Transcription

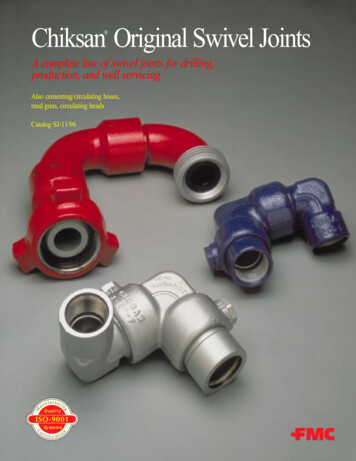

Chiksan Original Swivel Joints A complete line of swivel joints for drilling,production, and well servicingAlso cementing/circulating hoses,mud guns, circulating headsCatalog icatio

RedAlloy SteelFlanged ends faced and drilled to 150 lb flange specifications unless otherwise noted.Not available in Styles 80 or 10.3/8- to 4-inch sizes furnished with nitrile packing and brass or stainless steel anti-extrusion ring.6- to 12-inch sizes furnished with nitrile packing and stainless steel anti-extrusion ring.2- and 3-inch sizes available in Styles 30 and 40. 6- to 12-inch sizes available in all Styles except Style 20.Furnished with fluoroelastomer packing and stainless steel anti-extrusion ring. FMC does not warrant theperformance of any elastomer seal for sour gas service.7. Power make up must be used for line pipe threaded connections to achieve rated cold working pressure.8. 5-inch size available with threaded or beveled ends; limited to 3,000 psi cold working pressure.1.2.3.4.5.6.Weco figure1502 unionAlloy Steel20,00015,000Weco figure2002 union ,3NotesSour gas serviceFMC manufactures Chiksan sour gas swivel joints in accordance with the National Associationof Corrosion Engineers (NACE) Standard MR-01-75 and the American Petroleum Institute’s (API)Standard RP-14-E. These swivel joints are specially heat-treated and inspected for controlledhardness. Because the specially heat-treated steel required for sour gas service does not provide astrong enough bearing surface, Chiksan sour gas swivel joints use patented snap-in ball races toassure extra strength and high load-bearing capacity. Elastomeric packing is used to isolate theraces and bearings from line fluid. Weco figure1502 unionAlloy Steel15,000 Weco figure1502 union 43 21 2Weco figure1002 unionFemale linepipe threads Light Blue CF2Sizes, in. 11 2Female linepipe threads 11 4 1Female linepipe threadsRed 4 3Alloy Steel10,000Black 2 1 15,000Olive Green(Sour Gas)Alloy Steel 8 3Weco figure602 unionBeveled forweldingNPTNPTFlangedFlangedEndConnectionsWeco figure2202 union10,000Olive Green(Sour Gas)Alloy SteelCarbon SteelCarbon SteelCarbon SteelCarbon SteelDuctile IronCarbon SteelDuctile IronMaterialAlloy Steel7,500Olive Green(Sour Gas)6,000Silver10,0006,000Olive Green(Sour Gas)Black1,000Blue275Blue600175Dark GreenDark GreenCold WorkingPressure, psiColor CodeNotes All body materials meet ASTM or AISI standards. Consult factory for special sizes, styles, end connections, or packing units.Longsweep TripleStepSwivel JointsLongsweep Swivel JointsExtra High-PressureSwivel JointsHigh-PressureSwivel JointsLow-PressureSwivel JointsChiksan ModelsQuick Reference Chart

