Transcription

Managing Gravel Road MaintenanceTRB Webinar – April 10, 2012Presented by:Mr. Ken Skorseth, Program ManagerSD Local Transportation Assistance Program (LTAP)South Dakota State UniversityBrookings, SD

Managing Gravel Road MaintenanceBriefbackgroundof presenter:

Managing Gravel Road MaintenanceOverview of Seminar Roadway Shape & Drainage Crown. Avoiding High Shoulders. Surface Gravel Selection. Preservation of Gravel

Managing Gravel Road MaintenanceDesign Issue – Basic Geometrics: Be familiar with the AASHTOpublication: Geometric Design of VeryLow-Volume Local Roads (ADT 400) Commonly called the “Little GreenBook”.

Managing Gravel Road MaintenanceGreen Book and “Little Green Book”

Gravel Roads Design & Maintenance“Nearly 80% of the roads in the UShave traffic volumes of 400 vehiclesper day or less.”!! (quote from LittleGreen Book)It becomes very difficult to constructand maintain these very low-volumeroads to a high geometric standard.

Managing Gravel Road MaintenanceGuidelines for Total Roadway Width for New Construction of VeryLow-Volume Local Roads in Rural AreasFrom: AASHTO – Guidelines for Geometric Design of Very LowVolume Local Roads (ADT ational& 4.5--5522.0-22.0---6022.0-----Note: Total roadway width includes the width of both traveled way and shoulders.

Managing Gravel Road MaintenanceGuidelines for Total Roadway Width for New Construction of VeryLow-Volume Local Roads in Rural AreasFrom: AASHTO – Guidelines for Geometric Design of Very LowVolume Local Roads (ADT ational& eryAgriculturalAccessHighest guideline:20.0Agricultural access20.020.0 widthrequiringroadwayof 2621.0ft at design21.0speed of22.522.545 quiringroadway18.0widthof 2018.0ft at design18.018.018.0speedof -5522.0-22.0---6022.0-----2025Note: Total roadway width includes the width of both traveled way and shoulders.22.024.024.024.0

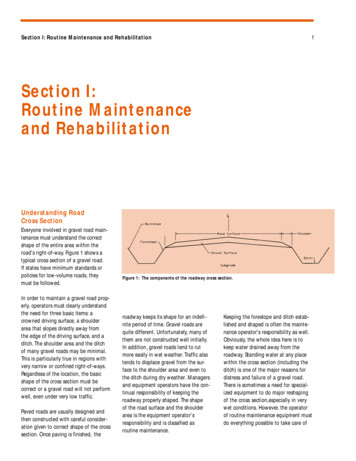

Managing Gravel Road MaintenanceRoadway CrownAn important issue is crown on gravel road surfaces.Generally recommended crown for gravel surfaces is 4%which is double the crown used in pavements.

Managing Gravel Road MaintenanceCrown: (con’t)Clear illustration of 2% crown on road to the left and 4% onthe road to the right. Water will not drain off an aggregatesurface with only 2% crown. This must be addressed indesign and during construction.

Managing Gravel Road Maintenance

Some roads have too little crown, some havetoo much.

Managing Gravel Road MaintenanceCrown gauges areHelpful

Managing Gravel Road MaintenanceCrown: (con’t)There are conflicting views on crown: 1/3 to 1/2 in. per ft. recommended byNACE manual Blading AggregateSurfaces – 1986 edition. 2 to 6% for “low-type pavements”recommended by AASHTO Green Bookpg 387 – 2001 edition.

Managing Gravel Road MaintenanceCrown: (con’t) The FHWA Gravel Roads Manualrecommends crown at or near 4%.Note: in arid and semi-arid regions,gravel roads may perform with lesscrown, but don’t use less than 3 %.

Managing Gravel Road MaintenanceMaintaining Roadway Shape: Perhaps the most critical issue iskeeping cutting edges straight. Many operators do not understand theimportance of this and/or do not knowhow to control it.

Managing Gravel Road MaintenanceCenter wear in the cutting edgeThis is a problem!

Managing Gravel Road MaintenanceCenter wear in the cutting edgeCreates a parabolic crown.Instead of correctshape.

Managing Gravel Road MaintenanceOnce roads develop parabolic shape, itbecomes hard to change.This centerwear occurredafter only sixhours of useon a badlyshaped road!!

