Transcription

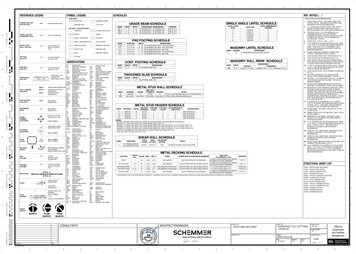

12REFERENCE LEGEND3SYMBOL LEGENDH-XHEADER DESIGNATIONMETAL STUDWALL CALLOUTLINTEL DESIGNATIONLETTER INDICATESMETAL STUD WALLTYPEXGROUTEARTH / COMPACTEDPLYWOODEARTH / NONCOMPACTEDWOOD (FINISH)RIGID INSULATIONMASONRY-CMU FACEJOINT FILLERMASONRY-CMUone and one half inches one foot6"0one inch one foot6"0SHEAR WALLCALLOUTDPAD FOOTINGCALLOUTSREFERENCENOTEROOM /FRAMINGELEVATIONEXTERIORELEVATION4three quarters inch one foot6"02CWALL FOOTINGCALLOUTSone half inch one foot0PLANDETAILXNEWCOLUMNLETTER INDICATESEXISTING COLUMNLINEX4three eighths inch one foot08one quarter inch one foot04LETTERINDICATES NEWCOLUMN LINEAREA AMATCHLINEAREA BLEVEL NATIONTITLEMARKER1VIEW NAMEGRAPHIC AREA FORDRAWINGDETAIL NUMBERTITLESCALE: 1/8" 1'-0"SCALE OF THE DRAWINGDIMENSIONDEAD LOADDRAWINGDOWELSEACH FACEEXPANSION JOINTELEVATION - GRADE ORBUILDINGELEVELEVATOREQEQUALEQUIP EQUIPMENTEWEACH WAYEXIST EXISTINGEXPNEXPANSIONEXTEXTERIORFFAHRENHEITFDFLOOR DRAINFDNFOUNDATIONFINFINISHFLRFLOORFTFEET (FOOT)FTGFOOTINGFVFIELD VERIFYGAGAGE OR GAUGEGALVGALVANIZEDGRTG GRATINGGWBGYPSUM WALLBOARDH or HT HEIGHT (HIGH)HDRHEADERHKHOOKHORIZ HORIZONTAL(LY)HPTHIGH POINTHSHIGH STRENGTHIDINSIDE DIAMETERININCHINSUL INSULATIONINTINTERIORKIP or K KILOPOUND (1000 LBS)KPKICK PLATEX)DEPTH4' - 10"4' - 10"4' - 10"LONGITUDINAL REINFORCING(3) #5 BARS BOT., (3) #5 BARS TOP(5) #5 BARS BOT., (5) #5 BARS TOP(6) #5 BARS BOT., (6) #5 BARS TOPLINTEL CLEARSPAN345678STIRRUPS#4 @ 24" O.C.#4 @ 24" O.C.#4 @ 12" O.C.PAD FOOTING SCHEDULEMARKF3.0BF3.5F4.0F5.0F6.0PLAN SIZE3'-0" X 3'-0"3'-6" X 3'-6"4'-0" X 4'-0"5'-0" X 5'-0"6'-0" X 6'-0"DEPTH4' - 10"4' - 10"4' - 10"4' - 10"1' - 6"REINFORCING(5) #6 BARS EACH WAY, TOP & BOTTOM(5) #6 BARS EACH WAY, TOP & BOTTOM(5) #5 BARS EACH WAY, BOTTOM(8) #6 BARS EACH WAY, TOP & BOTTOM(7) #6 BARS EACH WAY, BOTTOMLINTEL MINIMUM ENDBEARING4"4"4"8"8"8"LINTEL 3/823BEARINGREINFORCING8"16" BOND BEAM W/ (2) #5 CONT. @ BOT.MARKCF2-0LENGTH (LONG)POUNDSLOADINGLIVE LOADLONG LEG BACK TO BACKLONG LEG HORIZONTALLONG LEG VERTICALLINTELLONG LONGITUDINALLOW POINTLIGHT ECH INMINIMUMMISCMISCELLANEOUSNICNOT IN CONTRACTNONUMBERNRNOT REQUIREDNTSNOT TO SCALEOCON CENTER(S)OCEW ON CENTER EACH WAYODOUTSIDE DIAMETEROHOVERHEADOPNG WD PLYWOODPOLPOLISH(ED)PREFAB PREFABRICATEDPSPRESSED STEELPOUNDS PER SQUARE FOOTPSFPSIPOUNDS PER SQUARE INCHQTYQUANTITYRRADIUSRDROOF DRAINREFREFERENCEREINF REINFORCEMENTREQD REQUIREDRTUROOF TOP UNITSCHED SCHEDULESDISTEEL DECK INSTITUTESFSQUARE FOOT (FEET)SHTGSHEATHINGSIMSIMILARSJISTEEL JOIST INSTITUTESLSNOW LOADSLBBSHORT LEG BACK TO BACKSPECSPECIFICATIONSSSSTAINLESS STEELSTDSTANDARDSTGRSTRINGERSTIFFSTIFFENERSTIRR BTOCTOFTOSTOWTRANSTYPTEMPERATURETOP OFTOP OF BEAMTOP OF CONCRETETOP OF FOOTINGTOP OF STEELTOP OF WALLTRANSVERSETYPICALUNEXUNOUNEXCAVATEDUNLESS NOTED FWIDE (WIDTH)WITHWITHOUTWIDE FLANGEWIND LOADWORK POINTWEIGHTWELDED WIRE FABRICWIDTH2' - 0"DEPTH1' - 0"SHEAR WALL TYPE 'A' - MIN. L 6'-0"4 1/2" CONCRETE W/ 6X6 W2.9XW2.9 W.W.F. OVER1 1/2" TYPE 'C' 20 GAUGE NON-COMPOSITE METALDECK, TYPICAL (6" TOTAL THICKNESS) - SEEMETAL DECK SCHEDULE ON SHEET S-000 FORMORE INFORMATION.6SYMBOL INDICATES MOMENT CONNECTION TYPICAL. REFERENCE DETAIL 7/SF502.LIGHT GAUGE STEEL ROOF TRUSSES @ 24" O.C.LIGHT GAUGE CEE OUTRIGGERS @ 24" O.C.LIGHT GAUGE CEE-STUD GABLE FRAME ABOVESTUD WALL OR STEEL BEAM AS OCCURS. BRACETO ROOF STRUCTURE AS SHOWN IN DETAILS.1" TYPE 'E' 26 GAUGE METAL ROOF DECK, TYPICAL(U.N.O.) - SEE METAL DECK SCHEDULE ON SHEETS-000 FOR MORE INFORMATION.LIGHT GAUGE STEEL OVER FRAMING TRUSSES @24" O.C.PROVIDE (2) 600S162 12 GA. (50 KSI) STUDSBELOW TRUSS GIRDER BEARING - TYPICALPROVIDE 1 1/8" THICK BASE PLATE W/ 1" DIAMETERANCHOR BOLTS @ THIS COLUMN - TYPICAL @MOMENT FRAMESSLEEVE THRU GRADE BEAM FOR UTILITIES ASREQUIRED. REFERENCE TYPICAL DETAIL 8/SB501.PROVIDE 3/4"-THICK CEMDECK (OR EQUAL) OVERBOTTOM CHORD OF LIGHT GAUGE TRUSSES.SCREW INTO TRUSS BOTTOM CHORD @ 12" ONCENTER. PROVIDE LIGHT GAUGE STUD FRAMINGAS REQUIRED TO BOX OUT AROUND DUCTPENETRATIONS (COORDINATE W/ MECH.). TRUSSBOTTOM CHORDS SHALL BE DESIGNED FOR ALIVE LOAD OF 20 PSF.789MASONRY WALL REINF. SCHEDULECONT. FOOTING SCHEDULELLBSLDGLLLLBBLLHLLVLNTLLONGLPLT WTMASMATLMAXMC45MASONRY LINTEL SCHEDULEMARKL-1REINFORCING(3) #5 BARS LONG. BOTMARKWIDTHTYP.0' - 8"VERTICAL#5 @ 32" O.C. MAX.REINFORCINGHORIZONTALLADDER TYPE - 2 - W1.7 WIRES @ 16" O.C.1011THICKENED SLAB SCHEDULEMARKTS1-6WIDTH1' - 6"DEPTH1' - 0"12REINFORCING(3) #5 BARS LONG. BOT1315METAL STUD WALL SCHEDULEMARKATYP.MATERIAL600S162SEE ARCH.GAUGE16SEE ARCH.16MIN. YEILDSTRENGTH SPACINGNOTES50 KSI12"TYPICAL LOAD BEARING WALLS & EXTERIOR WALLSSEE ARCH. SEE ARCH. TYPICAL NON-LOAD BEARING WALLS17 3" CONCRETE W/ #3 BARS @ 12" O.C. OVER 2"TYPE 'C' 16 GAUGE NON-COMPOSITE METAL DECK,TYPICAL (U.N.O.) - SEE METAL DECK SCHEDULEON SHEET S-000 FOR MORE INFORMATION.18 FLOOR DRAIN - SEE MECH. AND SEE ARCH FORFLOOR SLOPE.19 SYMBOL INDICATES FOOTING STEP - SEE TYPICALDETAIL 9/SB501.20 MECHANICAL DUCTBANK - SEE MECH & SEEDETAILS 5 & 12 ON SB502 FOR CONDITIONS ATEXISTING BUILDINGS.21 2 1/2" CONCRETE W/ 6X6 W2.9XW2.9 W.W.F. OVER1 1/2" TYPE 'C' 20 GAUGE NON-COMPOSITE METALDECK, TYPICAL (U.N.O.) - SEE METAL DECKSCHEDULE ON SHEET S-000 FOR MOREINFORMATION.22 TORIS 4A 18 GA. ROOF DECK - SEE METAL DECKSCHEDULE ON SHEET S-000 FOR MOREINFORMATION.23 TORIS 5.5 18 GA. ROOF DECK - SEE METAL DECKSCHEDULE ON SHEET S-000 FOR MOREINFORMATION.24 WOOD TRUSS MANUFACTURER TO PROVIDE 16X12OPENING FOR MECHANICAL DUCT25 8 1/2" CONCRETE W/ #4 BARS @ 12" O.C. EA. WAYOVER 1 1/2" TYPE 'C' 20 GAUGE NON-COMPOSITEMETAL DECK, TYPICAL (10" TOTAL THICKNESS) SEE METAL DECK SCHEDULE ON SHEET S-000 FORMORE INFORMATION.METAL STUD HEADER SCHEDULEMARKMATERIALGAUGEMIN YIELD # OF KINGSTRENGTHSTUDS33 KSI150 KSI250 KSI250 KSI3# OF JACKSTUDS1223#10 SCREWS INTOKING STUD4468LEDGER ANGLEH-1600S16218SEE SCHEDULEH-2800S16216SEE SCHEDULEH-31000S16214SEE SCHEDULEH-41200S16212SEE SCHEDULENOTES:- INSTALL HEADERS PER SCHEDULE ABOVE IN LOAD BEARING EXTERIOR METAL STUD WALLS- HEADER 'H-1' SHALL BE USED FOR CLEAR SPANS LESS THAN 4'-0"- HEADER 'H-2' SHALL BE USED FOR CLEAR SPANS GREATER THAN OR EQUAL TO 4'-0" & LESS THAN 7'-0"- HEADER 'H-3' SHALL BE USED FOR CLEAR SPANS GREATER THAN OR EQUAL TO 7'-0" & LESS THAN 10'-0"- HEADER 'H-4' SHALL BE USED FOR CLEAR SPANS GREATER THAN OR EQUAL TO 10'-0" & LESS THAN 14'-0"- CONTACT ENGINEER OF RECORD FOR ANY CLEAR SPANS IN EXCESS OF 14'-0"- KING AND JACK STUDS SHALL BE 12 GA.SHEAR WALL ANCHORA5/8" DENS-GLASS OR5/8" GWB EACH FACE#6 @ 4"#6 @ 12"HD8NOTES18 GAUGE DOUBLE STUDS EACH ENDMETAL DECKING SCHEDULELOCATIONDEPTHGAUGE(IN.)MIN. IMIN. SFINISHCONNECTION TO SUPPORTING MEMBERSROOF1260.0400.067GALVANIZED36/4 PATTERN (#12 TEK SCREWS)ATTIC FLOOR1 1/2200.1860.224GALVANIZED36/4 PATTERN (5/8" DIA. PUDDLE WELD)ENTRANCE ROOFCAR PORT ROOF45 1/2"18163.4210.931.242.77GALVANIZED & NATACOATGALVANIZED & NATACOAT24/6 PATTERN (3/4" ARC PUDDLE WELD)24/6 PATTERN (3/4" ARC PUDDLE WELD)PATIO STOOP2160.7040.653GALVANIZED36/4 PATTERN (#12 TEK SCREWS)STRUCTURAL STOOP - SEE SHEET SB501 FORTYPICAL DETAIL. REFERENCE ARCHITECTURALDRAWINGS FOR STOOP DIMENSIONS.'C.J.' INDICATES CONTROL JOINT - SEE TYPICALDETAIL ON SHEET SB501 AND STRUCTURALNOTES ON SHEET S-001 FOR MORE INFORMATION.PROVIDE (2) #4 X 3'-0"-LONG BARS @ 4" O.C.CENTERED IN SLAB AT ALL RE-ENTRANTCORNERS WITHOUT CONTROL JOINTS (C.J.) ANDAT ENDS OF CONTROL JOINTS TERMINATEDWITHIN SLAB - TYPICAL.SIDE LAPS(#10 SCREWS, U.N.O.)