Transcription

DRIP IRRIGATION DESIGN & INSTALLATION GUIDERESIDENTIAL & COMMERCIAL IRRIGATION Built on Innovationhunterindustries.com

TABLE OF CONTENTSIntroductionInstallation1123456721 Preparation22 ProcedureAbout This Technical GuideAbout Hunter IndustriesPLDEco-WrapEco-Mat About Inline and Subsurface DripApplicationsLimitationsOperation and Maintenance24 Initial Operation25 Scheduling26 MaintenanceDesignAppendix A: Example Installation Details881020Appendix B: Technical Product DataWater QualitySoil Type and Water MovementComponents of an Inline Drip SystemCalculations2828282929Coefficient of VariationPLDEco-WrapEco-MatFittings

INTRODUCTIONThe combination of PLD, Eco-Wrap , and Eco-Matprovides a comprehensive suite of inline drip irrigationproducts for landscape professionals. Together, they aredesigned to efficiently irrigate any planted area. Irrigation’s most basic function is to provide water whereand when it is needed. Irrigation is not provided directlyto plants, but to the root zone of the soil. The root zonefunctions as a reservoir and is highly dependent on planttype, soil type, soil compaction, and other factors.Traditional irrigation projects water through the air. Aswater floods the surface, gravity is used to distributewater through the root zone. Distribution of waterthrough the air is dependent on the ability of emissiondevices to project water evenly and within the boundariesof the target area. External factors such as wind and heatincrease evaporation, affect droplet cohesion, patterndistribution and cutoff, and frequently result in overspray.The result? Significant water waste.Hunter’s inline drip products use capillarity to move waterin all directions through the root zone. Water isdistributed with maximum uniformity in all directions,providing the right amount of water exactly whereneeded to stimulate and sustain healthy root growth.When used below grade, inline drip irrigation significantlylimits the loss of water through evaporation.Eco-Mat supplements the soil’s ability to provide waterby increasing the carrying capacity through pore spaceinherent in the polypropylene fleece mat. This isespecially useful for applications with limited naturalwater-carrying capacity such as highly permeable soilsand planting media.ABOUT THIS TECHNICAL GUIDEThis guide outlines the application, design, and installation of Hunter’s inline drip products that providedesigners, installers, and irrigation managers a new classof irrigation technology. It is written for professionalswho have a solid understanding of basic irrigation anddesign practices. Technical information for the specification, design, installation, and operation of Hunter inlinedrip products, including PLD (Professional LandscapeDripline), Eco-Wrap, and Eco-Mat, are included.Information is organized sequentially; moving front toback in the order you’ll need it most. Under each topicessential information is placed at the beginning andbecomes progressively more detailed.ABOUT HUNTER INDUSTRIESHunter Industries is a family-owned global company thatprovides high quality, efficient solutions for the irrigation,outdoor lighting, and custom manufacturing industries.Headquartered in San Marcos, California since 1981,Hunter is a market leader in producing and marketing afull range of water-efficient, easy-to-use irrigation solutions for residential, commercial, and golf course applica-tions. Designed with the demands of irrigation professionals in mind, the current Hunter irrigation product lineincludes pop-up gear-driven rotors, high-efficiency rotarynozzles, spray sprinklers, valves, controllers, centralcontrollers, professional landscape drip and inline dripproducts, and weather sensors.Learn more. Visit hunterindustries.com or contact your local sales manager.1

PROFESSIONAL LANDSCAPE DRIPLINEPLD is professional grade inline drip tubing that incorporates the strongest UV inhibitors available, check valves,and pressure-compensating emitters with redundantemission paths. Hunter PLD is widely regarded as a highlyefficient, reliable drip solution.PLD Drip TubingProfessional-grade inline drip tubingPLD is suitable for at-grade, temporary, shallowsubsurface, and living wall applications for a variety ofplant material including groundcovers, grasses, shrubs,and trees. PLD is available in a wide range of emitterflow rates and spacing. PLD is offered in a range of flow rates, including0.4 GPH, 0.6 GPH, and 1.0 GPH PLD has an operating range of 15 to 50 PSI (emittersare pressure compensating within this range) Built-in check valves hold up to 5 ft. of head,preventing low emitter drainage and water waste PLD tubing has a tested burst pressure of 260 PSI The strongest inhibitors available provide superiorresistance to UV degradation for on-grade applications Two emitter paths provide redundancy and extraprotection against clogging2Website hunterindustries.com Customer Support 760-744-5240 Technical Service 760-591-7383

