Transcription

White PaperOctober 2021Keywords:Analytical Weighing, United States Pharmacopeia,USP 41 , USP 1251 ,European Pharmacopoeia Chapter 2.1.7.Use of laboratory balancesin the pharmaceutical industryChapters 41 and 1251 of the United States Pharmacopeia (USP)Chapter 2.1.7. of the European Pharmacopoeia (Ph. Eur.)Axel Taube, Dr. Ellen Hage, Dr. Julian Haller, Niclas LudolphSartorius Lab Instruments GmbH & Co. KG, Otto-Brenner-Strasse 20, 37079 GoettingenCorrespondenceEmail: metrology@sartorius.comAbstractPharmacopoeias are collections of recognized and binding quality regulations that specify, among other things, testrequirements and methods for the analysis of drugs. Both the European Pharmacopoeia (Ph. Eur.) and the United StatesPharmacopeia (USP) contain specific chapters that deal with the use of laboratory balances. The chapters emphasize thecriticality of weighing samples accurately in pharmaceutical analytical processes.The aim of this white paper is to present the testing requirements for laboratory balances as described in the relevantchapters of the pharmacopoeias and the associated certificates offered by Sartorius Service.Find out more: www.sartorius.com

United States Pharmacopeia (USP)requirementsThe United States Pharmacopeia Convention is a scientificand non-governmental organization through whichstandards for drugs and related products are set in theUnited States. The United States Pharmacopeia (USP) (1),published annually, is the official pharmacopeia for theUnited States of America. It deals with the use of laboratorybalances in two places. Firstly in Chapter 41 "Balances",and secondly in Chapter 1251 "Weighing on an AnalyticalBalance".The requirements of Chapter 41 are mandatory forweighing applications where "accurate weighing" isrequired. Compliance is checked as part of cGMP audits bythe Food and Drug Administration (FDA). Failure to complywill result in audit discrepancies.Chapter 1251 , on the other hand, like all USP chaptersfrom 1000 to 1999, is informal in nature, i.e., it providesimportant suggestions. However, the implementation ofthe recommendations made on the testing and use ofbalances is voluntary.Chapter 41 of the United StatesPharmacopeiaChapter 41 describes specific criteria for all balancesused for the "accurate sample weighing" of materials.The objective of Chapter 41 is to ensure that the errorintroduced by the weighing application for "accuratelyweighed" material is reduced to an acceptable or negligiblelevel, thereby ensuring that the effect on the total errorremains manageable. The respective chapters on themanufacture of medicinal products or ingredients explicitlystate if and which substances must be "accurately weighed"within the meaning of the USP and thus if thecorresponding balance must comply with therequirements set out in Chapter 41 .USP Chapter 41 contains three specific requirementsfor balances. Firstly, balances must be calibrated over theentire working range. In addition, they must meet tolerancerequirements for testing repeatability and accuracy.The repeatability test is used as a basis for checking if the"desired smallest net sample weight" can be made withinthe tolerance requirements of the USP.2CalibrationUSP Chapter 41 requires that accurate weighing ofsamples must be performed only on balances that arecalibrated over the entire working range. However, howand in which cycles the calibration has to be performed isnot more closely defined. Sartorius recommends regularcalibration in every case, based on the criticality of theapplication (see also the separate white paper "Testintervals and tolerances" (2)). The calibration result shouldbe documented in every case in a calibration certificate.Calibration certificates from accredited providers offer thegreatest possible security here, as they have a high level ofinternational recognition and ensure traceability of themeasurement results to national standards. See also theseparate white papers "Calibration certificates fromaccredited suppliers" (3), "The calibration certificateaccording to EURAMET cg-18" (4) and "Calibrationguideline EURAMET cg-18" (5).Repeatability and minimum sample weightThe repeatability requirement limits the weighing rangeto a usable working range by defining a minimum sampleweight. Weighing must not be carried out below theminimum sample weight.Repeatability testing is performed by weighing a test weightat least ten times. The weight of the test weight must bewithin the working range of the balance, but does not haveto be calibrated according to Chapter 41 . Similarly,repeatability as per USP Chapter 41 does not explicitlyrequire the use of a small weight because it is assumed thatrepeatability is independent of the test load used. Chapter 41 only requires that the test load be within the workingrange (i.e. not less than the minimum sample weight). Forpractical reasons (as for all repeatability measurements),Sartorius still recommends selecting a one-piece test loadhere if possible. On this point, the requirement set out inUSP Chapter 41 differs from the recommendation inChapter 1251 . Here it is recommended that the size of thetest weight for the repeatability test should not exceed afew percent of the weighing range of the balance.

