Transcription

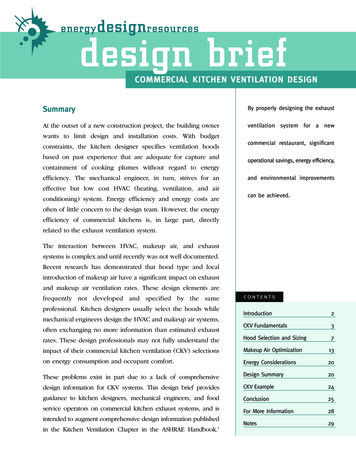

energy design resourcesdesign briefCOMMERCIAL KITCHEN VENTILATION DESIGNSummaryBy properly designing the exhaustAt the outset of a new construction project, the building ownerventilation system for a newwants to limit design and installation costs. With budgetconstraints, the kitchen designer specifies ventilation hoodsbased on past experience that are adequate for capture andcommercial restaurant, significantoperational savings, energy efficiency,containment of cooking plumes without regard to energyefficiency. The mechanical engineer, in turn, strives for anand environmental improvementseffective but low cost HVAC (heating, ventilation, and airconditioning) system. Energy efficiency and energy costs arecan be achieved.often of little concern to the design team. However, the energyefficiency of commercial kitchens is, in large part, directlyrelated to the exhaust ventilation system.The interaction between HVAC, makeup air, and exhaustsystems is complex and until recently was not well documented.Recent research has demonstrated that hood type and localintroduction of makeup air have a significant impact on exhaustand makeup air ventilation rates. These design elements arefrequently not developed and specified by the sameprofessional. Kitchen designers usually select the hoods whilecontentsIntroduction2CKV Fundamentals3rates. These design professionals may not fully understand theHood Selection and Sizing7impact of their commercial kitchen ventilation (CKV) selectionsMakeup Air Optimization13on energy consumption and occupant comfort.Energy Considerations20These problems exist in part due to a lack of comprehensiveDesign Summary20design information for CKV systems. This design brief providesCKV Example24guidance to kitchen designers, mechanical engineers, and foodConclusion25service operators on commercial kitchen exhaust systems, and isFor More Information28Notes29mechanical engineers design the HVAC and makeup air systems,often exchanging no more information than estimated exhaustintended to augment comprehensive design information publishedin the Kitchen Ventilation Chapter in the ASHRAE Handbook.1

CKV Design ResourcesThis brief focuses on methods of increasing the efficiency andInformation in this Design Brief is basedeffectiveness of the exhaust system while reducing the impacton the following two documents: Design Guide No. 1:Commercial Kitchen Ventilation –2Exhaust Hood Selection & Sizing.Design Guide No. 2: ImprovingCommercial Kitchen VentilationSystem Performance, Optimizing3Makeup Air.Additional information is provided inthe Notes section for the two designguides and other CKV resources.on the total building energy consumption and improving thekitchen environment. Key discussion areas include: The fundamentals of kitchen ventilation systems. The basics of hood selection and sizing. The influence and types of makeup air. Energy considerations for CKV systems. A summary of design strategies. A comparison of two CKV system designs.IntroductionIt has been shown that the HVAC load in a restaurant representsapproximately 30 percent of its total energy consumption.Depending on the facility layout, the kitchen ventilation systemcan account for up to 50 percent of the HVAC load including fanenergy, and may represent one of the larger energy-consumingend uses within a commercial food service facility. Unlikecooking appliances, which can be isolated for troubleshooting,the CKV system is affected by numerous components includingthe exhaust hood and the cooking appliances. To furthercomplicate matters, the CKV system is also a subsystem of theoverall building HVAC system.As the plume rises from the cooking appliances by naturalconvection, it is captured by the exhaust hood and removed bythe suction of the exhaust fan. Air in the proximity of theappliances and hood moves in to replace it. This replacementair, which originates as outside air, is referred to as makeup air(MUA). Fortunately, there is no “magic” to the relationshipbetween an exhaust hood and its requirement for replacementair. The physics are simple: air that exits the building throughexhaust hoods and fans for the CKV system must be replacedwith outside air that enters the building, either intentionally orPAGE2COMMERCIAL KITCHEN VENTILATION DESIGN