ECO-WRAPEco-Wrap is PLD encased in polypropylene fleece. Thepolypropylene wrap addresses two issues with othersubsurface irrigation systems: root intrusion and poorcapillary action of the soil. Eco-Wrap overcomes thesechallenges and provides significant advantages overtypical inline drip tubing without the use of chemicals orharmful metal residue, while accelerating lateral watermovement and greatly increasing emission area anduniformity.Eco-Wrap is recommended for all subsurface applicationsfor all types of plant material. Where freely draining soilsor planting media are anticipated, Hunter recommendsEco-Mat. Hunter Professional Landscape Dripline includes checkvalves and pressure compensating emitters at 0.6 GPHat 12" spacing Emitters saturate the fleece wrapping, which speedslateral movement and distribution throughout theroot zone Capillary action wicks water through the fleece andinto the soil in a widely distributed manner, reducingthe potential for tunneling or water waste due to gravity Unlike other products, the polypropylene fleece wrapprovides protection from root intrusion without usingtoxic chemicals, metal byproducts, or any otherproducts with a limited lifespanLearn more. Visit hunterindustries.com or contact your local sales manager.3

ECO-MAT Special engineered polypropylene fleece fabric mat,provides distribution to nearly 100% of the irrigatedareaEco-Mat uses a unique combination of specialized PLDand polypropylene fleece, which evenly disperses waterthroughout the target area. Eco-Mat also supplementsthe water holding capacity of the soil. Each square yardholds approximately one half gallon of water, availabledirectly to the root zone of the plant material. This isespecially useful in turf and applications that use rapidlydraining planting media such as rooftop gardens. Fleece mat supplements the soil’s natural waterholding capacity Uses Hunter Professional Landscape Dripline withcheck valves and pressure compensating emitters at0.6 GPH at 12" spacing Emitters saturate the wrapped tubing and then theEco-Mat with water. Once saturated, Eco-Mat provideswater to the entire landscaped area through capillaryactionEco-Mat is recommended for subsurface applicationsin traditional planters, intensive and extensive rooftopgardens for turf and sod-forming plant types, and shrubsand smaller plants with root zones generally 12" or less.Eco-Mat is ideal for completely uniform distribution, andparticularly suited for freely draining soils and engineeredgrowing media. Unlike any other product, Eco-Mat provides nearly100% distribution uniformity by using dispersed emission throughout the entire irrigated areaSEAM:polypropylene threadSPECIAL POLYPROPYLENE FLEECEPLD DRIPLINEDRIPLINE COVER:Special polypropylene fleeceLEED Water Efficiency (written from standpoint of LEED 2012)Hunter products contribute significantly to LEED BD C Water Efficiency (WE) Credits. Beginning in 2012, LEED BD C uses the USEPA’s WaterSense Water Budget Tool instead of local requirements to calculate a project’s water use baseline. Savings of 50% ormore beyond the baseline provide an additional credit. Water savings can be achieved using PLD, Eco-Wrap, or Eco-Mat to irrigateall types of plant material that require a subsurface solution. Since its distribution uniformity approaches 100%, Eco-Mat will providethe highest degree of savings. Total water savings can be enhanced by using one of Hunter’s weather sensors such as Solar Sync orET System.The Sustainable Sites InitiativeThe Sustainable Sites Initiative (2009) uses the same baseline approach as LEED 2012 to calculate irrigation water use. Hunterproducts provide significant water savings to achieve prerequisite 3.1 and to potentially achieve credit 3.2. Hunter drip irrigationand other products, such as ET-based controllers and MP Rotators, provide significantly higher efficiencies than the baselinecalculation assumes.Discussion of California MWELO (AB 1881)In 2010, California instituted a statewide requirement known as the Model Water Efficient Landscape Ordinance. This ordinancerestricts the volume of applied water allowed, and with few exceptions, prohibits overhead irrigation within 24" of hardscape, orshrub areas. Many more states are monitoring the effectiveness of this ordinance in reducing overspray and runoff and may followsuit. PLD, Eco-Wrap, and Eco-Mat provide the ideal irrigation solution for these areas.4Website hunterindustries.com Customer Support 760-744-5240 Technical Service 760-591-7383

