Transcription

Inspection of Shop FabricatedASTs per the SPCC RuleWayne B. Geyer, P.E.Steel Tank InstituteAA DivisionDivision ofof STI/SPFASTI/SPFA

“Few states have any certifications for ASTinstallers and it shows in the creativeways the tank systems are installed.”- John Cignatta, course instructor forSTI AST inspector certification

Review of 28 tanks at aMajor Facility Nearly 90% lackedadequate venting Over 50% lackedadequatecontainment Leaking tank Doorways in dikes No overfill alarms .

Review of 28 tanks at aMajor FacilitySpill ControlMissing itemNormal VentContainmentUL ListingOverfillEmergency VentSerious Other0204060% of tanks80100

Revised SPCC Rules References industrystandards– Tank inspection perAPI 653 or STISP001 Requires “IntegrityTesting”– Visual inspectionalone no longersufficient

Test Each AbovegroundContainer for Integrity Section 112.8(c)(6) On a regular schedule Combine visual inspection withanother testing technique– Hydrostatic testing – Radiographic testing– Ultrasonic testing– Acoustic emissions testing– Other nondestructive shell testing Frequently inspect the outside ofcontainer

Show me some tanks!!!

AST Standardsfor Shop Fabricated Tanks API - American Petroleum Institute UL - Underwriters Laboratories SwRI - Southwest Research Institute

API Specifications API 12F– “Specification for Shop Welded Tanks forStorage of Production Liquids”– Vertical, cylindrical only API 650, Appendix J– “Shop Assembled Welded Steel Tanksfor Oil Storage”– Vertical, cylindrical only

API Vertical Tanks

API Vertical-UL Horizontal Tanks

Underwriters Laboratories UL 142 “SteelAboveground Tanks forFlammable andCombustible Liquids” UL 2085 “ProtectedAboveground Tanks forFlammable andCombustible Liquids”

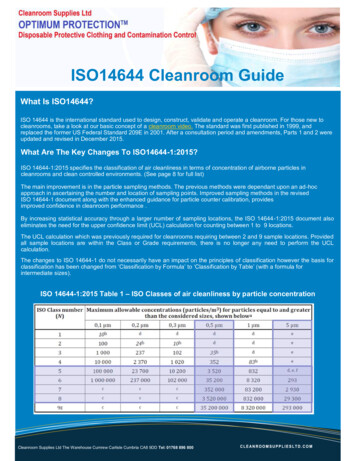

UL 142 Steel thickness

UL 142 type tanks

UL 142 type tanks

STI SP001-03Standard for Inspection ofIn Service ShopFabricated AbovegroundTanks for Storage ofCombustible andFlammable Liquids

How STI SP001 differs fromAPI 653 API 653 emphasis is the large, fieldconstructed tanks per API 650.– Strictly vertical tanks.– The bottom of the tank is not visible. API 653 requirements are neededbecause– Large volume– Large pressure

How STI SP001 differs fromAPI 653 API 650 includes equations forcalculating the steel thickness neededfor a particular tank. API 653 allows for / requires morejudgement by inspector

How STI SP001 differs fromAPI 653 Shop fabricated tanks– Tables that specify the steel thicknessbased on tank diameter and capacity.– Smaller capacities and smaller hydrostaticpressures– Capacity up to 50,000 gallons.– Manufactured in controlled shopenvironments

50,000 gallon tank

Corrosion concerns Check corrodedareas to findminimum thickness

Single wall tanks restingdirectly on the ground are aconcern!!

Periodic Inspection by tank owner Water inside tankVentsPipe connectionsExterior rinfueltanks.htm

Certified Inspection Performed by Qualified Tank Inspector– STI Trained and Certified– API Certified Every 10 Years All types of tanks (single and doublewall, on ground and elevated)

STI AST Inspector TrainingNEW for 2004 Level 1– Tank inspector Level 2– Tank systeminspector Michigan– May 24 - 28 New York– June 14 - 18 California– July 19 - 23 Tennessee– September 20 - 24

Level 2 – Tank System

STI Certified Inspection Tank type dictates inspection method:–Single wall not in contact withground–Single wall in contact withground–Double wall or double-bottom

Double wall or double-bottom Check leakdetection system Check for water orfuel in interstice

STI Certified Inspection UT Testing byscanning if possible– Most reliable methodfor determining wallthickness– Qualified UT inspectornecessary (ASNTSpecifications)

6. Certified Inspection Criteria Must compare remaining wallthickness to original thickness

STI SP031-04Standard for Repair ofIn Service ShopFabricatedAboveground Tanksfor Storage ofCombustible andFlammable Liquids

SP031 Repair Standard PatchesNew bottomsAdding openingsSupportmodifications Testing of repairs SupervisingPersonnel– STI inspectors– API inspectors Repair Personnel– Tank manufacturer– ASME welders– AWS welders

Not all that meets the eye!Tank owner surprises

Tank #1

Tank #1 No grounding anywhere Unsecured AST's in a flood plain (Not a single anchorbolt) Many Electric Code Violations Improperly Secured Conduits OSHA Access Issue on the back stairs and topplatform PVC Caps atop various nozzles (No Fire Rating forPVC) Labeling Issues

Tank #2

Tank #2 Unsupported Pipes Leaking SubmersibleTurbine Pump Combustible Materialsstored inside dike Kinked Flex Connector Poor Control on TankFilling Routine Spillage Improperly InstalledFuel Piping Conduits between fuelpipes in pipe trench No CP on buried fuelpipe runs Pipes and conduits tooclose in pipe trench Electric Code Violations Unsupported Conduits Missing Fire Diamonds

Tank #3

Tank #3 Unsupported conduits No fire diamonds Valve on Return Piping Improper labeling ofnozzles PVC Caps on various tanknozzles Flex Fuel lines secured toUnistrut with conduitclamps Normal vent on secondarytank's annular space No Vehicle DamageProtection (i.e., bollards) Tank not being stickedto check either ATGSaccuracy oraccumulation of water– Veeder-Root bottomwater floats can get hungup on shafts if rustymuck/mud forms inbottom)

Get the BIG picture first

From 20 feet away . Dirt spots on tank,fuel spilled? Coated forunderground? Tank next to river, isit anchored? Supports more than12 in. high? Enough openings ontop? Adequatecontainment? Paint condition? Level gauge visible? Condition offoundation?

Closer inspection Emergency ventcondition? Normal ventcondition? Weep holes? UseUV light here Adequate supports? Look inside tank, butwith proper trainingonly.

New STI StandardsCommitteeTo review inspection standardsSP001SP031

Does this Comply?

Inspection of TanksKeeps Things Happy

API 653 API 653 emphasis is the large, field constructed tanks per API 650. – Strictly vertical tanks. – The bottom of the tank is not visible. API 653 requirements are needed because –