otherwise. If replacement air doesn’t come in, the “used” airAppliance Duty Classificationsdoes not go out the exhaust hood, and problems begin. NotLight Duty Gas and electric ovens (includingstandard, bake, roasting, revolving,retherm, convection, combinationconvection/steamer, conveyor, deckor deck-style pizza, and pastry) Electric and gas steam-jacketedkettles Electric and gas compartmentsteamers (both pressure andatmospheric) Electric and gas cheesemelters Electric and gas rethermalizersonly will the building pressure become too negative, the hoodmay not capture and contain cooking effluents due to reducedexhaust flow. An effective CKV system requires proper airbalance. The designer, engineer, installer, and operator of thekitchen ventilation system must work together to ensure “air in”equals “air out” for an effective kitchen ventilation system.CKV Ventilation FundamentalsCooking AppliancesCooking appliances are categorized as light, medium, heavy,and extra-heavy duty depending on the strength of the thermalplume and the quantity of grease and smoke produced (seesidebar). The strength of the thermal plume is a major factor indetermining the exhaust rate. By their nature, these thermalplumes are very turbulent and different cooking processes havedifferent “surge” characteristics. For example, the plume fromhamburger cooking is strongest when flipping the burgers.Ovens and pressure fryers may have very little plume until theyare opened to remove food product. Open flame, nonthermostatically controlled appliances, such as underfiredbroilers and open top ranges, exhibit strong steady plumes.Thermostatically controlled appliances, such as griddles andfryers, have weaker plumes that fluctuate in sequence withthermostat cycling, particularly gas-fired equipment.Building codes distinguish between cooking processes thatcreate smoke and grease (e.g., frying, griddling, or charbroiling)and those that produce only heat and moisture (e.g.,dishwashing and some baking and steaming operations).Cooking that produces smoke and grease requires liquid-tightconstruction with a built-in fire suppression system (Type IMedium Duty Electric discrete element ranges(with or without oven) Electric and gas hot-top ranges Electric and gas griddles Electric and gas double-sidedgriddles Electric and gas fryers (includingopen deep-fat fryers, donut fryers,kettle fryers, and pressure fryers) Electric and gas pasta cookers Electric and gas conveyor(pizza) ovens Electric and gas tiltingskillets/braising pans Electric and gas rotisseriesHeavy Duty Electric and gas underfired broilers Electric and gas chain (conveyor)broilers Gas open-burner ranges(with or without oven) Electric and gas wok ranges Electric and gas overfired(upright) broilers SalamandersExtra Heavy DutyAppliances using solid fuel such aswood, charcoal, briquettes, andmesquite to provide all or part of theheat source for cooking.hood), while operations that produce only heat and moisture donot require liquid-tight construction or a fire suppression systemSource: ASHRAE Standard 1544(Type II hood).COMMERCIAL KITCHEN VENTILATION DESIGNPAGE3