ABOUT INLINE AND SUBSURFACE DRIPInline drip is ideal for all types of planted areas, includingspecialized sports applications, parks, streetscapes,commercial, and residential landscapes. Installing theemission system under the surface reduces or eliminatesdamage from heavy traffic, vandalism, ultraviolet degradation, and impact.Other types of irrigation systems require an exactpressure to maintain their pattern and distribution. Aspressures change, the performance of these systemsdegrades substantially. By contrast, inline drip irrigationallows very high distribution uniformity even at low orvarying pressures.Inline drip can significantly reduce water waste whilestimulating plant growth by providing the optimum watercontent to soil, avoiding “flood and drought” cycles thatcause root dieback, and avoiding anaerobic conditions.Subsurface applications further reduce water wastethrough evaporation.An injection system also provides the ability to maintaininline drip tubing by controlling mineral or biologicalbuildup by periodically injecting mild acid or traceamounts of chlorine.Where water supply or irrigation scheduling is problematic, subsurface irrigation may be used to extend thewatering window. Irrigation can be scheduled anytime,even during active use, without worry about increasedevaporation during the day. Extending the wateringwindow may allow lower flows, resulting in significant savings through reduced connection fees and materials costs.All Hunter inline drip products feature a speciallyengineered emitter that includes: Dual turbulent flow paths that promote scouringto prevent clogging from debris and dissolvedminerals Built-in check valve preventing low-emitterdrainage, retaining up to 5 ft. of waterDrip irrigation is an ideal solution for irregular or small Pressure compensation across a wide range ofareas. Inline drip irrigation limits the potential for liabilitypressure, from 15-50 PSIby reducing or eliminating overspray on buildings, Robust construction preventing crushing orwalkways, roadways, and other trafficked areas. Maininternal emitter damage even under heavy usetenance costs are often lower due to reduced overspray,runoff, erosion, compaction, water staining, and propertydamage. With no exposed emission equipment to get24 Hour Advance Wateringvandalized, stolen, damaged, misaligned, or worn out,Up to 24 hoursmaterial costs over the life of a project are substantiallydrip irrigationlower.A fertilizer injection (fertigation) system—for chemical ororganic products—can be easily introduced to inline dripsystems and distributed directly to plant root zones. Thisavoids human and animal contact and provides a moreeven distribution of material, minimizing material cost.8 hoursoverheadirrigationInline EmitterFeatures dual turbulent flow paths that promote scouring to preventclogging from debris and dissolved mineralsLearn more. Visit hunterindustries.com or contact your local sales manager.5

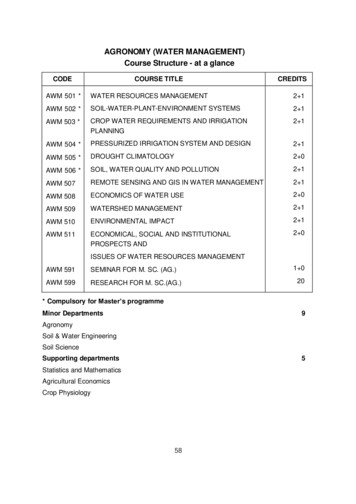

APPLICATIONSAPPLICATIONSPlant Type ApplicationHunter PLDHunter Eco-WrapHunter Eco-MatSubsurface irrigation of grasses, turf, or other sod-type plantsXXSubsurface irrigation of groundcovers and small shrubsXXSubsurface irrigation of trees and large shrubsXSpreading succulents, moss, other mat-type plantsXXHunter PLDHunter Eco-WrapHunter Eco-MatXXXXXTemporary irrigationXGroundcovers, shrubs, trees at grade (or less than 6" deep)XLandscape Area Type ApplicationLow traffic areasHigh traffic areasSpecialized sports applications, large turf areasXXXXXXXLiving wallsXXXCurved areas, borders, near vertical surfacesXXXSupplemental moisture for foundations and groundingXXXIrregular, small, or narrow areas; parking lot islandsRooftop landscapes (intensive and extensive)6Website hunterindustries.com Customer Support 760-744-5240 Technical Service 760-591-7383

