Transcription

LasersThe Powerof Choice

2ContentsLaser beam sourcesThe Power of ChoiceWith modern laser technology, nearly any manufacturing method can be realizedwith high quality and resource efficiency. When it comes to developing newproducts, you can rely on light to provide the right tool for your productionenvironment! To ensure you get exactly the technology and support you need,TRUMPF offers a unique range of lasers and laser systems combined with globalapplication consulting, integration support, and comprehensive after-sales service.Put simply, that’s the Power of Choice.How laser technology from TRUMPF is helping toshape the megatrends in production and society.Industries and trends4–7How to find out which laser technology offersthe best solution for you.Applications andtechnologies8–9How TRUMPF can help you transform a productconcept into a manufacturing process.Know-how and support10 – 11

Laser beam sourcesContents3Learn more about the benefits of each typeof laser in the TRUMPF product range.Laser beam sources12 – 29How to kit out your laser with focusing opticsand a sensor system to make your productionprocess even simpler and more reliable.Components30 – 37How TRUMPF lasers’ interfaces and control options ensure smooth integration in your production environment.Integration38 – 39How to get the right support from TRUMPF atthe right time – and delve even deeper into theworld of TRUMPF.TruServices.Your Partner in Performance40 – 41Discover the wide varietyof TRUMPF lasertechnologies in our film“The Power of Choice”:www.trumpf.info/fmpr6x

4Industries and trendsLaser beam sourcesYour industry,our motivationTRUMPF lasers are used in a wide variety of industries, from cuttingmicrometer-thin shapes out of display glass to welding centimeter-thickmetal for wind turbines. As a key technology leader, TRUMPF is continuouslyinvesting in research and development for new technologies and potentialfuture applications. The major trends shaping our society act as an incentiveto seek even better solutions for your innovative, efficient, and high-qualityproduction processes.See the versatility that working with laser tools offersacross all industries: www.trumpf.com/s/kecj9fMobilityWe may not have reachedthe stage where our lasers canbeam people from one placeto another. Yet they have alreadyproven their ability to supportthe mobility and logistical requirements of our society. That includes makingcars more efficient, trains lighter, aircraft safer,and ships more stable. Our lasers are also helpingto shape frontline themes such as e-mobility.– kgLightweight design with finely renderedlaser weld seams leads to reduced fuelconsumption and lower CO2 emissions.

Laser beam sourcesIndustries and trends13.5 nmis the wavelength of EUV light formicrochip production – generated withthe TRUMPF laser amplifier.CommunicationEffective communication is amust in today’s smart world. Ourlasers provide solutions for thekey process at the heart of modern technical communicationsystems – chip manufacturing.As part of Industry 4.0, TRUMPF is advancing digital connectivity in production with numeroussolutions.5

6Industries and trendsLaser beam sources100 cm2/sis the ablation rate of our short-pulse lasers,which facilitate the cost-effective productionof thin-film solar modules.EnergyIs saving energy a key priorityfor you and your industry, too?Our highly efficient lasers openthe door to energy-efficientproduction and help make yourcomponents lighter and tougher. TRUMPF lasers offer solutions for more energyefficiency in the wind power and photovoltaicsectors, to mention just a few.

Laser beam sourcesIndustries and trends1·10 –12 sStents made of nitinol or polymer cut byultrashort pulse lasers exhibit a high-quality,smooth surface so that no deposits canbuild up. That helps arteries stay open overthe long term.HealthTRUMPF lasers are used in medical technology to create preciselyrendered microstructures – andthe results are already having amajor impact on people’s healthand quality of life. TRUMPF isalso working together with the Max Planck Institute to develop atto-second laser technology thatcould, in the future, be used to detect tumors assmall as 1 mm.7

8ApplicationsYour application,our technologiesCouldn’t we just use the same type of beam source for every single laser machining application? No way! Practical experience has clearly shown thatevery application has different requirements when it comes to laser technology.TRUMPF offers a full range of industrially relevant beam sources, so we cangive you impartial advice on which technology will provide the best solutionfor your manufacturing business. Choose TRUMPF for your beam sources,system solutions, beam guidance components, focusing optics, and intelligentsensor systems – all from a single source.Laser beam sources

Laser beam sourcesApplications9Find out more about whatlasers can do and how youcould use laser technologyin your work here:www.trumpf.com/s/k4ivz1

