Transcription

PhEn-602Pharmaceutical Facility DesignNotes # 8J. ManfrediJ. ManfrediPhEn-602 Spring '091

Architecture & Layout ConsiderationsImportant to understand the manufacturing processesand conduct the facility programming.Facility layout must be an integrated design thatsatisfies the following: Process requirements Personnel flows Material flows (product, component and raw materialmovements) Equipment layout requirements Operational access requirements Maintenance access requirementsJ. ManfrediPhEn-602 Spring '092

Architecture & Layout ConsiderationsThe layout of the sterile manufacturing facilitymust be developed around the needs of thefacility.The needs of the facility are defined duringthe facility programming stage.J. ManfrediPhEn-602 Spring '093

Architecture & Layout ConsiderationsDuring the programming phase, the firm must definetheir true needs they must separate the “musthave” objectives from their “wants” objectives.This is often a very time consuming effort, since eachdepartment needs to re-think what is trulymandatory for their operation versus those itemsthat are desirable, but not essential to successfuloperations.Formal decision analysis may need to be performed.J. ManfrediPhEn-602 Spring '094

Architecture & Layout ConsiderationsArchitectural design must consider proper roomfinishes, environmental and safety considerations,and must ensure that design is compliant withbuilding codes and fire regulations.Structural framework and building exterior finishesmust take into account the interior roomenvironment (i.e.: Minimize the use of columns andexpansion joints within the cleaner areas of amanufacturing facility where possible).J. ManfrediPhEn-602 Spring '095

Architecture & Layout ConsiderationsThe architect must build the facility around theequipment and systems required for theprocess .Architect must understand the flow ofpersonnel and materials!J. ManfrediPhEn-602 Spring '096

Architecture & Layout Considerations Area classification and hazards must be reviewedAre potent compounds involved/handled?Are flammable liquids used in formulations?– Explosion proof design may be required. Explosion proof panels require special construction methods andimpact layout issues. Are chemically resistant finishes needed? Service penetrations and routing of utilities must considerinterior layout– Minimize piping mains above clean areas Route to less clean areas to the extent possible Location of process viewing panels (visibility) is importantJ. ManfrediPhEn-602 Spring '097

Architecture & Layout Considerations The designer must first understand the productand process requirements. Accommodation Schedule is the first stepAccomodationScheduleJ. ManfrediConceptualLayoutPhEn-602 Spring '09Equipment andFacility Layout8

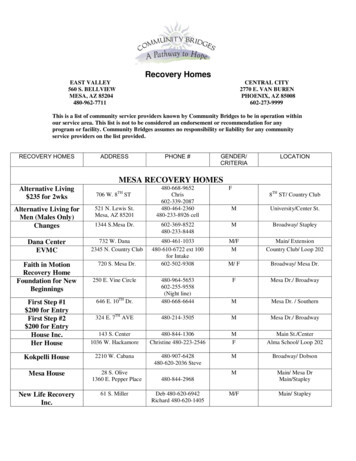

Architecture & Layout ConsiderationsAccommodation Schedule: Defines all areas that can influence unit operationsrequired for manufacturing as well as the relationshipsand flows between them Materials and personnel are primary focus Can be developed once the process is known– All process flow diagrams should be complete Also referred to as logic diagrams, or bubble diagramsJ. ManfrediPhEn-602 Spring '099

EXTERNALAREAFactoryChangeCORRIDORPersonnel eparationAreaAsepticChange/GownAUTOCLAVEASEPTIC COREJ. ManfrediINSPECTION &SECONDARYPACKAGINGPhEn-602 Spring '0910

Architecture & Layout ConsiderationsConceptual Layout Derived from Accommodation Schedule andequipment sizing needs Building blocks of equipment lines are developed Blocks of rooms are assembled based on necessaryadjacencies and process requirementJ. ManfrediPhEn-602 Spring '0911

