Transcription

Distributed by:FLANGED BALL VALVESASME CLASS 150 & 300REDUCED BORE:1/2” – 20” (DN 15 – 500) SERIES 7000The Jamesbury polymer-seated flanged ball valvesprovide industry leading performance andreliability. Offered in a wide variety of materials tosuit an extensive range of applications these valvesare designed and manufactured with all our latesttechnology and expertise.Unique SealingThe superior performance of Jamesbury ball valvesis achieved by the unique design of the seats. Theflexible lip seats exert continuous sealing pressureon the ball and automatically compensate for wearand changes in pressure and temperature, yieldingpositive bi-directional zero-leak shut-off. The stemseal sealing system ensures minimum emissions. Features And BenefitsRobust engineering design yields leading cyclelifeOutstanding quality provides confidenceFlexible lip seat provides bi-directional zero-leakshut-off and minimum maintenanceXtreme seats provide longer life and expandedpressure-temperature capabilityPatented stem seal system engineered to providesuperior emissions performance (1/2” - 2”)Live loaded stem packing enhances emissionsperformance and reduces maintenance (1/2” - 8”)ISO 5211 bonnet mounting design (1/2” - 8”)API 607 qualifiedAPI 608 compliance & grounding as standard (3” - 8”)ISO 15848-1 Class BH rated (1/2” - 8”)Standard materials meet requirements of NACEMR0103 and MR0175 (see p29)SIL 3 qualifiedMaterialsStandard products are available with carbon steelbody and stainless steel trim or all stainless steelconstruction. Special body and trim materials suchas Alloy 20, Hastelloy C, and others are availableupon request. For applications involving chemicals, acids, caustics, and steam we recommend ourXtreme seat material, which provides superior lifecycle and sealing performance compared to virginor filled PTFE. We can accommodate nearly anyspecial customer or application specific requirement. Fite-Tite ValvesAll Jamesbury Fire-Tite flanged ball valves are qualified to API 607 and ISO 10497. This ensures minimalleakage in the event of a fire.Emission-Pak ValvesJamesbury Emission-Pak products feature a doublestem seal packing system to provide additionalsealing performance for critical services. This featureis ISO 15848-1 Class AH rated.CE markedCE marked and documented product conformingto the European Pressure Equipment Directive(PED) 2014/68/EU and ATEX Directive 2014/34/EU isavailable as standard product. B107-1 EN 8/2017Automated AssembliesValves, actuators, and accessories designed tomate together with precision ensures superiorperformance.

B107-1 ENMETSOSPECIFICATIONSValve SizeFlow DataThe table at right provides flow coefficients for Jamesburyvalves covered in this bulletin. Cv values represent theflow of water at 60 F through the valve in U.S. gallons perminute at a pressure drop of 1 psi. The metric equivalent,Kv, is the flow of water at 16 C through the valve in cubicmeters per hour at a pressure drop of 1 kg/cm2. To convertCv to Kv, multiply by 0.8569.Valve Body RatingsThese are the maximum working pressure ratings of thevalve body only. The seat ratings, shown on the next page,determine the practical temperature and pressure limitations according to actual service conditions. Test pressuresare recommended pressures for hydrostatic test with ballhalf open.CvInchesDNStandard * Class 300 long patternMaximum Working Pressure, psiClass 150Class 300Temp FCarbonsteel316 StainlesssteelAlloy 20-20 to 100200300400500Test 190190170350Temp C-29 to 3893149204260Test PressureCarbonsteel19.617.715.813.811.730TECHNICAL BULLETIN 8/17316 57206205605154801100Maximum Working Pressure, barClass 150316 StainlessAlloy .713.113.111.711.711.7292424Valve Seat RatingsSeat ratings, indicated by solid lines in the charts on thenext page, are based on differential pressure with the valveball in the fully closed position and refer to seats only. Thedotted lines indicate maximum working pressures for WCBcarbon steel valve bodies. (Maximum working pressuresof other body materials are shown in the tables above.)The combination of dotted and solid lines indicates themaximum valve rating at specific pressure and temperature conditions. Valves with PTFE, Xtreme, PEEK , PFA, andUHMW polyethylene seats can be used in service to -60 F(-51 C) provided that the valve body material is suitablefor such a temperature. Carbon steel valves are rated to-20 F (-29 C).2Monel CarbonsteelCarbonsteel51.146.645.143.841.977Class 300316 Stainlesssteel49.642.238.535.733.475For saturated steam service, stainless steel trim is recommended at all pressures and is required above 200 psi(14 bar). See Bulletin B150-1. For more application information on seat materials, refer to Bulletin T140-1.Xtreme Performance and ValueXtreme seats provide longer life, expanded performanceboundaries, and the greatest possible value. Xtremematerial is unique, resulting from a technological breakthrough in our polymer research lab. The material is a proprietary fluoropolymer based blend that provides superiorquarter-turn performance.

