Transcription

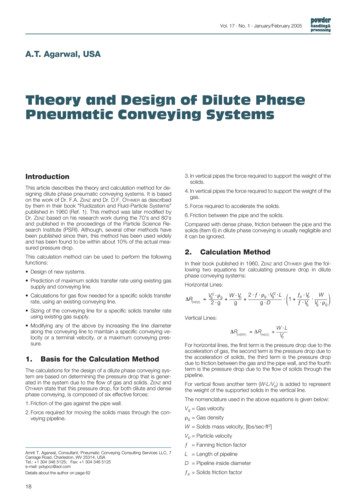

Vol. 17 · No. 1 · January/February 2005A.T. Agarwal, USATheory and Design of Dilute PhasePneumatic Conveying SystemsIntroductionThis article describes the theory and calculation method for designing dilute phase pneumatic conveying systems. It is basedon the work of Dr. F.A. ZENZ and Dr. D.F. OTHMER as describedby them in their book "Fluidization and Fluid-Particle Systems"published in 1960 (Ref. 1). This method was later modified byDr. ZENZ based on his research work during the 70's and 80'sand published in the proceedings of the Particle Science Research Institute (PSRI). Although, several other methods havebeen published since then, this method has been used widelyand has been found to be within about 10% of the actual measured pressure drop.This calculation method can be used to perform the followingfunctions:3. In vertical pipes the force required to support the weight of thesolids.4. In vertical pipes the force required to support the weight of thegas.5. Force required to accelerate the solids.6. Friction between the pipe and the solids.Compared with dense phase, friction between the pipe and thesolids (Item 6) in dilute phase conveying is usually negligible andit can be ignored.2.Calculation Method Design of new systems.In their book published in 1960, ZENZ and OTHMER give the following two equations for calculating pressure drop in dilutephase conveying systems: Prediction of maximum solids transfer rate using existing gassupply and conveying line.Horizontal Lines: Calculations for gas flow needed for a specific solids transferrate, using an existing conveying line. PT(HOZ) Sizing of the conveying line for a specific solids transfer rateusing existing gas supply.Vertical Lines: Modifying any of the above by increasing the line diameteralong the conveying line to maintain a specific conveying velocity or a terminal velocity, or a maximum conveying pressure.1.Basis for the Calculation MethodThe calculations for the design of a dilute phase conveying system are based on determining the pressure drop that is generated in the system due to the flow of gas and solids. ZENZ andOTHMER state that this pressure drop, for both dilute and densephase conveying, is composed of six effective forces:1. Friction of the gas against the pipe wall.2. Force required for moving the solids mass through the conveying pipeline.Vg2 · ρg W · Vp 2 · ƒ · ρg · Vg2 · L 2 ·ggg ·D PT(VERT) PT(HOZ) W·LVpFor horizontal lines, the first term is the pressure drop due to theacceleration of gas, the second term is the pressure drop due tothe acceleration of solids, the third term is the pressure dropdue to friction between the gas and the pipe wall, and the fourthterm is the pressure drop due to the flow of solids through thepipeline.For vertical flows another term (W·L/Vp) is added to representthe weight of the supported solids in the vertical line.The nomenclature used in the above equations is given below:Vg Gas velocityρg Gas densityW Solids mass velocity, [lbs/sec·ft2]Vp Particle velocityƒ Fanning friction factorAmrit T. Agarwal, Consultant, Pneumatic Conveying Consulting Services LLC, 7Carriage Road, Charleston, WV 25314, USATel.: 1 304 346 5125; Fax: 1 304 346 5125e-mail: polypcc@aol.comL Length of pipelineDetails about the author on page 62ƒp Solids friction factor18ƒp · VpW · 1 ·ƒ · Vg Vg · ρg D Pipeline inside diameter

