Transcription

INTRODUCTIONA World Leader In Precision Bearing TechnologyWelcome to the world of Barden Precision Bearings. Forover 100 years Barden/FAG has been a global leader inthe development of precision bearing technology. Wecan satisfy virtually any bearing need, enabling OEM andMRO users to fulfill all their machine tool requirementsfrom a single source.Barden works with a select network of authorizeddistributors chosen by their ability to offer qualityapplication engineering advice and product availability.We provide our distributors with training and support tokeep them up-to-date on our products and technologies.How This Catalog Is OrganizedThis catalog contains information and productspecifications on both Barden and FAG super precisionmachine tool bearings.If you have a copy of an earlier Barden catalog, you’llnotice this catalog is organized differently: It is dividedinto two primary sections: 1) Product, and 2) Engineering.Barden’s Super Precision Bearing plant in Danbury, Connecticut.The product sections are organized by type: Spindle Bearings Floating Displacement Bearings Super Precision Cylindrical Roller Bearings Double Direction Angular Contact Thrust Ball Bearings Ball Screw Support Bearings Axial-Radial Cylindrical Roller BearingsEach bearing type is grouped by bore diameter —from the smallest to the largest. Note that in the producttables both a Barden Basic Bearing Number and anFAG Basic Bearing Number are given. Bearings can bespecified using either basic bearing number, dependingupon bearing type.Fold-out pages can be found at the beginning ofeach of the six product sections. These fold-out pagescontain detailed descriptions of bearing nomenclatureby product type.We think these changes improve the usefulnessof our machine tool product catalog. Finding the rightBarden Precision Bearing for your application is noweasier than ever.We welcome any comments or suggestions you mayhave regarding our new format. And, as always, thankyou for choosing Barden.Barden · 2Barden’s Super Precision Bearing plant located in Plymouth, Devon, U.K.FAG’s Aerospace/Super Precision plant in Schweinfurt, Germany

Overview4Product Tables9Spindle Bearings1800HC/E, 1900HC/E, 100HC/E, 200HC/E, ZSB1900C/E, ZSB100C/EB718.C/E, B719.C/E, B70.C/E, B72.C/E, HS719.C/E, HS70.C/EFloating Displacement Bearings83FD10Super Precision Cylindrical Roller BearingsN19, N10, HCN10NN30, NNU49Double Direction Angular ContactThrust Ball Bearings931152344, 2347Ball Screw Support BearingsL, BSB, 7602, 7603129Axial-Radial Cylindrical Roller BearingsRTCEngineering141150Life Calculation for Super Precision Bearings Lubrication Tolerances for Super Precision Bearings Machining Tolerances for Mating Parts Speed-DependentFits Speeds, Deflection and Rigidity Handling of SuperPrecision BearingsIndex200

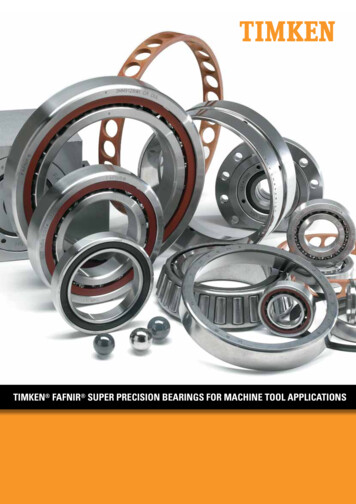

THE FINEST BEARINGS THAT CAN BE MADEOverviewBarden’s focus on super precisionbearing technology has long beendriven by the needs of our customersfor greater accuracy, higher runningspeeds, longer life and a sensitivityto cost.As a result, our entire R&D, designand manufacturing philosophyrevolves around delivering innovative bearing solutions, better productreliability and lower system costs.Meeting these stringent demandsrequires constant interaction withcustomers to learn more about theirspecific application requirements.Our own R&D efforts — along withour support of leading universitymechanical engineering and metallurgical research projects — have laidthe foundation for the developmentof new, ever more reliable precisionbearing products.While bearing tolerances arewell-defined by DIN/ISO or ABECstandards, Barden super precisionbearings routinely exceed eventhese stringent guidelines, resultingin the production of the finestbearings that can be made.In addition to meeting — or exceeding — the demanding tolerancerequirements of P4/ABEC 9 specifications, there are other Bardenimposed performance features notcovered by these standards.As a result, Barden super precisionbearings set standards unchallengedby any other bearing manufacturerin the world today when it comesto performance reliability, greateraccuracy, higher running speedsand longer life.Barden’s extensive product linemeans that whatever your application — from turning machines totextile winders to wood workingmachines — there’s a precisionbearing solution that’s right for you.Barden Super PrecisionMachine Tool BearingsMachine tools are the primaryapplication for Barden superprecision bearings. However, thewide range of super precisionbearing products offered by Bardenmeans that users can satisfy virtuallyany machine tool applicationrequirement — from spindles to ballscrews to turn tables — from a singlesource. If the machine tool bearingyou need is not listed in this catalog,special application specific productscan be developed upon request.Ask your Barden representativefor more details.Barden super precision bearingsBarden · 4

