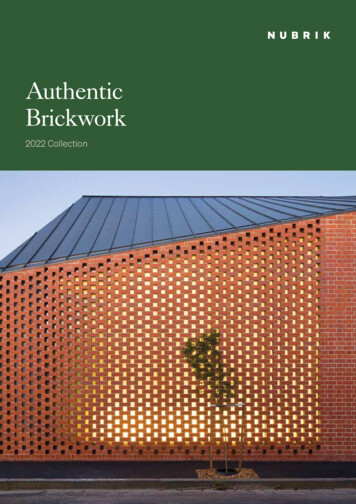

Transcription

Good Craftsmanship GuideBrickwork and Blockwork

IntroductionThis Good Craftsmanship Guidehighlights key problems with brickworkand blockwork and gives guidance onhow to avoid them. The problems arethose most commonly identifiedduring NHBC’s inspection of homesunder construction. All photographsare of defects and were taken on realbuilding sites.The Guide, based on the NHBCStandards, is intended for use byNHBC registered builders andinspection staff. NHBC 2002No reproduction without NHBC prior permission in writing.

ContentsSubstructure2Cavities4Wall ties6Mortar9Thermal insulation12Openings15Lintels20Cavity trays22Bonding26Movement joints30Separating walls32Appearance35Cold weather working38Additional guidance for timber frame401

SubstructureProblem to avoid:Rising dampWhat to do:locate dpc at least 150mm above external ground orpaving levelat least150mm2

stop cavity fill at least 225mm below the base dpcat least225mmuse the correct width dpcdo not allow dpc to project into cavity – it couldcatch mortar and debrislap dpc with dpm of floor slabdpcs clear of cavitydpc laps dpmslightprojection3

CavitiesProblems to avoid:Water crossing the cavityWhat to do:keep cavities uniform and to the width specified inthe design – at least 50mmstrike mortar off all joints as work proceedskeep cavities clear of droppings and debrisbatten keepscavity clear ofmortar droppings4

limit the height difference between the two leavesof a cavity wall under construction - never morethan 6 standard block coursesdo not over reach - wait for the next scaffolding lift5

Wall tiesProblems to avoid:Leaves of wall not tied together adequatelyWater crossing the cavity on wall tiesIncorrect wall ties usedWhat to do:ensure that ties are as specified, and are of thecorrect typewall tie should belevel or sloping tothe outsideoutside6inside

bed ties a minimum of 50mm into each leafkeep ties cleanensure ties are level or slope outwards slightlyensure drips face downwards in centre of cavitywall tie built at least 50mminto each leafdrip of wall tie placedcentrally in cavitycavitycontinued over7

Wall tiesspace ties correctly:- in walls - at reveals - at movement jointsCavity width betweenmasonry faces (mm)Maximum spacing (mm)HorizontallyVertically50 to 7576 to 10090075045045050 to 100(At jamb openings,movement joints, etc)within 150of opening300 or eachblock courseAt openings and movement joints, wall ties should be spaced at maximum300mm centres vertically even if this means cutting cavity insulation to insertthe tie. Doubling the number of wall ties at 450mm or 600mm centres verticallyis not an acceptable alternative.additional tiesat movement jointadditional tiesat openings 150mm450mm 900mm or750mmNote: Ties may need to be closer when supporting and retaining partial fillinsulation boards.8

MortarProblems to avoid:Low strengthVariations in mixPoor durabilityWhat to do:keep mixers and plant cleanstore materials correctlyensure that the mix is correct for:- bricks/blocks being used- location in building- exposure of area(see table on page 10)do not use masonry cement as if it is OPC. Moremasonry cement is needed - refer to manufacturer’srecommendationskeep mix proportions consistentcontinued over9

MortarMortar mixes for clay brickwork using ordinaryPortland or sulphate-resisting cement- high durabilityother exposurecategories- general usein areas of Severe orVery Severe exposure- high durability1 : 0 to 1/4 : 31 : 1/2 : 4 1/21 : 1 : 5 1/21 : 1/2 : 4 1/2Recommendedcement: lime:sand mix—1 : 3 1/21 : 5 1/21 : 3 1/2Recommendedcement: sand mixwith air-entrainingplasticiser—1:31 : 4 1/21:3Recommendedmasonry cement:sand mixLocationBelow dpc level andin chimney stacks- low permeabilityGeneral wall areaabove dpcCappings, copingsand sills10

do not use washing up liquidNote: do notoverdose; “moreis not better”- do not useunauthorisedadditives such aswashing up liquid.follow the manufacturer’s instructions when usingplasticisers or other additivesprotect and store retarded mortars correctly beforeuseuse retarded mortars within supplier’s/manufacturer’stime limitdo not knock up mortar which has started to setlay bricks and blocks on a full bed of mortar and fillperpend joints solidlydo not use recessed joints with full-fill cavity insulation11