(1) SIDE LAP FASTENER EACH SPACEBETWEEN SUPPORT MEMBERS(1) SIDE LAP FASTENER EACH SPACEBETWEEN SUPPORT MEMBERS1 1/2" FILLET WELD @ 24" O.C.1 1/2" FILLET WELD @ 24" O.C.(1) SIDE LAP FASTENER EACH SPACEBETWEEN SUPPORT MEMBERSABCDREMARKSTYPE "E"STRUCTURAL SHEET LISTTYPE "C"TORIS 4CATORIS 502SF503SF504SF505TYPE "C"*TORIS DECK TYPE IS AN EPIC METALS PRODUCT, CONTRACTOR OPTION TO SUBMIT EQUIVALENT PRODUCT FROM ANOTHER MANUFACTURER FOR APPROVALSTRUCTURAL INFO SHEETSTRUCTURAL NOTESSPECIAL INSPECTIONSFOUNDATION PLANTYPICAL FOUNDATION DETAILSFOUNDATION DETAILSATTIC FRAMING PLANROOF FRAMING PLANTYPICAL FRAMING DETAILSTYPICAL FRAMING DETAILSFRAMING DETAILSFRAMING DETAILSFRAMING NTS:16one eighth inch one foot048FDIMDLDWGDWLSSECTION/DETAIL NUMBERSHEET NUMBEREFINDICATES DIRECTION OF VIEW EJELSIMWIDTH1' - 6"2' - 0"2' - 6"GYPSUMLETTER INDICATESCIP WALL Y-VENEERANCHOR BOLTAMERICAN CONCRETEXLETTER INDICATESINSTITUTECMU WALL TYPEAFFABOVE FINISH FLOORAGGAGGREGATEAISCAMERICAN INSTITUTE OFSTEELCONSTRUCTIONSHEAR WALL TYPEALALUMINUMDESIGNATIONSHEAR WALL TYPE 'X'ANCHANCHORMIN L X'-X"SHEAR WALL LENGTH ANSIAMERICAN NATIONALSTANDARDS INSTITUTEAPPDAPPROVEDAPPROX APPROXIMATEARCHARCHITECTURAL ORARCHITECTGBX-XGRADE BEAM DESIGNATION AUTOAUTOMATICAVGAVERAGECONTINUOUS FOOTINGCFX-XLANGLEDESIGNATIONTHICKENED SLABTSX-XBLBUILDING LINEBLDGBUILDINGDESIGNATIONBLKGBLOCKINGBOBOTTOM OFBOTBOTTOMBRCG INGBSBOTH SIDESBWBOTH WAYSCCHANNEL (STRUCTURALREFERENCEXSHEETS)DESIGNATIONCFCUBIC FEETCIPCAST IN PLACECJCONTROL JOINT1ELEVATION LETTERCLCENTER LINECLRCLEARDIRECTION OF VIEWCMUCONCRETE MASONRY UNIT1 XX-XX 1COLCOLUMNSHEET NUMBERCOMP COMPRESSIBLE1CONC CONCRETECONN CONNECTIONCONSTR CONSTRUCTION JOINTDIRECTION OF VIEW1ELEVATION LETTERJTCONTCONTINUOUS(CONTINUATION)1 XX-XX 1CU YD CUBIC YARDSSHEET NUMBER1DDEPTH (DEEP)dPENNY (as in nail - 10d)DBLDOUBLEDEMODEMOLITIONDETAIL NUMBERXDIADIAMETERXX-XXSHEET NUMBERDIAGDIAGONALSECTION/DETAILSINGLE ANGLE LINTEL SCHEDULEGRADE BEAM SCHEDULEFLEXIBLE INSULATIONGRAVELABACICMU WALLCALLOUT91ABBREVIATIONS2BX8REF. NOTES (STUD WALLSTEELCIP WALLCALLOUT7MASONRY-VENEERMASONRY-CMU6"three inches one footL-X6PROJECT STRUCTURAL REFERENCED NOTESSECTION / ELEVATION VIEWCONCRETELINTEL CALLOUTIN MASONRY WALL1A5SCHEDULESPLAN VIEWSHEAR WALLHEADER CALLOUTIN STUD WALL4Drawing TitleARCHITECT/ENGINEERS:Project TitleSTRUCTURAL INFO SHEETApproved:CONSTRUCT CLC COTTAGE- 02106054.034Building Number54KMWDrawnS-000MJNDwg.of43VA FORM 08-62311234567Office ofConstructionand FacilitiesManagementDrawing NumberSIOUX FALLS, SDTSA PROJECTNO.:Project Number438-4208990Department ofVeterans Affairs

126"three inches one footthree quarters inch one foot6"02CGEOTECHNICAL1.2.3.4.5.CONCRETE AND REINFORCING1.CONCRETE STRENGTH (f'c @ 28 DAYS)A.FOOTINGS3,000 PSIB.FOUNDATION WALLS4,500 PSIC.GRADE SUPPORTED SLABS4,000 PSID.CONCRETE TOPPINGS4,000 PSIE.CONCRETE NOT SPECIFIED3,000 PSI2.ALL CONCRETE EXPOSED TO FREEZE-THAW CONDITIONS SHALL HAVE AMINIMUM STRENGTH (f'c @ 28 DAYS) OF 4,500 PSI. THIS DOES NOT INCLUDEFOOTINGS/GRADE BEAMS THAT ARE COVERED BY SOIL.3.CEMENT TYPE: PORTLAND TYPE I4.AGGREGATESA.NORMAL WEIGHT, 1 1/2" MAX. SIZE - ASTM C33B.PROVIDE AGGREGATES FREE OF MATERIALS WITH DELETERIOUSREACTIVITY TO ALKALI IN CEMENT, FROM A SINGLE SOURCE WITHDOCUMENTED SERVICE RECORD DATA OF AT LEAST 10 YEARSSATISFACTORY SERVICE IN SIMILAR APPLICATIONS AND SERVICECONDITIONS USING SIMILAR AGGREGATES AND CEMENTITIOUSMATERIALS.5.REINFORCING STEELASTM A615, GRADE 606.REINFORCING STEELASTM A706, WELDABLE7.WELDED WIRE FABRICASTM A1858.PREFORMED EXPANSION JOINT (1/2")ASTM D17511.2018 INTERNATIONAL BUILDING CODEACI 318-14 - BUILDING CODE REQUIREMENTS FOR STRUCTURAL CONCRETETMS 402-2016 - BUILDING