10Know-how and supportLaser beam sourcesYour needs, our supportWhether you already know exactly what you want or are looking for a tailor-made solution,we’re at your side right from the word go. The laser is a unique tool – and we’re passionateabout the opportunities it offers. TRUMPF has Laser Application Centers (LACs) all over theworld ready to cater to your needs. Because we believe you should always be able to find theright partner in the right place – with exactly the right technology to meet your needs.Tap into TRUMPF as USA:Farmington a project consultantSwitzerland:Grüsch & BaarUSA:Plymouth“We can provide you with advice and support from product conception through to production optimization. If theproduction process is defined in one of our LACs, thenwe can help you find an integrator if you need one. We’llwork together with you to get the production process upand running, and then optimize it until you are completelysatisfied with the results.”Antje Engler, System Support Manager, Plymouth Township a service partner“We are on hand with our tailor-made service packages to helpkeep your business running smoothly. If something goes wrong,our comprehensive remote services can quickly get things backon track even before it comes to that – thanks to TRUMPFCondition Based Services. We also offer an extensive range ofon-site training programs, functional enhancements, and a pplication services.”Benjamin Blocksdorf, Head of Sales Services Global, Ditzingen

Laser beam sourcesKnow-how and support11 a technology developer“We’ve been developing lasers at TRUMPF for more than40 years. Time and again we have transformed visions into realitywith the help of our research partners. And now you can usethis extraordinary know-how to gain a competitive edge. Takeour innovative ultrashort pulse lasers, for example. My projectpartners and I received the 2013 “Deutscher Zukunftspreis”(German Future Prize) for our work in this field – and it hasalready yielded a wealth of successful applications.”Find out more about howwe can assist you with ourLaser Application Centershere:www.trumpf.com/s/7smpvyDirk Sutter, Head of Development Group for Ultrashort Pulse Lasers, Schramberg an industry sector managerGermany:Ditzingen &SchrambergSouth Korea:SeoulChina:Dongguan“We take a unique industry sector approach that offersyou support long before you start using our lasers onyour production line. Our expert team already provideshelp during your development for industries such asthe automobile industry and consumer electronics. Wework together with you to exploit the full potential oflaser technology and develop tailor-made solutions inyour production. For example, in the automotive industry, lasers are used for machining high-strength materials, to realize laser brazing of components and in theconsumer electronics industry for display technologies.“Marc Kirchhoff, Head of Industry and Global Key Account Management,Ditzingen an applications specialistChina:TaicangJapan:Yokohama“Laser microprocessing is currently making its way into the worldof production, with more and more customers taking notice of ourwide range of ultrashort pulse lasers. My team and I are by yourside to provide optimal cost-effective process solutions, from thefeasibility study all the way to commissioning. To support ourcustomers, we rely on our broad capability comprising applicationconsultants, highly qualified application specialists, my many yearsof experience in the development of laser production systems, anda far-reaching network of globally active integrators.”Christoph Neugebauer, Micro Service and Support Group Leader, Ditzingen

12ProductsLaser beam sourcesYour production,our portfolioSolid-state lasersTruDisk14 – 17TruDiskgreen18 – 19TruFiber20 – 21TruPulse22 – 23TruMicro24 – 25TruMark26 – 27CO2 lasersTruFlow28 – 29

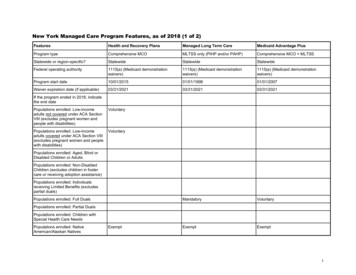

Laser beam sourcesProductsWhy chooseTRUMPF lasers?1234567Innovative solutionsHighest precision and qualityComprehensive portfolioGlobal application consultingLong-standing experienceIndustry expertsHigh level of availability(Remote Services)8 On-site service9 Customized services10 Industry 4.0 readyTruDiskWeldingPrecision weldingLaser metal depositionBrazingCuttingPrecision cuttingDrilling and ablationHardeningAdditive uMicroTruMarkTruFlow13

14Products – TruDiskLaser beam sourcesTruDisk01Maximum beam qualitythanks to disk technology02Optimized for Industry 4.0with intelligent hardware03Ultracompact andeasy to maintainthanks to its modular design04Flexible cooling conceptSupply temperature of up to 38 Cwith integrated cooler