Figure 1: Common ExhaustHood StylesExhaust HoodsThere is no piece of equipment that generates more controversywithin the food service equipment supply and design communitythan the exhaust hood due to the variety of styles and makeup aircombinations. The style and construction features of the exhausthood affect the design exhaust rate. The capacity of an exhausthood is measured typically in cubic feet per minute (cfm).Wall-mounted canopy hoods, single- or double-island canopyIsland Canopyhoods, and proximity hoods (which include backshelf, passover, or eyebrow) all have different capture areas and aremounted at different heights relative to the cooking equipment,as shown in Figure 1. Generally, for the identical thermal plumechallenge, a single-island canopy hood requires more exhaustthan a wall-mounted canopy hood, and a wall-mounted canopyhood requires more exhaust than a backshelf hood. Theperformance of a double-island canopy tends to emulate theDouble-Island Canopyperformance of two back-to-back wall-canopy hoods, althoughthe lack of a physical barrier between the two hood sectionsmakes the configuration more susceptible to cross drafts.Building codes provide basic construction and materialsrequirements for exhaust hoods, as well as prescriptive exhaustrates based on appliance duty and length of the hood (cfm perlinear foot) or open face area of the hood (cfm per square foot).Wall-Mounted CanopyThe codes also recognize exceptions for hoods that have beentested against a recognized standard, such as UnderwritersLaboratories (UL) Standard 710.5 Part of the UL standard is a“cooking smoke and flare up” test. This test is essentially acooking effluent capture and containment test where “noevidence of smoke of flame escaping outside the exhaust hood”must be observed. Hoods bearing a recognized laboratory markare called listed hoods, while those constructed to theProximity (Backshelf )Source: Design Guide No. 2,California Energy Commissionprescriptive requirements of the building code are calledunlisted hoods. Generally, a listed hood can be operated at alower exhaust rate than an unlisted hood of comparable styleand size over the same cook line.PAGE4COMMERCIAL KITCHEN VENTILATION DESIGN

Although a well-engineered proximity hood can be applied withsuccess at very low exhaust rates, if specified withoutperformance data and in accordance with maximum height andFigure 2: Examples ofProximity HoodDesignssetback permitted by code, this same type of hood may fail toeffectively capture and contain the cooking effluent at higherexhaust rates. For example, a backshelf hood applied to handle150 cfm per linear foot over medium duty equipment may failto effectively capture and contain 300 cfm per linear foot ormore. Figure 2 illustrates a “good” and “bad” application of aproximity hood.Laboratory testing of different combinations of appliances hasIneffective Hood Design and Applicationdemonstrated that minimum capture and containment rates varydue to appliance type and position under the hood. Forinstance, a heavy-duty appliance at the end of a hood is moreprone to spillage than the same appliance located in the middleof the hood.Exhaust CapacityAn exhaust fan in the ceiling could remove much of the heatproduced by cooking equipment. However, adding smoke,Effective Hood Design and Applicationvolatile organic compounds, grease particles, and vapor fromcooking creates a more complex mix, requiring a means toSource: Design Guide No. 1,Southern California Edisoncapture and contain the effluent to avoid health and firehazards. Exhaust hoods serve that purpose.The key issue for designers and engineers is knowing theappropriate exhaust rate, which is always dependent on thefollowing factors: the type and use of the cooking equipment under the hood. the style and geometry of the hood itself. how the makeup air, which may or may not be conditioned,is introduced into the kitchen.COMMERCIAL KITCHEN VENTILATION DESIGNPAGE5

We have all experienced the “can’t-open-the-door” syndromebecause the exhaust fan is sucking too hard on the inside of arestaurant creating negative building pressure. The mechanicaldesign may call for 8,000 cfm of air to be exhausted through thehood. But if only 6,000 cfm of outdoor air is able to squeeze inthrough closed dampers on rooftop units and undesirablepathways in the building envelope, then only 6,000 cfm isavailable to be exhausted through the hood. The exhaust fancreates more suction or negative pressure in an unsuccessfulattempt to pull more air through the hood.Performance TestingAs defined in ASTM F-1704 Standard Test Method for thePerformance of Commercial Kitchen Ventilation Systems6,“hood capture and containment is ability of the hood tocapture and contain grease-laden cooking vapors, convectiveheat, and other products of cooking processes.” Hood capturerefers to these products entering the hood reservoir from thearea under the hood, while containment refers to theseproducts staying in the hood reservoir and not spilling outinto the adjacent space. The phrase “minimum capture andcontainment” is defined as “the conditions of hood operationin which minimum exhaust flow rates are just sufficient tocapture and contain the products generated by the appliancein idle or heavy-load cooking conditions, and at anyintermediate prescribed load condition.”Performance testing in accordance with ASTM F-1704 occurs atvarious laboratories and may incorporate a schlieren flowvisualization system to verify capture and containment. Thissystem is a major breakthrough for visualizing thermal andeffluent plumes from cooking processes. “Schlieren” is derivedfrom the German word for “smear.” A schlieren systempresents an amplified optical image (see Figure 3) due to thedifferent air densities, similar to the mirage effect that is seenover hot pavement.PAGE6COMMERCIAL KITCHEN VENTILATION DESIGN

