Transcription

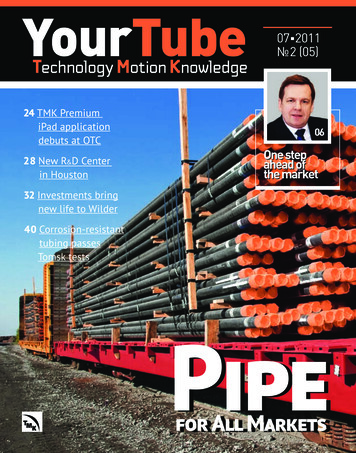

07 2011 2 (05)24 TMK PremiumiPad applicationdebuts at OTC28 New R&D Centerin Houston32 Investments bringnew life to Wilder40 Corrosion-resistanttubing passesTomsk tests06

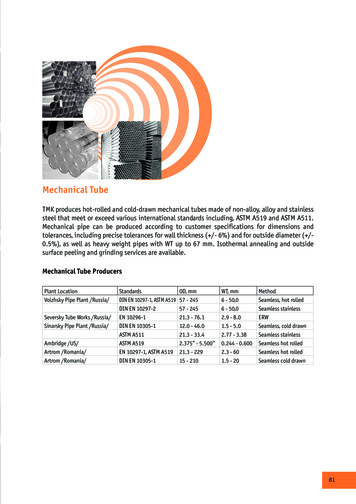

YourTube is targeted to threeaudience groups – hailingfrom various countries andначальникcontinents – andis published inparallel Russian, Romanian andEnglish editions. The highlightsof each magazine are different,depending on the division. Thisedition offers a compilation ofselected materials publishedin the Russian and Romanianeditions of YourTube No. 2 (05)Table of contents32As TMK IPSCO’s longest continuously operating plantcelebrates a major milestone, expansion of its facilitiespaves the way for future successNewsBulletin 10 Years of ProsperityTMKAnniversary:GlobalInterviewwith Dmitry Pumpyanskiy, Chairman of TMK’sBoard of LeaderDirectorsHistory of TMK: from a Local Manufacturer38to a GlobalTMK’sgrowthstrategyhasplayershelped init becomeanpipeindustryleaderand oneCompanyof the keythe globalmarketFirst inRussiato and uston Visit by Russian IndustrialistsHighlights Key Issues in Growing U.S.-RussianCommercial TiesBuilding Commercial rof sthat changebetweenAmericanandRussiancompaniesTrade Organizations Help TMK IPSCOKeep Pace with Technology, rcialOffigovernmentcerof TMK IPSCO,ScottBarnes,speakson interactionwithofficialsand thewisdomof joining publicassociationsCoverStoryTheEra ofTMK-INOX– aNANOjoint project between TMK and RUSNANOScienceAHalf CenturyRosNITIcelebratesofitsInnovation50th anniversaryProductionNorth American Customers Benefit fromTMK’s Global Product Line2News Bulletin6The Sales MatrixCover StoryKonstantin Semerikov, Senior Vice President at TMKand General Director of Trade House TMK, speaks onthe company’s strategy in the face of changes in globaltradeSales in the Americas – A Story of Growth40As in other regions where TMK is present, North andSouth America are key to the company’s operations.Two directors responsible for sales at TMK IPSCO –Chuck King and George Adams – discuss promisingdevelopments16The Artrom plant was one of the first in Romania to begincertifying its products, with the first certificates being receivedin 1993. National auditors did not exist at the time, socompanies had to apply to specialized foreign firms.When deciding on the certification of its products, TMKArtrom’s management has pursued the important goal ofentering export markets. The presence of product qualityassurances has helped the company implement ambitious plans.The criteria and certification requirements have changedover time. Customers now want to have pipe quality assurancesat all stages of production — from the raw material to finishingoperations. In 2010, at the request of customers, TMK-Artromreceived certification from Lloyd's Register for pipes used inship building, as well as for steel billets produced by TMK-Resitafor these pipes’ manufacture.Both Romanian facilities currently operate accordingto international standards in environmental protection,quality management, and occupational safety. They continueto work actively toward the certification of their products.Magdalena Popescu, Director of Quality, Health and Safety, andEnvironmental Protection at TMK-Artrom, said that the companyis ready to meet further requirements imposed by the market:“Customers are the most stringent auditors, because they knowwhat they need.”20Europe Is a Mosaic of Business Cultures44Strong global demand for energy continues to act as acatalyst for the growth in demand for tubular products.Market participants and analysts expect that this yearproduction volumes in the Russian pipe industry will growby 5 to 10 percent.The political crisis in the Middle East and refusal in theEuropean Union to develop nuclear energy in the wake ofthe accident at Japan’s Fukushima-1 plant have provokeda rise in oil prices. According to industry analysts’ mostconservative forecasts, the average oil price for 2011will be 96.80 per barrel. Rising oil prices are the