Transcription

Gravel Road Design &Maintenance PlanningJosh PlattPresident, Maine Environmental Solutions LLCIn Partnership WithKennebec CountySoil & Water Conservation District

TopicsRoad Construction Basics Surveying/Inventorying gravelroads Maintenance Planning Q&A

rials.html

What is a road? A way to get from Point A to Point BClear of vegetation and other obstacles.Constructed of material that holds up againstthe forces of weather and traffic.Shaped to keep water off, and away from thetraveled way.

Is clear of vegetation and other obstacles.

Is clear of vegetation and other obstacles. Constructed of material that holds up against theforces of weather and traffic.

Is clear of vegetation and other obstacles. Constructed of material that holds up against the forces ofweather and traffic. Shaped to keep water off, and away from the traveled way.

The Basics of Road Building All roads need to withstand the impacts ofvehicles and weather.This is accomplished by: Using the appropriate materials whenconstructing the roadShaping the road to efficiently drain water

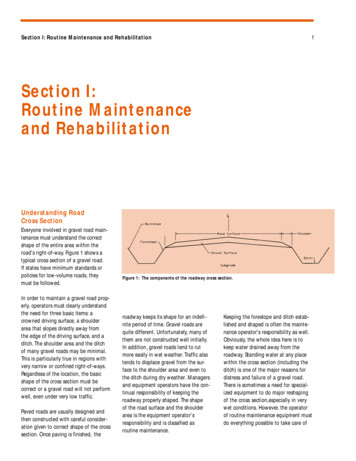

Parts of a Road (surface)

Parts of a Road (profile)Shoulder

Base Provides foundation for road, holds up vehiclesGravel contains lots of rock and drains wellLarger aggregate size than surface gravel – 4” minus

Fabric-Woven Geotextile-200 weight is best-Use on new roads or in wetareas of chronic erosion thatdon’t dry

No FabricFabric

Surface Provides a smooth, easily gradable driving surfaceKeep water out of road base (roof)Directs water into ditchesCrown – minimum of ¼” per footSuper-elevate

Surface Gravel-1.5 – ¾” minus material with7-12% fines-Bluestone gravel-crushed bluestone or slate with crusherdust included. Still 7-12% fines

Ditches Control the runoff from the road surfaceDrains water out of the road base materialsShape of ditch should be a “rounded V”Stabilizing ditches

Culverts Used toconvey waterunder a roadProperlysizedPropercompaction

Surveying Gravel RoadsTaking Inventory

Road Problems Common Problems: Road Surface Erosion/PotholesMudRoad Shoulder ErosionDitch ErosionCulvert Inlet/Outlet ErosionMost problems are due to poor road shapeand/or poor materials

Road InventoryCulvert Unstable inlet / outlet Clogged Crushed / BrokenDitch Slight Erosion Moderate Erosion Severe Erosion Bank Failure Inadequate DitchRoad Shoulder Erosion Slight Moderate SevereSurface Erosion Slight Moderate Severe

Culvert: Unstable inlet/outlet

Culvert: Unstable inlet/outlet

Culvert: Clogged

Culvert: Crushed

Ditch: Moderate Erosion

Ditch: Severe Erosion

Ditch: Bank Failure

Ditch: Inadequate Ditch

Road Shoulder: Mild Erosion

Road Shoulder: Moderate Erosion

Road Shoulder: Severe Erosion

Road Surface: Mild Erosion

Road Surface: Moderate Erosion

Road Surface: Severe Erosion

8 Steps to Managing Your Gravel Road1. Inventory road2. Assess condition using score sheets3. Determine specific road repairs4. Determine costs5. Establish priorities – 2 factors6. Create inspection schedule & checklist7. Establish yearly budget8. Keep a journal

What is in the Toolbox? Crowning, super-elevating, armoring surfaceBox cutting, fabricAlternative materialsBroad-base dipsRubber razorsArmored swales, rock sandwichesDitching, check dams, rip-rap, ECM blanketsNew or replacement culverts

Young Road - Site # 1Site # 1: 140’ section betweenDick Harvey driveway & Pole # 23 .Issue: Water not reaching ditches,ground water coming up throughroad, lack of crown and insufficientditching.Fix: Box cut 140’ section andinstall US 200 woven filter fabric, 1’of 3” minus base gravelcompacted in 6” lifts and 4” of 1”minus surface gravel with 7-12%fines. Road surface should beshaped and compacted to aminimum of ¼” per foot crownInstall 85’ of ditching on west sideof road between poles #21 & #23& tie into existing ditch to thenorth. Stabilize ditch with seed andhay.Priority #: 1

Cedar Point Road – Site # 4Site # 4: 300’ section from turnout atthe bottom of site # 3, around corner toCamp sign.Issue: Lack of ditching, surface erosion,road material accumulation at bottom ofhill.Fix: Install ditch on east side of road(Approx 230’) where water cannot get towoods and stabilize with 6” angular rock.(ditching this section will be a challengedue to site conditions)Super-elevate road surface (approx 300’)to east & direct water into new ditch thatwill end in a turnout at the bottom of thehill.Priority Ranking #: 2

Same site following implementation of recommendations

Pine Point – Site # 5Site # 9: From Pole 88 to Pole 91 for adistance of 630’Issue: Road is lower than surroundinggrade. Surface erosionis occurring and there is no way to getwater off road surface.Fix: This is the most challenging section ofHorse Point Road to address. Tosignificantly improve this section wouldrequire a complete rebuild to raise road 1’above existing grade.Steps: Install layer of Woven stabilizationfabric like US 200, over road surface usingspecs provided. Add 5” of 4” minus materialand compact with a roller. Add remaining 4”to a crown of ½” per foot and roll again.Add 3” of 1” or 1.5” minus surface graveland crown to ½” per foot androll a third time.Priority Ranking #: 3

Same site following implementation of recommendations –Day after Hurricane Irene

Gravel road maintenanceplans have proven to be thebest investmenta group can make in theirgravel road.

COSTS -Most plans MES prepares cost 600 - 800-An exceptionally long road with many complicated sitesmight cost 900 - 1200-Small investment to have a 10 year plan for properlymaintaining a road, spending your money in the rightareas and protecting your investment.

7847 x 3

Site # 9: From Pole 88 to Pole 91 for a distance of 630' Issue: Road is lower than surrounding grade. Surface erosion is occurring and there is no way to get water off road surface. Fix: This is the most challenging section of Horse Point Road to address.