F L A N G E D B A L L VA LV E S A S M E C L A S S 1 50 & 3 0 03” – 6” (DN 80 – 150) Standard BoreLow Temperature Limit forCarbon Steel (WCB)80050Class 30060040ZClass 150500Saturated30Steam400T30020200BUL10100X-60 0100200 300 400 500Temperature F600-50Temperature C50100 150 2000700Maximum Differential Pressure, psi700Maximum Differential Pressure, psi300 350Maximum Differential Pressure, bar800Temperature C100 150 200 25050600Class 300T500250SaturatedSteam50X40BU4003030020200Class 15010L100700300Maximum Differential Pressure, bar1/2” – 2” (DN 15 – 50) Standard Bore0B107-1 EN50-60 0-20100200300400500600Temperature F30020SaturatedSteam200T100U0-60010010BX200 300 400Temperature F500600010” (DN 250) Standard Bore Non-TrunnionTemperature C100200030030020Class 150 & 300SaturatedSteam20010T&B100U0-60X0100200300 400Temperature FMaximum Differential Pressure, barMaximum Differential Pressure, psi* ASME Class 300 Non-Trunnion is 275 psi (19 bar) max.5000600Trunnion Valves8” – 20” (DN 200 – 500) Standard BoreTemperature C-50800050100150200250Class 30050700600X4050030400T3002020010010Class 150Maximum Differential Pressure, bar300Maximum Differential Pressure, psiTemperature C1002000Maximum Differential Pressure, barMaximum Differential Pressure, psi8” (DN 200) Standard Bore Non-TrunnionSaturatedSteam-60 0-20100200300400500Temperature F* ASME Class 300 Non-Trunnion is 275 psi (19 bar) max.T PTFEL PEEKLEGEND:U UHMWZ TFMB PFAX Xtreme3TECHNICAL BULLETIN 8/17

B107-1 ENMETSO‘The Ultimate Process Automation Package for VPVL Pneumatic Actuators,V-Series, ADC-Series and QX-Series Electric Actuatorswith 1/2” – 8” (DN 15 – 200) Standard Port Series 7000Digital valve communication terminalsfor full automation capabilityAvailable for general purposeand hazardous duty serviceCast 300 Series SS bracketsfor corrosion resistanceFully guided stem, couplingand precision bracketassures optimum form, fitand performance17-4PH SS coupling forstrength and corrosionresistanceCompression plate and discsprings for high cycle thermaland pressure transients.Patented stem sealhas 3 engineered sealing zonesto provide multiple barriersfor long term sealing (1/2" – 2").323211Automation Performance and ValueValves combined with Jamesbury actuators offer a totaland Hawkeye digital monitors or VCTs, the packagesvalue and performance package. Available with pneuhave a wide range of applications. Visit our website at:matic Valv-Powr VPVL actuators, V-Series, ADC-Serieswww.metso.com/valvesand QX-Series electric actuators and with StoneL Quartz 4TECHNICAL BULLETIN 8/17