Figure 3: Schlieren ImagesThese images show hood performance at different exhaust rates per linerfoot (cfm/lf).Source: Architectural Energy CorporationHood Selection and SizingBuilding Code ConsiderationsA good understanding of how building code requirementsapply to kitchen design is essential for properly selecting andsizing exhaust hoods. Local or state building codes are usuallybased on one of the “model building codes” promulgated bynational code organizations (see sidebar on page 9). Thediscussion of building codes will be limited in this design briefto requirements that affect design exhaust and makeup airrates, which are usually found in the mechanical code portionof the overall building code.Historically, codes and test standards used temperature ratingsfor classifying cooking equipment. Although these temperatureratings roughly correlated with the ventilation requirement ofthe appliances, there were many gray areas. Duringdevelopment of ASHRAE Standard 154, it was recognized thatplume strength, which takes into account plume volume andsurge characteristics, as well as plume temperature, would be abetter measure for rating appliances for application in buildingcodes. The new measures, called duty ratings, were created forCOMMERCIAL KITCHEN VENTILATION DESIGNPAGE7

the majority of commercial cooking appliances under Standard154, and were recently adopted by the International MechanicalCode (IMC). The Kitchen Ventilation chapter of the ASHRAEHandbook applied the same concept to establish ranges ofexhaust rates for listed hoods.The IMC dictates exhaust rates based on hood type andappliance duty. Table 1 states these exhaust rates in cfm perlinear foot of hood, which in this case applies to thedistance from edge to edge along the front face of the hood.The code requires that the exhaust rate for the highest dutyrated appliance be applied to the entire hood. The isdictions, requires calculating exhaust rates based on thesquare footage of the capture area, describing capture areaas the open area defined by the lower edges of the hood.The UMC uses temperature classifications for appliances, asdescribed above. Both the IMC and the UMC require aminimum six-inch hood overhang, on the front and sides,for canopy-style hoods.The prescriptive mechanical code exhaust rate requirementsmust be conservative because the AHJ (authority havingjurisdiction) has no control over the design of an exhaust hoodor the positioning and diversity of appliances placed beneaththat hood. However, in cases where the CKV system design andTable 1. Unlisted Hood Exhaust Flow RatesIMC Minimum Exhaust Flow Rate for Unlisted Hoods(cfm per linear foot of hood)Light DutyEquipmentMedium DutyEquipmentHeavy DutyEquipmentExtra-Heavy DutyEquipmentWall-mounted Canopy200300400550Single Island Canopy400500600700Double Island Canopy250300400550Eye Brow250250not allowednot allowedBackshelf/Passover250300400not allowedType of HoodSource: ASHRAE HandbookPAGE8COMMERCIAL KITCHEN VENTILATION DESIGN

