Transcription

Futurebuild LVLresidentialDesign Guide J u ly 2 0 1 4Information contained within is specific to the Futurebuild range of LVL products and cannot beused with any other LVL products no matter how similar they may appear.

Contents1.0 Laminated Veneer Lumber.31.1 Futurebuild LVL.31.2 Application.41.3 Sustainability.41.4 Disclaimer.42.0 Product Range.52.1 Product Availability.63.0 General Design Considerations.73.1 CHH Software solutions.83.2 Manufacture.83.3 Structural Properties.83.4 Structural Reliability.83.5 Structural Certification.93.6 Quality Assurance.93.7 Durability.103.8 Preservative Treatment.104.0 Design Considerations – hyJOIST 1-beams.114.1 Bearing Support – Joist Not TransferringLoad From Upper Walls.114.2 Bearing Support For Joists Transferring UpperStorey Wall and Roof Loads at Supports.114.3 Bearing Support for Lower Storey of2 Storey Construction.124.4 Concentrated Loads from Jamb Studs/Posts.124.5 Web Holes for hyJOIST I-beams. 125.0 Design Considerations – Solid LVL.145.1 Fastening Futurebuild LVL.145.2 Storage of Futurebuild LVL.145.3 Rip Sawing Futurebuild LVL.145.4 Using Double Sections.156.0 Terminology.166.1 Span.166.2 Overhang Span (Cantilever).166.3 Holes in Members in Houses and ResidentialBuildings.166.4 Spacing.176.5 Load Widths.176.6 Determination of RoofLoad Width.176.7 Determination of Floor Load Width.186.8 Lintels.186.9 Roof Mass.186.10 Technical Support.187.0 Span Tables.197.1 Floor Beams or Bearers.197.2 Floor Joists.257.3 Walls.327.4 Ceiling Joists.367.5 Hanging Beams.377.6 Hip or Valley Rafters.387.6 Hip or Valley Rafters continued.397.7 Rafters.417.8 Rafter Span Tables.427.9 Roof Beams.448.0 Verandah Beams.47

futurebuild LVL1.0 Laminated Veneer LumberLaminated Veneer Lumber (LVL) is the engineered solution for residential housing design andconstruction. Futurebuild LVL is an engineered wood product with high structural reliabilityand performance, and consistent dimensional accuracy. It allows architects and designers tospecify Futurebuild LVL with confidence and is readily available in a range of thicknesses, depthsand lengths. Futurebuild LVL has been tried and trusted in Australasia for over 30 yearsMade in New ZealandAvailable FSC “Chain of Custody” certified on requestFully supported by Carter Holt Harvey Woodproducts design and technical expertiseEasy to work with using traditional building toolsClearly branded for easy identification on-siteEngineered to precise tolerances This guide is intended for use by professionals and good building practice must be followed atall times.1.1 Futurebuild LVL Manufactured by Carter Holt Harvey Woodproducts New Zealand, the Futurebuild LVL rangeis New Zealand’s leading brand of LVL. The Futurebuild LVL range of products features specificmaterial property ‘recipes’. As such the information contained within this guide is specific tothe Futurebuild LVL range and cannot be used with any other LVL product no matter howsimilar they may appear.For more information about the Futurebuild LVL range including technical notes and limit statedesign information visit www.chhwoodproducts.co.nzThe information contained in this manual relates specifically to Futurebuild LVL products manufacturedby Carter Holt Harvey Woodproducts and cannot be used with any other manufacturers LVL product nomatter how similar they may appear. Alternative LVL products can differ in a number of ways which may not be immediately obvious andsubstituting them for products is not appropriate and could in extreme cases lead to premature failure and/orbuildings which do not meet the requirements of the New Zealand Building Code.CHH Woodproducts Futurebuild LVL residential design guide 0800 585 244 www.chhwoodproducts.co.nz 3