Laser beam sourcesTruDisk – Products15The TruDisk disk laser provides you with immense power combinedwith maximum beam quality for manufacturing. It is the ideal partnerfor high-speed cutting, welding, and surface processing.08Integrated beam guidancefor maximum utilization of the laser07Always reproducible resultsthanks to 100% constant powerand the patented resonator design06Almost spatter-free weldingwith BrightLine Weld05Save energythanks to the high levelof operating efficiency andintelligent pulse functionFind out more about thebenefits and applicationsof the disk laser here:www.trumpf.com/s/sik0v2

16Products – TruDiskLaser beam sources0103Maximum beam qualityUltracompact and easy to maintainthanks to disk technologythanks to its modular designUsing a disk as a laser medium ensures brilliant beam quality –as low as 2 mm·mrad with TruDisk lasers. With a power spectrum of 1 kW to 16 kW, you can achieve optimal results in awide range of processes, from laser welding and cutting to lasermetal deposition, hardening, and generating of 3D parts.There is nothing smaller: Save space with an installation surfaceof less than 1 m² – including the cooling system! The modulardesign of the TruDisk also makes it extremely easy to service –individual components can be replaced quickly and easily. Thissaves time and increases machine availability.With the disk geometry, maximum power and beam quality are notmutually exclusive.Robust and modular optical design of the TruDisk.0204Optimized for Industry 4.0Flexible cooling conceptwith intelligent hardwareSupply temperature of up to 38 C with integrated coolerThe TruDisk is the ideal interface for your smart production:It is capable of synchronized data recording from all sensorsand provides high-quality information for virtual analysis. Thiscan be read out via the OPC UA interface on the laser. The laser thus creates the ideal hardware conditions for servicessuch as condition monitoring and predictive maintenance.The TruDisk uses a flexible cooling concept. You can choosebetween the standard variant with integrated heat exchangerand the optional integrated compressor cooler depending onthe temperature of your water supply. This does not changethe compact installation space of the laser. If a cooling watersupply is available, you can forget using an external coolingunit entirely.The TruDisk provides everything needed for smart production.TruDisk with integratedheat exchanger.TruDisk with integratedcompressor cooler.

Laser beam sourcesTruDisk – Products170507Save energyAlways reproducible resultsthanks to the high level of operating efficiencyand intelligent pulse functionthanks to 100% constant power and thepatented resonator designEnjoy the benefits of a high level of operating efficiency and anefficient pulse function. This enables the diode current of thedisk laser to be reduced to 0 A, even during extremely shortpauses in work. For longer processing breaks, the intelligentenergy management of the TruDisk laser ensures consistentenergy efficiency in operation – both during laser-on timesand laser-off times.With the TruDisk, you can benefit from the highest power stability available on the market – throughout the entire servicelife of your laser. When using the TruDisk, you can expect100% constant power right from the first millisecond. Thanksto its patented resonator design, the TruDisk can easily handleeven strong back-reflections. This enables you to process evenhighly reflective materials such as copper and other nonferrousmetals without compromises.Can-cap welding withoptimal precision.The diode current switches off completely, even during extremely short processing breaks in work. This saves you unnecessary energy costs.0608Almost spatter-free weldingIntegrated beam guidancewith BrightLine Weldfor maximum utilization of the laserWhether copper, steel or aluminum – with BrightLine Weld,welding is almost spatter-free and has the highest quality.The minimum spatter reduces dirt build-up on components,clamping fixtures and optics. With BrightLine Weld the feedrate is simultaneously increased, thereby significantly increasing the productivity. Your components need less finishingwork, and you benefit from low machine downtimes and lessfrequent changes of the protective glass.The new generation of the TruDisks with up to 4 laser outputs can be perfectly adapted to your system concept. Beamguidance is integrated into the compact laser housing. Usingseveral laser outputs enables you to increase the utilization ofthe laser, reduce part costs and boost system availability.Flexible setting of the intensity distribution with BrightLine Weld.Optics setup of the new generation TruDisk with up to 4 outputs.