Thermal insulationProblems to avoid:Water crossing the cavityThermal bridging (cold spots)What to do:follow the manufacturer’s instructions for built-ininsulation (see packaging)support the bottom row of boards/batts using tiesinsulate the whole wall area, including below dpcinstall boards/batts with staggered jointsbutt boards/batts closely with no gapsensure that insulation is fitted tightly against lintels,cavity trays and cavity closuresmaintain a minimum 50mm clear cavity betweenpartial cavity fill and the external leaf12

insulation cut to avoid leavinguninsulated gapslintelrevealblockskeep partial cavity fill securely in place using thecorrect clips for the type of tieensure that horizontal joints in partial cavity fillinsulation coincide with wall tiesties in vertical rows at joints between insulationboards (partial cavity fill)continued over13

Thermal insulationkeep the top edge of insulation clear of mortardroppingsboard keepstop edge ofinsulation andcavity clear ofmortar droppings14

OpeningsProblems to avoid:Water crossing the cavityPoorly fitted framesWhat to do:build masonry around:- the frame in-situ- a profile/template (frame fitted later)ensure openings are of the correct size and squarebutt brickwork closely against the frame (if built-in)(see diagram & photograph on page 16)continued over15

Openingsframes shouldnot be distortedprovide vertical dpcs at jambs (either separate orcombined as part of a proprietary cavity closer)install dpcs in one continuous lengthwhere separate vertical dpcs are used ensure theyprotrude about 25mm into the cavitysealant25 mm25 mmsealantNORMAL EXPOSURE16VERY SEVERE EXPOSURE

Note: Use ‘check’ reveals in Scotland, Northern Ireland, the Isle of Man andareas of Very Severe exposure.12mm rebate(excluding thicknessof any render)sealant'rebated' or'check' revealin areas of Verysevere exposure25 mmsealantextend vertical dpcs up to the lintel, and turn backtowards the inner leafinsulationverticaldpccontinued over17

Openingsprovide dpcs under jointed and permeable sills,turned up at the back and endsdpc turned upat back andends of sillfix frames securely into openings – level and plumbblock/pack frames at fixing points as necessaryTo prevent sagging and bowing, bay and bow type windows shouldbe adequately supported and secured to the structure to preventcasements becoming twisted.Bay windows should be properly linked to dpcs at reveals.bay windowsadequately supported18

19

LintelsProblem to avoid:Inadequate structural supportWhat to do:lintels should extend beyond the opening at eachend by at least the following:Span(m)Minimum bearing length (mm)Simple lintellintel combinedwith cavity trayup to 1.2over 1.2100150bed lintels on mortar20150150

provide padstones where required by the designdo not allow masonry to overhang edge of lintel bymore than 25mmoverhang notmore than25mmoverhang notmore than 25mmlintel toe projectsbeyond window headSTEEL LINTELbuild inner and outer leaves up together on steellintels to avoid twisting the flange (max. heightdifference 225mm)21

Cavity traysProblem to avoid:Water crossing the cavityWhat to do:provide cavity trays where required by the design–overlintels, roof abutments, air bricks, meter boxes, etc.install cavity trays in one continuous lengthextend trays at least 25mm beyond the cavityclosers, and cover the ends of lintelsshape cavity tray as shown:at least140mm totalrise incavity traydpc oversails lintel to protecttimber door and window heads22at least 100mmrise in cavitytray from frontof cavitygroove in window head preventsrain penetration

Note: Provide a cavity tray where a combined lintel does not have asuitable profile or durability and give complete protection to the top of thereveal and any vertical dpc. In Scotland, Northern Ireland, the Isle of Manand areas of severe or very severe exposure to driving rain, provideseparate damp-proof protection over all lintels.provide stop ends to cavity trays and combined lintelsprovide weep holes at max 450mm intervals (at leasttwo per opening) with fair-faced masonrystop endat least 2 weep holes peropening, not more than450mm apartcombined lintel projects at least 25mm beyond theouter face of cavity closurecontinued over23

Cavity traysprovide a cavity tray over air bricks, etc., extended150mm beyond each sideprovide a cavity tray over meter boxes (and a dpmbehind in areas of very severe exposure)cavitytraycavitytrayAIR BRICKMETER BOXprovide a cavity tray above full-fill insulation, unlessthe insulation is taken to the top of the wallprovide cavity trays at roof abutments overenclosed areas:– locate tray to link with flashing– the lowest tray should have two stop ends and aweephole24

preformedsteppedcavity traysat least85mm25

BondingProblems to avoid:Unstable wallsDifferential movementPoor appearanceWhat to do:set out work carefully to minimise cutting bricksand blockssill1/23/43/41/23/43/4brick bond set out at base of wallso that cut bricks occur below openingsmaintain a regular bonding pattern26

do not mix materials of different types in the samewalldifferent masonry types used to adjust coursingincorrect use of different masonry typescontinued over27

Bondingbond external walls to partitions and separatingwalls:- tooth alternate courses where blocks of the sametype are used- use wall ties or expanded metal (maximum300mm centres) to bond dissimilar materialsbond where blocks are of thesame typewhere joists are built into masonry (e.g. internalwalls), fully fill between joists without excessivemortar joints28