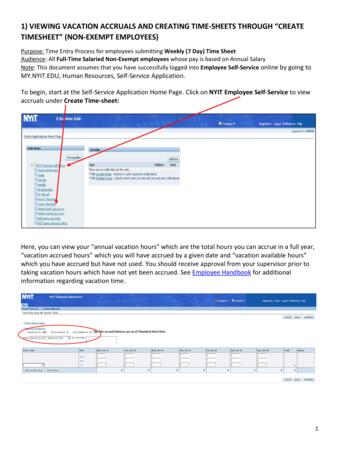

Repeatability is considered satisfactory if two times thestandard deviation of the measured values divided bythe smallest net weight to be weighed on the balance("desired smallest net weight") is not greater than 0.10%.The standard deviation as the result of the repeatabilitymeasurement is therefore set in relationship to the desiredsmallest net sample weight. If the USP requirement isfulfilled for the "desired smallest net sample weight",this ensures that the USP tolerance requirement forrepeatability is also fulfilled for each initial sample weightabove this value, since the relative error becomes smallerand smaller as the sample weight increases. The generalrounding rule of the USP should be noted in this context:The result is first rounded to the number of digits of theacceptance criterion. With the acceptance criterion of0.10% specified here, a result of e.g. 0.1049% is roundeddown to 0.10%, so the repeatability test is thereforeconsidered to have been passed in this case. On the otherhand, if the result is 0.1050%, the balance is rounded up to0.11%, so that in this case the balance does not pass therepeatability test.The repeatability test therefore restricts the working rangeof the balance downwards (see also separate white paperon the subject of minimum sample weight (6)). The smallestpossible sample weight on a balance, or minimum sampleweight (M), is 2000 times the standard deviation of therepeatability measurement; it represents the start of theworking range of the balance. Thus, if the standarddeviation s is, for example, s 0.00015 g, the smallestpossible sample weight M is M 0.3000 g 300 mg.USP chapter 41 defines another criterion if a standarddeviation s is very small. This relates to the scale interval (d)of the balance and states that if the standard deviations 0.41 d, the minimum load is 2000 x 0.41 d. The minimumsample weight is therefore limited to the smallest possiblevalue of 820 d. For a four-digit analytical balance withd 0.0001 g, for example, this means that the minimumsample weight can never be less than 0.0820 g or 82 mg.each test, setting the "desired smallest sample weight" tothe minimum sample weight would mean that the sampleweight that can be determined on a balance would changewith each test. For example, if users obtain the standarddeviation of s 5 μg in a repeatability measurement and setthe minimum sample weight for their balance to 2000 xs 10 mg accordingly, they run the risk that in a subsequentrepeatability measurement where the standard deviationchanges to, say, s 8 μg, the minimum sample weight willincrease to 2000 x s 16 mg. If, after the first measurement,weighing was carried out down to the minimum sampleweight, it would be questionable whether precedingweights between 10 mg and 16 mg complied with therequirements of the USP. It is therefore recommended,as also described in USP Chapter 41 , that the "desiredsmallest net sample weight" be determined by the useraccording to laboratory requirements and validated duringrepeatability testing.On balances used under USP regulations, the validated"minimum desirable net sample weight" should be clearlymarked. Some Sartorius balances allow you to enter this inthe service menu. Net sample weights below the "minimumdesirable net sample weight" are then displayed with awarning symbol.It should also be reiterated here that the mass of the tarevessel is not taken into account for the minimum sampleweight. This means that the minimum sample weightapplies over the entire weighing range of the balance,regardless of the tare load. As such, placing a weighingvessel on the balance precludes weights below theminimum sample weight; rather, the net weight of eachsample must be equal to or greater than the minimumsample weight, regardless of the tare weight.Since the repeatability is significantly influenced by theconditions at the place where the balances are installed,the test must be performed at the place of installation andshould be checked regularly.It is generally not advisable to adjust the "desired smallestsample weight" to the minimum sample weight valueresulting from the last repeatability measurement; instead,this should always be defined on the basis of the actuallaboratory requirements. As standard deviation is astatistical quantity and is subject to slight variations inFigure 1: Analytical weighing on a Cubis II balance.3