appliance configuration have been optimized, the code-Model Building Codesspecified exhaust rate may be significantly greater than what isHistorically, the United States hadthree organizations that sponsoredmodel building codes, which werethen adopted by local jurisdictions.These organizations sponsoreddevelopment of standardized buildingcodes, usually called “model buildingcodes,” to assure better codeuniformity within the three regions inwhich they evolved.required for effective capture and containment of the cookingplume. The code-based safety factor may be necessary for nonengineered systems, but can increase fan energy as well asplace an energy cost burden on the CKV system through itsdemand for more heated and cooled makeup air.When the energy crisis of the 1970s occurred, kitchenventilation systems became an obvious target. The industryresponded with two methods of reducing the amount ofreplacement air that had to be cooled or heated: (1) short-circuithoods, and (2) listed hoods.The first method, called “internal compensation,” was tointroduce the makeup air directly into the hood reservoir. Thisis more commonly known as short-circuit makeup air. Althoughshort-circuit hoods have been installed and operated with asmuch as 80 percent of replacement air being introducedinternally, field and laboratory investigations have shown thatthese hoods fail to capture and contain effluent adequately.Generally, not more than 15 percent of the replacement air canIn the northeast U.S., the BuildingOfficials Council Association sponsoredthe National Building Code. In thesoutheast U.S., the Southern BuildingCode Council International sponsoredthe Standard Building Code. In thewestern U.S., the International Councilof Building Code Officials sponsoredthe Uniform Building Code (UBC).California jurisdictions adopted theUBC, including the Uniform MechanicalCode (UMC).In 1994, these organizations formedthe International Code Council to unifytheir codes. In 2000, the first fulledition of the International BuildingCode (IBC) was published.be introduced internally without interfering with proper captureand containment.The second industry strategy was to test hoods underlaboratory conditions according to the test protocol specifiedby UL Standard 710 - Standard for Safety for Exhaust Hoods forCommercial Cooking Equipment, which covers materials andconstruction of exhaust hoods as well as capture andIn 2000, the National Fire ProtectionAssociation (NFPA) announced that itwould sponsor a complete buildingcode that would compete with theIMC. In 2002, NFPA published itsfirst edition.Mechanical code requirements forkitchen ventilation are similar amongthese model codes.containment performance. The capture and containmentperformance is based on testing a single appliance under arepresentative hood at up to three cooking temperatureoperating set points (400 F, 600 F, or 700 F). The UL listingreports the minimum performance rate determined under thislaboratory test. Designers should apply a safety factor toaddress dynamic conditions encountered in real kitchens.COMMERCIAL KITCHEN VENTILATION DESIGNPAGE9

Although manufacturers do not publish safety factors to beapplied to their minimum listed cfm, they will typicallyrecommend increasing the exhaust rate by five to 25 percentover the minimum listing.The ASTM Standard F-1704 covers exhaust hood capture andcontainment performance as well as heat gain from hoodedappliances. The current version does not address dynamicconditions, but there are amendments under consideration to adda dynamic test that would help quantify a safety factor. The captureand containment test in UL 710 and ASTM F-1704 are similar.While the exhaust rates shown in Table 1 are minimummandatory rates for unlisted hoods, the rates in Table 2 reflectthe typical range in design exhaust rates for listed hoods. Thevalues in this table may be useful for estimating the cfmadvantage offered by listed hoods over unlisted hoods for agiven project. However, in the final stage of design, exhaustrates may be adjusted to account for the following. Diversity of operations (how many of the appliances will beused at the same time). Position under the hood (appliances with strong thermalplumes, located at the end of a hood, tend to spill effluentmore easily than the same appliance located in the middleof the hood). Hood overhang (in combination with appliance pushback).Positioning a wall-mounted canopy hood over an applianceline with an 18-inch overhang can dramatically reduce therequired ventilation rate when compared to the minimumoverhang requirement of six inches. Some manufacturers listtheir hoods for a minimum 12-inch overhang, providing animmediate advantage over unlisted hoods. Appliance operating temperature (e.g. a griddle usedexclusively by a chain restaurant at 325ºF vs. 400ºF surfacetemperature) or other specifics of appliance design (e.g.18-inch vs. 24-inch deep griddle surface).PAGE10COMMERCIAL KITCHEN VENTILATION DESIGN