29

Movement jointsProblem to avoid:Excessive crackingWhat to do:provide movement joints in the outer leaf tominimise cracking:MaterialJoint width(mm) Normal spacingClay brick16Calcium silicate brick107.5 to 9mConcrete block and brick106mAny masonry in a parpet wall10half the above spacingsand 1.5m from corners(double the frequency)12m (15m maximum)The spacing of the first movement joint from a return should not be morethan half of the above dimensioninstall ties to each side of movement joints:Vertically- 300mm or each block courseHorizontally - within 150mm of the joint30

additional ties at movement jointadditional ties at openings 150mm450mm 900mm or 750mmuse correct filler material in joints, e.g. for claybrickwork:- flexible cellular polyethylene- cellular polyurethane- foam rubberensure sealant is at least 10mm deep to ensure agood bondeasily compressible filler12mmsealant31

Separating wallsProblems to avoid:Poor sound insulationInadequate firestoppingWhat to do:ensure block type and thickness complies with designdo not use cracked or damaged blocksuse only butterfly or other approved tiesmaintain clear cavity width (where applicable)bed all blocks and fully fill perpend jointsfill all gaps, however smallbond external walls to separating walls:- tooth alternate courses where blocks of the sametype are used- carry separating wall through to the cavity and tiethe inner leaf to it where the separating wall usesdenser blocks than the inner leaf of the external wall32

separating wall taken through and tied toinner leafdense blockseparating walllightweight blockinner leafcontinued over33

Separating wallsinstall a flexible cavity closer at junction ofseparating and external cavity wallscut/finish blockwork accurately at top of separatingwall. Blockwork should stop about 25mm below thetop of adjacent roof trusses for firestoppingfirestop betweenbattens aboveunderlayfirestop belowunderlaycavity barrier ofmineral wool or fireresisting board inboxed eaves34cavitybarrier inseparating wallthin board ascavity closerto avoid coldbridge

AppearanceProblems to avoid:Unsightly brickworkColour variationsMaterials damaged/stainedFinished work stainedWhat to do:ensure materials are stored correctly, away fromsite trafficprotect bricks/blocks from rain, mud splashes, etchandle materials carefully during constructiondo not use chipped or fractured bricks for faceworkkeep mortar mix and colour consistent (sandvariations may be significant)unless blended before delivery, mix bricks fromdifferent batches to avoid colour patchingcontinued over35

Appearanceuse a gauge rod marked with heights of openings tokeep courses to the correct heightkeep work level, plumb, and to design bondkeep perpend joints plumb36

protect new work from rain and frostkeep the workplace clean to reduce mortar splashesbrush off any mortar smears after initial set37

Cold weather workingProblem to avoid:Frost damageWhat to do:cover materials to prevent them becoming saturatedand damaged by frostprotection of sand,aggregates and cementprotection of bricks and blocks38

do not lay brickwork orblockwork when the airtemperature is below orlikely to fall below 2oC2 C0 Cprotect new work fromfrost when the airtemperature is below orlikely to fall below 2oCcover weighted downcover provides astill air space toinsulate the wallfrom frosttake down and rebuild work damaged by frost39

Additional guidancefor timber frameMuch of the guidance in previous sections applies alsoto timber frame. This section highlights additionalproblems specific to brickwork and blockwork used ascladding for timber frame homes.Problems to avoid:Moisture damage to the timber frameMasonry cladding not tied to frame adequatelyDamage due to movement of the timber frameInadequate control of fireWhat to do:repair any damage to breather membranefix ties to the studs, not the sheathinguse the fixings specified in the designspace ties in accordance with the design, but not morethan 600mm horizontal and 450mm vertical spacingsat jambs of openings set ties within 300mm of themasonry reveal at 300mm maximum vertical spacings40

make sure ties slope away from the sheathingallow for movement of the timber frame inaccordance with the design at:- the eaves- sills of openings- heads of openings- jambs of openingsdirection ofshrinkagegap toallow forshrinkagesealant betweenwindow sill andsubsilldirection ofshrinkagecontinued over41

Additional guidancefor timber framedirection ofshrinkageclearancedpcflexiblesealant atpoint ofmovementJAMB - EXPOSED SITEfor platform construction, use the designer’srecommendations or the following allowances toaccommodate differential movementLocationSuspended timber ground floorOtherwhen panels are supported onground floorground floor joists or perimeter joists constructionGround floor openings5mm3mmFirst floor openings12mm9mmSecond floor openings18mm15mmEaves and vergesAdd 3mm to the allowance for openings on that floor42

install cavity barriers in accordance with the designbreather membranelapped over dpc traydpcdpc43

Notes44

Notes45

NHBC, Buildmark House, Chiltern Avenue,Amersham, Bucks HP6 5APTel: 0870 241 4302 Fax: 01494 735201 www.nhbc.co.ukHB1786 11/02

insulation (see packaging) support the bottom row of boards/batts using ties insulate the whole wall area, including below dpc install boards/batts with staggered joints butt boards/batts closely with no gaps ensure that insulation is fitted tightly against lintels, cavity trays and cav