AccuracyThe accuracy requirement from Chapter 41 is a generalrequirement, i.e. if the requirement for accuracy is not met,the balance in its current state is not suitable for theaccurate weighing of sample substances.According to USP Chapter 41 , the accuracy of a balanceis sufficient if the weight value indicated by the balance iswithin 0.10% of the "true" test weight value when testedwith one or more suitable weights.A test weight is suitable if it has a mass between 5% and100% of the maximum load for the balance, and if themaximum permissible error (MPE) of the test weight doesnot exceed one third of the applied test limit for theaccuracy test (i.e. 0.033%). The test weight requirementis independent of the scale interval (d) of the balance.Specifically, for example, for a 5 g test weight, therequirement means that the error must not exceed0.00167 g (1.67 mg). According to the error limits of OIMLR111, test weights of accuracy class F₂ still meet thisrequirement (for weights 1 g). Here, an MPE of 0.5 mgapplies for a test weight of 5 g. According to ASTM E-617tolerances, test weights of accuracy class 4 safely meet therequirements (here, a 5 g weight of accuracy class 4 has apermissible MPE of 0.36 mg). Since the USP requirementfor test weights is formulated in relative terms, therequirements for small test weights are very strict. However,for test weights of 0.5 g, weights of classes E₂ and F₁ canbe used without any problems. For practical reasons,Sartorius recommends selecting a one-piece test loadhere as well, if possible.Sartorius USP 41 certificateWith a Sartorius USP 41 certificate, you receive acertificate showing equipment testing to USP Chapter 41 .On the first page, in addition to the customer andequipment data, the calibration status of the balance islisted with the last calibration date and calibrationcertificate number, if this information is known.The outcome of the repeatability and accuracy checkis also clearly displayed in one block of results. Whetherthe customer's "desired smallest net sample weight" hasbeen met is specified. In addition, the working range ofthe balance (minimum sample weight to maximum load)is listed.The test location is named on the second page. Theimportant thing to note here is that the measurement isonly valid at this location. When changing the location ofthe device, it is mandatory to repeat the test as describedabove. Also listed on the second page are the testequipment used and the accuracy class according to OIMLR111 or ASTM E-617. Furthermore, all measured values andthe evaluation are documented here again.4On the third page, the working range of the balance andthe desired smallest net sample weight are graphicallydisplayed in a double-logarithmic diagram. This makes itpossible to identify quickly and easily whether the desiredsmallest net sample weight is within the working rangedefined by the USP requirements. If the desired smallestnet sample weight is within the working range, the samplecan be weighed safely under USP conditions.Note: Premium balances from the Cubis series support theverification of the minimum sample weight according toUSP 41 , using a dedicated APP.Figure 2: Indication of the minimum sample weight for a Cubis seriesbalance.Chapter 1251 of the United StatesPharmacopeiaChapter 1251 of the USP is entitled "Weighing on anAnalytical Balance" and contains detailed information onthe qualification and operation of electronic balances.In the introduction, it is explicitly stated that therecommendations are not only valid for balances on which"accurate sample weighing" is performed, but for allbalances used in settings where analytical proceduresare performed.Many of the recommendations mentioned in chapter 1251 are of a rather general nature, as also described inthe Sartorius white paper "Reliable Weighing Results" (7).The following, therefore, focuses specifically on therecommended "Performance Qualification" test.Performance QualificationThe "Performance Qualification" section sets out specificmetrological tests and tolerances against which balancesshould be tested on a regular basis. The test frequencyshould be based on the criticality of the application, i.e. itshould be risk-based (see also the separate white paper"Test intervals and tolerances" (2)).

