Transcription

Second EditionMechanicalWorkshopPracticeK.C. John

MECHANICALWORKSHOP PRACTICESECOND EDITIONK.C. JOHNProfessor and HeadDepartment of Production EngineeringVidya Academy of Science and TechnologyThalakkottukara, ThrissurKeralaNew Delhi-1100012010

MECHANICAL WORKSHOP PRACTICE, Second EditionK.C. John 2010 by PHI Learning Private Limited, New Delhi. All rights reserved. No part of this bookmay be reproduced in any form, by mimeograph or any other means, without permissionin writing from the publisher.ISBN-978-81-203-4166-1The export rights of this book are vested solely with the publisher.Second Printing (Second Edition).September, 2010Published by Asoke K. Ghosh, PHI Learning Private Limited, M-97, Connaught Circus,New Delhi-110001 and Printed by Rajkamal Electric Press, Plot No. 2, Phase IV, HSIDC,Kundli-131028, Sonepat, Haryana.

ContentsPreface . ixModule A: Introduction to Workshop Practice1. WORKSHOP PROCESSES . 3–341.1 Classification of Manufacturing Processes31.2 Primary Shaping Processes41.2.1 Metal Casting41.2.2 Rolling51.2.3 Forging61.2.4 Extrusion71.2.5 Metal Drawing81.2.6 Powder Metallurgy81.2.7 Oxy-Gas Cutting91.2.8 Press Work91.2.9 Sheet Metal Work111.2.10 Metal Spinning111.3 Secondary Shaping Processes111.4 Joining Processes141.4.1 Welding15iii

ivContents1.4.2 Brazing and Soldering171.4.3 Screwing181.4.4 Riveting191.4.5 Shrink Fitting201.4.6 Adhesive bonding201.5 Surface Finishing Processes211.6 Processes Changing the Material Properties211.6.1 Heat Treatment of Ferrous Metals221.6.2 Heat Treatment of Nonferrous Metals241.6.3 Cold Working of Metals251.6.4 Hot Working of Metals251.6.5 Shot Peening261.7 Materials for Workshop Practice261.7.1 Classification of Engineering Materials27Exercises322. WORKSHOP PRACTICE AND RECORD WRITING . 35–412.1 Workshop Processes for Practice352.2 Safety Measures362.3 Preparing for the Workshop Practice382.4 Writing of the Work Record382.4.1 Writing of Work Record for a Study382.4.2 Writing of Work Record for a Practice392.5 Writing of the Fair Record40Exercises41Module B: Hand Working Processes3. FITTING . 45–753.1 Introduction to Bench Work and Fitting453.2 Work Holding Devices473.2.1 Work Bench473.2.2 Bench Vice473.2.3 Hand Vice483.2.4 V-block with Clamp483.3 Cutting Tools493.3.1 Files493.3.2 Hack Saw513.3.3 Chisels523.3.4 Hammers533.3.5 Scrapers543.3.6 Drills and Reamers543.3.7 Taps and Dies56

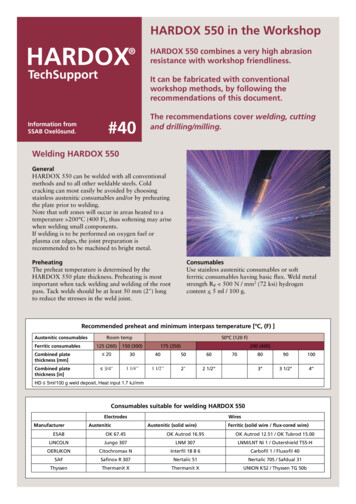

vContents3.4Measuring and Marking Tools573.4.1 Surface Plate573.4.2 Engineer’s Try Square573.4.3 Scribers583.4.4 Punches583.4.5 Steel Rule593.4.6 Vernier Caliper593.4.7 Outside and Inside Calipers603.4.8 Dividers613.4.9 Combination Set613.4.10 Micrometer623.4.11 Vernier Height Gauge623.4.12 Miscellaneous Gauges633.5 Tools for Assembling633.5.1 Spanners633.5.2 Pliers643.5.3 Screw Drivers643.5.4 Allen Keys643.6 Fitting Processes653.6.1 Marking Out653.6.2 Hack Sawing653.6.3 Chipping663.6.4 Filing663.6.5 Scraping673.6.6 Drilling and Reaming683.6.7 Tapping and Dieing693.6.8 Assembling693.7 Models for Fitting Practice70Exercises724. ARC WELDING . 76–944.1 Principle of Shielded Metal Arc Welding764.1.1 Arc Welding Principle764.1.2 Power Supply774.1.3 Welding Positions784.2 Welding Electrodes794.3 Arc Welding Equipment and Accessories804.3.1 Welding Equipment804.3.2 Operator Accessories824.4 Types of Welds824.4.1 Types of Welded Joints834.4.2 Edge Preparation844.4.3 Number and Arrangement of Runs84