Futurebuild LVL1.2 ApplicationThe span tables and technical information in this guide areintended to be used by designers or builders to select theappropriate Futurebuild LVL products for use in the framing ofhouses and similar buildings within the scope of NZS 3604. The tabulated data given applies for Futurebuild LVL membersinstalled in accordance with traditionally recognised framingpractice as described in NZS 3604 Timber Framed Buildings,the installation specifications contained in this guide and theFuturebuild LVL Residential Installation Guide.The software specification program designIT for housesprovides the ability to review reaction information for thedetermination of support and tie-down information whererequired. For more information or to download CHH designsoftware free of charge, visit www.chhsoftware.com or contactCHH Woodproducts on 0800 808 131. 1.3 SustainabilityFuturebuild LVL is manufactured from radiata pine, a plantationgrown medium density softwood. It is grown on tree farmswhich are tended and harvested to provide wood for LVLmanufacture and other applications. The crop is managedon a sustainable basis to yield millable trees. New Zealandplantations are managed in compliance with the New ZealandForest Accord, a voluntary agreement signed in 1991 betweenNew Zealand forest managers and environmental nongovernment organisations. Futurebuild LVL is manufacturedin New Zealand, at the CHH Woodproducts Marsden PointLaminated Veneer Mill. Futurebuild LVL is available ForestryStewardship Council (FSC) (SCS-COC-001316) certifiedupon request.1.4 DisclaimerThe information contained in this document is current as of July2014 and is based on data available to CHH Woodproducts atthe time of going to print. This publication replaces all previousCHH Woodproducts Futurebuild LVL residential designliterature. CHH Woodproducts reserves the right to change theinformation contained in this literature without prior notice. It isimportant that you call 0800 808 131to confirm that you have the most up to date informationavailable or refer to www.chhwoodproducts.co.nz4CHH Woodproducts has used all reasonable endeavours toensure the accuracy and reliability of the informationcontained in this document. This information does not replaceprofessional advice and we recommend that professional adviceshould be obtained specific to your circumstances. To the extentpermitted by law, CHH Woodproducts will not be liable for anyinaccuracies, omissions or errors in this information nor for anyactions taken in reliance on this information.CHH Woodproducts Futurebuild LVL residential design guide 0800 585 244 www.chhwoodproducts.co.nz

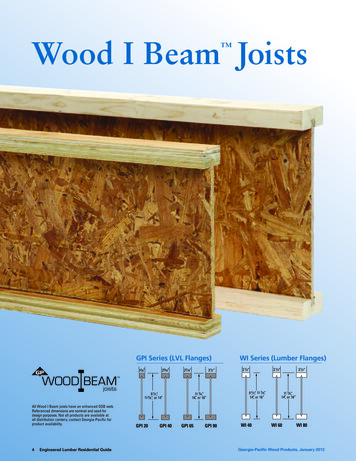

2.0 Product RangehyCHORD is available in smallersection sizes to match SG StructuralTimber such as Laserframe .hyCHORD is primarily specified asroof truss chords, but can also be usedfor lintels, rafters, purlins, floor joists,wall studs or other members wheresmaller section sizes are required.hy90 is a 90 mm thick LVL productmanufactured primarily for lintels orbeams to match 90 mm light timberframing. It has lower structuralproperties than hySPAN but itsthickness offers better memberstability when used as long spanstructural beams or columns.hyJOIST is an engineered ‘I-beam’utilising LVL flanges and a plywoodweb. It is ideally suited to floor joistand rafter applications due to its lightweight, straightness and the ability tocut large holes through the web(e.g. for services or ventilation)hyONE is a 90 mm thick, highstiffness and strength LVL productmanufactured primarily for lintels orfloor beams where large spans ordepth restrictions apply.hyBOUND is a treated boundaryjoist for enhanced weather protectionand to aid in the transfer of upperstorey loads.truFORM is manufactured for use inconcrete formwork and is suitable forjoists, bearers, walers and soldiers.edgeFORM is manufactured for use inconcrete formwork as edge boards. hySPAN has high structural propertiesand is available in a large range ofsizes and lengths. hySPAN is typicallyspecified for structural beams and isalso used for lintels, rafters and floorjoists in residential structures.Futurebuild LVL product rangeStructural ProductsFormwork Products Access Products Building SystemshyPLANK is a strong, lightweight LVLscaffold plank with significantly higherstructural reliability than sawn timber. hyFRAME is a CHH Woodproductsbuilding system designed for theagricultural market. Formwork and Access products are outside the scope of this guide. For more information on these products visitwww.chhwoodproducts.co.nz or contact CHH Woodproducts.CHH Woodproducts Futurebuild LVL residential design guide 0800 585 244 www.chhwoodproducts.co.nz 5