CODE REQUIREMENTS FOR MASONRY STRUCTURESAISC 360-16 - SPECIFICATION FOR STRUCTURAL STEEL BUILDINGSAISI S100-16 - NORTH AMERICAN SPECIFICATION FOR THE DESIGN OF COLDFORMED STEEL STRUCTURAL MEMBERSFLOOR LIVE LOAD1.CORRIDORS - FIRST FLOOR2.DINNING AREA3.OFFICE BUILDINGS - OFFICES4.RESIDENTIAL - PRIVATE ROOMS5.RESIDENTIAL - PUBLIC ROOMS6.RESIDENTIAL - CORRIDORS - SAME AS AREA SERVED7.SIDEWALKS, VEHICULAR DRIVEWAYS8.STAIRS AND EXIT WAYS9.STORAGE - LIGHTPSF1001005040100--250100125ROOF LIVE LOAD1.ROOF LIVE LOAD (MINIMUM, NON-REDUCIBLE)PSF20OTHER LIVE LOADS1.OFFICE PARTITIONS (LIVE LOAD):2.PARTITIONS (LATERAL LOAD):3.RAILING (LATERAL LOAD AT TOP):4.MECHANICAL EQUIPMENT ROOM15 PSF5 PSF50 PLF OR 200 LB150 PSF OR EQUIP.WEIGHT IFGREATERROOF SNOW LOAD1.GROUND SNOW LOAD (Pg):2.FLAT-ROOF SNOW LOAD (Pf):3.DRIFT SNOW LOAD4.SNOW EXPOSURE FACTOR (Ce):5.SNOW LOAD IMPORTANCE FACTOR (I):6.THERMAL FACTOR (Ct):40 PSF28 PSFPER ASCE 7-161.01.01.0WIND DESIGN DATA1.ULTIMATE DESIGN WIND SPEED (Vult):2.NOMINAL DESIGN WIND SPEED (Vasd):3.RISK CATEGORY:4.WIND EXPOSURE:5.INTERNAL PRESSURE COEFFICIENT (GCpi):6.COMPONENTS AND CLADDING DESIGN WIND PRESSURE:A.ROOF - ZONE 1B.ROOF - ZONE 2C.ROOF - ZONE 3D.WALL - ZONE 4E.WALL - ZONE 5EARTHQUAKE DESIGN DATA1.SEISMIC IMPORTANCE FACTOR (I):2.RISK CATEGORY:3.0.2 SEC SPECTRAL RESPONSE ACCELERATION (SS):4.1.0 SEC SPECTRAL RESPONSE ACCELERATION (S1):5.SITE CLASS:6.0.2 SEC SPECTRAL RESPONSE COEFFICIENT (SDS):7.1.0 SEC SPECTRAL RESPONSE COEFFICIENT (SD1):8.SEISMIC DESIGN CATEGORY:9.BASIC SEISMIC-FORCE-RESISTING SYSTEM:A.LIGHT GAUGE SHEAR WALLS10. DESIGN BASE SHEAR (V):11. SEISMIC RESPONSE COEFFICIENT (CS):12. RESPONSE MODIFICATION FACTOR (R):13. ANALYSIS PROCEDURE USED:A.EQUIVALENT LATERAL FORCE PROCEDURE122 MPH95 MPHIICATEGORY B /-0.184one half inch one foot02.three eighths inch one foot043.4.5.86.one quarter inch one foot047.UNIT COMPRESSIVE STRENGTH4.5.MORTAR TYPEGROUT TYPE6.7.8.MORTAR STRENGTH (28 DAYS)GROUT STRENGTH (28 DAYS)WIRE REINFORCING-38.18 PSF-60.84 PSF-78.44 PSF-28.1 PSF-34.7 PSF1.0II0.08980.0350D0.0960.056A4.5.STRUCTURAL TUBEANCHOR RODS6.7.8.BOLTED CONNECTIONSWELDED CONNECTIONSWELDED CONNECTIONS (GALVANIZED)9.HEADED CONCRETE ANCHORS (HCA)10.DEFORMED BAR ANCHORS (DBA)11.METAL DECKING12.LIGHT GAUGE STEEL STUDS/JOISTSA.12 TO 16 GAUGE (G60 GALV.)5.9 KIPS0.016.5B.18 GAUGE (G60 GALV.)5.6.7.1,500 PSIASTM C90NORMAL WEIGHT2,000 PSI (BASED ONNET AREA)ASTM C270, TYPE SASTM C476, 3/8" MAX.AGGREGATE SIZE1,800 PSIASTM C476 - 2,000 PSIASTM A82, STD. LADDERTYPE - 9 GAUGE ZINCCOATED PER ASTM A116- (DUR-O-WALL ORAPPROVED EQUAL @ 16"O.C. VERTICAL SPACING)8.9.10.ASTM A992, GRADE 50ASTM A36ASTM A53, GRADE B,SCH. 40ASTM A500, GRADE BASTM F1554, GRADE 55WITH WELDINGSUPPLEMENT S1ASTM A325NE70XX ELECTRODESE6010 OR E6011ELECTRODESASTM A108 GRADESC1010 THROUGH C1020(Fu 55 KSI)ASTM A108 & A496(Fy 70 KSI)ASTM A611 ORASTM A653-941.ALL WORK SHALL CONFORM TO THE REQUIREMENTS OF THE APPLICABLEBUILDING CODE.THE STRUCTURE HAS BEEN DESIGNED TO RESIST DESIGN LOADS ONLY AS ACOMPLETED STRUCTUREA.APPLICATION OF ANY LOADS TO THE PARTIALLY COMPLETEDSTRUCTURE SHALL BE CONSIDERED BY THE CONTRACTOR AND SOINCLUDED IN THE DESIGN OF THE SHORING, BRACING, FORMWORK, ANDANY OTHER SUPPORTING ELEMENTS PROVIDED FOR CONSTRUCTION OFTHE STRUCTURE.B.WHERE CONSTRUCTION MATERIAL AND EQUIPMENT ARE TEMPORARILYSTORED ON THE ROOF OR FLOOR FRAMING, THEY SHALL BEDISTRIBUTED SO THAT THE DESIGN LIVE LOAD AT THE LOADED AREA ISNOT EXCEEDED.C.DO NOT BACKFILL AGAINST WALLS OR OTHER STRUCTURAL ELEMENTSUNTIL SUCH ELEMENTS HAVE REACHED THEIR INTENDED STRENGTH,HAVE BEEN ADEQUATELY BRACED, AND/OR HAVE OTHER INTEGRALSTRUCTURAL ELEMENTS IN PLACE WHICH ARE INTENDED TO RESIST THELATERAL EARTH LOADS.LATERAL