Transcription

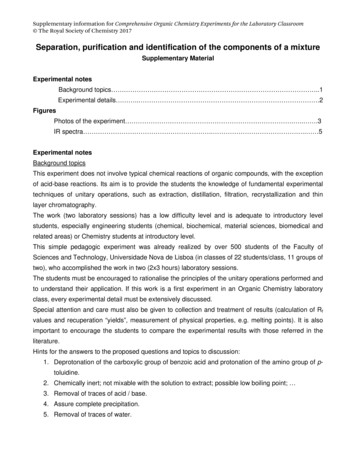

RECRYSTALLIZATION, FILTRATION AND MELTING POINTRecrystallization is one of the main purification methods for solid compounds on virtually anyscale, from mg to kg to tons. From the experimental point of view, the process ofrecrystallization comes down to a few basic steps:a) the solid is heated to reflux or near reflux of a solvent in a minimum amount of theappropriate solvent to produce a saturated solution;b) in case there is an insoluble residue, the hot solution is filtered to produce ahomogeneous solution and to remove the insoluble impurities;c) the homogeneous solution (or filtrate) is allowed to cool slowly to room or sub-ambienttemperature to produce crystals;d) the crystals are filtered off and washed with a small amount of COLD solvent, andsubsequently dried to yield the solid, which should have a higher degree of puritythan the original sample.The rationale for each step is fairly straightforward:It is known that the solubility of most compounds in a given solvent will increase atelevated temperatures. Therefore heating is used to dissolve the sample. It is also known thatthe solubility near the boiling point greatly increases, therefore it is imperative to bring thesolution to a boil. Furthermore, it is important to keep the volume of the solvent to the minimum,since recrystallizations from dilute solutions usually lead to poor yields of recovery of thematerial, if any. In this light, initially the smallest possible amount of solvent is added, and thesolution is heated. If the majority of the solid remains undissolved, additional amounts of solvent(in small portions) can be carefully added.During the cooling step, the molecules of a given compound will be assembling intoaggregates with the molecules that have a similar nature. These aggregates will grow in sizeand eventually will be deposited from solution to form a solid with a particular crystal lattice.Other types of molecules that are not capable of engaging in the same types of interactions withthe above aggregates (and/or possess a different size, shape) will be excluded from the solidand, ideally, will remain in the solution. Thus, a separation of one type of molecules from theothers can be achieved.Drying of the crystals (either in air at room temperature, or heated below the meltingpoint, or in vacuo) will rid of the solvent molecules to produce the desired compound in a purerform than the initial solid. The drying step is usually done either on air over a prolonged periodof time or under a vacuum. For air- and moisture-sensitive materials, the drying should be doneunder vacuum, and the solid should be stored in a dessicator.Solvent selection:Obviously, the most crucial step is the choice of an appropriate solvent. There are fewempirical rules that can be used as a guide to select a proper solvent, but for the most parts, theselection of the optimal recrystallization solvent is a trial and error method.Rule #1: Like dissolves like.Rule #2: The solid should be insoluble or only sparingly soluble in a cold solvent (roomtemperature or 0 oC usually refers to a cold solvent), and completely soluble in a hotsolvent. (This is an ideal behavior, which is rarely observed.)Rule #3: The impurities should have a different solubility profile in the particular solvent than thecompound of interest.Rule #4: The melting point of the compound should be higher than the boiling point of thesolventRule #5: Given the choice of solvents, the one with a lower boiling point will be a better option.1