Managing Gravel Road MaintenanceReducing center wear in the cutting edgePotentialsolutions:carbide cuttingedges or bits.

Managing Gravel Road MaintenanceGravel Roads – Managing MaintenanceFrequency of blade maintenance: Should be managed by observingsurface condition, not just bycalendar date. Don’t delay blade maintenance untilsurface distress becomes severe.

Managing Gravel Road MaintenanceGravel Roads – Managing MaintenanceFrequency of blade maintenance (con’t) In areas of high moisture, vegetation willcreep onto traveled way if blademaintenance is delayed. A good program of shoulder mowing isessential to gravel road maintenance.

Managing Gravel Road MaintenanceGravel Roads – Dealing with high shouldersThe high shoulder which obstructs drainage –a real problem on too many roads.

Managing Gravel Road MaintenanceProblem created by high shoulder

Managing Gravel Road MaintenanceShoulder drainage:Outstanding example!

Managing Gravel Road MaintenanceAggressive shoulder maintenanceInnovative tools to help reshape the highshoulder and recover gravel.

Managing Gravel Road MaintenanceOutstanding examplein confined ROW

Managing Gravel Road MaintenanceManagement Issue – Surface Gravel The issue of good surface gravel(aggregate) cannot be emphasizedenough!! Good aggregate surfacing differsfrom base and other constructionaggregates. When it’s right, problems diminish!

Managing Gravel Road MaintenanceSurface Gravel (con’t)Material Specifications Discussion: Many state DOTs do not have asurface aggregate spec. Many specifications that do existare quite loose and do not allowclose enough control of gradation.

Managing Gravel Road MaintenanceSurface Gravel (con’t)Too often, surface aggregate isperceived as not important, hencequality suffers.In study completed in Canada in2003 – samples were taken fromseveral aggregate supplier’sstockpiles being marketed as surfaceaggregate--- (con’t next slide)

Managing Gravel Road MaintenanceSurface Gravel (con’t)Only 14% of the samples met thecompanies own specifications whentested by independent labs! Qualitycontrol was almost nonexistent.Information from Material and PerformanceSpecifications for Wearing Course Aggregates onForest Roads by G. Legere & S. Mercier.

Managing Gravel Road MaintenanceSurface Gravel (con’t)Surface aggregate differs from baseaggregate in two fundamental ways: The need for more plastic fines to serveas binder. Smaller top-sized stone that will remainembedded in the surface.

Managing Gravel Road MaintenanceSurface Gravel (con’t)Similar ADT, Similar geometrics, butdifferent surface materials!

Managing Gravel Road MaintenanceSurface Gravel (con’t)Corrugation or“washboarding”which is surfacedistress that isdirectly related tosurface aggregatespecification

Managing Gravel Road MaintenanceSurface Gravel (con’t)Sample specifications comparison:Better whenmodified to 8 - 15

Managing Gravel Road MaintenanceSurface Gravel (con’t)Another sample spec:WisDOT CRUSHED AGGREGATE SHOULDER COURSEGradation No. 3SIEVE SIZE1 inch3/4 inch3/8 inchNo. 4No. 10No. 40No. 200CRUSHED GRAVEL10095 -10050 - 9035 - 7020 - 5510 - 359 - 15CRUSHED STONE10095-10050-9035-7015-555 - 15

Managing Gravel Road MaintenanceSurface Gravel (con’t)AASHTO’s Materials Manual – 2001edition, Designation M-147 has theserecommendations:“Where it is planned that the soil aggregate surfacecourse is to be maintained for several years withoutbituminous surface treatment-----, the engineer shouldspecify a minimum of 8% passing the----No. 200 sieve----, and should specify a maximum liquid limit of 35and plasticity index range of 4 to 9 in lieu of the limitsgiven in Section 2.2.2.

Managing Gravel Road Maintenance Preservation of gravel – conserving aprecious resource– High quality surface gravel results in lower lifecycle cost– Reduction of aggregate loss– Reduced frequency of blade maintenance– Stabilization may be very cost effective if trafficvolume is high

Current SDDOT Gravel Road TestProject Three test sections:– Hand County – northeast of Miller– Custer County – northwest of Custer– Brookings County – south of Volga Primary focus is on three gravel types:– Substandard but commonly used– Meets SDDOT Gravel Surfacing Spec– Modified SDDOT Spec – higher minimum onpercent passing #200 sieve and PI.

