Transcription

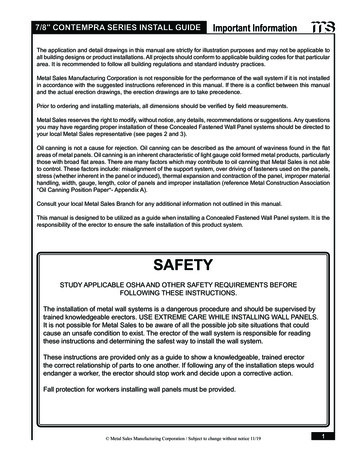

7/8" CONTEMPRA SERIES INSTALL GUIDEImportant InformationThe application and detail drawings in this manual are strictly for illustration purposes and may not be applicable toall building designs or product installations. All projects should conform to applicable building codes for that particulararea. It is recommended to follow all building regulations and standard industry practices.Metal Sales Manufacturing Corporation is not responsible for the performance of the wall system if it is not installedin accordance with the suggested instructions referenced in this manual. If there is a conflict between this manualand the actual erection drawings, the erection drawings are to take precedence.Prior to ordering and installing materials, all dimensions should be verified by field measurements.Metal Sales reserves the right to modify, without notice, any details, recommendations or suggestions. Any questionsyou may have regarding proper installation of these Concealed Fastened Wall Panel systems should be directed toyour local Metal Sales representative (see pages 2 and 3).Oil canning is not a cause for rejection. Oil canning can be described as the amount of waviness found in the flatareas of metal panels. Oil canning is an inherent characteristic of light gauge cold formed metal products, particularlythose with broad flat areas. There are many factors which may contribute to oil canning that Metal Sales is not ableto control. These factors include: misalignment of the support system, over driving of fasteners used on the panels,stress (whether inherent in the panel or induced), thermal expansion and contraction of the panel, improper materialhandling, width, gauge, length, color of panels and improper installation (reference Metal Construction Association"Oil Canning Position Paper"- Appendix A).Consult your local Metal Sales Branch for any additional information not outlined in this manual.This manual is designed to be utilized as a guide when installing a Concealed Fastened Wall Panel system. It is theresponsibility of the erector to ensure the safe installation of this product system.SAFETYSTUDY APPLICABLE OSHA AND OTHER SAFETY REQUIREMENTS BEFOREFOLLOWING THESE INSTRUCTIONS.The installation of metal wall systems is a dangerous procedure and should be supervised bytrained knowledgeable erectors. USE EXTREME CARE WHILE INSTALLING WALL PANELS.It is not possible for Metal Sales to be aware of all the possible job site situations that couldcause an unsafe condition to exist. The erector of the wall system is responsible for readingthese instructions and determining the safest way to install the wall system.These instructions are provided only as a guide to show a knowledgeable, trained erectorthe correct relationship of parts to one another. If following any of the installation steps wouldendanger a worker, the erector should stop work and decide upon a corrective action.Fall protection for workers installing wall panels must be provided. Metal Sales Manufacturing Corporation / Subject to change without notice 11/191

7/8" CONTEMPRA SERIES INSTALL GUIDE9Branch Territory Map818617213111414125,10719201513216NOTE: Shaded areas represent territories served by each location.TABLE OF CONTENTSImportant Information .1Branch Territory Map / Table of Contents .2Branch Locations .3General Instructions .4Panel Profiles .5Flashing Profiles .6-8Accessories / Fasteners.9Design Information .10-13DETAILSBase - H, V .14, 15Sill - H, V .16, 17Jamb - H, V .18, 19Head - H, V .20, 21Outside Corner - H, V .22, 23Inside Corner - H, V .24, 25Coping - H, V .26, 27Reveal - H .28Transition - V .29Care and Maintenance.30Notes .31'H' indicates horizontal panels, 'V' indicates vertical panels2 Metal Sales Manufacturing Corporation / Subject to change without notice 11/19