The structures and boiling points of some of the most commonly solvents used for theThe structures and boiling points of some of the most commonly solvents used for therecrystallizations are given in Figure 1.recrystallizations are given in Figure p. 65oCethanolb.p. 78oCdiethyl etherb.p. 35oCn-hexaneb.p. 69oCOOH3CCH3acetoneb.p. 56oCH3COCH2CH3ethyl acetateb.p. 77oCOtetrahydrofuranb.p. 65oCcyclohexaneb.p. 81oCOCH3Figure 1.tolueneb.p. 110oCO1,4-dioxaneb.p. 101oCLiterature sourcessources shouldshould bebe consultedconsulted forfor choosingchoosing solventssolvents forfor recrystallizationrecrystallization compoundneedstobepurifiedbyknown compounds. In cases where an unknown compound needs to be purified byrecrystallization, testingtesting ofof itsits solubilitysolubility shouldshould bebe conductedconducted beforebefore carryingcarrying outout thetherecrystallization,recrystallization. SmallSmall amountsamounts ofof solidsolid (usually(usually aa fewfew crystals)crystals) areare placedplaced inin smallsmall testtest solventand about 1 mL of the solvent is added. Immediate formation of the solution renders the solventineffective forfor thethe subsequentsubsequent crystallizations.crystallizations. IfIf thethe immediateimmediate dissolutiondissolution doesdoes notnot taketake place,place,ineffectivethe testtest tubetube isis shaken,shaken, andand thenthen itit isis gentlygently heated.heated. IfIf thethe dissolutiondissolution ofof thethe solventsolvent doesdoes ce, the solvent can be considered suitable for the subsequent crystallization. If the solid dded,thetesttubeisagainshakenanddid not dissolve, an additional 1 mL of the solvent is added, the test tube is again shaken andheated. TheThe presencepresence ofof thethe solidsolid indicatesindicates thatthat thethe solidsolid isis insolubleinsoluble inin thethe givengiven solvent.solvent. TableTableheated.can bebe usedused asas aa guideguide forfor initialinitial selectionselection ofof thethe recrystallizationrecrystallization solvent.solvent.11 canTable 1.1.TableCompound classclassCompoundHydrocarbonsHydrocarbonsHalogen containingcontaining stersNitro-containing lsAlcoholsCarboxylic acidsacidsCarboxylicSaltsSaltsSoluble arbons, halogen-containinghydrocarbons ethersethershydrocarbonsEstersEstersAlcohols, ethersethersAlcohols,Alcohols, waterwaterAlcohols,WaterWater22

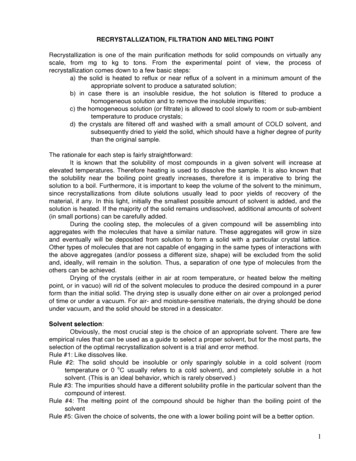

In many instances, a mixture of solvents must be used for recrystallization (“mixedsolvent” system). Usually, two solvents, which are completely miscible with each other over awide temperature range, are used: one in which the compound is quite or completely solubleeven at ambient temperature, and the second solvent in which the compound is insoluble. Twoapproaches can be applied:1. The compound is first completely dissolved in a hot solvent in which it is soluble,removed from the heat source and the other solvent is added until cloudiness startsto appear. This is the sign of the beginning of crystal formation. At this point themixture should be reheated to obtain a homogeneous, i.e., clear, solution, andallowed to cool to produce the crystals.2. The compound is added to the solvent in which it is insoluble, and the heterogeneousmixture is heated to a near boil, removed from the heat, and the second solvent isadded in small portions. The mixture is reheated after each addition of the secondsolvent. This procedure is continued until all compound is dissolved.In the above cases, the amounts of both solvents should be kept to the minimum to a)avoid the unnecessary use of too much solvent, and b) recrystallization from dilute solution isvery inefficient. Moreover, it is desirable that the boiling points of the two solvents should befairy close to each other, such that their ratio would not significantly change during the heatingcycles.The following is the list of commonly used solvent mixtures:ethanol – water, acetone – water, ethyl acetate – hexane, toluene – heptane.It is a good practice to weigh out the amount of recrystallized material, andapproximately measure the amount of the solvent. This will allow to quantitatively estimate theefficiency of the recrystallization process as well as it will be possible to rapidly reproduce therecrystallization, if necessary.Decolorizing agentsOn a number of occasions, the presence of highly colored impurities (even in the amountof 1% of the total weight of the sample) will significantly contribute to the color of thecompound. Colored impurities can be removed by the addition of decolorizing carbon (charcoal)to the hot, yet not boiling, solution. The charcoal has a very fine surface, which is filled with air.Once it is placed in a solution, the air is displaced by the solvent molecules; at boilingtemperatures, the displacement process is extremely rapid, which usually results in frothing ofthe solution and usually leads to the loss of the compound and potential injury. After thecharcoal is added, the solution is heated at or near the boiling point for several minutes, whilecontinuously being swirl to avoid bumping. Subsequently the charcoal is removed by gravityfiltration, and the filtrate is allowed to cool to yield the crystalline material.It should be pointed out that both the molecules of the desired compound and themolecules of the impurities are absorbed on the decolorizing carbon. Also, the use ofdecolorizing carbon is not specific for colored impurities, although due to the electronic featuresof colored compounds, they tend to have a higher affinity towards charcoal than the non-coloredones. However, it is much easier to detect the removal of colored impurities than those that arenot colored. Therefore, the application of too much of the decolorizing agent will lead to a loss ofthe material, and generally should be avoided.3