Pneumatic Conveying DesignVol. 17 · No. 1 · January/February 2005For pressure drop due to solids friction, ZENZ and OTHMER intheir book explained that some of the earlier investigations hadconcluded that the term (ƒp·Vp)/(ƒ·Vg) could be ignored but thatthe use of this term, in general, will predict pressure dropsgreater than those observed and thus can be considered conservative for design purposes. Further research on this topicwas carried out by ZENZ while he was at PSRI and he concludedthat this term should be replaced by a constant (K) because thisterm was dependent upon the physical properties of the solidsbeing conveyed. His investigation also concluded that becauseof many variables it was very difficult to develop an accuratecorrelation for calculating the value of K and therefore, the valueof K should be back-calculated from the actual pressure dropdata obtained from lab or plant tests.Eq. 2:Based on this work the term for solids pressure drop waschanged to:Eq. 3: Ps Pg · K · pressure drop due to solids flow Pg pressure drop due to gas flowK constant depending upon solids physical and frictionalpropertiesR ratio of solids to gas mass flow ratesThe next step is to develop a single equation for calculating thetotal pressure drop in a conveying system that may have bothhorizontal and vertical lines. In addition, a term Pmisc wasadded to account for pressure drop in any equipment such as adust collector that may be required at the end of the conveyingline.This equation consisting of six pressure drop terms is givenbelow: PT Pacc Pg Ps Hg Hs Pmisc4ƒ · L · ρg · Vg22g · D · 144 4ƒ · L · ρg · Vg29266 · DPressure drop due to friction between the solids andthe conveying pipeline, bends, diverter valves, and flexible hoses: Ps Pg · K · R (modified Zenz equation)Eq. 4: Ps Pg Note: In the above expression, the term "L" is thelength of the straight sections of the pipeline and is the"equivalent length" of the bends, diverter valves andflexible hoses.W Pg · K · RVg · ρgwhere,Pressure drop of gas due to frictional losses betweengas and the conveying pipeline and in any bends, diverter valves, and flexible hoses that may be in thepipeline:Pressure drop due to elevation of gas by Z feet: Hg Eq. 5:Pressure drop due to elevation of solids by Z feet. Hs Eq. 6: Z · ρg144 · gc Z · W · g144 · Vp · gcPressure drop due to miscellaneous equipment in theconveying system. Hmisc (It is a term that is not calculated but isentered as input data in the calculations). This term is a constant.NomenclatureThe nomenclature and the units that are used in the above sixequations are given below:D Pipe inside diameter (ft)ƒ Fanning friction factorg Acceleration due to gravity (32.2 ft/sec2)gc Constant (32.174 ft-lb/lb-sec2)K Friction multiplier for the solids conveyedL Pipe equivalent length (ft)R Solids to gas mass flow ratio (lb/lb)Vg Gas velocity (ft/sec)Vp Particle velocity (ft/sec)W Solids line loading (lbs/sec·ft2) Pmisc Pressure drop due to miscellaneous equipment.Z Elevation change in conveying line (ft)These six pressure drop terms given above are related to thetwo pressure drop equations given by ZENZ and OTHMER. Theseterms are then converted to the units that are commonly used inpneumatic conveying systems, resulting in the following equations where pressure drop is expressed in lbs/square inch.ρg Gas density (lbs/ft3)ƒ Fanning friction factorEq. 1:K Friction multiplierL Pipe equivalent lengthVp Solids velocityR Solids to Gas ratiowhere, PT total pressure drop in the system. Pacc Pressure drop due to acceleration of the solids fromtheir "at rest" condition at the pick-up point to their conveying velocity up to their exit from the conveying system. Pg Pressure drop of gas due to frictional losses betweenthe gas and the pipe wall. Ps Pressure drop of solids through the pipeline. Hg Pressure drop due to elevation of gas in vertical pipe. Hs Pressure drop due to elevation of solids in vertical pipe.Pressure drop due to acceleration of the solids fromtheir "at rest" condition at the pick-up point to the conveying velocity up to the exit from the conveying system: Pacc W · VPW · VP 144 · g4640To solve the above equations the value of the following termshas to be determined:These values are determined as follows:19