7/8" CONTEMPRA SERIES INSTALL GUIDEBranch Locations1. DENVER7990 East I-25 Frontage RoadLongmont, CO 80504303.702.5440800.289.7663800.289.1617 Fax8. SPOKANE2727 East Trent AvenueSpokane, WA 99202509.536.6000800.572.6565509.534.4427 Fax15. FONTANA14213 Whittram AvenueFontana, CA 92335909.829.8618800.782.7953909.829.9083 Fax2. JACKSONVILLE7110 Stuart AvenueJacksonville, FL 32254904.783.3660800.394.4419904.783.9175 Fax800.413.3292 Fax9. SEATTLE20213 84th Avenue, SouthKent, WA 98032253.872.5750800.431.3470 (Outside WA)800.742.7900 (Inside WA)253.872.2008 Fax16. ANCHORAGE4637 Old Seward HighwayAnchorage, AK 99503907.646.7663866.640.7663907.646.7664 Fax3. JEFFERSON352 East Erie StreetJefferson, OH 44047440.576.9070800.321.5833440.576.9242 Fax800.233.5719 Fax10. NEW ALBANY999 Park PlaceNew Albany, IN 47150812.944.2733812.944.1418 Fax11. ROCK ISLAND8111 West 29th StreetRock Island, IL 61201309.787.1200800.747.1206309.787.1833 Fax4. INDEPENDENCE1306 South Powell RoadIndependence, MO 64057816.796.0900800.747.0012816.796.0906 Fax12. DEER LAKE29 Pinedale Industrial RoadOrwigsburg, PA 17961570.366.2020800.544.2577570.366.1648 Fax800.544.2574 Fax5. SELLERSBURG7800 State Road 60Sellersburg, IN 47172812.246.1866800.999.7777812.246.0893 Fax800.477.9318 Fax13. TEMPLE3838 North General Bruce DriveTemple, TX 76501254.791.6650800.543.4415254.791.6655 Fax800.543.4473 Fax6. ROGERS22651 Industrial BoulevardRogers, MN 55374763.428.8080800.328.9316763.428.8525 Fax800.938.9119 Fax7. NASHVILLE4314 Hurricane Creek BoulevardAntioch, TN 37013615.641.7100800.251.8508615.641.7118 Fax800.419.4372 Fax14. WOODLAND1326 Paddock PlaceWoodland, CA 95776530.668.5690800.759.6019530.668.0901 Fax17. BAY CITY5209 Mackinaw RoadBay City, MI 48706989.686.5879888.777.7640989.686.5870 Fax888.777.0112 Fax18. DETROIT LAKES1435 Egret AvenueDetroit Lakes, MN 56501218.847.2988888.594.1394218.847.4835 Fax888.594.1454 Fax19. MOCKSVILLE188 Quality DriveMocksville, NC 27028336.751.6381800.228.6119336.751.6301 Fax800.228.7916 Fax20. FORT SMITH7510 Ball RoadFort Smith, AR 72908479.646.1176877.452.3915479.646.5204 Fax21. SIOUX FALLS2700 West 3rd Street, Suite 4Sioux Falls, SD 57104605.335.2745888.299.0024TECHNICAL SUPPORTTECHNICAL SERVICES545 South 3rd Street, Suite 200Louisville, KY 40202502.855.4300800.406.7387800.944.6884 Fax Metal Sales Manufacturing Corporation / Subject to change without notice 11/193

7/8" CONTEMPRA SERIES INSTALL GUIDEGeneral InstructionsSafetyUse proper safety gear, safe equipment and safe processes. Safety gear includes gloves, arm guards, safety gogglesand fall protection. Safe equipment includes maintained screw gun, saw, snips and folder. Safe processes includebeing aware of dangers and taking appropriate measures to avoid them.Material AvailabilityPanels are available in 24 ga, 22 ga and 20 ga steel and 0.032" aluminum. Flashings are available in 24 ga and 22ga steel and 0.032" aluminum. Only 24 ga panel and flashing materials, in standard colors, are stocked. Custom 24ga colors, all 22 ga, all 20 ga and all 0.032" materials are secured per project and require minimum order quantities.Material ReceiptUpon receipt of material, confirm all parts have been delivered and that there is no damage. Any shortages shouldbe reported to the Metal Sales contact. Transit damage should be noted on the bill of lading.Material StorageMaterial not used right away, should be stored inside, out of the elements. If inside storage is not available, tarp thematerial such that air can circulate. Elevate the crates off the ground and slope so that water will run off.HandlingTransport panels in the crates to the installation site. Adequate support for individual panels every 6' to 8' is necessary. Grasp a panel by one side and let the other side hang down.Wall ConditionBefore installing panels, ensure the wall support material is plumb, square and true. Variance from in-plane shouldnot exceed 1/4" in 10'.Wall AssemblyCover building envelope sheathing with a moisture barrier, such as peel-and-stick underlayment or synthetic buildingwrap for resistance to air and water penetration through the wall assembly. Install the moisture barrier horizontallyfrom the bottom upward, overlapping each run over the previous, lower run.SpacersSpacers with a minimum depth of 1/4" are recommended at clips and trims to hold the wall assembly off of the wallline and allow water to drain. Spacers may be shims, hat channels or furring strips installed to not hold water.Plan the WorkBefore installing panels on a wall section, plan for alignment with adjacent wall sections. Decide if the first panel willbe a full or partial panel. Consider the locations of wall penetrations and openings.Clip FastenersDo not overtighten the panel clip fasteners. The fasteners should be brought just to firm contact between the support material, panel and clip. Overtightening the clip fasteners can make installation of the next panel difficult. Thepanel must be capable of sliding along its length after the clips are installed. The number of fasteners per clip canbe either one or two, depending on the support material and the design load requirements.Installation PracticeFor horizontal panels, start at the bottom of the wall and work up the wall toward the top. Always 'shingle' panelsand trims so that water will run down off of one member on to the next. Ensure every surface has adequate slopeto permit water to run off and not collect on any surface. When installing panels, give effort to stay on module bychecking the coverage of each panel.Strippable FilmPanels and trim are typically provided with strippable film as protection against minor fabrication, transit and handlingdamage. The strippable film must be removed just before installation. Waiting until after panel installation to removethe strippable film or after significant exposure to sunlight or heat can make removal very difficult.4 Metal Sales Manufacturing Corporation / Subject to change without notice 11/19