X-life ultra bearingsBarden/FAG X-life ultra bearingsX-life ultra bearings are a trulyrevolutionary new bearing designmade from Cronidur 30, a patentedhigh-nitrogen steel originally developed by FAG for critical aerospaceapplications. X-life ultra bearingsoffer remarkable performancecharacteristics, longer life and are100 more corrosion resistant thanconventional stainless steels. X-lifeultra spindle bearings — consideredthe most advanced bearing availableon the market today in terms of loadcapacity and speed — are availablefor use in a wide range of precisionmachine tool applications in borediameters ranging from 20 – 120 mm.X-life ultra bearings are designedto meet the speed, accuracy andreliability requirements of today’shigh speed machining centers. X-lifeultra bearings can provide substantialsavings to both machine toolmanufacturers and end users.X-life ultra bearings allow spindlesto run at extremely high speedsunder varying lubrication conditions.X-life ultra bearings — whencompared to conventional hybridbearings — will run 30% faster. Also,dynamic load ratings increase by afactor of 2.20 and the permissiblecontact pressure for infinite fatiguelife rises from 2,000 MPa to 2,500MPa. Higher admissible contactpressure also allows use of a smallerbearing design which means a lowervelocity at unchanged speeds and acorresponding reduction in lubricantstress which results in a significantincrease in grease life. This combination of characteristics producesa bearing with a service life up to10 times longer than today’s hybridbearings! With grease lubricationand attention paid to applicationparameters, X-life ultra bearingsare able to operate at 1.5M dN.Speeds of up to 3.0M dN can beachieved with oil lubrication.Barden · 5

PRECISION TECHNOLOGYProduct FeaturesAccuracy to ABEC 9and BeyondBarden/FAG super precision angularcontact bearings meet — or exceed— ABEC 9 (Precision Class P2)specifications. These standardsapply to bearing geometry, overallaccuracy and parallelism.The experience gained with spindlebearings — both in production, andwith their practical application indiverse markets — has encouragedthe transfer of this technology toother types of bearings. For instance,it also applies to indexing tablebearings that meet the demands ofa higher precision class bearing.MaterialsRTC indexing table bearingsAll Barden super precision bearingsare available in either standard orhigh-grade material versions. Forexample, greater wear resistanceand longer material fatigue life canbe achieved by specifying X-lifeultra bearings that use Cronidur 30,a unique high nitrogen steel. Itsproperties — including bendingstrength and corrosion resistance —result in significantly extendedservice life, higher admissiblecontact pressure, higher admissiblespeeds and significantly enhancedlubricant service life.Ceramic hybrid bearings — siliconnitride (ceramic) balls and steel innerand outer rings — have proven tobe the high performance leader inprecision bearing design. Useful lifecan be extended 2 to 5 overBarden · 6Ceramic hybrid bearings

Sealed bearings, lubricated for lifeconventional steel ball bearingdesigns. Ceramic hybrids exhibitlow vibration levels and can runfaster than conventional bearings.The advantages of ceramic ballsin hybrid bearings — whencompared to conventional steelball bearings — include: reduced material and lubricantstresses due to the excellenttribological behavior of steeland ceramics reduced density with correspondingly lower centrifugal forces lower thermal expansioncoefficient with its positiveeffect on bearing preload higher elastic-modulus thathas a positive influence onbearing rigidity.These factors result in significantlyextended bearing life. For thisreason, hybrid bearings are commonly used even at lower speeds.Barden ultra filtered greaseLubricationAdequate lubrication is essential tothe successful performance of antifriction bearings. Increased speeds,higher temperatures, improvedaccuracy and reliability requirementsresult in the need for closer attentionto lubricant selection. Lubricant typeand quantity have a marked effecton the functional properties andservice life of bearings.Lubricant type also plays a criticalrole in deciding which bearingdesign should be specified for whichapplication. The selection of an oilor grease-lubricated bearing has apotentially enormous impact onoverall system operating costs.speeds. Before a lubricant can beapproved for such an application,however, it must undergo a rigorousBarden testing and approval process.Barden G-75, for example, is onesuch grease. Designed for high speedspindle bearing applications, G-75combines a fully synthetic base oilwith a polyurea thickener insteadof a barium complex soap thickener.It offers extremely high thermalstability, exceptional viscosity/temperature behavior characteristics,low base-oil bleed rate and higherservice life at high speeds (1.5M dN).Barden super precision bearings —and special Barden high-performance lubricants — permit reliablegrease lubrication, even at maximumBarden · 7