Operating experience of a chain restaurant may be factoredinto the equation. For example, the CKV system designexhaust rate (for the next new restaurant) may be increasedor decreased based on real-world assessments of the CKVsystem in recently constructed facilities.Table 2. Typical Exhaust Rates for Listed HoodsMinimum Exhaust Flow Rates for Listed Hoods(cfm per linear foot of hood)Type of HoodLight DutyEquipmentMedium DutyEquipmentHeavy DutyEquipmentExtra-Heavy DutyEquipmentWall-mounted Canopy150-200200-300200-400350 Single Island Canopy250-300300-400300-600550 Double Island Canopy150-200200-300250-400500 Eye Brow150-250150-250not allowednot allowedBackshelf/Passover100-200200-300300-400not recommendedSource: ASHRAE HandbookHood GeometryInterior angles close to, or at, the capture edge of the hoodimprove capture and containment performance, allowingreduced exhaust by directing effluent back towards the filters.Hoods designed with these better geometric features require asmuch as 20 percent less exhaust rate compared to hoodsidentical in size and shape without these features. Capture andcontainment performance may also be enhanced with activelow-flow, high-velocity air jets along the perimeter of the hood.Cross DraftsCross drafts can have a detrimental effect on all hood andappliance combinations. Cross drafts affect island canopy hoodsmore than wall-mounted canopy hoods. For example, pedestalfans used by staff for additional cooling can severely degradehood performance and make capture impossible. Cross draftscan also develop when the makeup air system is not workingcorrectly, causing air to be pulled from open drive-through orpass-through windows or doors.COMMERCIAL KITCHEN VENTILATION DESIGNPAGE11

Side Panels and OverhangSide or end panels permit a reduced exhaust rate in most cases,as all of the replacement air is drawn across the front of theequipment, which improves containment of the effluent plumegenerated by the hot equipment. Panels are a relativelyinexpensive way to improve capture and containment, andreduce the total exhaust rate. End panels also mitigate thenegative effect that cross drafts can have on hood performance.It is important to know that partial side panels can providealmost the same benefit as full panels. Also, end panels canimprove the performance of a double-island or single-islandcanopy hood, although the panels tend to alter the definition ofthose hoods as an island canopy.Safety Factors in Exhaust RatesSafety factors are typically applied to the design exhaust rate tocompensate for the uncertainty of the design process and theeffect that undesired air movement within the kitchen has onhood performance. Better designs allow reduced exhaust ratesand minimized energy costs while maintaining a margin ofsafety with respect to capture and containment.Idle ConditionsAppliances idle much of the day. Using two-speed orvariable exhaust flow rates to allow reductions in exhaustand makeup while appliances are idling help minimizeoperating costs. NFPA 96 - Standard for Ventilation Controland Fire Protection of Commercial Cooking Operations7 wasrecently amended to allow minimum exhaust duct velocity aslow as 500 fpm (feet per minute) at the exhaust collar andductwork. Typical design values of 1,500 to 1,800 fpm at theexhaust collar are still recommended for normal cookingconditions. This code change will facilitate the application ofdemand ventilation controls.PAGE12COMMERCIAL KITCHEN VENTILATION DESIGN

Makeup Air OptimizationMUA InfluenceThe design and engineering team should consider and plan forhow the makeup air is best introduced into the building. Thelayout of the HVAC and MUA supply air outlets or diffusers canaffect hood performance and can disrupt thermal plumes andhinder capture and containment.A restaurant operator who thinks that not installing adedicated makeup air supply will save money in both firstcost and operating cost is short sighted. By design, it may beacceptable to have all the makeup air provided throughrooftop HVAC units. This strategy has been adoptedsuccessfully by several leading quick-service restaurantchains. However, in full-service and institutional kitchens withlarger exhaust requirements, it may not be practical or energyefficient to supply 100 percent of the replacement air throughthe building HVAC system.The solution may be to specify an independent MUA supply.However, the challenge of a dedicated MUA supply is howto introduce air into the kitchen without disrupting theability of the hood to capture and causing discomfort for thekitchen staff. Most kitchens are not extremely large, anddumping 7,000 cfm of replacement air, for example, in frontof a cook line does not go as smoothly in practice as it lookson paper. Not only can makeup air velocities impact theability of the hood to capture and contain cooking effluent,locally supplied makeup air that is too cold or too hot cancreate an uncomfortable working environment and increasesignificantly the energy consumption of the HVAC system.Types of MUA SupplySince air removed from the kitchen through the exhaust hoodmust be replaced with an equal volume of outside replacementair, one or more of the following pathways are typically used.COMMERCIAL KITCHEN VENTILATION DESIGNPAGE13