viContents4.54.64.7Welding Symbols84Defects in Weld86Welding Practice874.7.1 Welding Procedure884.7.2 Striking and Maintaining the Arc4.7.3 Tack Welding894.7.4 Weaving the Electrode894.7.5 Safety Precautions90Exercises92885. SHEET METAL WORK . 95–1095.1 Metals Used955.2 Hand Tools975.2.1 Measuring Tools975.2.2 Marking Tools975.2.3 Cutting Tools985.2.4 Forming Tools985.2.5 Joining Tools1005.3 Sheet Metal Operations1005.3.1 Laying Out of Patterns1015.3.2 Cutting or Shearing1015.3.3 Bending and Forming1025.3.4 Drawing1025.3.5 Edge Forming1025.3.6 Joint Making1025.3.7 Soldering1045.3.8 Riveting1045.4 Sheet Metal Work Practice104Exercises1066. CARPENTRY .6.1 Materials Used in Carpentry1106.1.1 Timber1106.1.2 Classification of Wood1116.1.3 Indian Timber1126.1.4 Plywood1126.1.5 Auxiliary Materials1136.2 Tools for Wood Working1136.2.1 Measuring and Marking Tools1146.2.2 Cutting Tools1166.2.3 Striking Tools1176.2.4 Planing Tools1186.2.5 Work Holding Devices1196.2.6 Miscellaneous Tools121110–133

viiContents6.3 Wood Working Processes6.4 Carpentry Joints1266.5 Wood Working Machines6.6 Carpentry Practice129Exercises1311221277. BLACKSMITHY . 134–1477.1 Principle of Smithing and Forging1347.2 Heating Equipment1347.3 Tools and Appliances1357.3.1 Work Supporting Tools1357.3.2 Hammers1377.3.3 Tongs1377.3.4 Metal Shaping Tools1387.3.5 Measuring Tools1387.4 Heating of Metal1397.5 Forging Operations1397.5.1 Upsetting or Jumping1397.5.2 Drawing Out or Drawing Down1407.5.3 Punching and Drifting1417.5.4 Bending and Twisting1417.5.5 Setting Down and Finishing1417.5.6 Cutting1427.6 Smithing Practice1437.6.1 Smithing Procedure1437.6.2 Safety Measures143Exercises1458. FOUNDRY . 148–1648.1 Introduction to Metal Casting Processes1488.1.1 Sand Casting Process1488.1.2 Sand Mould1498.2 Patterns1508.2.1 Types of Patterns and Core Boxes1508.2.2 Pattern Allowances1528.2.3 Pattern Making1528.3 Tools and Equipment for Hand Moulding1528.4 Hand Moulding1548.4.1 Moulding Sand and Its Preparation1558.4.2 Bench Moulding1568.5 Melting and Pouring1578.6 Moulding Practice159Exercises161

viiiContents9. PLUMBING . 165–1999.1Introduction1659.2Pipes and Their Joints1669.3Pipe Fittings1679.4Valves and Meters1709.5Plumping Fixtures (Sanitary fittings)1759.6Sketching of Piping Layouts1789.7Water Supply System1799.8Rain Water Disposal System1809.9Sewage/Wastewater Disposal System1819.10 Plumbing for Industries1849.11 Plumber’s Tools1869.12 Accessories for Plumbing1899.13 Plumbing Practice190Exercises197Module C: Machining Processes10. TURNING . 203–22010.1 Introduction to Turning20310.1.1 Principle of Turning20310.1.2 Metal Cutting and Chip Formation20410.1.3 Cutting Speeds for Turning20510.1.4 Types of Turning Machines20610.2 Centre Lathe (Engine Lathe)20710.3 Accessories and Attachments21110.4 Tools for Measuring and Machining21310.4.1 Measuring and Marking Tools21310.4.2 Cutting Tools21410.5 Turning Operations21610.6 Turning Practice217Exercises218APPENDIX . 221–227SUGGESTED READING . 229INDEX . 231–233

PrefaceIn the modern engineering curriculum, with the emphasis on engineering science,workshop and laboratory practices have acquired greater importance in the recentyears. With major advancements in precise instrumentation and computerizedmanufacturing techniques, the same has become more sophisticated and specializedfield. To gain a basic knowledge of manufacturing process, a student entering the firstyear of degree or diploma must undertake a course on workshop practice. This giveshim/her an overall knowledge about various engineering materials, tools, equipmentand processes which are common in the engineering field. Multiple requests from mystudents and colleagues for a good supporting textbook were my motivation to writethe book Mechanical Workshop Practice.The favourable and warm reception of first edition of the book “MechanicalWorkshop Practice” gave me satisfaction and encouragement to bring out the secondedition. I have utilized this opportunity to revise the book little and add one chapteron Plumbing.This book consists of three modules. Module A is an introduction to workshoppractice. Its first chapter explains general principles and layout of workshop processessuch as primary and secondary shaping processes, metal joining methods, surfacefinishing, heat treatments and the materials for workpieces and tools. The secondchapter describes the importance of safety measures to be followed as well as theprocedure of writing the work and fair records of the practice.Module B deals with the hand working processes such as fitting, arc welding, sheetmetal work, carpentry, blacksmithy and foundry. Each chapter in this module initiallyix

Mechanical Workshop Practice25%OFFPublisher : PHI LearningISBN : 978812034 1661Author : JOHN, K. C.Type the URL : http://www.kopykitab.com/product/74 78Get this eBook

the book Mechanical Workshop Practice. The favourable and warm reception of first edition of the book "Mechanical Workshop Practice" gave me satisfaction and encouragement to bring out the second edition. I have utilized this opportunity to revise the book little and add one chapter on Plumbing. This book consists of three modules.