Architecture & Layout ConsiderationsEquipment Layout Scaled drawing derived from conceptual layout Defines precise room sizes, structural grids Access routes Building and fire codes, means of egress areestablished in this phase. Building blocks ofequipment lines are developed Blocks of rooms are assembled based on necessaryadjacencies and process requirements Part of detail design phase of project life cycleJ. ManfrediPhEn-602 Spring '0912

Architecture & Layout ConsiderationsAfter Equipment Layout Drawings are prepared, establishMaterial and Personnel Flows Superimposed on Equipment Layout Drawings Typically superimposed with directional arrows Primary purpose is to illustrate how to eliminate or minimizethe potential for contamination of the clean room productand personnel. Layout should prevent cross contamination One-way flow always preferred Provide separate entry and exit ways of possible, particularlyin changing areas. Separate gowning and de-gowning areas always preferredJ. ManfrediPhEn-602 Spring '0913

Architecture & Layout ConsiderationsMaterial and Personnel Flows One-way flow is always preferred, as long as all other needscan be maintained– Often not possible when retrofitting an existing facility Avoid simultaneous two-way flow through a common area– Door interlocks and alarms used for prevention Gowning areas separated entry from exit Layout should prevent entry of personnel into clean/criticalareas without first going through gowning room Airlocks should be used between areas of differentclassifications (e.g. between controlled and critical areas).– Airlocks should have door interlocks to prevent simultaneous two-way flowJ. ManfrediPhEn-602 Spring '0914

Architecture & Layout Considerations Personnel flows considered:– Manufacturing personnel– Maintenance personnel– Quality control personnelJ. ManfrediPhEn-602 Spring '0915

Architecture & Layout Considerations Material flows considered:– Raw materials– Finished goods– Waste– Product (In-process, Intermediate & Final)– Equipment Clean and dirty components Portable equipment Product containersJ. ManfrediPhEn-602 Spring '0916

Architecture & Layout Considerations Provide sufficient space for operations Provide sufficient space for movement, equipment access andegress for life safety code requirements Rooms must be sized only after you fully understand what goes intothe room, and the process that takes place between the four walls Can’t overlook need for extra space for portable items brought intothe room, such as carts. Mechanical and electrical equipment panels also need to be takeninto account.J. ManfrediPhEn-602 Spring '0917

Architecture & Layout ConsiderationsCost considerations in layout design: Layout has significant impact on the amount of materialsand therefore facility cost Minimize perimeter vs. internal area, to reduce costs ofexternal load bearing walls and insulation. Simple plan shapes are most economical– Square maximizes internal area, minimizes perimeter Minimize building height Minimize number and size of clean rooms, particularlyClass 100 rooms Minimize size of clean corridors and staging areasJ. ManfrediPhEn-602 Spring '0918

Architecture & Layout ConsiderationsMinimize height of building to extent possible.Height increases cost due to:– Increase in amount of perimeter wall for a given totalfloor area– Increased load on the structure Heavier load on columns and footings– Additional hoisting of materials and extra time taken byoperators to reach the higher floorsJ. ManfrediPhEn-602 Spring '0919

Architecture & Layout Considerations Thermal currents Unidirectional airflow shadingJ. ManfrediPhEn-602 Spring '0920

GMP’s21 CFR Part 211– Subpart C-Buildings and Facilities § 211.42 Design and construction features. (a) Any building or buildings used in the manufacture, processing,packing, or holding of a drug product shall be of suitable size,construction and location to facilitate cleaning, maintenance, andproper operations. (b) Any such building shall have adequate space for the orderlyplacement of equipment and materials to prevent mixups betweendifferent components, drug product containers, closures, labeling, inprocess materials, or drug products, and to prevent contamination. The flow of components, drug product containers, closures, labeling,in-process materials, and drug products through the building orbuildings shall be designed to prevent contamination. (c) Operations shall be performed within specifically defined areas ofadequate size.J. ManfrediPhEn-602 Spring '0921