Managing Gravel Road MaintenanceModified Section with Crusher FinesCuster County TestSectionsCrusher fineswere added andmixed on road

Managing Gravel Road MaintenanceSubstandardsection withcrushedlimestonecommonly usedby USFSCuster CountySections (con’t)

Managing Gravel Road MaintenanceSubstandard SectionBrookings CountyTest SectionsOnly one month afterconstruction withcompaction

Managing Gravel Road MaintenanceModified SectionBrookings CountySections (con’t)

Managing Gravel Road MaintenanceBrookings Countymodified section usedlandfill clay mixed onroadway

Managing Gravel Road MaintenanceThese things and many more arediscussed in the FHWA Gravel RoadsManual. It can be found online bysearching for “FHWA Gravel RoadsManual”

Managing Gravel Road MaintenanceYou may contact me at:Ken SkorsethSDSU/SDLTAPBox 2220-Harding HallBrookings, SD 57007-0199phone 800-422-0129fax 605-688-5880email: ken.skorseth@sdstate.edu

Thank You for listening!

Gravel RoadsManagement StrategiesTRB WebinarApril 10, 2012George Huntington, PE

Gravel Roads Management StrategiesWhat we will cover How are gravel roads managed? How should gravel roads be managed? How can we improve gravel roads management?

Gravel Roads Management:State-of-the-Practice Surveys–NACE–ND-LTAP Gravel Roads Management Experts’Project How are people managing theirgravel roads?

Surveys ND-LTAP Survey– 120 responses MT, ND, SD, WY in 2009– Barriers to Roadway Surface Management 87%: Software 64%: Data Collection 52%: Lack of Staff NACE Survey– 18 responses Annual Meeting in Fort Worth, Texas, April 2010– Results in following slides

NACE Survey ResultsCondition Data Collection and Storage 61% indicated that evaluation of theircounty’s dirt and gravel roads’ condition isperformed by supervisors and foremenwhen time allows using a visual ratingsystem and that their results are storedonly in their heads. 78% do not store dirt and gravel roadcondition data in a computer.

NACE Survey ResultsMaintenance Scheduling 33% perform routine surface blading onall roads in a district, and then repeat. 83% use neither a formal conditionmeasurement system nor gravelthicknesses to schedule regraveling.

What dirt andgravel roadsreports do yougenerate?Financial DataRoad CharacteristicsNeeds AssessmentsWork andMaintenance PlansTotal costs incurredCost by roadCost by task/activity/functionFinancial needsRevenueConditionsTrafficMileagesMaintenance needsMajor repairs and rehab'nWork schedulesMaintenance osts by road and taskFinancial needsWhat dirt andgravel roadreports are orwould beparticularlyuseful to you?RevenueMileagesConditionsTrafficMaintenance needsMajor repairs and rehab'nCyclic maintenance schedulesTriggered maintenance schedules

Gravel Roads Management Experts’ ProjectWhy and how it happened Based on conversations at TRB 2009– Lack of a gravel roads management process forlocal governments– Support from other LTAPs and WYDOT Emails, meetings and conversations– 2009 and 2010

Attended PittsburghmeetingParticipated in WebinarAttended Rapid CitymeetingAttended WashingtonmeetingTOTAL INPUTSOrganization/AffiliationCounties 24Municipalities 4State DOT 5FHWA 4USDA Forest Service 5Other Federal 5LTAP/TTAP 19Academia 8Other Public 4Private Software Providers 5TOTAL83emailed commentsExperts 0061121350000040021110103072101513152513189479

Objectives Minimal effort and costSimple methodApplicable resultsSave the agency moneyReduce user costsOperational efficiencyImproved communications

“I’m not sure if I should applaud theeffort or question the merit of the gravelroads management methodology ”- Dave Kieper, Park County, Wyoming“Geez you want to take on a lion don’t ya!But hey we need to start and improve onwhat we are doing with aggregatesurfaced roads.”- Pete Bolander, USDA Forest Service