FILTRATIONAfter the crystallization is finished, the crystals should be separated from the liquid. In principle,the supernatant solution can be decanted from the solid. However, a loss of the solid as well asan incomplete removal of the liquid, which might contain the impurities, will take place. A bettertechnique to separate the solid from the liquid is by filtration. Fundamentally, filtration is aprocess that involves passing the suspension of the solid in the liquid through a membrane thatis permeable only to a liquid. The filtrate, often called “mother solution” or “mother liquor”, iscollected in a separate receiving flask, whereas the solid remains on the membrane. Themembrane can be made of any inert material, as long as it is permeable to the solvent; and itcan be of any shape. The most common one, and the one, which will be used routinelythroughout this course, is filter paper. Cotton or glass wool are other permeable flexiblemembranes that can be used to filter fairly large solid particles from the solutions.Gravity filtrationThis technique is mostly used toremove impurities, drying or decolorizingagents. The set-up for the gravity filtration isvery simple (Figure 2), and it features a filterpaper, a funnel, ring clamp and a receivingcontainer, usually a beaker or anErlenmeyer flask are used. The properfolding of the filter paper is shown in Figure3. The folding of the filter paper provides anenhanced surface area as it insures a rapidfiltration.In gravity filtration, the filter can usually beemployed dry (no need to wet it with asolvent). Obviously, when gravity filtration isused to remove a drying agent, the filtershould NEVER be wetted with water!It should be kept in mind that the filter paper itselfcan also absorb small, but significant amounts of solvent.Therefore, the filter paper should always be rinsed withadditional amount of the fresh (cold) solvent to rid of themother solution, which can contain the impurities.Vacuum filtrationThis technique is usually used to collect solids fromthe solvents after either precipitation of recrystallization. Aset-up for vacuum filtration (Figure 4) is more elaboratethan that for the gravity filtration. It consists of a Buchnerfunnel, equipped with a flat round piece of a filter paper,neoprene adapter, a receiving flask with a vacuum outlet,which is connected to the vacuum trap (usually a secondvacuum filter flask) to prevent an incidental flow of liquid tothe vacuum pump. Similar to the gravity filtration, the filterpaper on the Buchner funnel should be wetted before starting the filtration. The solid on the filterpaper should be washed with additional amounts of the cold, pure solvent to remove the mothersolution. At this stage, the vacuum can be released, and the solvent is allowed to pass through4