NOTESBarden · 8

SPINDLE BEARINGSBarden · 9

SPINDLE BEARINGSBarden spindlebearings are highprecision, single row,angular contact ballbearings. Their specialdesign features —including contactgeometry, surfacedesign and otherproperties — resultin a bearing designthat offers highprecision, excellentDU DBDU DFDU DTspeedability, highFig. 1. Installation possibilities of a DU setrigidity and lowvibration characteristics.sets feature no mounting positionmarks at the circumference exceptThese bearings are readily availablefor their contact angle marks.in a wide range of standard sizes,making them suitable replacementsContact Angle Marksfor virtually any type of machineon Single Bearingstool application.“Universal” BearingsBarden “universal” bearings aremanufactured in such a way thatthey can be mounted in anyarrangement or combination ofsets — without suffering anyloss of bearing performance. Thisinstallation flexibility offers severallogistical advantages, including theeasy interchangeability of bearingstock. The bearings can bearranged according to the symbolon the outer ring surface (Fig. 1).In universal bearing sets the secondletter of the set designation is a U.Bearings of universal sets canbe mounted in any arrangementwithout suffering performancelosses. Therefore universal bearingBarden · 10The position of the contact angle ismarked by an arrow on the bearingouter circumference. The openside of the arrow faces the outerring lip end (Fig. 2).Spindle BearingNomenclatureAll Barden and FAG spindle bearingscan be identified — and specified —through use of a uniform nomenclature system.More detailed information onbearing nomenclature can be foundin the appropriate nomenclaturefold-out pages specific to eachproduct group.In addition to bearing nomenclature,markings on inner and outer ringsprovide vital information on: bearing width the tolerances of the inner ringbore and outside diameter the mounting direction, throughmarking on outer ring surface high point of eccentricity of theinner ring.Fig. 2. Contact angle marks ona single bearingThe FAG nomenclature shown inthe product tables is for referenceonly. All bearings are availableexclusively from Barden, and mustbe ordered using the Barden BasicBearing Number.

BARDEN BEARING NOMENCLATURE — SPINDLE BEARINGS11CZSB 1ZSB 108 H08 H0808CU LC RR U LCU LC RR U LBearing TypePreloadCLMHHybrid, standard design,Ceramic ballsXCX-life ultraCeramic ballsZSBHigh-speed bearing,Steel ballsCZSBHybrid high-speed bearing,Ceramic ballsXCZSB X-life ultraHigh-speed bearing,Ceramic ballsDimension Series10MO18001900100200Metric 9mm Max BoreUltra-light seriesLightweight seriesMedium seriesHeavy seriesLightMediumHeavyBearing ArrangementUSingle bearingAny arrangementDUSet of 2 universal bearingsTUSet of 3 universal bearingsQUSet of 4 universal bearingsPUSet of 5 universal bearingsDBSet of 2 bearingsBack-to-back arrangementDFSet of 2 bearingsFace-to-face arrangementDTSet of 2 bearingsTandem arrangementTBTSet of 3 bearingsTandem – O – arrangementQBCSet of 4 bearingsTandem – O – Tandem arrangem.Bore Reference Number6789000102030404 & up6 mm7 mm8 mm9 mm10 mm12 mm15 mm17 mm20 mmMultiply last two digits by five to get bore in mmCageHTextile laminated phenolic resin cageOuter ring centeredContact AngleCE15 25 SealingRRSeals at both sides and greased for lifeBarden · 11