“ while you might think a gravel road is agravel road, not all things are equal. Thereason a gravel road is in such lousy conditionin Wyoming, is probably not the same reason itis lousy in California or in Florida. I wouldeven say that sound knowledge of gravel roadmaintenance is not universal, but maybe thelack of sound knowledge is.”-Gene Calvert, Collier County, Florida(formerly Mendocino County, California and Wyoming LTAP)

Group of ExpertsWhat we learned Little consideration of user costs Little gravel roads’ performance data Limited use of cost data– Use of accounting line items, not road items Measuring conditions is difficult but notimpossible– Visual ratings Timing ‘Typical’ conditions– Automated systems– Gravel thickness

Products Final ReportProgramming GuideImplementation GuideReports and Guides currently available onthe Wyoming Technology Transfer Centerwebsite– Click on ‘Special Projects’

Final Report Literature Review and ytical MethodsSummary and ConclusionsRecommendationsAppendixes

Programming Guide General advice for datamanagers and programmers Detailed lists of fields in adatabase Process flowchartsMNT TYPEGRVL SRCGRVL TYPTRTM PRDTRTM MTD1 - Blading0 - Unknown/ Other 0 - Other/ Unknown 1 - CaCl flakes1 - Topical spray2 - Reshaping1 - This Pit1 - Base2 - MgCl brine 2 - Motor grader blended3 - Regravel2 - That Quarry2 - Surfacing3 - Reclaimer blended4 - Dust Control3 - Subbase5 - Stabilization4 - Chips6 - Isolated Repairs7 - Major Work8 - Drainage Maintenance9 - Other** May want to include lists for maintenance of, for example, signs, culverts, asphalt roads and so on

Implementation Guide Assessment Maintenance schedulingData Management Network-level outputsInventoryMaintenance and Cost TrackingCondition Data & Performance Monitoring– ‘Typical’ conditions– During routine maintenance

Gravel Roads ManagementKey Points Sustainability– Simplicity Primary Outcomes– Operational efficiency– Communications with public and officials Primary Obstacles– Performance measurement Rapidly changing conditions– Cost and maintenance tracking Inventory and roadway segments

Why manage gravel roads? Operational efficiency––––Routine maintenance frequencyRegravel frequency and timingConsider agency and user costsExamples: Will long-term performance and maintenance be betterserved with 3” of crushed gravel or 6” of pit run aggregate? How much are maintenance costs reduced by various dustcontrol agents? Are our culverts adequately maintained? Communicating needs to elected officials andthe public

Why change how we manage gravel roads now? Maintenance costs are increasing– Fuel– Materials– Labor– Equipment Budgets are steady or shrinking Information costs are decreasing– Easier and more efficient informationmanagement

Issues and Problems with GRM Computers– Availability and expertise Performance assessment– How to measure ‘conditions’ Operational efficiency– Maintenance schedules– Economics of gravel types and thicknesses– Economics of dust suppression and soilstabilization Tightening budgets– Justification to elected officials and the public

GRM Strategies and Solutions Maintenance Policies– Service Levels– Functional/Maintenance Classes (AASHTO) Cyclic and Triggered Maintenance– Work Schedules Needs Assessments Performance Prediction Condition Monitoring Cost and Maintenance Tracking– Maintenance Segments

Maintenance Policies Snow plowing policies as a starting point

Maintenance Policies Expand beyond plowingpolicies to overall qualityand level of maintenance,like Pitkin County(Aspen), Colorado– High, Moderate, Low andLimited service roads– Roads listed by class– Addresses variouselements, such as PlowingGradingMowingHerbicidesDust controlCross drainageSide drainageSignageTree/shrub trimmingand removal– Side slopes– Road surfacing– Parking areas–––––––––

Maintenance Scheduling Cyclic– On a set schedule– Maintainers patrol their route, maintaining eachroad in its turn, on their schedule Triggered– In response to observed conditions As reported to the agency As maintainers observe roadway conditions Most agencies and maintainers use a hybridof these approaches.