---Specifically, four performance tests are recommended forevaluating a balance:SensitivityLinearityEccentricity errorRepeatabilitySensitivity, linearity, and eccentricity errors all contributeto the systematic deviation of a balance, thus limiting itsaccuracy. The testing of these parameters representsgeneral requirements, i.e. if the set requirements are notmet, the balance is not suitable for use. Provided thataccurate weighing is carried out on balances in accordancewith USP Chapter 41 , an acceptance criterion of 0.05%applies to the above tests. For weighing in otherapplications, the acceptance criterion can be defined bythe customer.As in Chapter 41 , the maximum permissible error (MPE)of the test weight must not exceed one-third of the appliedtest limit (i.e. 0.016% in this case), which specifically meansthat for test weights of 0.5 g, tests can be performedwith weights of accuracy classes F₂ (OIML R111) or better.When using test weights of 0.5 g, the requirement maynot be met.The fourth recommended repeatability test, like therepeatability test in Chapter 41 , restricts the workingrange of the balance downward to a minimum sampleweight.The general rounding rule of the USP must also beobserved for these tests, in which the result is first roundedto the number of digits of the acceptance criterion and onlythen is the comparison made with the acceptance criterion.SensitivityBefore testing the sensitivity, a balance should always becalibrated (if possible with an internal calibration weight).When testing sensitivity, a test weight is placed on thebalance once. If possible, the test should be performed witha one-piece weight in the range of the maximum load.The Sartorius recommendation here is to use a test weightwith min. 80% of the maximum load. For a balance witha maximum load of 120 g, this means a test with a 100 gtest weight.EccentricityIn the eccentricity test, a test weight is placed on theweighing pan, first in the center and then in four off-centerpositions. If possible, the test should be performed witha one-piece weight at a minimum of 30% of the max.The test is performed in the same way as for the calibrationaccording to EURAMET-cg-18 (see separate white paper):"Calibration Guideline EURAMET cg-18 (5)).The largest deviation of the weight value in an off-centerposition from the center load must not exceed theacceptance criterion (0.05% for balances on whichaccurate weighing is performed). This means, for example,no more than 0.025 g when using a 50 g test weight.LinearityWhen testing linearity, a load value is applied to the balanceat several points over the entire weighing range. Linearitydescribes the proportionality between the applied loadsand the displayed values. The test is performed in the sameway as for the drafting of a balance test report and is setout in the separate white paper "Testing and evaluatingbalances against different tolerance requirements" (8).The deviation from the linearity characteristic curve mustnot exceed the acceptance criterion (0.05% for balanceson which accurate weighing is performed) at any test pointduring this test. This test is therefore sensitive, especially inthe lower weighing range of the balance.RepeatabilityThe repeatability test under Chapter 1251 is identical tothe repeatability test under Chapter 41 . However, there isa difference in the choice of the test weight. Chapter 1251 explicitly requires a small test weight here ( 10% of max).Sartorius recommends a one-piece test weight here. Forcritical applications, a typical tare object (container, vessel,etc.) can be placed on the weighing pan as a pre-load fortesting.Sartorius USP 1251 certificateThe Sartorius USP 1251 certificate documents compliancewith the acceptance criteria as described in chapter 1251 of the USP.The deviation between the weight value of the test weightand the displayed value of the balance must not exceed theacceptance criterion (0.05% for balances on whichaccurate weighing is performed). For the above examplewith a 100 g test weight, the display rounded to two decimalplaces must therefore be between (and including) 99.95 gand 100.05 g for the test to be passed.5