7/8" CONTEMPRA SERIES INSTALL GUIDECN88-1212Panel ProfilesAsymmetrical Rib12" Coverage3"7C/8"Panel can be produced in lengths from 5' to 30'.CN88-1653Product No.CoverageDescriptionThickFinish276904112"1 rib24 gaGalvalume (ACG)27690XX12"1 rib24 gaPVDF Painted296904112"1 rib22 gaGalvalume (ACG)29690XX12"1 rib22 gaPVDF Painted30690XX12"1 rib20 gaPVDF Painted27690XXA12"1 rib0.032"PVDF Painted AluminumAsymmetrical Rib16" Coverage51/3"3"7C/8"62 45 Panel can be produced in lengths from 5' to 30'.Product No.CoverageDescriptionThickFinish276954116"3 ribs24 gaGalvalume (ACG)27695XX16"3 ribs24 gaPVDF Painted296954116"3 ribs22 gaGalvalume (ACG)29695XX16"3 ribs22 gaPVDF Painted30695XX16"3 ribs20 gaPVDF Painted27695XXA16"3 ribs0.032"PVDF Painted Aluminum Metal Sales Manufacturing Corporation / Subject to change without notice 11/195

7/8" CONTEMPRA SERIES INSTALL GUIDEBASE TRIM 7/8"C25/8"95 5/8"ClosedHem1 /8"3C-CLOSURE 7/8"1"C1 /8"123/4"Flashing ProfilesProduct No.LengthThickFinish587064110'-2"24 gaGalvalume (ACG)58706XX10'-2"24 gaPVDF Painted607064110'-2"22 gaGalvalume (ACG)60706XX10'-2"22 gaPVDF Painted58706XXA10'-2"0.032"PVDF AluminumFlashing Stretch Out 51/8"Product No.LengthThickFinish587104110'-2"24 gaGalvalume (ACG)58710XX10'-2"24 gaPVDF Painted607104110'-2"22 gaGalvalume (ACG)60710XX10'-2"22 gaPVDF Painted58710XXA10'-2"0.032"PVDF AluminumFlashing Stretch Out 4 /8"7Z-CLOSURE 7/8"1"1 /8"1C1"OUTSIDE CORNERC3"OpenHem1"3"ThickFinish587254110'-2"24 gaGalvalume (ACG)58725XX10'-2"24 gaPVDF Painted607254110'-2"22 gaGalvalume (ACG)60725XX10'-2"22 gaPVDF Painted58725XXA10'-2"0.032"PVDF AluminumFlashing Stretch Out 3 /8"Product No.LengthThickFinish587244110'-2"24 gaGalvalume (ACG)58724XX10'-2"24 gaPVDF Painted607244110'-2"22 gaGalvalume (ACG)60724XX10'-2"22 gaPVDF Painted58724XXA10'-2"0.032"PVDF AluminumFlashing Stretch Out 8 /8"1OpenHem1"INSIDE CORNER3"1"C3"OpenHem6Length1This Flashing can be used as an alternate to C-Closure.OpenHemProduct No.Product No.LengthThickFinish587264110'-2"24 gaGalvalume (ACG)58726XX10'-2"24 gaPVDF Painted607264110'-2"22 gaGalvalume (ACG)60726XX10'-2"22 gaPVDF Painted58726XXA10'-2"0.032"PVDF AluminumFlashing Stretch Out 8 /8"11" Metal Sales Manufacturing Corporation / Subject to change without notice 11/19