mainprecondition for the further expansion of oil production.Relatively recently, pipe manufacturers have been ableto use new technologies to open up deposits of shale gas.The fact that investment companies consider shale gas tobe a promising resource in the energy sector is evidencedby recent transactions in this market involving several largeglobal firms.EducationPiotr Galitzine Speaks to BoothExecutive MBA Class of 2012TMK IPSCO’s Chairman, Piotr Galitzine, touches basewith studentsMarketsTMK-Artrom Conquers AmericaIt took Artom 20 years to prevail in the highlycompetitive North American marketAccording to IHS CERA, global production of shale gas could reach 180billion cubic meters per year by 2018.Triumph of Oil and GasOur PartnersThe Tomsk RouteCorrosion-resistant tubing made of steel containingchromium — a product of TMK’s expertise — brilliantlypasses industrial testing at Tomskneft’s ChkalovskoyefieldAdrian Popescu, President & CEO of TMK’s EuropeanDivision, speaks on key changes to TMK’s salespractices in EuropeTMK-Artom: Full CertificationImmune to CorrosionTubing made from steel containing 13percent chromiumthreaded with TMK FMT Premium Connections – TMKbrings a new high-tech product to the Russian market12Magdalena Popescu, Director of Quality, Health and Safety, andEnvironmental Protection at TMK-Artrom.Production30 Years On, Big InvestmentsBring New Life to Wilder24Business CommunityA Week to Celebrate – OTC 2011TMK’s booth at OTC 2011 drew considerable interestfrom visitors, and the gala party organized by thecompany was the week’s most lively event28ScienceNew Era of R&D Begins in HoustonGround is broken on the new R&D Centerin Houston# 2 (05) july 2011Incorporator:Project manager:Svetlana BazylchikBazylchikSI@TMK-group.comEditor’s office address:Russia, 105062, Moscow, 40Pokrovka Street, Bldg. 2aTel.: 7 (495) 775 7600Fax: 7 (495) 775 7601E-mail: pr@TMK-group.comwww.TMK-group.comCertificate of a publicationNo. FS77-40128 of June 11, 2010The edition is registered with theFederal Service for Supervision inthe Sphere of Communications,Information Technology and MassCommunications.Any use of the materials withoutthe editors' consent is prohibitedPrinted in the Print.Market LLCprinting office.Print run is 4,000 copies.01 YOURTUBEPublication printer: ЛЮДИPEOPLE Group129085, Moscow, 21 Zvezdny Boulevard, bldg. 1, office 18Tel.: 7 (495) 988 1806E-mail: ask@vashagazeta.comEditor-in-Chief: Yelena Kostyuk Art director: Maksim GuelikDesigner: Aleksandra Marochkova Correspondents: Ivonne Baez (USA),Mikhail Cherkasov (Russia), Adam Fuss (USA) Production Director: OlegMerochkin Color correction: Sergey SouslovProof-reading: Lexica

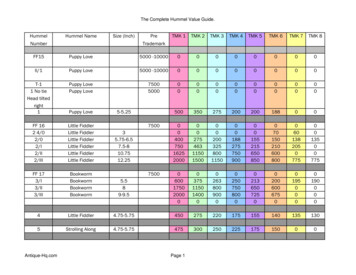

news RECENT DEVELOPMENTS IN PREMIUMTMK has started production of the new TMK CWB premiumconnection for use in casing string. The Volzhsky Pipe Plantwill be responsible for commercial manufacture of pipesthreaded with TMK CWB connections.TMK CWB is an upgraded version of the buttressconnection, which is widely used by Russian oil and gascompanies. TMK CWB has two unique characteristics. The firstis the presence of an additional thrust face, which is designedfor precise fixation given the tightness in the assemblyprocess. This allows for an increase in the connection’sgas-tightness and operational efficiency. The second is theconnection’s ability to be coupled with other types of threadsand to be used as an adapter.The new product type was developed and brought toproduction by specialists from TMK-Premium Service. TMKCWB has been successfully tested for gas-tightness undercombined load at VNIITneft. TAGMET HOSTS METAL TRADERSto merchandise cars. Thedelegation had a chance toview the modern equipment atTAGMET — the steel vacuumdegassing unit and thecontinuous casting machinesin the open-hearth shop,and Russia’s only PQF mill,which uses three-roll standtechnology.Volumes of TMK Pipe Shipments in 2011 (thousands of tonnes)25002000 15.3% 17.5%783500 7.4%80510007291500January—June 2011January—June 20101,8642,166 16.2%946In the first six