Requirements from chapter 2.1.7.of the European PharmacopoeiaThe European Pharmacopoeia (Ph. Eur.) (9) containsstandards for the quality control of medicinal products.In the "Convention on the Composition of a EuropeanPharmacopoeia," the contracting states undertake"to take the necessary measures to ensure that themonographs adopted on the basis of Articles 6 and 7, whichwill constitute the European Pharmacopoeia, constituteofficial standards applicable within their territories."To ensure traceability of the measurement results aftermaintenance or adjustment work, repairs or a change oflocation of the balance, performing an input (as found)calibration is explicitly required before this work. Sartoriusoffers input (as found) calibrations for all calibrations.Both the input (as found) and output (as left) calibrationsare documented in a calibration certificate. See also theseparate white papers "The calibration certificate accordingto EURAMET cg-18" (4) and "Calibration guidelineEURAMET cg-18" (5).Chapter 2.1.7. entitled "Balances for analytical purposes”,which first appeared in Supplement 10.6 (07/2021) to thePh. Eur., describes principles for the use of balances usedin analytical procedures. In explicit terms, weighingprocedures performed as part of tests designed todetermine compliance with a monograph must beperformed in accordance with the principles set forthin this chapter.Performance testingThe purpose of performance testing is to determine therandom and systematic error of a balance and thus verifythe precision and accuracy of the balance. Twoperformance tests are required in this context as perChapter 2.1.7: firstly, repeatability, to check the precision ofthe balance, and secondly, sensitivity, to check the accuracyof the balance. Before testing the sensitivity, a balanceshould always be adjusted (if possible with the internaladjustment weight).Many of the recommendations are of a general nature,as also described in the Sartorius white paper"Reliable Weighing Results" (7).For the tests according to Ph. Eur., the result is first roundedto the number of digits of the acceptance criterion and onlythen is the comparison with the acceptance criterion made.Equipment PerformanceBalances must be calibrated regularly in accordance withChapter 2.1.7. and checked by conducting performancetests between calibrations to ensure compliance withpredefined requirements. The user must define thefrequency of calibrations and tests in the qualitymanagement system. Sartorius recommends matching thefrequency to the criticality of the application (see also theseparate white paper "Test intervals and tolerances" (2)).RepeatabilityWhen weighing small quantities, the measurementuncertainty of the balance is determined in particular by therandom error. This is estimated by specifying the standarddeviation. The repeatability test from Chapter 2.1.7. is largelyidentical to the repeatability test described in USP Chapter 41 . The only significant difference is the test load to beused. In accordance with Chapter 2.1.7. of the Ph. Eur., thisshould be 5% of max but at least 100 mg.CalibrationCalibration by the user or a suitable service providermust be performed regularly according to Chapter 2.1.7.The aim of calibration is to ensure the traceability of themeasurement results to national standards. In this case,Sartorius recommends calibration by a calibrationlaboratory accredited to ISO IEC 17025, as its calibrationcertificates are internationally recognized as proof oftraceability (see also the white paper "Calibrationcertificates from accredited providers" (3)).When determining the standard deviation, the test weightis weighed at least ten times in succession, with the balanceset to zero between each weighing.Balance typeScale interval (readability), dPrecision balances 10-1 g to 10-3 g 100 mg to 1 mg 0.1 g to0.001 gAnalytical balances 10-4 g 0.1 mg 0.0001 gSemi-micro balances 10-5 g 10 µg 0.01 mg 0.00001 gMicro balances 10-6 g 1 µg 0.001 mg 0.000001 gUltra-micro balances 10-7 g 0.1 µg 0.0001 mg 0.0000001 gTable 1: Balance types according to Chapter 2.1.7. of the EuropeanPharmacopoeia (9).6