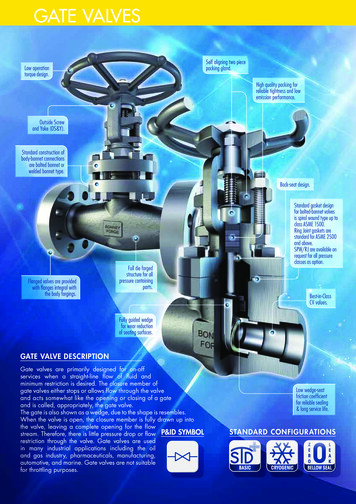

F L A N G E D B A L L VA LV E S A S M E C L A S S 1 50 & 3 0 0B107-1 ENDIMENSIONS1/2” - 2” (DN15 - 50) Series 7150 ASME Class 150 andSeries 7300 & 730S ASME Class 300 (Non-Trunnion)4 Holes Ø L on A Ø M Bolt Circle17SOPENJamesbury25, 2616, 19120, 29, 31KØR8647, 13JØCØ E Port Dia.HF GØ N thru both endsP No. of holes235TØ D Bolt CircleTyp. both endsHex. Size XBAValve Sizeinches1/23/411-1/22Valve SizeDN1520254050Series 7150 ASME Class 150 Approximate Dimensions - 08118127165178B4951566767Valve lve 899T1313141819X1318223238Series 7150 ASME Class 150 Approximate Dimensions - mmCDEFGHJKLMNPR89 60 13 27 34 41 86 127 M5 36 164899 70 18 31 38 45 89 127 M5 36 1648108 79 22 42 52 66 94 165 M5 42 16413127 99 32 53 66 84 108 203 M6 50 16416152 121 38 57 71 89 113 203 M6 50 19416ISOBonnetApproxWeight eight kgF03F03F04F05F051.62.03.45.27.3Series 7300 & 730S ASME Class 300 Approximate Dimensions - 90.881.251.50Series 7300 & 730S ASME Class 300 Approximate Dimensions - mm730SA108118127165178B4951566767CD95 67117 83124 89155 114165 38ApproxISOWeight lbBonnet730S 7300F035.06.0F038.08.0F049.59.5F0517.5 16.0F0521.0 22.0ApproxISOWeight kgBonnet730S 7300F032.32.7F033.63.6F044.34.3F057.97.3F059.5 10.05TECHNICAL BULLETIN 8/17

B107-1 ENMETSOPart No.Part NameBILLS OF MATERIALS AND PARTS LISTFire-Tite 1/2” – 2” (DN15 – 50) Standard Port Series 7000 ValvesBody MaterialCarbon Steel316 Stainless SteelAlloy 20(22)(36)(35)Carbon steel ASTM316 Stainless steel ASTMAlloy 20 ASTM A351A216 Type WCBA351 Type CF8MType CN7MCarbon steel ASTM316 Stainless steelAlloy 20 ASTM A351 TypeA216 Type WCBASTM A351 Type CF8MCN7M1Body2Insert3Ball316 Stainless steel, Monel, Hastelloy CAlloy 204Stem316 Stainless steel, Monel, Hastelloy CAlloy 205678131617192025262931SeatBody SealSecondary Stem SealPrimary Stem SealStem BearingHex NutHandleLock WasherCompression PlateSocket Cap ScrewHandle Stop SpacerHex Cap ScrewDisc SpringsPart No.Part NamePTFE, Xtreme, PFATFMGraphitePTFE (w/ PTFE seats), TFM (w/ Xtreme & PFA seats)PTFE, Filled PTFECarbon steel (zinc plated)300 Series Stainless steelCarbon steel (zinc plated)300 Series Stainless steelCarbon steel (zinc plated)300 Series Stainless steel316 Stainless steel300 Series Stainless steel300 Series Stainless steel300 Series Stainless steel (Monel if Chlorine or NACE)Inconel BILLS OF MATERIALS AND PARTS LISTNon Fire-Tite 1/2” – 2” (DN 15 – 50) Standard Port Series 7000 ValvesBody MaterialCarbon Steel316 Stainless SteelAlloy 20(22)(36)(35)Carbon steel ASTM316 Stainless steel ASTMAlloy 20 ASTM A351A216 Type WCBA351 Type CF8MType CN7MCarbon steel ASTM316 Stainless steel ASTMAlloy 20 ASTM A351A216 Type WCBA351 Type CF8MType CN7M1Body2Insert3Ball316 Stainless Steel, Monel, Hastelloy C4Stem316 Stainless Steel, Monel, Hastelloy C56SeatBody Seal8Primary Stem Seal10161719202223Stem GuideHex NutHandleLock WasherCompression PlateIdentification TagPop Rivet24Stem Bearing25262931Socket Cap ScrewHandle Stop SpacerHex Cap ScrewDisc SpringsNote 1:6Alloy 20MonelMonelMonel(71)Monel ASTM A494Type M35-1Monel ASTM A494Type M35-1Monel, Hastelloy C asspecifiedMonel, Hastelloy C asspecifiedPTFE, Xtreme, PFA, PEEK & UHMWPETFM (w/Xtreme seats), UHMWPE (w/UHMWPE seats), Graphite (w/PEEK seats)PTFE (w/ PTFE seats), TFM (w/ Xtreme & PFA seats), UHMWPE (w/ UHMWPE seats),Graphite (w/PEEK seats)PEEK (PEEK seated valves)Carbon steel (zinc plated)300 Series Stainless steelCarbon steel (zinc plated)300 Series Stainless steelCarbon steel (zinc plated)300 Series Stainless steel316 Stainless steelMonelStainless steelStainless steelPTFE (w/ PTFE seats), Filled PTFE (w/ Xtreme & PFA seats), PEEK (w/ PEEK seats),UHMWPE (w/UHMWPE seats)300 Series Stainless steel300 Series Stainless steel300 Series Stainless steel (Monel if Chlorine or NACE)MonelInconel17-4 PH stems required with PEEK seatsTECHNICAL BULLETIN 8/17Alloy 20Monel(71)Monel ASTM A494Type M35-1Monel ASTM A494 TypeM35-1Monel, Hastelloy C asspecifiedMonel, Hastelloy C asspecified1