7/8" CONTEMPRA SERIES INSTALL GUIDEPANEL STARTERClosedHem25/8"1 /8"1C95 95 1 /8"121/2"ThickFinish587284110'-2"24 gaGalvalume (ACG)58728XX10'-2"24 gaPVDF Painted607284110'-2"22 gaGalvalume (ACG)60728XX10'-2"22 gaPVDF Painted58728XXA10'-2"0.032"PVDF AluminumProduct No.LengthThickFinish587364110'-2"24 gaGalvalume (ACG)58736XX10'-2"24 gaPVDF Painted607364110'-2"22 gaGalvalume (ACG)60736XX10'-2"22 gaPVDF Painted58736XXA10'-2"0.032"PVDF AluminumFlashing Stretch Out 61/8"ClosedHemREVEAL1"LengthFlashing Stretch Out 4 /8"TRANSITION 7/8"2"Product No.3OpenHemCFlashing Profiles1"COpenHemOpenHem3"Product No.LengthThickFinish587404110'-2"24 gaGalvalume (ACG)58740XX10'-2"24 gaPVDF Painted607404110'-2"22 gaGalvalume (ACG)60740XX10'-2"22 gaPVDF Painted58740XXA10'-2"0.032"PVDF AluminumFlashing Stretch Out 5 /8"1SILL/JAMB TRIM4"/2"1X21/2"OpenHemHEAD TRIM 7/8"C95 95 11/8"LengthThickFinish587184110'-2"24 gaGalvalume (ACG)58718XX10'-2"24 gaPVDF Painted607184110'-2"22 gaGalvalume (ACG)60718XX10'-2"22 gaPVDF Painted58718XXA10'-2"0.032"PVDF AluminumFlashing Stretch Out 8"1"21/2"Product No.2 /2"1CX 95 for Sill or 90 for JambProduct No.LengthThickFinish587204110'-2"24 gaGalvalume (ACG)58720XX10'-2"24 gaPVDF Painted607204110'-2"22 gaGalvalume (ACG)60720XX10'-2"22 gaPVDF Painted58720XXA10'-2"0.032"PVDF AluminumFlashing Stretch Out 10 /8"5/2"14" Metal Sales Manufacturing Corporation / Subject to change without notice 11/197

7/8" CONTEMPRA SERIES INSTALL GUIDECOPINGwidth variesWidthProduct No.LengthThickFinish8"58714XX10'-2"24 gaPVDF Painted10"58715XX10'-2"24 gaPVDF Painted12"58716XX10'-2"24 gaPVDF Painted8"60714XX10'-2"22 gaPVDF Painted10"60715XX10'-2"22 gaPVDF Painted12"60716XX10'-2"22 gaPVDF Painted8"58714XXA10'-2"0.032"PVDF Aluminum10"58715XXA10'-2"0.032"PVDF Aluminum12"58716XXA10'-2"0.032"PVDF AluminumC85 95 2"4"ClosedHemFlashing Profiles1"OpenHemFlashing Stretch Out 151/2", 171/2" or 191/2"COPING CLEAT1"85 3"CPANEL END CLOSURE 7/8"1"/8"C11/8"25/8"ThickFinish587344110'-2"24 gaGalvalume (ACG)58734XX10'-2"24 gaPVDF Painted607344110'-2"22 gaGalvalume (ACG)60734XX10'-2"22 gaPVDF Painted58734XXA10'-2"0.032"PVDF AluminumProduct No.LengthThickFinish587304110'-2"24 gaGalvalume (ACG)58730XX10'-2"24 gaPVDF Painted607304110'-2"22 gaGalvalume (ACG)60730XX10'-2"22 gaPVDF Painted58730XXA10'-2"0.032"PVDF AluminumFlashing Stretch Out 55/8"OFFSET CLEAT1"158 Product No.LengthThickFinish580649910'-2"24 gaPVDF PaintedFlashing Stretch Out 3"111/2"/2"WINDOW CLOSURE 7/8"11/16"C11/4"LengthFlashing Stretch Out 41/2"ClosedHem7Product No.CProduct No.LengthThickFinish587424110'-2"24 gaGalvalume (ACG)58742XX10'-2"24 gaPVDF Painted607424110'-2"22 gaGalvalume (ACG)60742XX10'-2"22 gaPVDF Painted58742XXA10'-2"0.032"PVDF Aluminum1"3"8 Metal Sales Manufacturing Corporation / Subject to change without notice 11/19