Example Equipment LayoutJ. ManfrediPhEn-602 Spring '0922

Architecture & Layout Considerations Room criteria sheets help to define the requirements upfront (alsoreferred to as Lab Cards)Room Name:General Area:Room no.Main Compounding RoomCompounding128StructuralHoistMonorailFloor pits (scales)J. ManfrediOperational Issues:Three fixed tanks, 100 L, 500 L, 1,000 Lwash downSpecial material handlingPurified water Drop (3 use points)Miscellaneous:Wall bumpersRoof hatchesArmor plate on doorsShelvingStorage cabinetPhEn-602 Spring '0923

Architecture & Layout ConsiderationsGowning rooms play a critical role in the facility layout.Cleanroom clothing: Designed to limit the rate of particle generation from theperson Designed to limit the rate of particle generation from the cleanroom garment. In cleanrooms where contamination is not as important (e.g.pharmaceutical areas and Class 100,000 areas), smock, cap andshoe covers may be appropriate.J. ManfrediPhEn-602 Spring '0924

Architecture & Layout ConsiderationsChanging rooms:Two grades (levels) of changing rooms Low (standard)– From normal clothing (street clothes) to factory(clean) clothing High (standard)– From clean clothing to full coverage suitJ. ManfrediPhEn-602 Spring '0925

Architecture & Layout ConsiderationsCleanroom clothing requirements are found in: IEST Recommended Practice RP-CC-003.2 EU GuidelinesJ. ManfrediPhEn-602 Spring '0926

Architecture & Layout ConsiderationsCleanroom clothing: In cleanrooms where contamination iscritical, (e.g. Class 10,000 and Class 100areas), a full coverage coverall, hood, boots,mask, gloves and goggles are worn.J. ManfrediPhEn-602 Spring '0927

Architecture & Layout ConsiderationsGray zones: Service space or maintenancespace typically adjacent to the productionroom Contains the majority of piping, valves, electricalconduit and other utilities that support themanufacturing area. Maintenance personnel have separate access tothese areas, allowing less stringent gowningrequirements, and allows for maintenancewithout shutting down or disrupting themanufacturing operationJ. ManfrediPhEn-602 Spring '0928

Example LayoutM aterials AirlockASEPTICFILLINGROOMAREAASEPTIC CORRIDORPREPARATIONAREAOVENChange room/Gowning AreaJ. ManfrediPhEn-602 Spring '0929

Material & Personnel Flow IAL ENTRYASEPTIC CORRIDORPERSONNEL ENTRYGOW NINGAREA - INOVENChange room /ExitJ. ManfrediPhEn-602 Spring '0930

Receiving DockReceiving Dept.Incoming MaterialsFinalAsepticProcessingControlled Pharm CorridorWash andPrepAseptic CoreDesirableLayoutSecondary PackagingShipping Dept.Loading DockJ. ManfrediPhEn-602 Spring '0931

Less Desirable LayoutLoading DockShipping andReceivingWash andPrepJ. ManfrediSecondaryPackagingAseptic CorePhEn-602 Spring '09Final AsepticProcessing32

Materials of Construction &Surface FinishesJ. ManfrediPhEn-602 Spring '0933

Materials of Construction &Surface Finishes § 211.42 Design and construction features. There shall be separate or defined areas for thefirm's operations to prevent contamination ormixups as follows: (10) Aseptic processing, which includes asappropriate: (I) Floors, walls, and ceilings of smooth, hardsurfaces that are easily cleanable;J. ManfrediPhEn-602 Spring '0934

Materials of Construction &Surface Finishes There is no such thing as FDA endorsed materials Surface finishes should be smooth, non-shedding, nonporous, and resistant to sustaining microbial growth Finishes must withstand repeated cleaning andsanitization* without evidence of rust, or peeling paint.*Cleaning and sanitization agents includedetergents and disinfectants, as well as hot WFI. Stainless steel often used throughout the facilitybecause of its appearance, durability, smoothness, andresistance to rust, peeling and sheddingJ. ManfrediPhEn-602 Spring '0935