Cyclic Maintenance SchedulingDivide the road networkinto SECTIONSDevelop a table ofMAINTENANCE STRATEGIESAssign a MAINTENANCE STRATEGY to each SECTIONDetermine next maintenanceTASK for each SECTION andWHEN this task should beperformedRECORDtask andsectionANALYZE performanceof each SECTIONPRIORITIZE tasks on allsections based on WHENeach task is due; Developprioritized list of TASKSPerform maintenanceTASKSRECORD SurfaceCONDITIONS

Triggered Maintenance Scheduling Set thresholds for maintenance– Canadian logging operations– Gravel thicknesses Complaints ‘Check Roads’ Maintainers’observations

Network Level Outputs Conditions– Monitoring– Prediction Financial tables– Needs Road tables and maps

Gravel Roads Management:Strategies to TacticsStrategies: Maintenance policies,maintenance scheduling, network-level planning Agency Assessment– Current information management– Inventory– What tools do we have?– What methods might we implement?– What obstacles must we overcome?

Management Methods Maintenance and Construction Policies– Snow removal– Surface type– Maintenance frequency– Other activities and features Conditions– Past, Present and Future Historical Costs Maintenance History– Inventory and Segmentation

Management Tools Inventory– Segmentation Field Data– Time cards, work orders, equipment logs– Maintenance performed Condition Data– Asphalt: Yes.?– Gravel: No.? Cost Data Analysis– Spreadsheet models Reports

Obstacles Software– Capable administrator Analytical Goals Data Collection– Inventory– Performance/Condition Maintenance and Cost Tracking– Inventory Time and Money!!!

Assessment:What improvements are needed?– How are cost data tracked, stored, analyzed, used andpresented?– How are network conditions assessed, used, recordedand presented?– How are maintenance strategies established for eachroad section?– Is the unsealed road network managed as efficiently aspractical? Can this be documented?– Is information provided to the public and to electedofficials that let them understand road and streetmanagement well enough to make good decisionsregarding funding and other higher level managementdecisions?

Assessment:What have you got? Political and Professional SupportFinancial ResourcesInformationHardware, Software, GPS & GIS Personnel– Succession!!!

InventoryMaintenanceManagementSegments Segment ID Location– Road– Begin– End Surface Type Length Lots of others

Data Management Types– Manual– Spreadsheet & Database– Geographic Information System (GIS) Sources– Commercial package– Free package– In-House

Condition Data andPerformance Monitoring Visual ‘windshield’ survey: PASER; WY-LTAP– Quick– Training Deduct value method: USACE URCI– Distress extent and severity– Time consuming Automated systems– Becoming easier Gravel thickness– Excavation– GPR

Surface Condition EvaluationProblemsSolutions Rapidly changingconditions Ride Quality Rating Guide– Weather– Maintenance– Traffic Subjective ‘windshield’rating methods Automated systems– Varied vehicle paths– Timing– Wyoming LTAP website Evaluate under ‘typical’conditions.– At least several weeks aftersurface maintenance.– Don’t evaluate right after aheavy precipitation eventor spring thaw. Evaluate by operatorimmediately beforemaintenance.

Maintenance andCost Tracking Line items and the ‘accountants’ issue– Maintenance tasks Is information telling you all it could?

When deciding howto maintain yourroads, do youcare Whether gravel is hauled by yourtrucks or by a contractor’s trucks?Whether the gravel fixed soft spotsor regraveled a whole section?

Eight Maintenance Tasks BladingReshapingRegravelDust ControlStabilizationIsolated RepairsMajor WorkDrainage Maintenance

Closing Thoughts Common problems – Inventory not properly segmented– Maintenance line items– Lack of performance evaluation records Simple solutions ––––Good, segmented inventoryVisual condition ratingMaintenance policiesMaintenance schedules Ultimate goals – More efficient operations– Better communications

How do we save money? Don’t over-maintain– Very low-volume roads Consider user costs– Do the washboards come right back? Haul higher quality gravel when cost-effective– Save blading costs– Reduce dust– Reduce regraveling frequency Use dust suppressantsand soil stabilizers whencost-effective

Gravel Roads Management:Summary Computer expertise isopening up options Inventory Segmentation Condition and performance measurementneeds to be well timed, and it is important Maintenance policies Maintenance scheduling and cost tracking Goals: Efficiency and Communication

Gravel RoadsManagement StrategiesGeorge Huntington, PE

Book". Managing Gravel Road Maintenance . . Note: Total roadway width includes the width of both traveled way and shoulders. Guidelines for Total Roadway Width for New Construction of Very . crown, but don't use less than 3 %. Managing Gravel Road Maintenance .