FAG BEARING NOMENCLATURE — SPINDLE BEARINGSHSS 70 08 C.T.P4S.ULHCB 70 08 C DLR .T.P4S.ULB 70 08 C.2RSD.T.P4S.ULB 70 08 C.T.P4S.UL.L75Bearing TypeBHCBXCBHSHSSHCHCSXCXCSStandard design,Steel ballsHybrid, standard design,Ceramic ballsX-life ultraCeramic ballsHigh-speed bearingSteel ballsHigh-speed bearing,Steel balls, sealedHigh-speed bearing,Ceramic ballsHigh-speed bearing,Ceramic balls, sealedX-life ultraHigh-speed bearing,Ceramic ballsX-life ultraHigh-speed bearing,Ceramic balls, sealedDimension Series7187197072Ultra-light seriesLightweight seriesMedium seriesHeavy seriesBore Reference Number67890001020304056 mm7 mm8 mm9 mm10 mm12 mm15 mm17 mm4 · 5 20 mm5 · 5 25 mmContact AngleCEGrease Filling by ManufacturerL75FAG grease Arcanol L75 fornon-sealed bearingsBearings with seals at bothsides are lubricated for lifewith L75PreloadLMHLightMediumHeavyBearing ArrangementUSingle bearingAny arrangementDUSet of 2 universal bearingsTUSet of 3 universal bearingsQUSet of 4 universal bearingsPUSet of 5 universal bearingsDBSet of 2 bearingsBack-to-back arrangementDFSet of 2 bearingsFace-to-face arrangementDTSet of 2 bearingsTandem arrangementTBTSet of 3 bearingsTandem – O – arrangementQBCSet of 4 bearingsTandem – O – Tandem arrangement15 25 External FormDLRDIRECT LUBEDirect lubrication via OD,integral O-ringsSealing.2RSDAccuracyP4SFAG standard (ABEC 7 nominaltolerances, ABEC 9 running accuracies)CageSeals at both sides and greasedfor lifeSealed designs are marked witha point ( ) in the bearing tablesTTPATextile laminated phenolic resin cageOuter ring centeredTextile laminated phenolic resin cageOuter ring centered, Series B718Barden · 12

SPINDLE BEARING INSTALLATION NOTESDesignation and Markingof Bearing SetsBearing sets consist of bearings withmatched bore and outside diameters.The first letter refers to the numberof bearings in a set.D .2 bearings DuplexT.3 bearings TriplexQ .4 bearings QuadruplexReady-to-mount bearing sets featurea defined order of bearings. Thesecond and third letters refer to thepreloading of the bearings withinthe set:B .back-to-back arrangementF.face-to-face arrangementT.tandem arrangementBT .back-to-back arrangementagainst a tandem set of 2or 3 bearingsFT.face-to-face arrangementagainst a tandem set of 2or 3 bearingsDBTBTIn ready-to-mount bearing sets theoverall large arrow indicates theposition of the bearing within theset. The load direction (contact angleposition) is indicated through thesmall arrow symbol at the circumference of the single bearing.DFTFTDTQBCExamples of ready-to-mount bearing setsBarden · 13

SPINDLE BEARINGSX-life Ultra BearingsX-life ultra bearings were designedto achieve maximum speeds, loadsand long life. They are hybridbearings combining rings made ofCronidur 30, a high nitrogen stainlesssteel and ceramic (Silicone Nitride)balls. Compared to conventionalbearing steels, Cronidur 30 exhibitsa substantially finer grain structure,thus ensuring cooler operation andhigher admissible contact pressure.Most bearing designs are availableas X-life ultra bearings. The extendedservice life of X-life ultra bearings —10 that of conventional bearings— can help reduce system costs.Additional long life benefits can beobtained through the use of noncontacting “seals.”X-life ultra bearingsCeramic Hybrid BearingsHybrid bearings — steel rings andceramic balls — are now a popularchoice for many spindle bearingapplications. Originally developedfor use at high speeds, hybridbearings are now being specified forlower speed applications becauseof their proven quality/performancereliability and long service life. Useof grease lubricated bearings canfurther increase useful life andreduce system costs.Silicone nitride (ceramic) balls are used in all Barden hybridbearing designsBarden · 14

Direct Lube (DLR) BearingsWhere grease lubrication can’t beused, direct lube bearings may bethe solution. Direct lube bearingsensure reliable lubricant feed veryclose to the point of contact. Thisis achieved by a circumferentialgroove and radial supply holes.Integral precision O-rings seal thebearing against the spindle housing.Because of this special design,high performance is coupled witha reduction of the overall bearingsystem cost.Direct Lube (DLR) BearingSealed Spindle BearingsSealed spindle bearings allow theuse of a more economical greaselubrication system. These bearingsare factory-filled with Barden’s highperformance G-75 grease, then fittedwith non-contact seals on both sides.The advantages of sealed spindlebearings are: Non-contacting seal design Greased for life lubrication Box-to-spindle (ready forassembly) Interchangeable with standardspindle bearings Proper grease quantity Controlled greasing process Elimination of contaminationduring handling Enhanced performance dueto added sealing and greasenear contact zoneSealed spindle bearingsBarden · 15