LOAD RESISTING SYSTEM: ALL LATERAL LOAD RESISTANCE ANDSTABILITY IN THE COMPLETED STRUCTURE IS PROVIDED BY:A.N-S DIRECTION: LIGHT GAUGE SHEARWALLS & CMU SHEARWALLSB.E-W DIRECTION: LIGHT GAUGE SHEARWALLS & STEEL MOMENT FRAMESC.ROOF DIAPHRAGM: METAL DECKD.FLOOR DIAPHRAGM: CONCRETE OVER METAL DECKSTEEL STABILITY: STRUCTURAL STEEL FRAMING INDICATED IN THESE PLANSREQUIRES INTERACTION WITH NON-STRUCTURAL STEEL ELEMENTS FORSTRENGTH AND/OR STABILITY. SEE PLANS FOR SPECIFIC LOCATIONS OFTHESE NON-STRUCTURAL STEEL ELEMENTS WHICH ARE LISTED BELOW:A.CMU SHEARWALLSB.METAL FLOOR DECKING WITH CONCRETE TOPPINGC.METAL ROOF DECKINGD.LIGHT GAUGE SHEARWALLSDETAILS ON THE DRAWINGS INDICATED AS "TYPICAL" APPLY IN ALL AREASWHERE CONDITIONS SIMILAR TO THE DETAIL OCCUR.THE STRUCTURAL DRAWINGS ARE NOT INTENDED FOR USE AS SHOPERECTION DRAWINGS. REPRODUCTION OF THESE DRAWINGS IN LIEU OFPREPARATION OF SHOP ERECTION DRAWINGS SIGNIFIES THE USERS'ACCEPTANCE THAT ALL INFORMATION SHOWN IS CORRECT AND APPROPRIATEFOR SHOP DRAWINGS AND THAT THE USER WILL BE FULLY RESPONSIBLE FOREXPENSES THAT MAY OCCUR FROM SAID ACCEPTANCE.UNLESS SPECIFICALLY NOTED, THERE ARE NO PROVISIONS MADE FORFUTURE FLOORS, ROOFS, OR OTHER LOADS.2.3.4.5.6BASIS OF DESIGN: THE FOUNDATION SYSTEM DESIGN IS BASED ON THERECOMMENDATIONS OF GEOTECHNICAL REPORT NO. 06054.034 DATEDSEPTEMBER 1, 2016 PREPARED BY SCHEMMER.FOUNDATION SYSTEM: SHALLOW FOOTINGSMAXIMUM ALLOWABLE SOIL BEARING CAPACITY2,500 PSFLATERAL EARTH PRESSURE:A.PASSIVE RESISTANCE180 PCFB.ACTIVE PRESSURE50 PCFC.AT-REST PRESSURE65 PCFSUBGRADE PREPARATION:A.HEAVILY ORGANIC OR ROOT INFESTED TOPSOIL SHALL BE EXCAVATED ANDDISCARDED OR STOCKPILED FOR LATER USE IN COVERING FINISHEDLANDSCAPED AREAS AFTER CONSTRUCTION. REMOVE TOPSOIL TO AMINIMUM DEPTH OF 8 INCHES. DEEPER STRIPPING SHALL BE DONE IFORGANIC MATERIALS REMAIN BELOW A DEPTH OF 8 INCHES.B.REMOVE ALL EXISTING STRUCTURES TO BE DEMOLISHED PRIOR TOGRADING. THIS INCLUDES PAVING, SIDEWALKS, AND OTHERMISCELLANEOUS SMALL STRUCTURES.SURCHARGE REQUIREMENTS:A.PROVIDE SURCHARGE AS OUTLINED IN GEOTECH REPORTSTRUCTURAL FILL REQUIREMENTS:A.CLEAN, INORGANIC, LOW TO MEDIUM PLASTICITY LEAN CLAY (CL) OR SILT(ML), OR A COMBINATION OF THESE TWO MATERIALSB.MAXIMUM LIQUID LIMIT (LL)45C.MAXIMUM PLASTICITY INDEX22D.WATER CONTENT (% OF OPTIMUM) /-3%E.MAXIMUM LOOSE LIFT8"F.MINIMUM COMPACTION95% (STANDARDPROCTOR TESTASTM D-698)SPREAD FOOTINGS SHALL BE PLACED ON NEAT, CLEAN AND DRY EXCAVATIONS.EXTREME CARE SHALL BE TAKEN WHEN EXCAVATING NEAR THE BEARINGSURFACE. FOOT TRAFFIC SHALL BE KEPT TO A MINIMUM NECESSARY TO PLACETHE FOOTING REINFORCEMENT AND CONCRETE.CONTRACTOR SHALL PROVIDE FOR ADEQUATE DRAINAGE OF SURFACE WATERAWAY FROM THE STRUCTURE AND EXCAVATED AREAS DURING CONSTRUCTION.THIS INCLUDES NECESSARY PUMPING, TRENCHING, BACKFILL AND/OR DIKECONSTRUCTION.GRANULAR SUBBASE UNDER SLAB ON GRADE:A.MINIMUM THICKNESSSEE PLANB.MINIMUM COMPACTION95% (STANDARDPROCTOR TESTASTM D-698)C.GRADATION REQUIREMENTSa.100% PASSING THE 3/4" SIEVEb.LESS THAN 15% PASSING THE 100 SIEVEc.LESS THAN 2% PASSING THE 200 SIEVECONTRACTOR SHALL CHECK AND VERIFY ALL DIMENSIONS AND EXISTINGCONDITIONS AND REPORT ANY DISCREPANCIES TO THE ENGINEER BEFOREPROCEEDING WITH ANY PHASE OF THE WORK.ANY PROPRIETARY STRUCTURAL SYSTEMS THAT ARE COMPOSED OFCOMPONENTS TO BE FIELD ERECTED SHALL BE SUPERVISED BY THE SUPPLIERDURING MANUFACTURING, DELIVERY, HANDLING, STORAGE, AND ERECTION INACCORDANCE WITH THE INSTRUCTIONS PREPARED BY THE SUPPLIER.CROSS REFERENCE STRUCTURAL DRAWINGS WITH MECHANICAL ANDELECTRICAL DRAWINGS, AND WITH THE ACTUAL EQUIPMENT SUPPLIED TO THEPROJECT, FOR THE LOCATION AND SIZE OF ALL SLAB OPENINGS, SLEEVES,INSERTS, FLOOR DEPRESSIONS, BLOCK-OUTS, CURBS, ANCHORS, BOLTS, ETC.REQUIRED