As in USP Chapter 41 , repeatability is consideredsatisfactory in European Pharmacopoeia Chapter 2.1.7.if two times the standard deviation of the measured valuesdivided by the smallest net weight (msnw smallest netweight) to be weighed on the balance is not greaterthan 0.10%.2 smsnw 100 0,10In the case of a standard deviation of 0.41 d, the standarddeviation is also replaced here by 0.41 d, so that even underthe European Pharmacopoeia the minimum sample weightmsnw on a balance cannot go below 820 d.SensitivityThe accuracy of the balance is checked when testing thesensitivity. Since accuracy is also affected by linearity andeccentricity, an acceptance criterion of 0.05% applies tosensitivity testing, while linearity and eccentricity testingmay be omitted.As with the accuracy test in USP Chapter 41 , thesensitivity test is a general requirement, i.e. if therequirement is not met, the balance is not usable in itscurrent state.During the test, a one-piece test weight of 5% of the maxis placed on the balance once. If the deviation is in therange of 0.05%, the test is considered to have beenpassed. The accuracy requirements for the test weight areidentical to the requirements of Chapter 41 of the USP,i.e. test weights of accuracy classes F₁ (according to OIMLR111) or Class 4 (according to ASTM E-617) are generallysufficient here as well.Use of internal test weightsChapter 2.1.7. of the European Pharmacopoeia explicitlyrecommends the use of internal calibration/adjustmentequipment, which most modern laboratory balances havetoday. Their use can reduce the frequency of sensitivitytests with external reference weights. This explicitlyspecifies that when using internal calibration/adjustmentequipment, a daily sensitivity check using an externalreference weight is not required. Nevertheless, Chapter2.1.7. recommends performing a sensitivity test with anexternal test weight on a regular basis in order to detectpossible problems with the integrated weights.Sartorius Ph. Eur. 2.1.7. certificateA certificate documenting compliance with the acceptancecriteria according to Ph. Eur. 2.1.7. will be available frommid‑2021.Figure 3: Weighing out the smallest amounts of substances on a microbalance.7

-Sartorius RecommendationBalances used in the pharmaceutical field for analyticalprocedures must be checked according to the provisionsof Chapter 41 of the USP or Chapter 2.1.7 of theEuropean Pharmacopoeia.Balances must be calibrated regularly. Accreditedcalibration, which allows traceability of the weighingresults to national standards, is strongly recommended.This white paper is part of the white paper bundle"Best Practice Guide: Lab Weighing”. To be able todynamically add updates and corrections and at the sametime giving users as clear a reference as possible, forexample in their QM documentation, versions are provided.Version historyVersionDateChanges1.0March 2021Initial version1.1October 2021Correction of typosBibliography1. United States Pharmacopeia and National Formulary(USP 43 - NF38); 2019.2. Sartorius white paper: Testing intervals and tolerances(how are testing intervals and tolerances definedpractically and on the basis of risk), 2021 (planned).GermanySartorius Lab Instruments GmbH & Co. KGOtto-Brenner-Strasse 2037079 Göttingen, GermanyPhone 49 551 308 0F or further information, visitwww.sartorius.comSpecifications subject to change without notice.Copyright Sartorius Lab Instruments GmbH & Co. KG.Status: 10 2021--Determine a minimum sample weight that is alsoadhered to with the following provisions and have itchecked regularly.The smallest sample to be weighed on the balance shouldbe clearly documented on the balance.Performance tests should be carried out regularly by theuser between calibrations. These should be based on thecriticality of the application.3. Sartorius white paper: Calibration certificate fromaccredited providers (what advantage does ouraccreditation offer the user), 2021.4. Sartorius white paper: The calibration certificateaccording to EURAMET cg-18 (understandingcalibration certificates and applying results in practice),2021 (planned).5. Sartorius white paper: Calibration guidelineEURAMET cg-18 for electronic, non-automaticbalances (specifications, options and implementationof the guideline by Sartorius), 2020.6. Sartorius white paper: Lowest sample weight accordingto USP 41 , OIML R76 and EURAMET cg-18 (how largeshould the lowest sample be, in order to achievereliable weighing results?), 2020.7. Sartorius white paper: Reliable Weighing Results(How to Correctly Handle Laboratory Balances andSamples), 2020.8. Sartorius white paper: The Sartorius balance testcertificate (tests against manufacturer or customertolerances), 2020.9. European Pharmacopoeia; 2021.USASartorius Corporation565 Johnson AvenueBohemia, NY 11716Phone 1 631 254 4249Toll-free 1 800 635 2906

Sartorius USP 41 certificate With a Sartorius USP 41 certificate, you receive a certificate showing equipment testing to USP Chapter 41 . On the first page, in addition to the customer and equipment data, the calibration status of the balance is listed with the last calibration date and calibration