months of 2011, TMKshipped 2,166,000 tonnes of steel pipeto customers, which is a 16.2 percentincrease in comparison to the first sixmonths of 2010. Shipments of largediameter pipe amounted to roughly377,000 tonnes, which is a 33.7 percentincrease in comparison to the sameperiod in 2010. Shipments of OCTGincreased by 7.4 percent compared to thesame period of 2010. In the first half ofthe year, TMK IPSCO shipments of tubularproducts amounted to roughly 479,000tonnes, exceeding by 16.3 percent thevolumes shipped in same period of 2010.The largest increase was observed inthe line pipe segment, which was due toincreased volumes of hydrocarbons thatneeded to be transported to processingand storage sites. Demand for premiumproducts is also growing. The growingshale development in the U.S., where TMKIPSCO’s share of premium connectionstraders is beneficial toboth parties. Vadim Braynis,Managing Director of ArielTrade, expressed satisfactionwith TMK’s flexible marketingpractices. Taking into accountthe wishes of customers, thecompany’s facilities haveorganized truck delivery oftheir products and its transport1,058 RECORD LEVELSwhere a number of issueswere discussed, such as themodernization of productionfacilities, product quality, andstrengthening TMK’s positionin international markets. It wasnoted that the developmentof a dealer network, long-termcontracts and guaranteedsupply by plants to metal1,220TAGMET was recently thevenue for a metal traders'conference that was held underthe name “10 Years of TMK onRegional Markets — Results andOutlook.” The organizers wereTMK and the Russian Unionof Metal and Steel Suppliers(RSPM). More than 120 dealerstook part in the conference0SeamlesspipesWeldedpipesused in gas production exceeds 30percent, has allowed the companyto optimistically forecast additionalvolume for its American division. In thefirst six months of 2011, TMK shipped02 YOURTUBETotalpipesIncludingOCTGapproximately 236,000 premiumconnections developed in its Russian(TMK family) and American (ULTRA)divisions, which is 3.2 percent more thanin the first six months of 2010.Vladimir Sazonov, Director of Quality at TMK IPSCO, and Mike Brown,Manager of Process Engineering at TMK IPSCO. SIX SIGMA ACADEMYIn March, TMK launched a project to train managersheading up improvement projects on the methodologyof Lean Six Sigma. The training session lasts five monthsand is designed for production and technical personnel atTMK plants, as well as for employees of the managementcompany. Each month, the course consists of one week oftheoretical training and one week of practical training onthe corresponding stages of DMAIC — Define, Measure,Analyze, Implement, and Control. The theory is taught byRobert Vaughn, Director of the Six Sigma Academy (NewYork), Mike Brown, Manager of Process Engineering at TMKIPSCO and a Six Sigma “Black Belt”, and other professionals.Vladimir Sazonov, Director of Quality at TMK IPSCO,provides advice on the practical training sessions. TMK PF AND ULTRA-QX RECEIVEINTERNATIONAL CERTIFICATIONTMK has successfully conducted qualification tests for TMK PFand ULTRA-QX premium connections (Grade P110, OD 245mm,wall thickness 11.99mm) in accordance with the ISO 13679CAL IV standard. The tests were conducted at the Oil StatesIndustries international testing center (Aberdeen, UK), whichis where the world’s largest oil and gas companies performproduct qualification.The tests were conducted by TMK-Premium Service, whichtested TMK products for the first time for compliance with theISO 13679 CAL IV standard.03 YOURTUBE