FOR INSTALLATION.PROVIDE ADEQUATE STRUCTURAL FRAMING AS APPROVED BY THE ENGINEERFOR ALL REQUIRED MECHANICAL OPENINGS THROUGH SLABS, WALLS, FLOORDECK, ETC., AND SUPPORT OF ALL MECHANICAL EQUIPMENT. OPENINGS SHALLNOT BE PERMITTED THROUGH BEAMS UNLESS SPECIFICALLY DETAILED BY THEENGINEER.REFER TO ARCHITECTURAL DRAWINGS FOR ALL SURFACE FINISHES,DIMENSIONS, AND LOCATIONS OF SLAB DROPS, MASONRY CONTROL JOINTS,AND WALL OPENING REQUIREMENTS.169COLD-FORMED METAL TRUSSES(REFERENCE SPECIFICATION SECTION 054400 IN PROJECT MANUAL)1.1.4.5.6.7.8.9.DESIGN CRITERIA: MASONRY SHALL BE CONSTRUCTED PER THE REQUIREMENTSOF ACI 530.UNIT TYPES: SEE SPECIFICATION SECTION 042000UNIT COMPRESSIVE STRENGTH: SEE MATERIAL DATA NOTES AND SPECIFICATIONSECTION 042000MORTAR: SEE MATERIAL DATA NOTES AND SPECIFICATION SECTION 042000GROUT: SEE MATERIAL DATA NOTES AND SPECIFICATION SECTION 042000CMU REINFORCING: UNLESS NOTED OTHERWISE, REINFORCE ALL CMU WALLSWITH VERTICAL #5 @ 32" O.C. FILL ALL REINFORCED CELLS WITH GROUT.MINIMUM GROUT BETWEEN MASONRY AND REINFORCING SHALL BE 1/2". MINIMUMGROUT BETWEEN PAIRS OF REINFORCING BARS SHALL BE 3/4".A.PROVIDE #5 VERTICAL REINFORCING AT THE FOLLOWING LOCATIONS:a.AT ALL CORNERS OF CMU WALLSb.AT ALL ENDS OF CMU WALLSc.EACH SIDE OF CONTROL JOINTSd.EACH SIDE OF WALL OPENINGSB.SEE ARCHITECTURAL DRAWINGS FOR LOCATIONS OF CONTROL JOINTS.BOND BEAMSA.LOCATED AT TOP OF ALL CMU WALLS AND WHERE INDICATED IN DETAILSB.MINIMUM DEPTH UNLESS OTHERWISE NOTED 8".C.REINFORCING - (2) #4 CONTINUOUS. LAP SPLICE 28 IN.D.CORNER DOWELS - (2) #4 RIGHT ANGLE DOWELS THAT LAP A MINIMUM OF2'-0" WITH ADJACENT BOND BEAM REINFORCING. IF BOND BEAMS ATINTERSECTING WALLS MEET AT DIFFERENT ELEVATIONS, EXTEND BOTHBOND BEAMS AROUND INTERSECTING CORNER TO FIRST INTERIORREINFORCED CELL, BUT NOT LESS THAN 4 FEET.E.EXTEND BOND BEAMS THROUGH CONTROL JOINTS, BUT INTERRUPT BONDBEAM REINFORCING AT CONTROL JOINTS.LINTEL BEARING: PROVIDE A MINIMUM OF 8 INCHES BEARING AT EACH END.CONTROL JOINTS: EXCEPT WHERE OFFSETS OR SLIP JOINTS ARE SHOWN,CONTROL JOINTS SHALL BE A CONTINUOUS VERTICAL LINE FROM TOP OFFOOTING TO TOP OF MASONRY WALL. SPACE CONTROL JOINTS AS FOLLOWS:A.INTERIOR WALLS36 FT. O.C. MAX.B.EXTERIOR WALLS24 FT. O.C. MAX.2.STRUCTURAL STEEL FRAMING(REFERENCE SPECIFICATION SECTION 051200 IN PROJECT MANUAL)GENERAL STRUCTURAL STEEL REQUIREMENTS1.DESIGN CRITERIA: STRUCTURAL STEEL SHALL BE INSTALLED PER THEREQUIREMENTS OF AISC 360.2.STRUCTURAL STEEL GRADES: SEE MATERIAL DATA NOTES ANDSPECIFICATION SECTION 0512003.ANCHOR AND BOLT GRADES: SEE MATERIAL DATA NOTES AND SPECIFICATIONSECTION 0512004.WELD ELECTRODES: SEE MATERIAL DATA NOTES AND SPECIFICATIONSECTION 0512005.BEARING CONNECTIONS: UNLESS OTHERWISE NOTED, ALL BEAMCONNECTIONS SHALL BE SIMPLE FRAMED SHEAR BEARING CONNECTIONS INACCORDANCE WITH THE AISC "SPECIFICATIONS FOR STRUCTURAL JOINTSUSING ASTM A325 OR A490 BOLTS."6.DESIGN OF CONNECTIONS: BEAM CONNECTIONS SHALL BE AS DETAILED ONTHE PLANS. ALTERNATIVE CONNECTIONS, DESIGNED BY A LICENSEDENGINEER FOR THE FABRICATOR, MAY BE UTILIZED PROVIDED THEALTERNATIVE CONNECTION PROVIDES THE SAME LOAD CARRYING CAPACITYOF THE ORIGINAL DESIGN.7.SPLICES: STEEL FABRICATOR SHALL VERIFY WITH ENGINEER ALL BEAMSPLICES OTHER THAN THOSE SHOWN ON THE PLANS. ANY FULLPENETRATION SHOP SPLICES APPROVED BY THE ENGINEER SHALL BEINSPECTED BY RADIOGRAPHIC METHODS BY A TESTING LABORATORYAPPROVED BY THE ENGINEER AND PAID FOR BY THE FABRICATOR.8.OPPOSING CONNECTIONS: WHERE BEAMS ARE BOLTED ON TWO SIDES OF ACOMMON PLATE OR WEB, THE CONNECTIONS SHALL BE DETAILED WITH ANADDITIONAL ROW OF BOLTS ON ONE SIDE THAT IS NOT SHARED WITH THEOTHER SIDE TO ALLOW INDEPENDENT BOLTING DURING ERECTION.9.STEEL