Table 1: futurebuild lvl standard product range ProductThickness (mm)Depth (mm)28150170200240hySPAN300 360400 Futurebuild LVL product range2.1 Product Availability4563333333334506003333333200240 300360400240300hyONE 360400333390hyCHORD 140190200hyJOIST300360400240hyBOUND 3003604004.8 – 6.0, 7.2 m4.8 – 6.0, 7.2 m5.4, 6.0, 7.2 m5.4, 7.2 m4.8*, 6.0*, 7.2 m*4.8*, 6.0*, 7.2 m*3333333332004.8 – 7.2 m4.8*, 6.0*, 7.2 m*333240 2.4 – 13.2 m3333333333150hy9090Length(0.6 m incrementswhere indicated)2.4 – 13.2 m4.8, 6.0 m* Indicates untreated product available on a make to order basis. Additional lead times may apply Non standard products and lengths may be available subject to production availability. Additional lead times may apply A comprehensive range of accessories including joist hangers, blocking and web stiffeners are available. Contact CHH Woodproducts or refer to "designIT forhouses" software for more informationAvailable treated only6Available either untreated or treatedCHH Woodproducts Futurebuild LVL residential design guide 0800 585 244 www.chhwoodproducts.co.nz

3.0 General Design Considerations AS/NZS 1170:2002/3 Structural Design Actions NZS 3603:1993 Timber Structures Standard, an AcceptableSolution to NZBC Clause 1 Structure. The spans given in these tables have been developed byexperienced timber design engineers in accordance withNZS3603:1993 and include the most up-to-date loadingcombinations from AS/NZS 1170.All tables are suitable for ground snow loads up to 1.0 kPa. Forsnow loads over 1.0 kPa refer to designIT for houses software.Member SpecificationIn selecting an appropriate beam size, specifiers should alsoconsider the applicability of design deflection limits for the beamsintended use. Deflection limits applied in this guide may not besuitable for some designs and further advice should be obtained.Reaction/Support ConsiderationsFor tie down, support and reaction information refer to designITfor houses software.Deflection LimitsFloor loading applied includes an allowance for: Floor mass not exceeding 40 kg/m , unless otherwise notified Live load of up to 1.5 kPa/1.8 kN, for use in domestic houses2For other situations, such as decks, balconies, tiled areas andapartment floors, designIT for houses software should beused for specification where alternate loading conditionsmay be applied. For commercial, industrial and other heavilyloaded floors use designIT for Commercial Floors or contactCHH Woodproducts.The deflection limits used in these span tables have beendetermined on the basis of experience with the knownserviceability performance of individual member types in typicalapplications. Where reduced deflections or higher levels ofperformance are required consult designIT for houses softwareor select members that have an increased spanning capabilityas required. DL – Dead Load, sometimes referred to as permanent load,considers load that is deemed to apply for periods of more than6 months.LL – Live Load, sometimes referred to as transient load, is loadthat is considered to be temporary in its nature.Wind LoadingUnless noted otherwise, the tables given in this guide aresuitable for applications in building wind zones up to very high(VH) exposure.Dynamic – Dynamic serviceability limits are applied to floorjoists and relate to the dynamic response of a floor joist to load.The 1 kN for 2 mm deflection is provided to reflect a dynamicperformance level of the floor corresponding 8 Hz.CHH Woodproducts Futurebuild LVL residential design guide 0800 585 244 www.chhwoodproducts.co.nz Guidance has been taken from AS 1684.1:1999, Residentialtimber-framed construction, Part 1: Design criteria, and reviewedto ensure agreement with NZS 3604:2011 Timber FramedBuildings. When selected and installed in accordance withthe specifications, details and limitations in this guide and theResidential Installation Guide, Futurebuild LVL will comply withthe requirements of the New Zealand Building Code.Snow LoadingFuturebuild LVL general design considerationsThe design methodology used in the preparation of this guidecomplies with the requirements of the following design standards:7