the filter paper by gravity. This assures a closer contactof the solid with solvent and aids in removing theresidual mother solution. The vacuum can be reappliedafter most of the liquid passed through the funnel tocompletely dry the solid.Vacuum filtration should not be used for filteringhot solutions. During filtration some of the solvent isevaporated, which cools down the solution. Sinceapplication of vacuum will enhance the rate of solventevaporation, the solution will cool off much faster thanat ambient pressure. This can lead to prematurecrystallization of the solid on the filter paper. Theclogging of the filter paper will occur, which willsignificantly slow down the filtration process. It will alsolead to the contamination of the solid, since thesolubility of impurities can decrease at lowertemperatures as well.MELTING POINTPhysical properties, such as melting point, boiling point, density, refractive index, etc areused extensively for the identification and characterization of organic compounds. Thecompound can be considered pure, if its physical properties are not changed after severalrounds of purification either by recrystallization, sublimation, distillation, etc.Melting point is a temperature at which the solid and liquid phases of the compound arein the equilibrium. In other words, the melting point is a point at which a solid undergoes atransition to a liquid. The melting point is one of the main physical constants of a solidsubstance. In general, a melting point refers to a temperature range. A sharp melting point(within 1-2 oC range – this of course depends on how high the melting point is) will beindicative of a pure sample. The purer the sample, the narrower the melting point. The melting–cooling cycle can be repeated many times without a significant change of the melting pointrange. A chemical decomposition might have taken place, if large, i.e., 2-3 oC, deviations areobserved during the second heating cycle. A melting point of the pure sample depends on thestrength of the crystal lattice. Therefore, small amounts of impurities, which are capable ofdisrupting the crystal lattice, will lead to lowering of the melting point of the sample as comparedto the melting point of the pure sample. Such change is also accompanied by the increase of themelting point range, which may significantly exceed 2oC limit. For the majority of cases, theimpurity will lower the melting point and broaden the range. However, there are some cases,when an increase of the melting point is observed.Impurity can be classified as any substance that differs from the main compound withrespect to chemical composition, physical state, etc. For example: solvent molecules that arenot removed from the sample after the crystallization, by-products that are produced in thechemical reaction, decomposed compound due to storage or handling conditions, just to name afew.A good indication of the purity of the compound can be established by admixing thesample with the standard, whose purity has been established by other means. If there is nochange in the melting point of a compound taken alone and in a mixture, the compound can beconsidered pure. This approach can also be used in establishing the identity and purity of two5

samples with the same melting points: equal amounts of both samples should be thoroughlymixed, and if theirs melting points are unchanged, both samples can be considered identical. Ifthe melting point of the mixture changes – the two samples are not identical. However,isomorphous compounds, which are different in their chemical compositions might not lead todeviations of the melting points in their mixtures.A number of organic compounds decompose below or at their melting point. Thisprocess is accompanied by a color change (usually dark brown) and/or gas evolution. In suchcases, the temperature of decomposition is used as a physical constant. The decompositionpoint depends strongly on the rate at which the sample is heated, and therefore in many casescannot be precisely reproduced.There is a correlation between the structure of a compound and its melting point. It hasbeen noted that more symmetric compounds will have higher melting point than their nonsymmetric homologues. Furthermore, the presence of functional groups capable of formingintermolecular hydrogen bonds will lead to higher melting points as opposed to compoundsfeaturing groups that promote intramolecular hydrogen bonds.Procedure for the melting point determination:Finely ground and completely dried (water or solvents are impurities) solid is placed intoa capillary tube, which is sealed from one end (Figure 5A). Large chunks of solid should not beused for the melting point determination, because a non-uniformed heat transfer is likely to takeplace and contribute to the incorrect readings. The solid should be placed on a clean watchglass. The open end of the capillary tube is dipped into the solid, and the solid is shaken into thebottom of the capillary tube by carefully dropping the capillary through a long glass or plastictube, which rests on the bench (Figure 5B). Repeat this process several times to assure thatsolid is tightly packed in the capillary, i.e., there are no air-holes. Usually 2-3 mm of the solid willbe sufficient for the melting point determination. For the compounds that are known to sublime,the open end of the capillary tube should be sealed before the melting point is taken. Fluffysolids are difficult to pack in the melting point capillary tubes. In this case, a fine wire, with adiameter smaller than the capillary should be used to pack the sample. The packed capillary isplace into the melting point apparatus (Figure 5C).6