PROTECTION: ALL STRUCTURAL STEEL SHALL BE CLEANED ANDPAINTED WITH PRIMER PER SPECIFICATION SECTION 051200, UNLESS NOTEDOTHERWISE.10. STEEL PROTECTION: WHERE STEEL IS INDICATED AS GALVANIZED, PROVIDEHOT-DIPPED GALVANIZED SURFACE PER SPECIFICATION SECTION 051200.11. SHOP DRAWINGS: SEE SPECIFICATION SECTION 051200 FOR SUBMITTALREQUIREMENTS.12. SLIDE BEARINGS: WHERE SHOWN ON THE DRAWINGS, TEFLON SLIDE BEARINGPADS SHALL BE PROVIDED. BEARING PADS SHALL BE DURA-SLIDE ASMANUFACTURED BY TOBI ENGINEERING, INC. OR APPROVED EQUAL.13. WELDING: ALL WELDING SHALL BE PERFORMED BY QUALIFIED WELDERS PERAWS STANDARD QUALIFICATION PROCEDURES.14. COMPLETE PENETRATION WELDS: COMPLETE PENETRATION WELDEDCONNECTIONS SHALL BE PROVIDED WHERE INDICATED. A MINIMUM OF 10%OF ALL FIELD AND SHOP FULL PENETRATION WELDS SHALL BE TESTED BY XRAY OR ULTRASONIC PROCEDURES. (SEE SPECIFICATIONS FOR OTHERTESTING.)GENERAL CONCRETE REQUIREMENTS1.CONCRETE BATCH DESIGN(S) SHALL BE PROPORTIONED AND PRODUCED INACCORDANCE WITH ACI 318, IN PARTICULAR CHAPTER 5, AND ACI 301. MIX ANDDELIVER IN ACCORDANCE WITH ASTM C94.2.CONCRETE STRENGTH: SEE MATERIAL DATA NOTES & SPECIFICATION SECTION0330003.SLUMP LIMITS: SEE SPECIFICATION SECTION 0330004.MAXIMUM W/C RATIO: SEE SPECIFICATION SECTION 0330005.AIR ENTRAINMENT: SEE SPECIFICATION SECTION 0330006.ADMIXTURES: SEE SPECIFICATION SECTION 0330007.FLY ASH: SEE SPECIFICATION SECTION 0330008.CONCRETE TO CONCRETE COLD JOINTS - PROVIDE 1/4" INTENTIONALLYROUGHENED SURFACE AT ALL HORIZONTAL JOINTS.9.EXPOSED CORNERS: PROVIDE A 3/4" CHAMFER AT ALL EXPOSED CONCRETECORNERS.10. CURING: SEE SPECIFICATION SECTION 03300011. REINFORCING BAR WELDING: ABSOLUTELY NO WELDING OF REINFORCING BARSOR TORCHING TO BEND REINFORCING BARS SHALL BE ALLOWED WITHOUT THESPECIFIC APPROVAL OF THE ENGINEER.12. MINIMUM CONCRETE CLEAR TION WALLSa.TOP1-1/2"b.BOTTOM3"c.SIDES2"C.INTERIOR SLABS (TOP)SEE TYPICAL SLABJOINT DETAILON SHEET SB501D.OTHER COVER REQUIREMENTS SHALL BE AS NOTED IN APPLICABLEDETAILS.13. NON-METALLIC, SHRINKAGE-RESISTANT GROUT: SEE SPECIFICATION SECTION05120014. WATERSTOPS: SEE SPECIFICATION SECTION 0330003.DESIGN CRITERIA: TRUSS VENDOR IS TO SUBMIT TO THE ARCHITECT,ENGINEER, AND CITY DESIGN CALCULATIONS BY A LICENSED ENGINEERAND SHOP DRAWINGS FOR REVIEW PRIOR TO FABRICATION. SHOPDRAWINGS ARE TO SHOW ALL TEMPORARY AND PERMANENT BRACINGREQUIRED BY DESIGN. DESIGN CALCULATIONS SHALL BE SEALED BY THELICENSED ENGINEER.DESIGN RESPONSIBILITIES - TRUSSES SHALL BE DESIGNED UNDER THEFOLLOWING FORMAT:A.LATERAL FORCES APPLIED TO THE TRUSSES, SUCH AS DRAG TRUSSLOADS, COLLECTORS, ETC., ARE INDICATED ON THE PLANS WHEREAPPLICABLE.B.ALL TRUSS-TO-TRUSS CONNECTIONS ARE THE RESPONSIBILITY OFTHE TRUSS ENGINEER.C.DRAG LOADS (HORIZONTAL TRUSS TRANSFERS) CONNECTIONSBETWEEN THE TRUSS AND THE STRUCTURE ARE INDICATED ON THEPLANS WHERE APPLICABLE.D.ALL TRUSS-TO-STRUCTURE (WALLS OR BEAMS) CONNECTIONS AREINDICATED ON THE PLANS WHERE APPLICABLE.E.IT IS THE RESPONSIBILITY OF THE TRUSS ENGINEER TO DEVELOP THELOADING REQUIRED TO IMPLEMENT THE REQUIRED SNOW LOADS PERIBC AND ASCE 7 SPECIFICATIONS. THIS INCLUDES ADDITIONAL SNOWLOAD AT EAVES, AND UNBALANCED LOADING ON THE GABLE AND HIPROOFS.F.IT IS THE RESPONSIBILITY OF THE TRUSS ENGINEER TO REVIEW ALLOF THE INDICATED DESIGN SPECIFICATIONS, ROOF TRUSS SUPPORTS,AND DRAG DETAILS AND TO INCORPORATE THESE REQUIREMENTSINTO THE ENGINEERING DESIGN OF THE ROOF TRUSS SYSTEM.G.THE TRUSS ENGINEER SHOULD DEVELOP A TRUSS LAYOUT PLAN FORTHE TRUSS SYSTEM THAT CLEARLY INDICATES THE TRUSS VERTICALSUPPORT CONDITIONS, TRUSS-TO-TRUSS CONNECTIONS, DRAGTRUSSES AND COLLECTORS, AND ANY OTHER FIELD-INSTALLEDREINFORCEMENT, INCLUDING FIELD-INSTALLED TOP CHORDREINFORCEMENT AT EAVES