Pneumatic Conveying Design2.1Fanning Friction Factor ƒ2.4The Reynold's number (NRe) is first calculatedNRe D · Vg · ρgµgwhere µg is the gas viscosity in lbs/(ft·sec)After this, the Fanning friction factor is calculated using the following equation developed from the charts given in CRANE'STechnical Paper No. 410 (pages A-23, A24) on the "Flow ofFluids".Eq. 7:ƒ 0.3317 2ε logn 3.7·DNRe where ε is the pipe roughness factor. Pipe roughness factor depends on if the pipe is internally smooth, rough, or very rough.The value of this factor based on test data is given below:for internally smooth pipes,ε 0.00015;for shot-peened pipes,ε 0.0005;2.2Vol. 17 · No. 1 · January/February 2005Friction Multiplier (K)Solids Velocity (Vp)Solids velocity is always less than the gas velocity because ofthe drag forces between the gas and the solids. This differenceis called the slip factor. For most of coarse or hard solids this slipfactor is about 0.8, which means that the solids velocity is 80%of the gas velocity. Therefore, for these materials use a solidsvelocity 20% less than the gas velocity Vg, i.e.Vp 0.8·VgFor fine powders solids velocity is closer to the gas velocity. Forthese materials use a slip factor of 0.9 instead of 0.8. This valuegenerally ranges from 0.7 to 0.95. Lighter and smaller materialshave higher values than those of larger and heavier particles.2.4.1 Solids Velocity in Long Radius BendsFor a 90 degree radius bend, solids velocity at the exit of thebend Vp2 is 0.8 times the solids velocity at the inlet of the bendVp1. The factor "0.8" is a typical value but it ranges from 0.6 to0.9 depending upon the properties of the solids. For bends thatare less than 90 degrees, the exit velocity Vp2 is Degree of bend· (1 0.8) · Vp1Vp2 1 90 2.4.2 Solids Velocity after Leaving a BendThe value of the Friction Multiplier (K) is not calculated but isdetermined experimentally or retrieved from data bank. Itsvalue is different for different materials. Its range is typically 0.4to 4.0After leaving a 90 degree bend, use a default value of 20 pipe diameters to calculate the length of the straight pipe for the solidsto re-accelerate to their original velocity at the inlet of the bend(Vp1).2.32.5Pipe Equivalent Length (L)For straight pipes use the actual length of the pipe.For components such as bends, diverter valves, and flexiblehoses, use their equivalent length expressed in pipe diametersof the conveying pipe. Typical equivalent length values are givenbelow:Component:Equivalent LengthBends90 bend, long radius,(10 to 1 radius to diameter ratio):40, or 20 ftwhichever is moreDiverter Valves45 degree divert angle:2030 degree divert angle:10Flexible HosesStainless steel, with lined interior:3 x pipe lengthRubber or vinyl hose:5 x pipe lengthFor bends that are less than 90 , use equivalent length as: 40 ·Degree of Bend90For special bends such as short radius bends, Hammerteck,Gamma, pocket-T's, etc., increase the value of 40 to a highernumber. For example, for a typical conveying system with about5 bends increase the calculated pressure drop value by 10%.For 10 bends increase it by 20%. These numbers are based onlab tests or plant data.20Solids to Air Ratio RCalculations are based on using the following term as given byZENZ and OTHMER:R Wm Vg · ρgA · Vg · ρgWhere m is the solids mass flow rate in lbs/sec and A is thecross-sectional area of the pipe in ft2. The gas mass flow rate inlbs/sec is calculated based on the actual cfm of gas and gasdensity introduced into the conveying system by the gas mover,and the internal cross-sectional area of the pipe. Gas can be airor any other gas. Use air as default if use of a different gas is notgiven.For pressure type conveying systems, reduce the gas mass flowrate by 5% (default value) to account for gas leakage through arotary valve, if a rotary valve is used to feed the solids. For moreaccurate results, change this default value by calculating actualrotary valve leakage (both clearance and displacement).For the gas density term ρg, make corrections if the inlet conditions are different from standard conditions (68 F, 14.7 psia).2.6Gas Density along the Conveying Line:Gas density depends upon gas pressure and gas temperature.For most conveying systems, gas temperature can be assumedto be constant. Therefore, only changes in pressure will changethe gas density. Because the pressure either increases or decreases along the conveying line, depending upon whether it isa vacuum system or a pressure system, gas density will alsokeep on increasing or decreasing. For calculating the pressuredrop due the flow of gas, divide the conveying line into smalllengths such as 5 or 10 ft, start from the point where inlet gasdensity is known (such as ambient conditions), and calculatethe exit pressure and corresponding gas density for this small

Pneumatic Conveying DesignVol. 17 · No. 1 · January/February 2005section. Then use this exit gas density as the inlet gas densityfor the next pipe section. Repeat this procedure until reachingthe end of the conveying line. For vacuum systems, start fromthe pick-up point and end at the blower inlet. For pressure systems, start from the end of the conveying line and return to thepick-up point.2.7Addition or Removal of Gas along theConveying LineIf some conveying systems, gas is added or removed from theconveying system at any point along the route of the conveyingline. In this case, re-calculate the gas mass flow and the solidsto gas ratio, and use the new gas flow for the pressure drop calculations after this injection point.3.Calculation ProcedureThe procedure given below for running these calculations isbased on the Microsoft Excel spreadsheet method.3.1Step 1:The first step is to define the objectives for the calculations andto gather data that is needed for these calculations.Flow of Solids: Pg · K · RElevation of gas: Z · ρg · g144 · gcElevation of solids: Z · W · g144 · Vp · gcMisc. Pressure Drop:3.3Assume that it is in a dust collector atthe end of the conveying line and is0.2 psi.Step 3:Enter the input data in a spreadsheet form as shown in worksheets 1 and 2. Enter all of the input data in worksheet 1 exceptfor the conveying pipeline data. Enter the pipeline dat

pneumatic conveying systems, resulting in the following equa-tions where pressure drop is expressed in lbs/square inch. Eq. 1: Pressure drop due to acceleration of the solids from their "at rest" condition at the pick-up point to the con-veying velocity up to the exit from the conveying sys-tem: P acc W·V P 144 ·g W·V P 4640 P T P acc PFile Size: 207KBPage Count: 6People also search fordense vs dilute phase conveyingpneumatic conveying system designdilute phase conveying calculatorpneumatic material conveying systems