Materials of Construction & SurfaceFinishes Ledges, joints, and corners difficult to reach shouldbe minimized Door hardware should be minimized– Use proximity sensors wherever possible A cleanroom should be built airtight, where possibleInternal surfaces smooth and suitable for cleaningSurfaces must be resistant to impactJoints should be free of openings that could harbordirt or microbes Crack and crevice-free constructionJ. ManfrediPhEn-602 Spring '0936

Materials of Construction & SurfaceFinishes Concealed, sealed sprinklers should be used to avoidcommunication between cleanroom and interstitialspace Electrical outlets should be covered/sealed suitablefor washdown service Predetermined routes for removing/installing tanksand other stationary equipment– Removable wall panels often used to avoid tear-out later. Bumper guards on doors and corridors that aresubjected to heavy equipment travelJ. ManfrediPhEn-602 Spring '0937

Materials of Construction & SurfaceFinishes Platforms typically stainless steel, includingdecking, stairs and support structure Stainless steel screens on HEPA filters Stainless steel benches for gowning areas Recessed fire extinguishers with stainless steelframe All access panels stainless steelJ. ManfrediPhEn-602 Spring '0938

Materials of Construction & SurfaceFinishesJ. ManfrediPhEn-602 Spring '0939

Materials of Construction & SurfaceFinishesFlooring: Consider aesthetics, durability and cleanability Epoxy terrazzo:– hard, durable long-lasting surface with excellent chemical resistance– Very expensive to install Epoxy Resin Systems: (e.g. Stonhard)––––Very popular in the Pharmaceutical industryEasier to install than TerrazzoModerate durability and chemical resistanceModerate price Welded Vinyl/PVC Sheet (e.g. Mipolam)– Durability an issue in high-traffic areas– Often used with identical wall system for matchingJ. ManfrediPhEn-602 Spring '0940

Materials of Construction & SurfaceFinishesMipolamJ. ManfrediPhEn-602 Spring '0941

Materials of Construction & Surface FinishesTypical seamless epoxy resin flooring system1.PolyurethaneCoating(Gloss or Matte)2.Epoxy Clear Coat3.Broadcast4.Epoxy Coat5.Heavy Duty Mortar6.CornerCrete SlurryPrimer7.SubstrateJ. ManfrediPhEn-602 Spring '0942

Flooring Epoxy terrazzo:– hard, durable longlasting surface withexcellent chemicalresistance– Very expensive toinstallJ. ManfrediPhEn-602 Spring '0943

Materials of Construction & SurfaceFinishesRadius cove base typicallyusedJ. ManfrediRadius cove base in modularconstructionPhEn-602 Spring '0944

Materials of Construction & SurfaceFinishesFlooring/drains Drains should be avoided in Class 100through Class 10,000 rooms. Acceptable in Class 100,000 roomsJ. ManfrediPhEn-602 Spring '0945

Materials of Construction & SurfaceFinishesCeiling Systems Same issues are important: aesthetics, durability and cleanability Gypsum Wall-board (GWB) with finish coat of epoxy paint– Pro’s: Flexible, easy to use Most common in the industry– Con’s: Restricts future above-ceiling access Requires careful coordination with other trades duringconstruction. (e.g. piping penetrations, HVAC diffusers, lightfixtures, filter housings).J. ManfrediPhEn-602 Spring '0946

Materials of Construction & Surface FinishesCeiling Systems Lay-in grid ceilings (http://www.cleanroomeng.com/products ceiling.cfm) J. ManfrediUse gasketed clean-room tilesSeams and joints still a potential breeding ground for bacteriaPhEn-602 Spring '0947

Materials of Construction & Surface FinishesLight fixtures Lay-in grid ceilings– sealed units with stainless trim TeardropJ. ManfrediPhEn-602 Spring '0948