Figure 4: Types of MUASupply IntegratedWith the HoodPlenumThe following MUA types are shownfrom top to bottom: short circuit,air curtain supply, front face supply,perforated perimeter supply, andbackwall supply. Transfer air – for instance, air from the dining room. Displacement diffusers, which may be floor- orwall-mounted. Ceiling diffusers with louvers that are two-way,three-way, or four-way. Slot diffusers located in the ceiling. Ceiling diffusers with a perforated face. Integrated hood plenum including (see Figure 4):1. Short circuit or internal supply.2. Air curtain supply.3. Front face supply.4. Perforated perimeter supply.5. Backwall or rear supply.6. Combinations of the above.MUA StrategiesMakeup air that is supplied through displacement ventilationdiffusers remote from the hood, perforated diffusers locatedin the ceiling as far as possible from the hood, or as transferair from the dining room generally works well if air velocitiesapproaching the hood are less than 75 fpm. Makeup airintroduced in close proximity to an exhaust hood has thepotential, however, to interfere with the hood’s ability tocapture and contain. The chances of makeup air affectinghood performance increases as the percentage of the locallysupplied MUA (relative to the total exhaust) is increased. Infact, the rule-of-thumb that uses 80 percent for sizing airflowthrough a MUA unit can be a recipe for trouble, particularlyif the engineer or designer over specified the exhaust flowSource: Design Guide No. 2,California Energy CommissionPAGE14rate from the start.COMMERCIAL KITCHEN VENTILATION DESIGN

Temperature of the locally supplied makeup air can alsoimpact hood performance as air density or buoyancy impactsthe dynamics of air movement around the hood. Generally,hotter MUA temperatures (e.g., 90 F) will affect hoodperformance more adversely than cooler air (e.g., 75 F). Inmost temperate climates, such as many areas in California,evaporative cooling is an effective method of maintainingMUA temperatures within a range that is comfortable forkitchen staff and does not hamper hood performance.However, the maintenance requirements of evaporativecoolers must be factored into the equation.The primary recommendation for minimizing the impact thatlocally supplied MUA will have on hood performance is tominimize the velocity (fpm) of the makeup air as it isintroduced near the hood. This can be accomplished byminimizing the volume (cfm) of makeup air through any onepathway, by maximizing the area of the grilles or diffusersthrough which the MUA is supplied, or by using acombination of pathways.The first step in reducing the MUA requirement is to minimizethe design exhaust rate. This can be accomplished by prudentselection and application of UL Listed hoods and takingadvantage of the exhaust flow recommendations from hoodsuppliers for the cookline under consideration. Exhaust hoodmanufacturers’ sales and engineering departments haveextensive experience that CKV consultants can tap to helpminimize design exhaust rates.The second step in reducing MUA flow is to take credit foroutside air that must be supplied by the HVAC system to pending on the architectural layout between the kitchenand the dining room, it

This design brief provides guidance to kitchen designers, mechanical engineers, and food service operators on commercial kitchen exhaust systems, and is intended to augment comprehensive design information published in the Kitchen Ventilation Chapter in the ASHRAE Handbook.1 energydesignresources COMMERCIAL KITCHEN VENTILATION DESIGNFile Size: 1MB