Accessories / Fasteners7/8" CONTEMPRA SERIES INSTALL GUIDECONCEALED FASTENED CLIPProduct No.Size49342002 /4" x 1 /4" x /4"133WT/200Finish30.00 lbsG90GalvanizedUNIVERSAL CLOSUREDOUBLE BEAD TAPE SEALANTProduct No.DescriptionWT/EaType64111001" x 1 /2" x 50'4.00 lbsFoam64111991" x 1 /2" x 10'0.80 lbsFoamDescriptionWT/Ctn.Type/8" x /16" x 25'40.00 lbsButyl11Product No.64038997320 Rolls per CartonTUBE SEALANTPOP RIVETPANCAKE HEAD DRILLERLOW PROFILE WOOD SCREWSELF DRILLER XLDescriptionWT/EaColor6402800Acrylic Tube Sealant3.31 lbsClear64028XXTube Sealant3.31 lbsColor MatchFinishProduct No.PANCAKE HEAD WOOD SCREWWOOD SCREW XLProduct No.DescriptionWT/25082402011/8" x /8" Pop Rivet0.75 lbsBare82402XX1/8" x 3/8" Pop Rivet0.75 lbsPaintedProduct No.DescriptionWT/250Finish8243100#10-12 x 1" PH Wood Screw1.90 lbsPlated3Product No.DescriptionWT/250Finish8242100#10-16 x 1" PH Driller1.90 lbsPlatedProduct No.DescriptionWT/250Finish8244100#12-11 x 11/2" LP Wood Screw2.75 lbsPaintedProduct No.DescriptionWT/250Finish8212300#10-14 x 1 /2" Wood Screw XL3.75 lbsPlated82123XX#10-14 x 1 /2" Wood Screw XL3.75 lbsPaintedProduct No.DescriptionWT/250Finish8235300#12-14 x 1 /4" Self Driller XL3.75 lbsPlated82353XX#12-14 x 1 /4" Self Driller XL3.75 lbsPainted1111 Metal Sales Manufacturing Corporation / Subject to change without notice 11/199

Design Information7/8" CONTEMPRA SERIES INSTALL GUIDECN88-1212Asymmetrical RibFASTENING INFORMATION Concealed Fastened Clip is 21/4" x 13/4" x 3/4", from 16 ga,G90 material with 2 fastener holes. Clip Fastener(s) should be driven just to contact betweenfastener head / clip / panel / support. Beyond contact,the clip can crush the open hem of the panel and makeengagement of the next panel difficult. Overdriven fastenerswill cause panel distortions.PANEL ATTACHMENT Fasteners should extend 1/2" or more past the inside faceof the support material for steel and wood sheathing supportmaterials. Clip Fasteners:Attaching to Wood:Concealed FastenedClip#12-11 x 11/2" Low Profile Wood ScrewAttaching to Steel:Clip Fastener 18 ga: 1/4"-13 Deck Screw 18 ga, 12 ga: #10-16 Pancake Head Driller 12 ga: 1/4"-14 Self Driller, No WasherINSTALLATION DIRECTIONHorizontally-oriented panels must be installed from the bottom to the top.Vertically-oriented panels may be installed from the right-to-left or left-to-right.ALLOWABLE UNIFORM LOADS, psfFor various clip spacingsSTEEL SECTION PROPERTIESThickWidth Yield Weightinksipsf24ga12501.20Top In Compression Bottom In CompressionInward LoadOutward 12097593823103846643301. Theoretical section properties have been calculated per AISI 2012 'North American Specification for the Design of Cold-Formed Steel StructuralMembers'. Ixx and Sxx are effective section properties for deflection and bending.2. Allowable loads are calculated in accordance with AISI 2012 specifications considering bending, shear, combined bending and shear, deflectionand load testing on 16 ga girts. Allowable loads consider the 3 or more equal spans condition. Panel weight is not considered.3. Deflection consideration is limited by a maximum deflection ratio of L/180 of span.4. Allowable loads do not include a 1/3 stress increase for wind.ALLOWABLE UNIFORM LOADS, psfFor various clip spacingsALUMINUM SECTION PROPERTIESInward LoadOutward 7101. Section properties have been calculated per 2010 Aluminum Design Manual. I and S are section properties for deflection and bending.2. Allowable load is calculated in accordance with 2010 Aluminum Design Manual specifications considering bending, shear, combined bending andshear, deflection and load testing on 16 ga girts. Allowable load does not address web crippling or other fasteners or support materials. Allowable loadsconsider the 3 or more equal spans condition. Panel weight is not considered.3. Deflection consideration is limited by a maximum deflection ratio of L/180 of span.4. Allowable loads do not include a 1/3 stress increase in wind.10 Metal Sales Manufacturing Corporation / Subject to change without notice 11/19