F L A N G E D B A L L VA LV E S A S M E C L A S S 1 50 & 3 0 0B107-1 ENDIMENSIONS3” - 6” (DN80 - 150) Series 7150 ASME Class 150 andSeries 7300 & 730S ASME Class 300 (Non-Trunnion)M Bolt CircleL232213R424S772702913Fire-Tite 2030Non Fire-Tite8H2C Typ.31FE Port711563TD Bolt CircleN Size of holesP Number of holesBTyp.ASeries 7150 ASME Class 150 Approximate Dimensions - inchesValve 0F07F07F103963124Series 7150 ASME Class 150 Approximate Dimensions - mmValve F07F102956Series 7300 & 730S ASME Class 300 Approximate Dimensions - inchesValve Size7300 730SinchesAA346BCDE11.12 8.00 3.75 8.25 6.62 2.3112.00 9.00 4.39 10.00 7.88 3.0015.88 10.50 4.95 12.50 10.62 73Series 7300 & 730S ASME Class 300 Approximate Dimensions - mmValve Size7300 7F07F10F127TECHNICAL BULLETIN 8/17

B107-1 ENMETSOPart No.Part NameBILLS OF MATERIALS AND PARTS LISTFire-Tite 3” – 6” (DN80 – 150) Standard Port Series 7000 ValvesBody MaterialCarbon Steel316 Stainless SteelAlloy 20(22)(36)(35)Carbon Steel ASTM A216316 Stainless SteelAlloy 20 ASTM A351Type WCBASTM A351 Type CF8MType CN7MCarbon Steel ASTM A216 316 Stainless Steel ASTMAlloy 20 ASTM A351Type WCBA351 Type CF8MType CN7M1Body2Insert3Ball316 Stainless Steel, Monel, Hastelloy CAlloy 204Stem316 Stainless Steel, Monel, Hastelloy CAlloy 205678132022232930SeatBody SealSecondary Stem SealStem SealThrust BearingCompression Plate1Identification TagPop RivetBonnet StudBonnet Stud Nut31Disc Springs707172Top Grounding SpringBottom Grounding SpringRetaining RingPart No.12PTFE, Xtreme, PFATFMGraphitePTFE (w/ PTFE seats), TFM (w/ Xtreme & PFA seats)PTFE, Filled PTFE316 Stainless SteelStainless SteelStainless SteelASTM A193 GR. B8, B8C, B8T or B8M, MonelASTM A194 GR. 8B, 8CB, 8MB, 8TB, 8FB, MonelMonelInconelBILLS OF MATERIALS AND PARTS LISTNon Fire- Tite 3” – 6” ( DN 80 – 150) Standard Port Series 7000 ValvesBody MaterialPart NameCarbon Steel316 Stainless SteelAlloy 20(22)(36)(35)Carbon Steel ASTM316 Stainless Steel ASTMAlloy 20 ASTM A351BodyA216 Type WCBA351 Type CF8MType CN7MCarbon Steel316 Stainless Steel ASTMAlloy 20 ASTM A351InsertASTM A216 Type WCBA351 Type CF8MType CN7MBall316 Stainless Steel, Monel, Hastelloy C4Stem316 Stainless Steel, Monel, Hastelloy C56SeatBody Seal8Stem Seal13202223Thrust BearingCompression PlateIdentification TagPop Rivet24Thrust Bearing293031707172Bonnet StudBonnet Stud NutDisc SpringsTop Grounding SpringBottom Grounding SpringRetaining RingAlloy 20Alloy 20Monel(71)Monel ASTM A494M35-1Monel ASTM A494M35-1Monel, Hastelloy C asspecifiedMonel, Hastelloy C asspecifiedPTFE, Xtreme, PFA, PEEK & UHMWPETFM (w/ PTFE, Xtreme, PFA seats) , UHMWPE (w/ UHMWPE seats), Graphite (w/ PEEK seats)PTFE (w/ PTFE seats), TFM (w/ Xtreme & PFA seats), UHMWPE (w/ UHMWPE seats),Graphite (w/ PEEK seats)PTFE, Filled PTFE316 Stainless SteelMonelStainless SteelStainless SteelPTFE (w/ PTFE seats), Filled PTFE (w/ Xtreme & PFA seats), PEEK (w/ PEEK seats),UHMWPE (w/ UHMWPE seats)ASTM A193 GR. B8, B8C, B8T or B8M, MonelASTM A194 GR. 8B, 8CB, 8MB, 8TB, 8FB, MonelInconelStainless SteelInconelStainless SteelNote 1: Compression plate and body seal are Monel for valves with Monel or Hastelloy C trim.Note 2: 17-4PH stems are required with PEEK seats.TECHNICAL BULLETIN 8/17Monel, Hastelloy C asspecifiedStainless SteelInconelStainless Steel38Monel(71)Monel ASTM A494M35-1Monel ASTM A494M35-1Monel, Hastelloy C asspecified2