Chiksan Original Swivel JointsWhy you should standardize withChiksan Original Swivel JointsWidest selectionin the oilfieldChiksan swivel joints come in 3/8- to 12inch sizes and can handle pressures to 20,000psi. Sour gas models (see page 6) are limitedto 15,000 psi. Eight Chiksan styles or assembly configurations are available from stock.These styles (see page 4) can be combined inan unlimited variety of ways to suit practicallyany installation. End connections arethreaded, integral Weco wing union, beveledfor welding or flanged. Sour gas swivel jointshave Weco wing union end connections.Pressure-tight seals protectbearings from line fluidChiksan swivel joints come standardequipped with nitrile packing and bonded,brass anti-extrusion ring. 6- to 12-inch sizeshave stainless steel anti-extrusion ring. Theanti-extrusion ring serves as a retainer andbearing to reduce friction between the resilientpacking material and the packing chamber asthe joint is turned. These dynamic-sealpacking units protect ball races and bearingsfrom line fluid through the stated pressurerange, including vacuum or suction service, to225 F. Longsweep TripleStep models have asecondary O-ring seal which prevents minorleakage past the primary seal from contactingthe bearings. These swivel joints also have aleak detection port between the packing andO-ring seal. If leakage past the packingshould occur, it is forced through the leakdetection port, signalling the need for packingreplacement.Bearings key torotation, strengthTo assure long, dependable operation,Chiksan ball bearings are matched to loadingand service conditions. Although the size,type, and number of bearings vary, Chiksanlow-pressure, high-pressure, and extra highpressure swivel joints all have two rows ofbearings in each swivel and flame-hardenedball races. Longsweep and LongsweepTripleStep swivel joints have three rows ofbearings in each swivel for improved loadcapacities. All Longsweep and LongsweepTripleStep swivel joints for standard servicehave carburized and hardened ball races.Smooth, round boreminimizes flow restrictionsChiksan swivel joints have smooth, roundbores to minimize turbulence and keep pressure drop low. Longsweep and LongsweepTripleStep swivel joints have extra-long radiuselbows for even better flow characteristics andreduced chance of washout when handlingabrasives at extremely high pressures.Simple maintenanceOnly occasional light greasing with asmall, hand-held grease gun is required tokeep Chiksan swivel joints on the job. Ifpacking, bearings, or ball plugs should needreplacing because of leakage, field repair kitsare available. Easy-to-follow instructionscome with each repair kit.Table of ContentsChiksan Swivel JointsLow-Pressure Swivel Joints .High-Pressure Swivel Joints .Extra High-Pressure Swivel Joints .Longsweep Swivel Joints .Longsweep TripleStep Swivel Joints .Chiksan Styles and Component PartsLow- and High-Pressure Swivel Joints .Extra High-Pressure and Longsweep Swivel Joints .Sour Gas Service .Lubricants .Chiksan Swivel Joint SpecificaionsLow-Pressure Swivel Joints .High-Pressure Swivel Joints .Extra High-Pressure Swivel Joints .Longsweep Swivel Joints .Longsweep TripleStep Swivel Joints .Chiksan Cementing and Circulating Hoses .Chiksan Mud Mixing Guns .Chiksan Circulating Heads .How to Order .Warnings and Safety Instructions .2223345661788991011121213

Chiksan Original Swivel JointsLow-Pressure Swivel Joints175 psi (12 bar) to 1,000 psi (70 bar) cold workingpressure; 3/4- to 12-inch sizesRecommended serviceTransfer lines, temporary flow lines, discharge lines,auxiliary flow lines, water lines, and other general-serviceoilfield applicationsHigh-Pressure and ExtraHigh-Pressure Swivel JointsLow-Pressure Swivel Joint,Style 506,000 psi (414 bar) cold working pressure;3/8- to 4-inch sizes10,000 psi (690 bar) cold working pressure;2-inch sizeRecommended serviceHydraulic control lines, mud lines, rotary line connections, BOP lines, test lines, water lines, offshore wellheadconnections, cementing and circulating hoses, and chokeand-kill linesNOTE: Available for sour gas service at 6,000 psi(414 bar) cold working pressure; integral Weco wingunion end connections; consult factory for other endconnections, dimensions, and weights.High-Pressure Swivel Joint,Style 50Longsweep Swivel Joints7,500 psi (517 bar), 10,000 psi (690 bar), 15,000 psi (1034bar), and 20,000 psi (1380 bar) cold working pressure;1- to 4-inch sizesRecommended serviceLong-radius elbows designed especially forhigh-pressure sour gas abrasive applications such asfracturing, choke-and-kill lines, cementing and circulatinghoses, acidizing, and test linesLongsweep Swivel Joint,Style 50NOTE: Available for sour gas service at 7,500 psi (517 bar),10,000 psi (690 bar), and 15,000 psi (1034 bar) coldworking pressure; 1, 2, 3, and 4-inch sizes; integral Wecowing union end connections only.See Specifications Table (pages 7, 8, and 9) for styles, sizes, end connections, dimensions, and weights.2

Chiksan Original Swivel JointsLongsweep TripleStepSwivel Joints15,000 psi (1034 bar) cold working pressure;3-inch sizePatented seal meets allapplications from vacuum to20,000 psi, -50 F to 300 FAdded erosion allowanceunder ball races with noincrease in size or weightTeflon seal lasts up tofive times longer thanelastomer sealsRecommended serviceLong-radius elbows designed especially for highpressure abrasive applications such as fracturing,choke-and-kill lines, cementing and circulating hoses,acidizing, and test linesFeatures & Benefits“Stepped” ball race design: A patent pending “stepped”ball race design significantly increases bending and axialload capacities for greater strength, safety, and life.Additionally, the stepped design adds considerable wallthickness under the male ball races to increase erosionallowance.Patented Teflon seal: FMC’s world proven Straight-BoreTeflon* Seal (SBTS) provides unsurpassed sealabilityand lasts up to five times longer than elastomer seals.The SBTS is compatible with all known oilfield fluidsfrom vacuum to 20,000 psi, -50 F to 300 F (-46 C to149 C) and is impervious to chemical attack andexplosive gas decompression.New alloy steelprovides superiorhardnessPositive back-up seal protectsball races against operatingenvironmentsEnvironmental seal andhigh-performance greaseeliminate routine greasingAdvanced material selection: The TripleStep swiveljoint is manufactured from forged alloy steel with aclosely controlled, proprietary chemical composition andheat treatment to assure superior toughness, ductility, casedepth, case hardness, and core strength with no increasein size or weight.Longsweeep TripleStep Swivel JointEliminates routine maintenance: An improvedenvironmental seal reduces the potential for corrosion inthe ball race area. The integrity of the seal and the use ofa high-performance grease during initial assemblyeliminates the need for periodic greasing.See Specifications Table (page 9) for styles, sizes, end connections, dimensions, and weights.3