7/8" CONTEMPRA SERIES INSTALL GUIDECN88-1212Fastener GuideAsymmetrical RibCN88-1212on 16 ga GirtsWall Fastener Spacing (feet)Wind Speed (mph)Exposure Category100C110C120C130C140C150C160C170C20 ft, Mean Roof Height40 ft, Mean Roof Height60 ft, Mean Roof HeightFieldThickness -15.1 psf24 ga6.0022 ga6.0020 ga6.000.032"5.50Edge-18.6 psf6.006.006.005.50FieldThickness -17.4 psf24 ga6.0022 ga6.0020 ga6.000.032"5.50Edge-21.5 psf6.006.006.005.00Thickness24 ga22 ga20 ga0.032"Field-19 psf6.006.006.005.50Edge-23.4 psf6.006.006.005.00FieldThickness -18.2 psf24 ga6.0022 ga6.0020 ga6.000.032"5.50Edge-22.5 psf6.006.006.005.00FieldThickness -21.1 psf24 ga6.0022 ga6.0020 ga6.000.032"5.50Edge-26 psf6.006.006.005.00Thickness24 ga22 ga20 ga0.032"Field-23 psf6.006.006.005.00Edge-28.4 psf6.006.006.004.50FieldThickness -21.7 psf24 ga6.0022 ga6.0020 ga6.000.032"5.00Edge-26.8 psf6.006.006.005.00FieldThickness -25.1 psf24 ga6.0022 ga6.0020 ga6.000.032"5.00Edge-31 psf5.505.505.504.50FieldThickness -27.4 psf24 ga6.0022 ga6.0020 ga6.000.032"5.00Edge-33.8 psf5.505.505.504.50FieldThickness -25.5 psf24 ga6.0022 ga6.0020 ga6.000.032"5.00Edge-31.4 psf5.505.505.504.50FieldThickness -29.5 psf24 ga6.0022 ga6.0020 ga6.000.032"4.50Edge-36.4 psf5.505.505.504.00FieldThickness -32.1 psf24 ga5.5022 ga5.5020 ga5.500.032"4.50Edge-39.6 psf5.005.005.004.00FieldThickness -29.5 psf24 ga6.0022 ga6.0020 ga6.000.032"4.50Edge-36.5 psf5.505.505.504.00FieldThickness -34.2 psf24 ga5.5022 ga5.5020 ga5.500.032"4.50Edge-42.2 psf5.005.005.003.50FieldThickness -37.2 psf24 ga5.5022 ga5.5020 ga5.500.032"4.00Edge-46 psf5.005.005.003.50FieldThickness -33.9 psf24 ga5.5022 ga5.5020 ga5.500.032"4.50Edge-41.9 psf5.005.005.003.50FieldThickness -39.2 psf24 ga5.0022 ga5.0020 ga5.000.032"4.00Edge-48.4 psf4.504.504.503.00FieldThickness -42.7 psf24 ga5.0022 ga5.0020 ga5.000.032"3.50Edge-52.8 psf4.504.504.503.00FieldThickness -38.6 psf24 ga5.5022 ga5.5020 ga5.500.032"4.00Edge-47.6 psf5.005.005.003.00FieldThickness -44.6 psf24 ga5.0022 ga5.0020 ga5.000.032"3.50Edge-55.1 psf4.504.504.502.50FieldThickness -48.6 psf24 ga4.5022 ga4.5020 ga4.500.032"3.00Edge-60 psf4.004.004.002.50FieldThickness -43.6 psf24 ga5.0022 ga5.0020 ga5.000.032"3.50Edge-53.8 psf4.504.504.503.00FieldThickness -50.4 psf24 ga4.5022 ga4.5020 ga4.500.032"3.00Edge-62.2 psf4.004.004.002.00FieldThickness -54.9 psf24 ga4.5022 ga4.5020 ga4.500.032"N.G.Edge-67.8 psf3.503.503.50N.G.Notes:1. Allowable spacing is based on capacities determined inAISI 2012, North American Specification for the Design of ColdStructural Members and ADM 2010, Aluminum Design Manual.2. Allowable spacing is based on an applied load determined usingASCE 7-10 for the wind speeds and Wind Exposures tabulated.Assumptions include a tributary area of 10 square feet, an Enclosedbuilding, a Topographic Factor of 1.0 andpanel bearing length of 2.5 inches.3. Allowable spacing is determined using the IBC 2015suction and pressure, the combination is 0.6W.4. Testing is the basis for the load carrying capacity. Metal Sales Manufacturing Corporation / Subject to change without notice 11/1911