news TMK AT HANNOVER MESSETMK and Trade House TMK participated inHannover Messe 2011, an industrial exhibitionthat was held in early April in Hannover,Germany. Hannover Messe is the largestindustrial and economic forum that is activelyused by government officials and businessleaders from many countries as a platformto promote goods and services, as well as tosupport contacts with foreign partners.Hannover Messe received more than 230,000visitors in total. More than 6,500 companiesfrom 65 countries arrived in Hannover toshowcase their achievements and to shareinnovative solutions.During the exhibition, numerous meetingswith customers took place at TMK’s booth. Thebooth was also visited by a delegation fromthe Sverdlov regional government, which washeaded by Governor Alexander Misharin andMinister of Economics Mikhail Maksimov. NEW TITLE FOR ADRIAN POPESCUIn April, Adrian Popescu, President & CEO of TMK’s EuropeanDivision, celebrated his 50TH birthday. He has been with TMKArtrom for 26 years. To celebrate his birthday, a delegation headedby Dmitry Pumpyanskiy, Chairman of TMK’s Board of Directors,arrived in Romania. The delegation included company leaders,friends and associates. Pumpyanskiy congratulated Popescu inRomanian, pleasantly surprising everyone present.“Adrian is a professional of the highest level and is wholeheartedly devoted to the company. He is respected not only inRomania, where under his leadership TMK-Artrom and TMK-Resitahave become absolute manufacturing leaders,” said Pumpyanskiy.“Adrian has gone from being a machine operator apprentice atArtom to President and today not only stands in control of theRomanian facilities, but is also the President of TMK’s EuropeanDivision.”For his operational and commercial successes and his loyaltyto the company, Popescu was awarded the title “Honored TMKWorker.” A distinctive emblem and an honorary document werepresented to him by TMK CEO, Alexander Shiryaev. ULTRA SQUEEZES COMPETITORSTMK completed a shipment of casing with ULTRA SFpremium connections to Gazprom Neft.The shipment contained grade P110 casing withULTRA SF connections (OD 127mm, wall thickness9.19mm) that was produced by TMK IPSCO. The product isdesignated for use at the Urmanskoye field in the TomskRegion.“Previously Gazprom Neft imported this type of pipefrom our global competitors. Now, having complementedour premium connections portfolio with Ultra threadsdeveloped by TMK IPSCO, our U.S. Division, TMK cansupply a large range of world-class premium products toRussian oil and gas companies,” said Alexander Shiryaev,TMK CEO. RECENT DEVELOPMENTSTAGMET has mastered the productionof pipes and couplings of size 177.8 x9.19 mm. These are seamless casingand couplings made of Grade P110steel based on U.S. API Spec 5CT. Thepipe modified by TAGMET with a TMKPF connection is designed for usein sour service environments, wherehigh connection strength is especiallyimportant.The connection’s gas-tightness isensured by the presence of a “metalmetal” pressurized center. The conicalsurface of the pipe and couplings create astop and an additional gas-tight barrier.Heat treatment regimes were chosenfor the newly-developed pipe andcouplings. The results of mechanicaltesting of pipes and couplings werepositive. Samples of these products are TMK-PREMIUM SERVICE SHOWS OFFLukoil’s V International Scientific Conference on Drilling has takenplace. TMK-Premium Service’s exhibition stand was specially developedfor the conference. Aluminum models of Premium-threaded pipe weremade in full size.The forum between TMK-Premium Service developed an agreementfor industrial trials of TMK PF connections in order to determine theirpossible use in offshore drilling.In mid-May, Trade House TMK and TMK-Premium Service took partin the 35 TH conference on the topic of “New Technical and ProcessDesign Solutions in the Construction of Onshore and OffshoreWells.” The conference was organized by the Association of DrillingContractors.TMK’s presentation sparked great interest among industryprofessionals. In particular, they were interested in the project tocreate a new line of casing with premium connections, which is beingimplemented at the Orsky Machine-Building Plant.04 YOURTUBE05 YOURTUBEnow at VNIITneft where they will betested for sulfide cracking.The new product was developedin the pipe welding shop at TAGMET.Manufacture of ERW pipe with an ODof 219mm and wall thickness of 8 mmaccording to the GOST 10704 and GOST10705 standards has commenced. Thesepipes are used to build pipelines and invarious types of construction.