CHH Software Solutions include specification software forboth residential and non-residential structural systems. Theyenable designers and engineers, even those unfamiliar with thespecifics of timber engineering to produce high quality, reliablespecifications using engineered wood products.Residential SoftwaredesignIT for houses is a software tool for allbuilding practitioners for designing with theFuturebuild LVL range of engineered wood products and otherselected materials for houses and similar structures. designIT for houses enables a wide range of applications to beconsidered, including floor layouts, wind and other loads, which arenot included in this publication without the need for engineeringknowledge or the exercise of professional engineering judgment.The designIT Site app has been developed as a handyreference tool for the specifier or tradesman on the go.It is a trimmed down version of designIT for houses.floorIT site is a smartphone app to aid specifiers in thespecification, selection and estimation of quantities for arange of flooring applications.layITout is an integrated design and layouttool that allows users to enter a house plan,propose and then design a floor joist layout for a fully integratedengineered floor system. Non Residential SoftwaredesignIT for Commercial Floors is asoftware tool for all building practitionersfor designing with the Futurebuild LVL range of engineeredwood products and other selected materials in commercial,industrial and other heavily loaded floors.The computeIT software suite is designed to aid in thespecification of heavy structural members and non residentialstructural systems. It includes three software packages;computeIT for beams, computeIT toolkit and computeIT forportal frames. computeIT for beams is an all purposebeam analysis package that enablesengineers to develop design solutions for a range of engineeredwood products.computeIT toolkIT is a series of designtools allowing quick and easy design ofbeams, columns, rigid moment connections, purlins and girts.computeIT for portal frames is a fullyintegrated portal frame design, analysisand specification package for the development of optimised timberdesign solutions.slabIT site is an app for the design of truFORM andgripFORM members for use as joists and bearers forforming slab soffits. Futurebuild LVL general design considerations3.1 CHH Software solutionsFor more information or to download CHH software free of charge,visit www.chhsoftware.com or contact CHH Woodproducts.3.2 ManufactureFuturebuild LVL is manufactured by using phenolic adhesive tolaminate radiata pine veneer, in a continuous assembly in whichthe grain direction of all veneers is orientated in the longitudinaldirection. It is pressed as a 1.2 m nominal width continuousbillet in various standard thicknesses, docked to any specifiedlength and then ripped into standard widths for use as structuralbeams etc.For product range and size information refer to section 2.1Product Availability.3.3 Structural PropertiesThe structural properties for Futurebuild LVL have been determinedby testing in accordance with the requirements of AS/NZS 4357 andsection 4 of AS/NZS 4063.2:2010 and so comply with the provisionsof the NZ Building Code through clause C2.3 in NZS3603.Refer to the Futurebuild LVL Specific Engineering Design Guidefor engineering design information.3.4 Structural ReliabilityFuturebuild LVL is manufactured by laminating various grades ofveneer in a predetermined pattern to impart predictable andreliable structural properties. The uniformity of LVL is the key to itshigh strength and stiffness properties and its reputation for reliableand predictable performance. It is the reliability of LVL that makesit a genuine engineering material suitable for high load, high riskapplications such as large span portal frames.8For ordinary applications the reliability of LVL, illustratedgraphically in Figure 1, rewards specifiers and builders with theconfidence of meeting customer expectations and reductionin the incidence of expensive and disruptive call backs.CHH Woodproducts Futurebuild LVL residential design guide 0800 585 244 www.chhwoodproducts.co.nz

Figure 1: LVL Reliability CurveFrequencyRange of deflections anticipated for ordinary timber Futurebuild LVL general design considerationsRange of deflections anticipated for LVL20 mm24 mmDeflectionDesignDeflection3.5 Structural CertificationThe span tables and details in this guide for Futurebuild LVL havebeen designed in accordance with sound and widely acceptedengineering principles. The design properties of Futurebuild LVL in this guide weredetermined in accordance with clauses 2.3 and C2.3 of NZS 3603:“Timber Structures Standard.” Futurebuild LVL is ProductCertified by the Engineered Wood Products Association ofAustralasia (EWPAA) as being manufactured in accordance withthe joint New Zealand / Australian Standard AS/NZS 4357:“Structural Laminated Veneer Lumber.” The EWPAA is accreditedfor product certification by the Joint Accreditation System ofAustralia and New Zealand (JAS-ANZ).Structural design is in accordance with NZS 3603 (verificationmethod B1/VM1, 6.1) with loads and deflection criteria as indicatedon the tables. Serviceability and other criteria were selected usingguidelines available from joint Australian / New Zealand standardstechnical committees and correspond to those used in NZS 3604,(Acceptable Solution B1 / AS1, 4.1).When installed in accordance with the specifications, details andlimitations in this guide and the Residential Installation Guide,Futurebuild LVL members will comply with the requirements ofthe New Zealand Building Code.3.6 Quality AssuranceFuturebuild LVL is manufactured in a fully quality controlled process,independently third party audited by the Engineered WoodProducts Association of Australia (EWPAA). The EWPAA certifiesFuturebuild LVL manufactured by CHH Woodproducts at itsMarsden Point (New Zealand) mill.Participation and compliance with the requirements of theEWPAA’s process based quality control scheme includesproduct testing and monitoring of properties. It provides thebasis for the EWPAA’s Product Certification of Futurebuild LVLas conforming to the requirements of AS/NZS 4357 (StructuralLaminated Veneer Lumber). Conformance with AS/NZS 4357ensures that Futurebuild LVL is suitable for structural applicationsin accordance with NZS 3603 Timber Structures Standard andNZS 3604 Timber Framed Buildings.The EWPAA’s product certification scheme is accredited underthe government Joint Accreditation System of Australia andNew Zealand (JAS-ANZ).CHH Woodproducts Futurebuild LVL residential design guide 0800 585 244 www.chhwoodproducts.co.nz 9