18Products – TruDisk greenLaser beam sourcesTruDisk withgreen wavelengthHigh quality and maximum reproducibility0401Robust, reliable andindustrial suitabilityHigh quality forcopper processingthanks to proven disk technologywith green wavelength0302Ideal for all surfacesMinimal spatterwhether oxidized, sandblasted, etchedor highly polishedthanks to uniform heating

Laser beam sourcesTruDisk green – Products190103High quality for copper processingIdeal for all surfaceswith green wavelengthwhether oxidized, sandblasted, etched or highly polishedGreen light is better absorbed than infrared light when processing highly reflective materials such as copper. The improvedabsorption of green light generally leads to a much better input of the laser power to the workpiece. With TruDisk laserswith a green wavelength, you can choose between pulsed orCW mode as best suits your application. In both cases, youbenefit from fast, highly efficient welding processes throughthe combination of green wavelength and high output power.Thanks to the extremely low scattered radiation produced bythese pulses, you can almost always work without additionalshielding for temperature-sensitive electronic components.With the green TruDisk lasers, you always achieve the samehigh level of quality in your welding results without needingto carry out readjustments, for various copper surfaces: oxidized,sand-blasted, etched or highly polished. The smooth processusing green light ensures that you produce very robust copperwelds of consistently high quality. You can even work withoutany expensive upstream surface treatment processing such assand blasting or tinning.400 µm400 µmTruDisk 1020: Heat conduction welding of copper foil with v 10 m/min,weld bead and cross-section.Expect the best results on any copper surfaces.0204Minimal spatterRobust, reliable and industrialsuitabilitythanks to uniform heatingThe optimal input coupling of the green laser beam ensuressmooth weld pool dynamics. Because of this, the TruDisk laseris perfectly suited for both heat conduction welding and high- quality deep penetration welding of copper. The mate rial isheated evenly, and you can consistently achieve a reproducible,almost spatter-free process with a wider tolerance range. Thisenables you to prevent expensive reject parts or even undetected faults in components as well as short circuits. In deeppene tration welding, the lasers can produce a reproducibleand constant welding depth.2 mmWelding of copper contacts on DCB substrate with well controlled welding depth using TruDisk 1020.2 mmthanks to proven disk technologyWhen it comes to robustness, reliability, and industrial suitability, put your trust in the TruDisk lasers. TRUMPF can offer you aunique complete package: laser, laser light cable, focusing opticsand a sensor system – developed and tested for the greenwavelength. Thanks to their excellent beam quality, TruDisklasers are ideal for highly productive scanner applications.2 mmWelding of electronic componentswith minimum spatter formationthanks to green wavelength.500 μmWelding of battery foil stacks consisting of 100 copper foils with TruDisk 2021.Left: Regular seam surface without ejections. Right: Cross-section of the porelessweld seam with large joint area.Using TruDisk with green wavelength enables to weld copper with superb s tability and minimal spatter.

20Products – TruFiberLaser beam sourcesTruFiberTruFiber boasts a small footprint and excellent beam quality.01Comprehensive solution froma single sourcefor easy integration04A compactpower packeasy to integrate0203100% constantprocess resultsOptimized forIndustry 4.0for most demandingquality expectationsas a future-ready platform

Laser beam sourcesTruFiber – Products0103Comprehensive solution from a single sourceOptimized for Industry 4.0for easy integrationAt TRUMPF, lasers, control, beam guidance, processing opticsand sensor systems are optimally coordinated to each other.This also applies to the TruFiber, for example, in conjunctionwith the programmable focusing optics (PFO). The VisionLineimage processing system detects characteristics on components and ensures that welding always happens in the rightplace. Furthermore, CalibrationLine checks the focus positionand laser power at regular intervals.21as a future-ready platformWith the TruFiber you can take a big step towards your SmartFactory. Due to the laser’s connectivity via OPC/UA, optimumnetworking of the fiber laser is guaranteed. Using FactoryGate you can integrate several devices into the network. WithTRUMPF Condition Monitoring you also have full transparencyat all times concerning all laser states via dashboards. Theprecision time protocol ensures precisely timed coordinationof all sensors, and remote access ensures convenient servicefrom anywhere.Analyse and control your productionprocesses with a remote connectionto the laser using secure IT technology, TRUMPF Condition Monitoring,predictive maintenance, quality datastorage and dashboards for visualizing data.The programmable focusing optics(PFO) can be set up quickly andhas the right configuration for allmachining processes.VisionLine image processing isused to avoid defective parts.PL02100% constant process resultsThe Performance Level measures the reliability of the safetyfunction in accordance with EN 13849.eTop safetyclass.for most demanding quality expectationsWith its particularly robust design concept, the TruFiberwithstands disturbance factors and external stress and strain.The integrated laser power control measures and regulatesthe laser power in real time to 1% accuracy. The TruFiber hascomprehensive mechanisms for protecting the laser againstback-reflections.The TruFiber’s high level of safety is an invaluable feature. With PerformanceLevel e, the switching off/on times of the safety circuit EMERGENCY SHUTDOWNare guaranteed to be as low as 25 ms and 90 ms respectively.04A compact power packeasy to integrateOur TruFiber P compact Series belong to TRUMPF’s compactcategory of CW lasers and are available in a handy 19-inchrack format with laser powers of up to 2 kW. Machine andsystem engineers are responsible for the operational safetyof these laser systems.A dehumidification unit is optionallyavailable for use in tropical regions.The integrated laser power controlmeasures and regulates the laserpower precisely and steadily to thenearest 1%, regardless of the surrounding conditions.Are you interested? You can find out everything else about theTRUMPF fiber laser here: www.trumpf.com/s/nto43r