cover storyTHE SALES MATRIXTMK conducts well thought-out trade practices, maintaining a presence in majormarkets and steadily expanding in promising pipe-consuming regions. At the sametime, the world is already changing, forcing global market participants to rethinktheir manufacturing and sales approaches. KONSTANTIN SEMERIKOV, Senior VicePresident at TMK and General Director of Trade House TMK, tells us about theglobal company’s sales strategy and tactics.Mr. Semerikov, what does the TMKsales system look like now with itsnewly formed divisions in Europeand North America?Our system is centralized, with acertain amount of independencefor our European and Americandivisions. The effectiveness of thisapproach is proven by our positivesales trends. Our sales are based ona hybrid, matrix approach: geographic distribution on the one hand andproduct distribution on the other.We are the strongest in the regionswhere we have manufacturingfacilities—in our domestic markets.This is explained by our economicand logistics systems, possessionof country-specific solutions toprotect our market and on the wholeby our better knowledge of localparticulars.Over 85 percent of the productsmanufactured by our Russian facilitiesare delivered to the former SovietUnion—Russia and other CIS countries. Over 90 percent of TMK-Artrom’sproducts go to European customers.In turn, TMK IPSCO’s facilities sell over95 percent of their products in theUnited States.At the same time, in all “domestic”markets, we also offer product gradesthat are in short supply, which our facilities in the given region don’t havebut which are manufactured at ourother facilities. Thus, we are expanding our product offerings to providecustomers with a fairly wide rangeof products. With the Moscow-basedTrade House in charge of overall coordination, the trading unit located ineach given region is our leader whenit comes to ensuring a comprehensivesupply to domestic markets. If we offera full line of products to Europe, forexample, the leading coordinator willbe TMK-Europe, in North America, itwill be TMK IPSCO; and in SoutheastAsia, it will be Trade House TMK inMoscow.Of course, we are striving to expand our presence in other pipe-consuming regions. Today, TMK exportsproducts to more than 65 countries.We have created and continue todevelop the necessary infrastructureto advance this expansion of tradingcompanies and representative officesaround the world.Do the products of all the company’sfacilities carry the same brand in themarket?All our products are sold under theTMK brand. The product certificatesand tags list TMK first, and then themanufacturing facility. The existenceof a single brand improves recognition, as well as loyalty among bothold and new customers. We have agood example from TMK IPSCO’sexperience: when the companyreturned to the Canadian market,former customers recognized itfirst under the IPSCO brand as ithad been known there before TMKacquired American assets. They06 YOURTUBErecognized it and came back withorders. But now the Canadian marketknows the TMK brand well and wedon’t just supply standard productsthere, but specialty pipes for the oiland gas industry.Are there differences among theRussian, European, and Americandistribution channels?In Russia, we sell through the TradeHouse and its subsidiaries. We alsosell some general-purpose products through our dealers in Russiaand other CIS countries. TMK hasthe largest dealer network, whichcurrently includes 88 authorizedrepresentatives. In Romania, wesell our products through two channels: through metal traders anddirectly to end users. But in NorthAmerica, our trade is mostly throughdistributors.Is it hard to reach the end user inNorth America, or is there someother reason?It’s a specific feature of the localmarkets in the U.S. and Canada. Thedistributors don’t just buy and sellpipe; rather, they provide additionalservices to their customers—oiland gas companies. In other words,they perform the functions of a pipedistribution center. The distributorprovides the very same services ofinspection, delivery, modified andjust-in-time deliveries, or, on theother hand, acceptance of returns.The end user pays only for productsthat are actually used without havingto maintain that entire infrastructure.In Russia, for example, there is afundamental difference. For historical reasons, each major companyhas developed its own pipe distribution center. Unlike Russia, in the U.S.there are many small companiesthat cannot afford to maintain theirown centers. The U.S. has over 1,000oil and gas companies, from littleones with one or two rigs to majorones like