Futurebuild LVL general design considerations3.7 Durability10Futurebuild LVL is manufactured to meet the requirements ofthe New Zealand Building Code Clause B2 Durability. As such,if the product is used in accordance with CHH Woodproductsspecifications and good building practices, and treated tothe levels prescribed in NZS 3602, Timber and Woodbased Products for Use in Building, it will comply with therequirements of the NZ Building Code.The recent changes to the New Zealand Building Code ClauseB2 Durability (Amendment 8) have provided clarification aroundAcceptable Solutions for various treatment levels of LVL, theseinclude the use of untreated LVL, H1.2 glueline and surface spraytreated LVL, and H3.1 Azole LOSP treated LVL options.There is no change to how LVL can be applied untreated insituations where it is protected from weather (with no risk ofmoisture penetration conducive to decay) i.e. mid floors, subfloors, etc. This is identified in Sections C and E of Table 1 ofNZS 3602.With regard to treated LVL, citing of NZS 3604:2011 in ClauseB2/AS1 dictates that if LVL is not specifically referred to inNZS3602 the LVL can be preservative treated to the samelevel as that required in Clause B2/AS1 of the New ZealandBuilding Code for kiln dried Radiata Pine. Clause B2/AS1 allowsfor treatment to be to either a H1.2 or H3.1 LOSP Azole level.This includes situations covered by NZS 3602 Table 1 SectionD, “Members protected from the weather but with a risk ofmoisture penetration conducive to decay.” This would include,for example, enclosed external framing situations includinglintels, studs, boundary joists, etc.Two Acceptable Solution options exist specifically for treatedLVL in Clause B2/AS1:1. H3.1 Azole LOSP treated, or2. H1.2 glueline treated with a surface spray.LVL products must be protected from water, condensation anddampness by good detailing. For uses where there is risk oftemporary moisture, use appropriate treatment levels.For more information, refer to technical note Futurebuild LVL:Durability and Moisture Statement available fromwww.chhwoodproducts.co.nzSub-floor ApplicationsGood building practice ensures that raised timber floors arewell ventilated underneath, as such the durability of thesefloors is subject to the floor space being ventilated for the lifeof the building to the provisions of NZS 3604 or E2/AS1. Thisis intended to eliminate the possibility of decay for sub-floormembers and flooring therefore, in accordance with NZS 3602,untreated Futurebuild LVL may be safely used where standardpractices for ventilation and clearance are followed.External UseFuturebuild LVL is NOT recommended for fully weatherexposed applications, such as open deck joists andpergola beams.3.8 Preservative TreatmentFor weather-protected applications covered by NZS 3602Section D, “Members protected from the weather but with arisk of moisture penetration conducive to decay”, LVL can beeither H1.2 glueline treated with a surface spray (in accordancewith NZS 3640) or H3.1 Azole LOSP treated to Table 6.2 ofNZS 3640. Both treatments meet the requirements intended byH1.2 of the New Zealand Building Code Clause B2/AS1and NZS 3604.LVL can be preservative treated for weather-protectedapplications, such as verandah beams and for poorly ventilatedor damp sub-floor applications.All H3.1 LOSP treated LVL is envelope treated. Where sectionends are cut, ends must be coated with a brush on timberpreservative. Holdfast Metalex End Seal is recommended.CHH Woodproducts Futurebuild LVL residential design guide 0800 585 244 www.chhwoodproducts.co.nz