F L A N G E D B A L L VA LV E S A S M E C L A S S 1 50 & 3 0 0B107-1 ENDIMENSIONS8” (DN 200) Series 7150 ASME Class 150M Bolt CircleL232224137R47270208Fire-TiteS29303113Non Fire-TiteH2F71C Typ.E Port1T 5 3Typ.6D Bolt CircleN Size of holesP Number of holes33 32BAValveSizeinches8ValveSizeDN200Series 7150 Emission-Pak ASME Class 150 Approximate Dimensions - 2ISOPatternF12Weightkg128Series 7150 Emission-Pak ASME Class 150 Approximate Dimensions - 9TECHNICAL BULLETIN 8/17

B107-1 ENMETSOPart No.Part NameBILLS OF MATERIALS AND PARTS LISTFire- Tite 8” (DN 200) Standard Port Series 7150 ValvesBody MaterialCarbon Steel316 Stainless SteelAlloy 20(22)(36)(35)Carbon Steel ASTM A216 316 Stainless Steel ASTMAlloy 20 ASTM A351Type WCBA351 Type CF8MType CN7MCarbon Steel ASTM A216 316 Stainless Steel ASTMAlloy 20 ASTM A351Type WCBA351 Type CF8MType CN7M1Body2Body Cap3Ball316 Stainless Steel, Monel, Hastelloy CAlloy 204Stem316 Stainless Steel, Monel, Hastelloy CAlloy 205Seat6Body Seal78132022232930313233707172Secondary Stem SealStem SealThrust BearingCompression PlateIdentification TagPop RivetBonnet StudBonnet Stud NutDisc SpringsBody StudBody Stud NutTop Grounding SpringBottom Grounding SpringRetaining RingPart No.Part NamePTFE, Xtreme, PFASpiral WoundSpiral Wound Graphite/316 Stainless SteelGraphite/Alloy 20GraphitePTFE (w/ PTFE seats), TFM (w/ Xtreme & PFA seats)PTFE, Filled PTFE316 Stainless SteelStainless SteelStainless SteelASTM A193 GR. B8, B8C, B8T or B8M, MonelASTM A194 GR. 8B, 8CB, 8MB, 8TB, 8FB, MonelInconelASTM A193 GR. B8, B8C, B8T or B8M, MonelASTM A194 GR. 8B, 8CB, 8MB, 8TB, 8FB, MonelStainless SteelInconelStainless SteelBILLS OF MATERIALS AND PARTS LISTNon Fire- Tite 8” (DN 200) Standard Port Series 7150 ValvesBody MaterialCarbon Steel316 Stainless SteelAlloy 20(22)(36)(35)Carbon Steel ASTM A216 316 Stainless Steel ASTMAlloy 20 ASTM A351Type WCBA351 Type CF8MType CN7MCarbon Steel ASTM A216 316 Stainless Steel ASTMAlloy 20 ASTM A351Type WCBA351 Type CF8MType CN7M1Body2Body Cap3Ball316 Stainless Steel, Monel, Hastelloy CAlloy 204Stem316 Stainless Steel, Monel, Hastelloy CAlloy 205Seat6Body Seal8132022232930313233707172Stem SealThrust BearingCompression PlateIdentification TagPop RivetBonnet StudBonnet Stud NutDisc SpringsBody StudBody Stud NutTop Grounding SpringBottom Grounding SpringRetaining Ring10TECHNICAL BULLETIN 8/17Spiral Wound PTFE/316Stainless SteelPTFE, Xtreme, PFASpiral Wound PTFE/Spiral Wound PTFE/Alloy 20MonelPTFE (w/ PTFE seats), TFM (w/ Xtreme & PFA seats)PTFE, Filled PTFE316 Stainless SteelStainless SteelStainless SteelASTM A193 GR. B8, B8C, B8T or B8M, MonelASTM A194 GR. 8B, 8CB, 8MB, 8TB, 8FB, MonelInconelASTM A193 GR. B8, B8C, B8T or B8M, MonelASTM A194 GR. 8B, 8CB, 8MB, 8TB, 8FB, MonelStainless SteelInconelStainless SteelMonel(71)Monel ASTM A494M35-1Monel ASTM A494M35-1Monel, Hastelloy C asspecifiedMonel, Hastelloy C asspecifiedSpiral WoundGraphite/MonelMonelMonel(71)Monel ASTM A494M35-1Monel ASTM A494M35-1Monel, Hastelloy C asspecifiedMonel, Hastelloy C asspecifiedMonel