Chiksan Styles and Component PartsChiksan swivel joints are available fromstock in eight basic styles or configurations.These styles permit 360-degree rotation andmovement in one, two, or three planes. Theycan be combined in an unlimited variety ofways to suit practically any installation.All Chiksan swivel joints are assembledusing two or more standard pieces. Component piece numbers are shown here with thevarious Chiksan swivel joint styles.NOTE: Although Chiksan swivel joints canbe rotated while under fluid pressure, theyare not recommended for services requiringcontinuous rotary motion.Low-Pressure and High-Pressure Swivel JointsNo. 3 pc.No. 6 pc.No. 4 pc.No. 3 pc.No. 4 pc.Style 20Single swivel couplingNo. 1 pc.No. 5 pc.Style 40Single swivel with two elbowsStyle 30Single swivel with one elbowNo. 1 pc.No. 1 pc.No. 3 pc.No. 5 pc.No. 5 pc.No. 3 pc.Style 50Two swivels with two elbowsNo. 1 pc.No. 3 pc.Style 60Two swivels with one elbowNo. 2 pc.No. 1 pc.No. 5 pc.Style 70Two swivels with three elbowsNo. 2 pc.No. 3 pc.No. 3 pc.No. 5 pc.No. 3 pc.Style 80Three swivels with three elbowsStyle 10Three swivels with two elbows4

Chiksan Styles and Component PartsExtra High-Pressure Swivel JointsNo. 4 pc.No. 4 pc.No. 5 pc.No. 2 pc.No. 3 pc.No. 6 pc.No. 3 pc.Style 20Single swivel couplingNo. 3 pc.No. 4 pc.Style 30Single swivel with one elbowStyle 40Single swivel with two elbowsStyle 50Two swivels with two elbowsNo. 6 pc.No. 3 pc.No. 2 pc.No. 4 pc.No. 2 pc.No. 2 pc.No. 2 pc.No. 3 pc.No. 3 pc.No. 4 pc.No. 6 pc.No. 2 pc.No. 5 pc.Style 60Two swivels with one elbowStyle 70Two swivels with three elbowsNo. 2 pc.Style 80Three swivels with three elbowsStyle 10Three swivels with two elbowsLongsweep and TripleStep Swivel JointsNo. 4 pc.No. 5 pc.No. 4 pc.No. 4 pc.No. 2 pc.No. 2 pc.No. 6 pc.No. 3 pc.No. 3 pc.No. 3 pc.Style 30Single swivel with one elbowNo. 4 pc.Style 40Single swivel with two elbowsNo. 2 pc.Style 50Two swivels with two elbowsNo. 2 pc.No. 2 pc.No. 5 pc.No. 2 pc.No. 2 pc.No. 5 pc.No. 6 pc.No. 6 pc.Style 70Two swivels with three elbowsStyle 60Two swivels with one elbowStyle 80Three swivels with three elbows5No. 3 pc.Style 10Three swivels with two elbows

Sour Gas ServiceFMCmanufactures Chiksan sourgas swivel joints in accordance with theNational Association of Corrosion Engineers(NACE) Standard MR-01-75 and theAmerican Petroleum Institute’s (API)Standard RP-14-E. These swivel joints arespecially heat-treated and inspected forcontrolled hardness. Because the speciallyheat-treated steel required for sour gas doesnot provide a hard enough bearing surface,Chiksan sour gas swivel joints use snap-inball races (shown at right) for extra strengthand high load-bearing capacity. Elastomericpacking with stainless steel anti-extrusionring and secondary O-ring seal are used toisolate the races and bearings from line fluid.Sour gas swivel joints also have a leakdetection port between the packing and theO-ring seal. If leakage past the packingshould occur, it is forced through the port,signalling the need for packing replacement.For positive identification, all Chiksan sourgas swivel joints are stamped “Sour Gas”using low-stress dot stamping and paintedwith an olive green, zinc-chromate primerthat’s unique to sour gas equipment.Female snap-inracesFluoroelastomerpackingMale snap-inracesSecondaryO-ring sealChiksan Longsweep sour-gas swivel jointLubricants for Chiksan Swivel JointsLubricants for Chiksan swivel joints areformulated for year-r

FMC does not w arrant the performance of any elastomer seal for sour g as service. 7. Power make up must be used for line pipe threaded connections to achie ve rated cold working pressure. 8. 5-inch size available with threaded or be veled ends; limited to 3,000 psi cold w orking pressure. Sour gas service FMC manufactures Chiksan sour g as swivel joints in accordance with the National .