Materials of Construction & Surface FinishesFor Class 100 throughClass 10,000 (Grade A andGrade B areas), radiuscoves are often used in theceiling to wall junction as wellRadius cove where ceilingmeets wall. (modularconstruction shown).J. ManfrediPhEn-602 Spring '0949

Materials of Construction & Surface FinishesWall systems Consider aesthetics, durability and cleanability Gypsum Wall-board (GWB) with epoxy paintfinish Concrete Block/concrete block with plaster Epoxy Resin walls Welded sheet PVC (e.g. Mipolam)– Typically used in higher class areas (e.g. Class 100)J. ManfrediPhEn-602 Spring '0950

Materials of Construction & Surface FinishesWall systems(Vision Panels) Flush with the wall toeliminate ledges Often Stainless frame,double pane Free of gaps along theperimeterJ. ManfrediPhEn-602 Spring '0951

Materials of Construction & Surface FinishesCleanroom DoorsFull glass or half glass architectural aluminum doors are available with avariety of hardware options, including pivot hinges, surface mounted closers,concealed closers, panic hardware, and locksets.J. ManfrediPhEn-602 Spring '0952

Materials of Construction & Surface FinishesSteel DoorsGlazed or flush steel doors integrate into the aluminum door frames utilizing butthinges at the jamb connection.J. ManfrediPhEn-602 Spring '0953

Materials of Construction & Surface FinishesElectric SlidingSliding doors easily integrate into wall systems and are available in any size witha variety of hardware available including push button entries and motion sensors.J. ManfrediPhEn-602 Spring '0954

Materials of Construction & Surface FinishesHigh-Speed Roll-Up DoorsRoll Up Doors offer advantages over swinging doors, sliding doors, and stripcurtains. Doors can be created up to 18' x 18'. Suitable for Class 100,000 to Class10,000 applications. The door opens and closes quickly reducing the time thecleanroom interior is exposed.J. ManfrediPhEn-602 Spring '0955

Materials of Construction & Surface FinishesGlazingWindows and doors can be glazed with a variety of options as specified by theproject requirements. One can choose from tempered glass, tinted glass, Lexan,acrylic, static dissipative, film-covered glass or solid panelsJ. ManfrediPhEn-602 Spring '0956

Materials of Construction & Surface FinishesAIR SHOWERSChambers located between the clean room and an outside environment thatremove particulate contamination from clean room garments as personnel passthrough. The chambers may include HEPA filters, interlocking doors, a recirculating air system, and air nozzles in various patterns through which filteredair is blown onto the personnel in the shower. The high-velocity air is moved overthe worker, removing particulate contamination from the worker's garments.J. ManfrediPhEn-602 Spring '0957

Materials of Construction & Surface FinishesModular Cleanroom FacilitiesSelf-contained facilities built off-site under controlledconditions, then delivered and integrated into the finalpoint of use location with the minimal amount ofreassembly. Very popular alternative.Three ISPE Facility of the Year Awards were given tofirms that utilized the modular concept.– Novo-Nordisk, Denmark– Baxter Biopharma Solutions, Bloomington, Indiana– GSKJ. ManfrediPhEn-602 Spring '0958

Materials of Construction & Surface FinishesModular Clean-room Facilities Pre-engineered, pre-fabricated walls and top decks thatcan support weight of air handling equipment, ceilingsand filters. Can assemble relatively quickly in the field. One source for virtually everything for the cleanroom,airhandling, HEPA filters, wall panels, lighting,windows, doors, instrumentation and controls, all builtinto the package. Wall and ceiling systems typically of metal panels withspecial coatings that resist cleaning agents and giveaesthetically pleasing look. Can opt for PVC finished panels or stainless steel finishpanels also.J. ManfrediPhEn-602 Spring '0959

