces of the stopper (respectively,the side capillary) and the density bottle with tissue.ATTENTION:Be careful not to remove any liquid from the capillary. Thesample liquid must be exactly level with the upper end of thecapillary.Density bottle with stopper6. Determine the weight of the filled density bottle.Calculate the density from the mass (weight) and the volume ofthe liquid at the reference temperature of 20 C. The volume isengraved on the bottle. The equation is:Density (ρ) Mass (m)/Volume (V)Take the buoyancy of the air into account for weighing.Note:Calibrated density bottles always carry a unique identificationnumber on all component parts.Use only parts with the same number together.www.brand.de17

Glass Volumetric Instruments · Pipetting AidsWorking with pipetting aidsPipetting aids are indispensable for working with pipettes.Types of pipetting aids: motorized pipetting aids manual pipetting aidsPipetting using the mouth or with a tube and mouthpieceis not allowed. A pipetting aid should always be used forthis. This significantly decreases the risk of infection orinjury.Motorized pipetting aidsMotorized pipetting aids are ideal for pipetting longer series(e.g., for cell cultures).e.g., accu-jet pro by BRANDThe variable motor speed control and a special valve systemenable sensitive operation with pipettes from 0.1 to 200 ml.An integrated check valve in connection with a membrane filtereffectively protects against penetrating liquids. To protect againstcorrosion, an active pressure compensation diverts vapors outside.HandlingPipetting is controlled throug

BRAND GMBH CO KG P.O. Box 1155 97861 Wertheim/Main · Germany Telephone: 49 9342 808-0 Fax: 49 9342 808-98000 E-Mail: info@brand.de Internet: www.brand.de Introduction Volumetric measurement plays a central role in the laboratory.