SPINDLE BEARINGSSingleBarden BasicBearing NumberDuplexDimensionsdDBrsminr1sminShaft & ShoulderHousing DimensionsdaDararbh12 H12 max maxDirect Lube (DLR)DLR DimensionsBNSNSBLoad 770.550.530.550.53Designation examples:BardenFAGBarden · 16Sealed designZSB10M6ERRUL(HSS706E.T.P4S.UL)Hybrid ceramic designC10M6HCUL(HCB706C.T.P4S.UL)

SPINDLE BEARINGS10M HC/E, ZSB10M C/EC: Contact Angle α 15 / E: Contact Angle α 25 High Speed Design (ZSB)Unloading andard PreloadFV �� .747.516.234.414.833.114.833.1–––––– .T.P4SNAxial RigiditySaLMSealedDesignStandard Design* speeds indicated are for spring preloads.FAG BasicBearing Number †HN/µmX-life ultra designXC10M6HEUL(XCB706E.T.P4S.UL)Weightkg†FAG Basic Bearing Number is for reference only. All bearings are available exclusivelyfrom Barden, and must be ordered using the Barden Basic Bearing Number.Barden · 176–7

SPINDLE BEARINGSSingleBarden BasicBearing NumberDuplexDimensionsdDBrsminr1sminShaft & ShoulderHousing DimensionsdaDararbh12 H12 max maxDirect Lube (DLR)DLR DimensionsBNSNSBLoad 1.661.601.431.371.000.951.000.95Designation examples:BardenFAGBarden · 18Sealed designZSB10M8HERRUL(HSS708E.T.P4S.UL)Hybrid ceramic designC10M8HCUL(HCB708C.T.P4S.UL)

SPINDLE BEARINGS10M HC/E, ZSB10M C/EC: Contact Angle α 15 / E: Contact Angle α 25 High Speed Design (ZSB)Unloading andard PreloadFV ––– ––––– .T.P4SNAxial RigiditySaLMSealedDesignStandard Design* speeds indicated are for spring preloads.FAG BasicBearing Number †HN/µmX-life ultra designXC10M8HEDUL(XCB708E.T.P4S.DUL)Weightkg†FAG Basic Bearing Number is for reference only. All bearings are available exclusivelyfrom Barden, and must be ordered using the Barden Basic Bearing Number.Barden · 198–9

SPINDLE BEARINGSSingleBarden BasicBearing NumberDuplexDimensionsdDBrsminr1sminShaft & ShoulderHousing DimensionsdaDararbh12 H12 max maxDirect Lube (DLR)DLR DimensionsBNSNSBLoad 0.300.300.300.300.300.600.600.600.60Designation examples:BardenFAGBarden · .10.10.10.10.10.10.10.10.10.10.10.60.60.60.6Sealed 01.062.902.802.041.96Hybrid ceramic designC100HCUL(HCB7000C.T.P4S.UL)

SPINDLE BEARINGS1800HC/E, 1900HC/E, 100HC/E, 200HC/E,ZSB1900C/E, ZSB100C/EC: Contact Angle α 15 / E: Contact Angle α 25 High Speed Design (ZSB)AttainableSpeed*GreaseOilminimalmin-1Standard PreloadFV 1000090000Unloading ForceKaELMHNAxial 182977893964X-life ultra designXC100HCUL(XCB7000C.T.P4S.UL)* speeds indicated are for spring eightFAG BasicBearing Number 3243274419311931921395781Standard .988.238.880.7–––– .T.P4SHCB7200C.T.P4SHCB7200E.T.P4S†FAG Basic Bearing Number is for reference only. All bearings are available exclusivelyfrom Barden, and must be ordered using the Barden Basic Bearing Number.Barden · 2110

SPINDLE BEARINGSSingleBarden BasicBearing NumberDuplexDimensionsdDBrsminr1sminShaft & ShoulderHousing DimensionsdaDararbh12 H12 max maxDirect Lube (DLR)DLR DimensionsBNSNSBLoad n examples:BardenFAGBarden · 0.30.30.30.30.30.30.30.30.30.30.30.30.30.30.30

How This Catalog Is Organized This catalog contains information and product specifications on both Barden and FAG super pr ecision machine tool bearings. If you have a copy of an earlier Barden catalog, you ’ll notice this catalog is organized differently: It is divided i