F L A N G E D B A L L VA LV E S A S M E C L A S S 1 50 & 3 0 0B107-1 ENDIMENSIONS10” (DN 250) Series 7150 ASME Class 150 and8” & 10” (DN 200 & 250) Series 7300 & 730S ASME Class 300 (Trunnion & Non-Trunnion)UVWØN187071709 6623, 1965 16 121413 10S5R2Cap Style for8" (DN200) 730S10" (DN 250) 7150 &10" (DN 250) 730SØC Typ.8GK0.500(12.7)ØE Port1791 92389Ball Protrusion For10" (DN250) 7150 1& 10" (DN 250) 730S 1BT Typ.D Bolt CircleL Size of HolesM Number of holesAValve Sizeinches10Valve SizeDN250Series 7150 ASME Class 150 Approximate Dimensions – inchesA13.00B5.85A330B149CD16.00 14.25C406D362E8.00GK15.60 10.22L**1.00M12N2.54R2.88S1.82T1.19Series 7150 ASME Class 150 Approximate Dimensions – mmEGKL**MNRST203 396 eries 7300 & 730S ASME Class 300 Approximate Dimensions – inchesValve 0 11.50 10.12 5.12 15.00 13.00 6.00 12.07 7.74 1.00 12 1.95 2.76 1.39 1.68 9.06 3.541018.00 13.00 10.85 5.85 17.50 15.25 8.00 15.60 10.22 1.13 16 2.54 2.88 1.82 1.88 9.06 3.54Series 7300 & 730S ASME Class 300 Approximate Dimensions – mmValve Size7300 730S 7300 730SDNCDEGK L** MNRSTUAABB200419282257130 381 330 152 307 147 25 12 50 70 35 43 230250457330276149 445 387 203 396 260 29 16 65 73 46 48 230Weightlb465Weightkg211Weight lbWX1-81-8N/AN/A7300 730S340695327576Weight kgVW*X7300730S90901-81-8N/AN/A154315148261* Screw-thread dimensions are in inches.** Holes in the body cap are threaded: 8” (DN 200) 730S (7/8-9 x 1.25 deep), 10” (DN 250) 7150 (7/8-9 x 1.13 deep), 10” (DN 250) 730S (1-8 x 1.38 deep)1 The ball only protrudes from the flange face (in the closed position) on the 10” (DN 250) 7150 and 10” (DN 250) 730S. This is because they have thesame F-F dimension and the same ball. Each of these also has the special insert with tapped pipe flange bolt holes.11TECHNICAL BULLETIN 8/17