Materials of Construction & Surface FinishesModular Clean-room Facilities – Sample ManufacturerPharmaWall System from PortaFab.“Designed specifically for pharmaceuticaland biotechnology facilities, thePharmaWall System utilizes a patentpending "Z" clip design that integrateswith our 1/2" (12.7 mm) thick panels to behung off a metal stud framework or anexisting wall. The non-progressive systemallows for the easy removal of panels.By connecting to a metal stud frameworkyou no longer have to be limited with thedepth of your utility chases. All piping,mechanical and electrical processes can beeasily integrated within 3-5/8", 6", 12" or18" cavities without having to create a"double" wall out of two free-standingpartition walls.”J. ManfrediPhEn-602 Spring '0960

Materials of Construction & Surface FinishesModular Clean-room Facilities – Sample ManufacturerPharmaWall System from PortaFab.Process & Utility Integration“Piping penetrations and enclosures can beeasily created by utilizing the PharmaWallsystem design. The radius cove details andcleanable surfaces meet the requirements for aclean space and allow for future pipingexpansion capability.Process service panels are easily integrated intothe PharmaWall system in a recessed mannerthat minimizes ledges and joints. The panelscan be designed to allow maintenance accessand provide for future piping expansion.The PharmaSystem's modular design alsoallows cleanroom designers and contractors theability to make field modifications during theinstallation process. This flexibility providesfor a number of potential design cost savings.”J. ManfrediPhEn-602 Spring '0961

Materials of Construction & Surface FinishesModular Clean Room Facilities: Reasons why modular construction may be used:–––Compressed construction timeFlexibility for future changesOther reasons: Overcome local skill shortagesReduced weightReduce number of contractors used during construction– Rely on the modular firm? Pre-qualification testing and customer inspection of thefacilities are completed before shipment to assurecompliance. Increased safety (Transferred to vendor?)J. ManfrediPhEn-602 Spring '0962

Materials of Construction & Surface FinishesModular Clean Room FacilitiesImpediments to use of modular construction: Generally more expensive than the traditional “stickbuilt” clean room Increased engineering costs Early design freeze which may reduce flexibility of scope Complicated interface (coordination) issues Absence of a robust economic advantage Must complete flooring, sprinklers, and other utilities inthe field (i.e.: water, electric, specialty gases, etc)J. ManfrediPhEn-602 Spring '0963

Room Pressurization Both US and EU requires that rooms of higher grade must beat higher pressure levels. Typically 0.05” water column difference between classes. Ensures air flows from cleaner areas to dirtier areas. Class100 filling rooms always have the highest pressure. Class 100 fill rooms will sometimes have regions that are class10,000 (there is no requirement to have the entire room atclass 100) however the room is still considered a class 100room in terms of pressure levels.J. ManfrediPhEn-602 Spring '0964

External AreasStreets, Offices, RestaurantTransition ZoneBrings people, materials, etc. fromexternal areas to the manufacturingareas in a “controlled” mannerClean AreaProvides a protectiveenvelope to minimize thechallenge to the Critical AreasCritical Processing AreaPeopleChangeChangeE.g.: Point of moveOutersContainer/ClosuresJ. ManfrediPhEn-602 Spring '0965

Classification Levels within an Aseptic FacilityNested Manufacturing Zones (Five Zones)LOCKERROOM ENTRYAREAPHARMACEUTICALAREACLASS 100,000PREPARATION AREACLASS 100,000CORRIDORASEPTIC CORRIDORCLASS 10,000CLASS 10,000BACKGROUNDFILLINGROOMCLASS100REGIONCLASS 100,000CORRIDORPHARMACEUTICALAREAJ. ManfrediPhEn-602 Spring '0966

Clean Room Pressurization - ExampleSample SterileManufacturing SuiteFilling RoomClass 100Highest ass 10,0000.10”J. ManfrediPhEn-602 Spring ”67

AnotherexampleofcascadingroompressuresJ. ManfrediPhEn-602 Spring '0968

Example of an actual facility layoutJ. ManfrediPhEn-602 Spring '0969

Architectural design must consider proper room finishes, environmental and safety considerations, and must ensure that design is compliant with building codes and fire regulations. Structural framework and building exterior finishes must take into account the interio