Design Information7/8" CONTEMPRA SERIES INSTALL GUIDECN88-1653Asymmetrical RibFASTENING INFORMATION Concealed Fastened Clip is 21/4" x 13/4" x 3/4", from 16 ga,G90 material with 2 fastener holes. Clip Fastener(s) should be driven just to contact betweenfastener head / clip / panel / support. Beyond contact,the clip can crush the open hem of the panel and makeengagement of the next panel difficult. Overdriven fastenerswill cause panel distortions.PANEL ATTACHMENT Fasteners should extend 1/2" or more past the inside faceof the support material for steel and wood sheathing supportmaterials. Clip Fasteners:Attaching to Wood:Concealed FastenedClip#12-11 x 11/2" Low Profile Wood ScrewAttaching to Steel:Clip Fastener 18 ga: 1/4"-13 Deck Screw 18 ga, 12 ga: #10-16 Pancake Head Driller 12 ga: 1/4"-14 Self Driller, No WasherINSTALLATION DIRECTIONHorizontally-oriented panels must be installed from the bottom to the top.Vertically-oriented panels may be installed from the right-to-left or left-to-right.ALLOWABLE UNIFORM LOADS, psfFor various clip spacingsSTEEL SECTION PROPERTIESGaWidth Yield WeightinksipsfTop In Compression Bottom In ard LoadOutward 0.13450.06900.13391209771472389735741261. Theoretical section properties have been calculated per AISI 2012 'North American Specification for the Design of Cold-Formed Steel StructuralMembers'. Ixx and Sxx are effective section properties for deflection and bending.2. Allowable loads are calculated in accordance with AISI 2012 specifications considering bending, shear, combined bending and shear, deflection,load testing on 16 ga girts and load testing of comparable profiles. Allowable loads consider the 3 or more equal spans condition. Panelweight is not considered.3. Deflection consideration is limited by a maximum deflection ratio of L/180 of span.4. Allowable loads do not include a 1/3 stress increase for wind.ALLOWABLE UNIFORM LOADS, psfFor various clip spacingsALUMINUM SECTION PROPERTIESInward LoadOutward 735231. Section properties have been calculated per 2010 Aluminum Design Manual. I and S are section properties for deflection and bending.2. Allowable load is calculated in accordance with 2010 Aluminum Design Manual specifications considering bending, shear, combined bending andshear, deflection, load testing on 16 ga girts and load testing of comparable profiles. Allowable load does not address web crippling or other fastenersor support materials. Allowable loads consider the 3 or more equal spans condition. Panel weight is not considered.3. Deflection consideration is limited by a maximum deflection ratio of L/180 of span.4. Allowable loads do not include a 1/3 stress increase in wind.12 Metal Sales Manufacturing Corporation / Subject to change without notice 11/19