B107-1 ENMETSOBILLS OF MATERIALS AND PARTS LIST10” (DN 250) Series 7150, 8” & 10” (DN 200 & 250) Series 7300 & Part NameBodyBody CapBallStemSeatStem RetainerGland FollowerCompression Plate1Body StudStem Retainer BoltStudNutNutIdentification TagRivetBody Gasket1Stem Retainer Seal1PackingStem BearingSecondary Stem SealTrunnion2Bearing Spacer2Trunnion Bearing2Body MaterialCarbon Steel (22) All Series316 Stainless Steel (36) All SeriesCarbon steel ASTM A216 Gr WCB316 Stainless steel ASTM A351 Gr CF8MCarbon steel ASTM A216 Gr WCB316 Stainless steel ASTM A351 Gr CF8M316 Stainless steel, Alloy 20, Monel1, Hastelloy C1 - as specified316 Stainless steel, Monel1, Hastelloy C1, 17-4 PH - as specifiedXtreme, PTFE - as specifiedCarbon steel ASTM A216 Gr WCBStainless steel ASTM A351 Gr CF8MCarbon Steel, Stainless steel, Monel1Stainless steel, Monel1ASTM A193 Gr B7; Gr B7M; Gr B8, B8C, B8T or B8MASTM A193 Gr B7; Gr B7M; Gr B8, B8C, B8T or B8MASTM A193 Gr B7; Gr B7M; Gr B8, B8C, B8T or B8MASTM A194 Gr 2H; Gr2HM; Gr 8B, 8CB, 8MB, 8TB, 8FBASTM A194 Gr 2H; Gr 2HM; Gr 8B, 8CB, 8MB, 8TB, 8FBStainless steelStainless steelSpiral Wound PTFE / 316 Stainless steel1Spiral Wound PTFE / 316 Stainless steel1PTFE, molecularly enhanced PTFE (Xtreme-seated valves)Filled PTFEGraphiteCarbon SteelStainless steelFilled PTFE316 Stainless steelNote 1: Compression plate, body gasket, stem retainer gasket, and gland follower are Monel for valves with Monel or Hastelloy C trim.Note 2: Parts 89, 91 and 92 are removed from values without trunnions.12TECHNICAL BULLETIN 8/17

F L A N G E D B A L L VA LV E S A S M E C L A S S 1 50 & 3 0 0B107-1 ENDIMENSIONS12” – 20” (DN 300 – 500) Series 7150 ASME Class 150 andSeries 7300 ASME Class 300 and 12” (DN 300) Series 730S ASME Class 300 (Trunnion)3435UUVVWW616" – 20" (DN 400–500)Type 7300332022, 37, 23, 36 3014" – 16" (DN 350–400)Type 715012" (DN 300) Type 730SP421Bonnet 12" (DN 300) Type 730S18" – 20" (DN 450–500) Type 715012" & 14" (DN 300 & 250) Type 7300292532øN146 218R357G8KøC Typ.øE Port27Q2628513TTyp.BD Bolt CircleL Size of HolesM Number of Holes10A11Series 7150 ASME Class 150 Approximate Dimensions - inchesValve 253.253.25Valve 3865537551179V1.19 8.00 3.251.31 8.00 3.251.38 10.00 3.251.5 11.13 5.301.62 11.13 5.30Series 7150 ASME Class 150 Approximate Dimensions - mm* Screw-thread dimensions are in inches** Holes in the body cap are threaded: 12” (DN 300) 730S (1-8 x 1.44 deep), 14” (DN 350) 7150 (1-8 x 1.31 deep), 16” (DN 400) 7150 (1-1/8-8 x 1.69 deep)13TECHNICAL BULLETIN 8/17