22Products – TruPulseLaser beam sourcesTruPulsePulsed solid-state lasers emit short, powerful bursts of light.That makes them perfect for spot and seam welding as well as cutting.05Short pulseswith greatvariability04Innovativetechnologydue to differentwaveformswith flexible controlof the pulse widthand peak power06Broadapplicationspectrumfor a great varietyof applications01100%constantpowerkeeps yourprocesses stable0203High-precision10 μs pulsesVersatile andeasy to maintainget the job done where others failthanks to its modular design

Laser beam sourcesTruPulse – Products230104100% constant powerInnovative technologykeeps your processes stablewith flexible control of the pulse width and peak powerReal-time laser power control ensures that the output powerreaching the workpiece matches your settings perfectly. Theresult: stable processes and reproducible results. This appliesto the entire service life of your laser – regardless of the surrounding conditions. And that makes the TruPulse the perfecttool for even the trickiest applications.The TruPulse nano laser is based on state-of-the-art fiber lasertechnology offering power levels of 20 to several 100 W.It offers integrators and users highly flexible control of bothpulse width and peak power. The unique PulseTune functionenables market-leading pulse repetition frequencies combinedwith simultaneous maintenance of peak power.05Short pulses with great variabilitydue to different waveformsStable processparameters are a mustwhen it comes to creating nonporous,heliumtight weldseams in pacemakers.Featuring up to 48 preprogrammed waveforms offering pulsesin the range of single-digit nanoseconds to microseconds.This enables pulse parameters to be perfectly optimized forindividual applications, which in turn raises process qualityand productivity.02High-precision 10 μs pulsesget the job done where others fail06Broad application spectrumfor a great variety of applicationsWith a pulse rate of 10 μs, the laser can closely match the actual pulse shape to the desired pulse shape. That means youalways get the graphically programmed shape combinedwith superior pulse-to-pulse stability. A pulse power of severalkilowatts for a few milliseconds makes welding and cuttingpossible in situations where other methods fail.03TruPulse nano lasers use a range of beam qualities, developedto maximize performance for a diverse range of applications:from patented welding techniques for dissimilar metals to drilling and microcutting to marking, engraving and cleaning –our short-pulse lasers provide the right parameters across theboard. These pulsed fiber lasers operate maintenance-free,enabling you to concentrate on the result, making time-consuming maintenance plans a thing of the past.Versatile and easy to maintainthanks to its modular designWith the TruPulse you benefit from a wide product portfolio.Thanks to the modular design, all its components can be repaired or replaced on site should the need arise. Equippedwith up to six laser outputs, the versatile TruPulse can serveone or more processing stations at a time through energy- ortime-sharing configurations.A great variety of products can be welded, regardless of their material, thicknessor the combination of different metals. With the short-pulse welding process,combinations of thin metal parts can be joined. This also includes highly reflective and conductive metals – perfect for applications such as battery welding.Thanks to theirmodular optical design,TruPulse lasers can beadapted to each andevery requirement.Visit our website if you would like to know more about the TruPulse:www.trumpf.com/s/ky1lnq

24Products – TruMicroLaser beam sourcesTruMicroShort and ultrashort laser pulses enable precisehigh-speed machining in all industrial sectors.0105Intelligentlaser controlCustomized pulsespulse duration, energyand wavelength forspecific applicationswith power modulatoraccurate to a single pulse04Complete flexibility02Minimal heat inputthanks to high peak pulse powerof ultrashort laser pulsesat all wavelengths andpulse durations03Easy integrationinto any production environment