NECESSARY TO EXECUTE THE TRUSSSYSTEM DESIGN. THE TRUSS ROOF FRAMING PLAN SHALL BE SEALEDBY A LICENSED PROFESSIONAL ENGINEER AND BE INCLUDED WITHTHE INDIVIDUAL TRUSS CUT SHEETS. THE TRUSS ENGINEER SHOULDALSO PROVIDE PROPER SUPERVISION OF ANY TRUSS COMPANYTECHNICIANS.H.TRUSS BRACING: TEMPORARY ERECTION BRACING AND PERMANENTWEB BRACING SHALL BE DESIGNED BY THE TRUSS MANUFACTURER.I.THE TRUSS ENGINEER SHALL DESIGN TRUSSES AND APPLICABLECONNECTIONS FOR BLAST LOADS INDENTIFIED IN THE PROJECTSPECIFICATIONS. LATTERAL BLAST LOADS FROM THE WALLS SHALLBE CONSIDERED IN THE DESIGN.METAL TRUSS DESIGN LOADS (IN ADDITION TO SELF-WEIGHT)A.ROOF DEAD LOAD (TOP CHORD)10 PSFB.ROOF DEAD LOAD (BOTTOM CHORD)A.MECHANICAL ROOMS & CORRIDORS25 PSFB.ALL OTHER AREAS10 PSFC.FLOOR DEAD LOAD (TOP CHORD)15 PSFD.FLOOR DEAD LOAD (BOTTOM CHORD)A.MECHANICAL ROOMS & CORRIDORS25 PSFB.ALL OTHER AREAS10 PSFE.ROOF LIVE LOAD (TOP CHORD)SEE DESIGNCRITERIANOTESF.ROOF LIVE LOAD (BOTTOM CHORD)10 PSFG.FLOOR LIVE LOAD (TOP CHORD)SEE DESIGNCRITERIANOTES1.SLAB ON GRADE REQUIREMENTS1.SLAB THICKNESS: SEE PLAN2.SLAB REINFORCING: SEE PLAN3.GRANULAR SUBBASE: SEE GEOTECHNICAL NOTES4.VAPOR RETARDER: SEE SPECIFICATION SECTION 033000. LAP AND TAPE ALLJOINTS AND HOLES.5.CRACK CONTROL JOINTS (WHETHER CONSTRUCTION JOINTS OR SAWED JOINTS)IN SLABS ON GRADE SHALL OCCUR AS SHOWN AND ACROSS ALL DOOROPENINGS. LOCATE JOINTS AT RE-ENTRANT CORNERS OF SLABS.A.MAXIMUM SPACING OF CONTROL JOINTS: 12 FEET6.CURING: CONCRETE SHALL BE MAINTAINED IN A MOIST CONDITION FOR AMINIMUM OF SEVEN DAYS AFTER ITS PLACEMENT. APPROVED CURING: SEESPECIFICATION SECTION 0330007.SEAL ALL EXPOSED CONSTRUCTION/CRACK CONTROL JOINTS.A.SEALANT: SEE ARCHITECTURE.8.FLOOR FINISH & FLATNESS CRITERIA: SEE SPECIFICATION SECTION 0330002.3.4.5.1.2.3.4.5.6.ROOF/FLOOR SHEATHING: SEE MATERIAL DATA NOTES AND SPECIFICATIONSECTION 061600WALL SHEATHING: SEE MATERIAL DATA NOTES AND SPECIFICATIONSECTION 061600ROOF/FLOOR SHEATHING NAILING: COMMON WIRE NAILS SHALL BE USEDAND PENETRATE SUPPORTING MEMBERS A MINIMUM OF 1-5/8". INDIVIDUALPIECES OF SHEATHING SHALL NOT BE LESS THAN 24" IN THEIR SHORTESTPLAN DIRECTION NOR LESS THAN 8 SQ. FT. IN AREA:A.ROOF SHEATHING:a.SHEET EDGES10d @ 6" O.C.b.INTERMEDIATE FRAMING MEMBERS10d @ 12" O.C.B.FLOOR SHEATHING:a.SHEET EDGES10d @ 6" O.C.b.PANEL FIELD10d @ 12" O.C.WALL SHEATHING NAILING: SEE SHEAR WALL SCHEDULE AND TYPICALSHEAR WALL DETAILSPROVIDE BLOCKING OR PANEL EDGE CLIPS AT ALL PANEL EDGES.OPENINGS IN SHEATHING: EDGES OF ALL OPENINGS THROUGH SHEATHINGSHALL BE NAILED PER THE REQUIRED EDGE NAILING ABOVE.1.2.3.4.5.6.DESIGN CRITERIA: COLD-FORMED METAL FRAMING SHALL BE INSTALLED PERTHE REQUIREMENTS OF AISI NAS.LIGHT GAUGE STEEL STUDS/JOISTS: SEE MATERIAL DATA NOTES ANDSPECIFICATION SECTION 054000REFERENCE PLANS AND SCHEDULES FOR GAUGE AND SPACING OF LIGHTGAUGE STEEL STUDS/JOISTS.LIGHT GAUGE STEEL BOTTOM TRACK AT LOAD BEARING WALLS:A.BOTTOM TRACK SHALL BE GALVANIZEDB.FASTEN TO FOUNDATION AT SHEAR WALLS PER SHEAR WALLSCHEDULE & TYPICAL DETAILS.C.FASTEN AT ALL OTHER LOAD BEARING WALLS PER DETAILS INDICATEDON PLAN.FRAMING AT WALL OPENINGS: SEE TYPICAL DETAILS FOR HEAD AND SILLFRAMING AT WALL OPENINGS.FRAMING AT FLOOR/ROOF OPENINGS: PROVIDE DOUBLE HEADERS ANDDOUBLE JOISTS EACH SIDE OF ALL OPENINGS IN FLOORS AND ROOFSUNLESS DETAILED OTHERWISE.BLOCKING AND BRIDGING AT STUDS: SEE SPECIFICATION SEC

7 light gauge steel roof trusses @ 24" o.c. 8 light gauge cee outriggers @ 24" o.c. 9 light gauge cee-stud gable frame above stud wall or steel beam as occurs. brace to roof structure as shown in details. 10 1" type 'e' 26 gauge metal roof deck, typical (u.n.o.) - see metal deck schedule on sheet s-000 for more information. 11 light gauge steel .