B107-1 ENMETSOValveSize ��–Series 730S & 7300 ASME Class 300 Approximate Dimensions – inches7300†CDEGKL** MNPQRB–20.50 17.75 10.00 21.76 11.13 1.25 16 3.00 1.05 – 3.1312.63 20.50 17.75 10.00 21.76 11.13 1.25 16 3.00 – 0.71 3.1313.00 23.00 20.25 10.00 21.76 11.13 1.25 20 3.00 –– 3.1314.00 25.50 22.50 12.00 23.51 12.63 1.38 20 3.50 ––420.81 28.00 24.75 13.25 24.94 14.00 1.38 24 3.50 ––416.00 30.50 27.00 15.25 26.12 15.25 1.38 24 3.50 ––Series 730S & 7300 ASME Class 300 Approximate Dimensions – mm7300†CDEGK L** MNPQRB–521 451 254 553 283 32 16 76 25–80321 521 451 254 553 283 32 16 76–18 80330 584 514 254 553 283 32 20 76––80356 648 572 305 597 321 35 20 89–– 102529 711 623 337 633 356 35 24 89–– 102406 775 686 387 663 387 35 24 89–– 102Weight 13.0013.005.305.305.307.007.007.00730S 73001/2-13 7401/2-13 –1/2-13 —3/4-10 —3/4-10 —3/4-10 —–9701130170020003000Weight 781781/2-131/2-131/2-133/4-103/4-103/4-10730S 7300336–————–4175137719071361* Screw-thread dimensions are in inches.** Holes in the body cap are threaded: 12” (DN 300) 730S (1-8 x 1.44 deep), 14” (DN 350) 7150 (1-8 x 1.31 deep), 16” (DN 400) 7150 (1-1/8-8 x 1.69 deep).† 18-inch (DN 450) valve is designated 3334353637Note 1:Note 2:Note 3:Note 4:14BILLS OF MATERIALS AND PARTS LIST12” – 20” (DN 300 – 500) Series 7150, 12” – 20” (DN 300 – 500) Series 7300, 18” (DN 450) Series 73LO,and 12” (DN 300) Series 730S (Trunnion)Body MaterialPart NameCarbon Steel (22) All Series316 Stainless Steel (36) All SeriesBodyCarbon steel ASTM A216 Type WCB316 Stainless steel ASTM A351 Type CF8MBody CapCarbon steel ASTM A216 Type WCB316 Stainless steel - ASTM A351 Type CF8MBall316 Stainless steel, Alloy 20, Monel1, Hastelloy C1 - as specifiedStemAlloy 20, 316 Stainless steel, 17-4PH Stainless steel, Monel1, Hastelloy C1 - as specifiedSeatPTFE, filled PTFE, - as specifiedBody SealSpiral-wound PTFE/316 Stainless steel1Secondary Stem SealGraphiteStem BearingFilled PTFEBody StudASTM A193 Gr. B7; Gr. B7M; Gr. B8, B8C, B8T or B8MNutASTM A194 Gr. 2H, 2HB, or Gr. 2HM; Gr. 8B, 8CB, 8MB, or 8TBBonnet StudsASTM A193 Gr. B7; Gr. B7M; Gr. B8, B8C, B8T or B8MBonnet Stud NutASTM A194 Gr. 2H, 2HB, or Gr. 2HM; Gr. 8B, 8CB, 8MB, or 8TBCompression PlateCarbon steelStainless steel, Monel 2Compression RingStainless steelIdentification TagStainless steelDrive ScrewStainless steelStem Retainer SealGraphiteTrunnion PlateCarbon steel, Type WCB316 Stainless steel1, Type CF8MTrunnion Bearing316 Stainless-steel-backed glass-filled PTFEBearing SpacerFilled PTFEHex. Hd. Cap ScrewCarbon steel ASTM A193 Gr. B7 or B7MStem RetainerCarbon steel Type WCB316 Stainless steel type CF8MUpper Stem SealPTFEKeyCarbon steelSc. Hd. Cap Screw3ASTM A193 Gr. B7; Gr. B7M; Gr. B8, B8C, or B8TTrunnion RingCarbon steelStainless steelTag: Trunnion BallStainless steelCaution Tag4Stainless steelWhen trim is Alloy 20 or Monel, body seal is PTFE Monel, when trim is Hastelloy C, seal is PTFE Hastelloy C.When trim is Alloy 20, Monel, or Hastelloy C, compression plate is Monel.For 14” & 16” (DN 350 & 400) 7150 and 12” (DN 300) 730S only.For 12”, 14”, & 16” (DN 300, 350, & 400) 7150 and 12” (DN 300) 730S& 7300 only.TECHNICAL BULLETIN 8/17

F L A N G E D B A L L VA LV E S A S M E C L A S S 1 50 & 3 0 0B107-1 ENVALVE TORQUE DATAUse these torque charts as a guide for actuator selection. Additional requirements may be imposed by mediacharacteristics, trim, and frequency of valve operation. Forclean lubricating fluid service, required torque for PTFE(T), Xtreme (X) and filled PTFE (M) seated valves only maybe reduced 20% when the valve is equipped with corrosion resistant trim. For difficult services such as slurriesand semi-solids, and for oxygen, increase values by 50%.If in doubt, err on the side of safety by using a larger actuator than would normally be selected.Torque output values and actuator selection tables for thedifferent types of Jamesbury actuators are contained inthe bulletins listed below.Manual Gear ActuatorsB-Series Piston ActuatorsQuadra-Powr X Spring DiaphragmRotary ActuatorsValv-Powr Series VPVLVPVL Stainless SteelV-Series Electric ActuatorsADC Electric ActuatorsLC Series Electric ActuatorsESR-Series Electric ActuatorsQ6-Series Electric ActuatorsQX-Series Electric 202-1 & A203-1A204-1A205-1A207-1ASME Class 150 and 300

1/2" - 2" (DN15 - 50) Series 7150 ASME Class 150 and Series 7300 & 730S ASME Class 300 (Non-Trunnion) J amesbury OPEN 4 Holes Ø L on A Ø M Bolt Circle Ø E Port Dia. 25, 26 16, 19 20, 29, 31 1 S 7, 13 8 ØR 4 6 17 3 5 2 T Ø N thru both ends P No. of holes Hex. Size X Ø D Bolt Circle Typ. both ends K J ØC A B F G H FLANGED BALL VALVES .