ExxonMobil. The distribu-tors don’t always target the verysame oil and gas company but normally supply 100 or 200 companiesin a region. But in Russia, the fiveoil “majors” cover over 70 percent ofproduction.Americans are certainly willing topay for service, but they don’t wantto incur the huge investment costsof developing their own logisticsunits.Why doesn’t TMK have its own retailnetwork?07 YOURTUBEAny warehousing businessrequires considerable investment.To date, our priorities have beeninvesting in the development ofproduction capacity, and that policyhas proven wise. Our existing dealernetwork provides the necessarylevel of sales in the regional Russianand other CIS markets. Even so, weare now implementing a warehousetrading program. Trade House TMKleases warehouse space from ourRussian companies, where we storea wide range of pipes made by

cover storythose companies. The existence ofwarehouse stockpiles enables usto respond quickly to fulfill ordersand thereby increase sales volumeaccordingly. Customers have a needfor a wide range of products, butour working capital is insufficient.We solve this problem by investingour working capital in the development of stockpiles. In doing so, weare adhering to best practice in theindustry.Is TMK alone in Russia in followingthis practice?Others do it as well to a varying extent, but we have consciously decided to hold intermediate stockpilesat facilities whose products belongspecifically to the Trade House. Thatway we are able to make quick sales.What are the specific features ofyour relationships with major dealers?For this category, we build in specialincentive programs on the idea of alower unit price for greater volume.This practice is mutually beneficial.For us it means a stable workload,work scheduling, and more predictable financial performance accordingly. Our customers in the industrialpipe segment observe our resultsvery attentively. Say a major clientin the machine-building segment,KAMAZ, has rated TMK as a class-Asupplier, thereby rating the qualityof our products and service. In turn,we react sensitively to the slightestchange in our rating. If we suddenlysee a weakening of our position,we will do everything possible torestore it.How do you structure your relationships with key customers?Our most important customers arecompanies in the oil and gas sector,which accounts for over 70 percentof TMK’s shipments. Half of this volume is seamless OCTG. A large shareof these shipments is large diameterpipe, whose principal customers areGazprom and Transneft. Our priorityrelationships are long-term and wehave established these relationships with all the major oil and gascompanies in Russia. Our Russianmanufacturing facilities cooperatedclosely with oil companies evenbefore the formation of TMK.Now TMK, having consolidatedthe major pipe producers in Russia,is the unconditional leader for Russian oil companies. About 60 percentof all seamless oil-industry pipesare supplied by TMK. Our oil andgas service is also oriented towardsRussian oil producers. The specificfeatures of the oil and gas marketare such that among companiesthat directly use tubular products,an enormous number of contrac-08 YOURTUBEtors work in that field, providingengineering and other associatedservices in the organization ofthe oil production process. Theyoften consist of a business that hasbeen spun off from a major globalcompany and bring state-of-the-arttechnologies from foreign companies to Russia.Experience has shown that establishing relationships with theseentities is a guarantee that ourproducts will be used and applied inspecific fields. And while we previously thought we had to expand ourrelationship with ExxonMobil, wenow understand that we must alsoestablish ties with the subcontractors they select for regional tenders.With these trends in mind, we haveboosted our efforts in this area, andall of our facilities are now becoming qualified both with end usersand with service companies. This isone of the areas that promotes ourpresence in the oil and gas producing regions of the world.What are the general supply trends inthe global tubular products market?The tubular component in globaltrade is shrinking as standardquality tubulars are more frequentlybeing handled through regionalsales. Global trade is shifting tothe premium product types. Forexample, until very recently highstrength casing was considered anitem of global trade. In other words,it could be sold in every part of theworld and the share of such saleswas large. Today, this share is declining because local manufacturerswho meet regional demands for casing have