The melting point apparatus,Mel-Temp, is shown in Figure 6. Thecapillary is placed into the holder of themetal block, and the phase transitionof the sample is visually monitoredthrough a magnifying glass uponheating. Since the melting point is arange, the lower limit will be thetemperature at which some of thecrystals start to melt, i.e., there areonly a few drops of the liquid phasethat are visible, and the upper limit isthe temperature at which no solidphase remains in the capillary. Theaccuracy of melting point shouldusually be within 0.5oC. It is imperativeto slowly heat up the sample, 1-2 oC /min. A rapid increase in temperaturewill result in high level of inaccuracy ofthe melting point determination. In this instance, it is easier to record a lower melting point thanthe true melting point, since the reading of the thermometer lags behind the temperature of theheating block. The melting point measurement can be repeated one or two more times with thesame capillary, once the capillary and the metal block of the Mel-Temp apparatus reachedambient or cooler (10-20 oC) temperature below the melting point range. The sample is notrecovered from the capillary. The capillary should be disposed into a broken-glass container.Thermometer calibration:The accuracy of the melting point depends strongly on the quality and the calibration ofthe thermometer. Calibration of a thermometer is accomplished with the use of a set of knownstandards. It is important to perform a calibration over a range of temperature, since the errorvaries over different temperatures, and it is unlikely that a linear correlation will be observed. Byplotting an actual melting point versus the Mel-Temp reading will result in a curve, which can beused to correct all the measured melting points of synthesize and/or purified compounds. Thiscurve is valid only for this specific thermometer.The melting point of a compound that is measured without the calibration curve will bereported as an “uncorrected melting point.” If the calibration curve is used, the melting point ofthe compound will be reported as “corrected melting point.” In the majority of literature accounts,however, uncorrected melting points are reported.7

HOT FILTRATION SETUPfluttedfilter papercompound solventsmall amountof solventsand bathRECRYSTALLIZATION FLOW CHARTImpure Solidadd solvent (room temperature)heat to dissolveinsolubleimpurities& charcoaltreat with charcoalhot filtration (gravity)YESsolution withcolored impuritiesNOsolution withinsoluble impuritiesYEShot filtration(gravity)insoluble impuritiesfiltrateNOfiltratesolution withno visible impurities1) allow to cool to room temperaturethen place in ice2) vacuum filterrinse precipitate with cold solventdrypure solid(measure mpcalculate recoveryyield)1) evaporate a little bitof solventand cool down2) vacuum filterrinse precipitatewith cold solventfiltrate(mother liquor)filtratesecond crop (less pure)8

PROBLEMS1. A student had 1.00 g of an impure solid, which had to be purified by recrystallization. Thestudent used 50ml of the appropriate solvent to carry on the recrystallization. In the end0.77 g of the solid was isolated. What is the efficiency (i.e., yield) of recrystallizationprocess?2. For recrystallizations you generally need to use an Erlenmeyer flask or a test tube.Propose a reason or two, why would not be advisable to use a beaker asrecrystallization container.3. Is there any good reason, why one should not vacuum filter hot solutions? Briefly justify.4. List major step in identifying suitable recrystallization solvents.5. What is the reason for charcoal during recrystallizations? Could you use charcoal as astand lone step, i.e., not in a recrystallization experiment?6. For a filtration of hot solutions, would you rather use a stemless funnel or the one with astem? Briefly explain your answer.7. Often, inaccurate melting points are recorded when the heating of the melting pointapparatus is too rapid. Under such circumstances, would the recorded melting point behigher or lower than the true melting point?8. Why it is important to tightly pack the melting point capillary tube?9. Why do you need to use finely powdered sample to measure the melting point?9

2. The compound is added to the solvent in which it is insoluble, and the heterogeneous mixture is heated to a near boil, removed from the heat, and the second solvent is added in small portions. The mixture is reheated after each addition of the second solvent. This procedure is co