Rooftop LandscapesRetaining WallsEco-Wrap and Eco-Mat are particularly suited for rooftopand other on-deck applications. Whether intensiveor extensive, these applications typically use a freelydraining lightweight planting media. Because this mediahas large particle size and pore volume, the capillarityof this media can be greatly reduced when comparedto topsoil. Other irrigation systems quickly exceed themedia’s ability to move water via capillary action. Gravitytakes over, moving water rapidly down through the mediaand into the drainage layer, resulting in water waste. EcoWrap and Eco-Mat widely distribute the point of emission,mitigating this problem.Inline drip irrigation is ideal for all types of retaining walls,including walls with planted pockets, or just planted areasat the top or base of the wall. Its compact form allowsirrigation even in the tightest of plant pockets. Inline dripprevents overspray and limits runoff, preventing damageto walls and limiting liability.Living WallsPLD, Eco-Wrap, and Eco-Mat are ideal for irrigating livingwalls. Typically comprised of planted pockets supportedand separated by fabric or other structure, these applications face the same challenges as rooftop landscapes. It’snecessary to ensure that emitters are evenly spaced inthe planted pockets by matching the inline spacing to theplanted structure, or by splicing as required. When usingEco-Wrap or Eco-Mat with separated planting pockets,cut the fleece between the pockets to prevent wickingoutside each cell. When using Eco-Mat, fold the fleeceblanket to conform to the perimeter of each cell, maximizing contact with the planting media. Eco-Mat supplements the media’s holding capacity, providing an extrareservoir of water.Retrofitting Existing SystemsPLD is ideal for surface application in existing shrub andgroundcover areas where minimal disturbance is required.Adaptors easily convert existing sprinkler risers to 17 mminsert fittings for use with inline drip tubing. In turf areasEco-Wrap can be trenched and backfilled. Where turfareas are being installed or replaced, consider Eco-Mat asa water-saving alternative to traditional irrigation systems.Specialized Sports ApplicationsInline subsurface drip provides a non-intrusive way toirrigate turf athletic fields while avoiding the compactionproblems that plague traditional systems. Compactionis exacerbated by heavy use in saturated conditions andseriously affects playability and turf grass health. The useof capillary action to distribute water laterally (insteadof overhead irrigation and gravity) avoids the flood andsoak cycle that damages fields. Subsurface irrigationprotects equipment from impact and sunlight, protectsplayers from tripping, avoids impact hazards, and reducesmaintenance and/or replacement.LIMITATIONSSubsurface irrigation has significant differences whencompared to overhead irrigation. Maintenance practicesmust be scheduled regularly and are proactive, ratherthan reactive. Under certain conditions, supplementalirrigation may be required to:Subsurface PLD applications should be reviewed for rootintrusion potential, and should not be used at depthsgreater than 6". For all subsurface applications underturf, Hunter recommends Eco-Wrap or Eco-Mat. Grow in sod and other plants until theyadapt to the subsurface irrigation system Wash salt, dirt, smog, or other deleteriousmaterial off foliage Water in granular and other topicallyapplied fertilizers Sufficiently wet broadcast seed to assureeven germinationLearn more. Visit hunterindustries.com or contact your local sales manager.7

DESIGNPrior to designing a system, collect the following information: Point-of-connection information, including staticpressure and available flow Proposed grading (used to determine inline tubingorientation and modify spacing or separate hydrozoneswhere needed) Irrigation water type (potable, non-potable but treated,well, etc.) and characteristics Proposed planting, including relative water needs of allspecies, and sizes at planting and maturity Soil type (important for determining dripline emitter andline spacing) Local conditions, including elevation differences, localclimate data (ETo), and other site specific information A scaled plan of the site and area to be irrigatedWATER QUALITYWater quality can significantly affect the operation andlongevity of inline drip irrigation systems. Below aregeneral parameters that can be identified by a waterquality test. Values less than or equal to the low columnare ideal for inline drip irrigation.CHEMICAL WATER QUALITY FOR THE CLOGGING POTENTIAL OF DRIP IRRIGATIONDescriptionClogging danger with the following concentrationpHLowModerateHigh 7.07.0 – 7.5 7.5Particulate matter* 3030 – 100 100Total dissolved solids* 500500 – 2,000 2,000Ferrous* 0.10.1 – 1.5 1.5Manganese* 0.10.1 – 1.5 1.5Calcium* 4040 – 80 80Carbonate density* 150150 – 300 300Hydrogen Sulfide* 0.20.2 – 2.0 2.0Bacteria (quantity/ml) 10,00010,000 – 50,000 50,000* Concentration in mg per liter (mg/L) or parts per million (PPM)SOIL TYPE AND WATER MOVEMENTSoil texture affects water movement. Emitter flow rate,spacing, and line spacing must be adjusted to compensate. The table below provides general guidelines. Whenunsure about the exact classification, use the tighterspacing. Even if the application rate exceeds a soil’sexpected intake rate, proper application of water canbe achieved through scheduling.RECOMMENDED SPACING FOR BASIC SOIL TYPES8Soil TypeClayLoamSandEmitter flow rate0.4 GPH0.6 GPH1.0 GPHEmitter spacing24"18"12"Row spacing18" – 24"16"-22"12"-18"Differences in recommended spacing and flow rates aredue to the physical properties of soil as related to watermovement.In descending order of particle size, soil is broadly classified into sand, loam, and clay. Particle size affects capillarity. As particle sizes decrease, capillary forces increase.Greater capillary force allows more water movementthrough the soil in all directions. Lesser capillary forcelimits the amount of water movement. As more wateris added, gravity begins to draw water downward. Thedownward movement of water due to gravity is greaterfor soils with larger particle size.Website hunterindustries.com Customer Support 760-744-5240 Technical Service 760-591-7383