7/8" CONTEMPRA SERIES INSTALL GUIDECN88-1653Fastener GuideAsymmetrical RibCN88-1653on 16 ga GirtsWall Fastener Spacing (feet)Wind Speed (mph)Exposure Category100C110C120C130C140C150C160C170C20 ft, Mean Roof Height40 ft, Mean Roof Height60 ft, Mean Roof HeightFieldThickness -15.1 psf24 ga6.0022 ga6.0020 ga6.000.032"6.00Edge-18.6 psf6.006.006.006.00FieldThickness -17.4 psf24 ga6.0022 ga6.0020 ga6.000.032"6.00Edge-21.5 psf6.006.006.006.00Thickness24 ga22 ga20 ga0.032"Field-19 psf6.006.006.006.00Edge-23.4 psf6.006.006.005.50FieldThickness -18.2 psf24 ga6.0022 ga6.0020 ga6.000.032"6.00Edge-22.5 psf6.006.006.005.50FieldThickness -21.1 psf24 ga6.0022 ga6.0020 ga6.000.032"6.00Edge-26 psf5.505.505.505.50Thickness24 ga22 ga20 ga0.032"Field-23 psf6.006.006.005.50Edge-28.4 psf5.505.505.505.50FieldThickness -21.7 psf24 ga6.0022 ga6.0020 ga6.000.032"6.00Edge-26.8 psf5.505.505.505.50FieldThickness -25.1 psf24 ga6.0022 ga6.0020 ga6.000.032"5.50Edge-31 psf5.505.505.505.00FieldThickness -27.4 psf24 ga5.5022 ga5.5020 ga5.500.032"5.50Edge-33.8 psf5.505.505.505.00FieldThickness -25.5 psf24 ga6.0022 ga6.0020 ga6.000.032"5.50Edge-31.4 psf5.505.505.505.00FieldThickness -29.5 psf24 ga5.5022 ga5.5020 ga5.500.032"5.00Edge-36.4 psf5.005.005.004.50FieldThickness -32.1 psf24 ga5.5022 ga5.5020 ga5.500.032"5.00Edge-39.6 psf5.005.005.004.50FieldThickness -29.5 psf24 ga5.5022 ga5.5020 ga5.500.032"5.00Edge-36.5 psf5.005.005.004.50FieldThickness -34.2 psf24 ga5.0022 ga5.0020 ga5.000.032"5.00Edge-42.2 psf4.504.504.504.00FieldThickness -37.2 psf24 ga5.0022 ga5.0020 ga5.000.032"4.50Edge-46 psf4.504.504.504.00FieldThickness -33.9 psf24 ga5.5022 ga5.5020 ga5.500.032"5.00Edge-41.9 psf5.005.005.004.00FieldThickness -39.2 psf24 ga5.0022 ga5.0020 ga5.000.032"4.50Edge-48.4 psf4.504.504.503.50FieldThickness -42.7 psf24 ga4.5022 ga4.5020 ga4.500.032"4.00Edge-52.8 psf4.004.004.003.50FieldThickness -38.6 psf24 ga5.0022 ga5.0020 ga5.000.032"4.50Edge-47.6 psf4.504.504.503.50FieldThickness -44.6 psf24 ga4.5022 ga4.5020 ga4.500.032"4.00Edge-55.1 psf4.004.004.003.00FieldThickness -48.6 psf24 ga4.5022 ga4.5020 ga4.500.032"3.50Edge-60 psf3.503.503.502.50FieldThickness -43.6 psf24 ga4.5022 ga4.5020 ga4.500.032"4.00Edge-53.8 psf4.004.004.003.00FieldThickness -50.4 psf24 ga4.0022 ga4.0020 ga4.000.032"3.50Edge-62.2 psf3.503.503.502.50FieldThickness -54.9 psf24 ga4.0022 ga4.0020 ga4.000.032"3.00Edge-67.8 psf3.003.003.002.00Notes:1. Allowable spacing is based on capacities determined inAISI 2012, North American Specification for the Design of ColdStructural Members and ADM 2010, Aluminum Design Manual.2. Allowable spacing is based on an applied load determined usingASCE 7-10 for the wind speeds and Wind Exposures tabulated.Assumptions include a tributary area of 10 square feet, an Enclosedbuilding, a Topographic Factor of 1.0 andpanel bearing length of 2.5 inches.3. Allowable spacing is determined using the IBC 2015suction and pressure, the combination is 0.6W.4. Testing is the basis for the load carrying capacity. Metal Sales Manufacturing Corporation / Subject to change without notice 11/1913

7/8" CONTEMPRA SERIES INSTALL GUIDECare and MaintenanceThough factory-applied pre-painted finishes are very durable and will last many years, eventually it may be desirable tothoroughly clean or repaint them.Dirt pickup may cause apparent discoloration of the paint when it has been exposed in some dirt-laden atmospheres forlong periods of time. In areas of strong sunlight, slight chalking may c

1. Section properties have been calculated per 2010 Aluminum Design Manual. I and S are section properties for deflection and bending. 2. Allowable load is calculated in accordance with 2010 Aluminum Design Manual specifications considering bending, shear, combined bending and shear, deflection and load testing on 16 ga girts.