appeared in many parts ofthe world. These regions include theMiddle East, Southeast Asia, Europe,Latin America and so forth. So theglobal trade today is more abouttrade in high-tech premium products, of which there are a limitedamount on the market at the moment. Such products are in demandand sold worldwide, regardless ofthe manufacturer’s geography.How is TMK responding to thismarket challenge?As one of the world’s leadingmanufacturers, TMK fully accountsfor the new trends in its operations,especially when it comes to meetingthe need to offer highly complicatedproduct types that are traded inworld market. Our newly-createdPremium division, which includesproduction and intellectual assetsof TMK IPSCO and our Russian facilities, is working to develop premiumproducts. Our program of expansioninto promising markets is tied specifically to comprehensive deliveries of premium-class goods. Thesemarkets are Africa, Latin America,and Southeast Asia. Naturally, thereis tight competition in these regions,but we believe our presence therewill be justified.What is TMK’s potential for salesgrowth of internationally tradedgoods?We have been measuring the upward trend in demand for tubularproducts for a long time. Oil andgas companies are expanding intothe permafrost, where they require thermally insulated pipe and“thermal cases,” and into viscouscrudes, for which they also requireinsulated pipe capable of deliveringheat-transfer agents to the pay zone.When producing fluids with highgas content, they require specialgas-tight connections and the use ofGrade X80 pipe has already becomeroutine. Companies are engaged inoffshore drilling. LUKoil is alreadyproducing from the northern Caspian Sea and Gazmorneft and Rosneft have plans to develop offshorefields in the Black Sea.In creating a technical andtechnological platform for manufactureing next-generation products,we have carried out large-scalemodernization projects at all ourfacilities. From this standpoint, weare completely ready to meet themarket challenges.To demonstrate compliance withour customers’ technical requirements, we undergo qualification ofour products with major companies.For example, we are now undergoing qualification for the Trans-Alaskapipeline, for the Shtokman gas andcondensate field and other promising projects. It is no secret that inrealizing the Shtokman project,Gazpromneft will not be alone inimposing requirements on suppliers;Global trade today is more abouttrade in high-tech premium products.Such products are in demand andsold worldwide, regardless of themanufacturer’s geography.its foreign partners Total and Statoilwill do so as well. We are ready forthis and our technical developmentsare under way.Our TMK PF premium connectionsrecently passed ISO 13679 CAL IVcertification. This proves the worldclass quality of our thread and allowsus to enter the pool of leading globalsuppliers of tubular products forboth onshore and offshore complexdrilling and hydrocarbon productionprojects. We are proving our technical capabilities to supply high-techproducts. In addition, we are workingunder research cooperation contractswith oil and gas companies. Takentogether, all this supplements ourunderstanding of customer needsand allows us to move forward rapidly on our chosen path.What are the specific featuresof doing business in the post-Sovietspace?The CIS (Commonwealth of Independent States) market is extremelyimportant to us because it is developing rapidly. New fields are beingdeveloped and pipeline projects areunderway. The state companies working in the CIS countries are practically integrated into the all-Russian gastransport system. For us, this is anenormous plus. Moreover, the republics of the former Soviet Union havetechnical regulations developed backin the Soviet days. And the opinionof Russian institutes such as the Russian Scientific Research Institute ofNatural Gases and Gas Technologies(VNIIgaz) carries great weight. All thisplays into our hands as sellers.Joint ventures with foreignparticipation have recently begun to appear in the CIS. This is apromising class of customers but amore complicated one for us in thismarket. Relations with them requireflexibility, agility, a higher levelof technical support for sales andadministrative support. And ther

of each magazine are di erent, depending on the division. This edition o ers a compilation of selected materials published in the Russian and Romanian editions of YourTube No. 2 (05) Table of contents Coordonatorii proiectului: Svetlana Bazylchik, TMK BazylchikSI@tmk-group.com Natalia Svyatoslavskaya, Media-Service svyatoslavskaya@mail.ru