Laser beam sourcesTruMicro – Products250103Intelligent laser controlEasy integrationwith power modulator accurate to a single pulseinto any production environmentSimply smart: The ultraquick power modulator maintains thepower and pulse energy at exactly the required level, regardlessof external factors. With pulse picking, adjustment of the rep etition rate with single-pulse precision (pulse on demand) andpulse-specific control of pulse trains (burst), pulse energy, andpulse intensity you always have the pulse you need. For idealresults at complex tasks – around the clock in industrial use.TruMicro lasers are inherently integration-friendly and havenumerous interfaces that facilitate integration into your production system. The fieldbus interfaces include Profibus, EtherCatand DeviceNet, so that your TruMicro is easily compatible withall standardized protocols. Standardized software interfaces(OPC UA) enable communication between laser and production system.04Complete flexibilityat all wavelengths and pulse durations10 µmThe high peak pulsepower of the shortand ultrashortpulse lasers arecapable of drillingprecise holes indelicate materials.Use the TruMicro short and ultrashort pulse lasers to get complete flexibility at your factory: Any pulse frequency for the TruMicro 2000 can be chosen using the linear amplifier regardless of the pulse energy used. The laser can be mounted horizontally or vertically and does not need a pump light cable. Furthermore, you can adjust the pulse duration almost infinitely to findthe perfect parameter for your application. With the TruMicroSeries 5000 you are working with infrared, green or ultravioletlight, either using picosecond or femtosecond pulses.02Minimal heat inputthanks to high peak pulse power of ultrashort laser pulsesWith pico- and femtosecond pulses, the intensities are so highthat the material is directly ionized. Precise processing withoutundesired heat influence is the result – this is known as coldmaterial removal. Even delicate materials can be processed reliably. Whether semiconductors, metals, plastics or brittle-hardmaterials: spatter, cracks and material bulging are a thing ofthe past.The TruMicro Serie 5000 offers the best parameters for your process. Choosea suitable combination from a variety of pulse durations, pulse energies andwavelengths.05Customized pulsespulse duration, energy and wavelength for specific applicationsPower and pulse energy – the pulses can be adapted to your requirements, for example, to achieve maximum stability throughour patented quadruple monitoring of the beam source – withthe pulse energy monitored for each individual pulse. The powercan be regulated from 2 to 100%, even during the process.Microdrillings with diameters of 80 µm in 0.1 mm thick glass. Precise holes ofthis type are generated by ultrashort laser pulses and are used, for example, tocreate connections between circuit layers in electronic components that areseparated by a glass layer (so-called through glass vias).You can find everything you need to know about the TRUMPF short andultrashort pulse lasers here:www.trumpf.com/s/ultrashortpulsedlasers

26Products – TruMarkLaser beam sourcesTruMarkTruMark lasers make it faster and easier than ever to achieve perfect marking results.They can create customized, permanent, high-quality markings on virtually any material.0104The freedomto chooseImmediate qualitycontrolin every waythanks to image processing02Easy integrationand automationthanks to a broad rangeof functions03Intuitive operationthanks to innovative solutions

Laser beam sourcesTruMark – Products270103The freedom to chooseIntuitive operationin every waythanks to innovative solutionsYou have access to the ideal solution for every power class – regardless of material, machining speed, wavelength and component geometries you wish to use. Depending on the application, fiber lasers with high average power, rod lasers with highpeak pulse power or ultrashort pulse lasers are used. You canalso use TruMark lasers for machining or cleaning surfaces, forexample in order to prepare surfaces for welding or adhesiveapplication or for optimizing tribological characteristics.TruMark lasers are easy, safe and quick to use, even for lessexperienced operators. This is ensured by intuitive operatingsoftware and innovative solutions for setting up processessuch as the pilot laser, the focus finder, the navigator or imageprocessing solutions for automatic positioning of markingson the workpiece. These enable you to productively, flexibly,and cost-effectively create first-class markings.Data Matrix Code(DMC) and cleartext for permanenttraceability inbatch production.The TruMark 5010is a compact,all-in-one solution.0204Easy integration and automationImmediate quality controlthanks to a broad range of functionsthanks to image processingWhether you’re looking to

Maximum beam quality thanks to disk technology Using a disk as a laser medium ensures brilliant beam quality - as low as 2 mm·mrad with TruDisk lasers. With a power spec-trum of 1 kW to 16 kW, you can achieve optimal results in a wide range of processes, from laser welding and cutting to laser