4.0 Design Considerations – hyJOIST 1-beams The following design considerations should be taken into account inthe design and detailing of hyJOIST floor systems sized and specifiedwithin this guide. 4.1 Bearing Support – Joist Not Transferring Load From Upper Walls30 minimum30 minimum Figure 2: For joists not transferring load from upper walls30 minimum30 minimumSee Table 2Table 2: MINIMUM BEARING for hyJOIST i-beams SUPPORTING FLOOR LOADS ONLY End SupportsSingle or Continuous SpanIntermediate SupportsContinuous SpanJoint Spacing (mm)ALL450Minimum Bearing (mm)304530Bearingminimum30 minimumMinimum– Heavy(mm)LoadfromFloorsroof and30 minimum3030 minimum30 minimum30 minimumUpper/Single storey wallsRoof and wall loads6006530 minimum7530 minimum55See Table 2See Table 2ContinuousSpan hyJOIST4.2 B earing Support For Joists Transferring Upper Storey Wall andRoof Loads at SupportsContinuoushyJOIST blockingFigure 3: End Supports – Single or Continuous SpanFigure 4: Intermediate Supports – Continuous SpanRoof and wall loadsRoof and wall loadsLoad from roof andMINIMUM BEARINGUpper/SinglestoreyLoad fromroofwallsandUpper/Single storey wallsBearingBearingBearingMINIMUM BEARINGMINIMUM BEARINGJamb stud or post Minimumbearing to be as for joists supporting floor loadsContinuousSpan hyJOIST yJOISTContinuous hyJOISTblocking.blockinghyJOISTblockingFor joists supporting load bearing walls at end supports,provide bearing as specified in table 3 or alternativelyinstall continuous hyJOIST blocking/hyBOUND boundary joist,and maintain a minimum hyJOIST bearing as per table 2.Futurebuild LVL design considerations – hyJOISThyJOIST I-Beams are ideally suited for long span, low loadapplications such as floor joists and rafters.MINIMUMBEARINGMINIMUMBEARINGMinimum bearing to be as for joists supporting floor loads only.Load bearingwallto be tosupportedcontinuousfull floordepthloads only.Minimumbearingbe as forbyjoistssupportinghyJOISTblocking.Loadbearing wall to be supported by continuous full depthhyJOIST blocking.For joists supporting load bearing walls at end supports,provideas specifiedloadin table3 orwallsalternativelyForbearingjoists supportingbearingat end supports, blocking/hyBOUNDboundary joist,installprovidecontinuoushyJOISTbearingas specifiedin table 3 or alternatively bearing as per table 2.and maintaina minimumhyJOISThyJOISTblocking/hyBOUND boundary joist,install continuousand maintain a minimum hyJOIST bearing as per table 2.Table 3: minimum bearing for hyJOIST i-beams TRANSFERRING UPPER STOREY ROOF OR FLOOR LOADS One or more compression blocks ofsimilar combined cross sectional areaType jamb stud or postto that ofLoadthe supported450Joist Spacing (mm)Single nail to flange as shown600Jamb stud or poststud (mm)or postMinimum JambBearingLight Roof and ceiling30Heavy Roof and ceiling45651Load bearing wall aligned under2901. If web stiffeners installed bearing may be reduced to 45 mm2. If web stiffeners installed bearing may be reduced to 65 mm For all cases bearing may be reduced to 30 mm if continuous full depth blocking or compression blocks are installed designIT for houses software may give a reduced bearing requirementOne orcompression Roof mass allowancesaremoredefinedin Table 7blocks of similarOnecombinedcrosssectional areaor morecompressionblocks ofSingle nail to flange as shownto that of thesupportedjambcrossstudsectionalor post areasimilarcombinedSingle nail to flange as shown CHHWoodproducts FuturebuildLVLresidentialdesignguide 0800 585 244 www.chhwoodproducts.co.nzto that of the supported jamb stud or postLoad bearing wall aligned under11

Load from roof andUpper/Single storey wallsContinuousSpan hyJOISTContinuoushyJOIST blocking Futurebuild LVL design considerations – hyJOIST 4.3 Bearing Support for Lower Storey of Two Storey ConstructionIn most cases continuous hyJOIST blocking will be adequateto support the roof, wall and floor loads. Refer to designITMINIMUMfor houses software for confirmation.Continuous full depth hyJOIST blocking should be installedto transfer compression loads from load bearing walls toBearingMINIMUM BEARINGthe supports. BEARINGMinimum bearing to be as for joists supporting floor loads only.For joists supporting load bearing walls at end supports,bearing wall to be supported by continuous full depthprovide bearing as specified in table 3 or alternatively4.4 ConcentratedLoadsfromJamb ll continuous hyJOIST blocking/hyBOUND and maintain a minimum hyJOIST bea

the design methodology used in the preparation of this guide complies with the requirements of the following design standards: as/nZs 1170:2002/3 structural design actions nZs 3603:1993 timber structures standard, an acceptable solution to nZbC Clause 1 structure. guidance has bee