For soils with smaller particle size, emitters can bespaced farther apart because capillary force will drawwater farther before gravity pulls it down. For soils withlarge particle size, water will almost immediately beginmoving downward. Emitters must be spaced closertogether to spread the water through lesser capillaryaction before it is lost below the root zone due to gravity.Use the following table as a guideline for spacing: If youare unsure of the exact soil type, or know that soils willdiffer on a site, use the minimum recommended spacingand the maximum recommended flow rate to ensure thatwater is evenly distributed.Soils of differing particle size will also accept water atdiffering rates. Soils with larger particles have larger voids,or pores, to accept water. Generally, the application rateof an inline drip system should not exceed the basic intakerate of the soil. (The basic intake rate of the soil is the rateat which the soil absorbs water after the initial applicationof water in a dry condition.) Basic intake rate estimatescan be obtained from the USDA Web Soil Survey, or thetable below. If the intake rate is exceeded by the irrigation system, water can be “pulsed” through the soil byscheduling several cycles of irrigation.If a jar is not available, conduct a “ball” test to determinebasic soil type: squeeze a moist ball of soil in your hand,then rub the soil between your fingers. Sand feels gritty,won’t form a ball, and will fall apart. Loam soil is smooth,slick, partially gritty, and forms a ball that crumbles easily.Clay soil is smooth, sticky, somewhat plastic feeling, andwill form a ball that does not crumble easily.SOIL INFILTRATION RATESSoil TypeMaximum application rate (in/hr) on slopes0-5%5-8%8-12%Sand, coarse1.5-2.01.0-1.50.75-1.0Sand, fine0.75-1.00.5-0.80.4-0.6Loam, silt loam0.3-0.50.25-0.40.15-0.3Clay, clay loam0.150.100.08Soil TypesSoil Test Sample 40%70%CLAY50%%%80%%SILTYLOAMSILT10010%SANDYLOAMY LOAMLOAM SANDMEDIUMLOAM9020%70SILTY CLAYLOAMCLAYSANDYCLAY 50%60%70%80%90%100SAND PercentageDetermine Soil TypeTest the soil in the target area after all grading operations are complete and amendments have been incorporated. If a laboratory soilanalysis is not possible, a simple field test to determine soil texture is to place a sample in a jar and fill half-way with water. Thoroughly shake the jar, ensuring the soil is suspended. Allow settling for at least 2 hours, then measure each layer to determine thepercentage of each type (in ascending order: sand, loam, and clay).Learn more. Visit hunterindustries.com or contact your local sales manager.9

COMPONENTS OF AN INLINE DRIP SYSTEMThis section addresses design considerations for each component of an inline drip system, moving from the valvedownstream to the flushing device. For more information about other irrigation components,see http://www.hunterindustries.com.ControllerValveA controller is the “brain” of everyirrigation system. Hunter controllersprovide effective tools for irrigationmanagement. For projects larger than30 zones, Hunter recommends theuse of two-wire decoder technology,available for both ACC and I-Corecontrollers. For areas without ACpower, Hunter’s wall mount orin-valve-box battery controllers areideal. All controllers are compatiblewith PLD, Eco-Wrap, and Eco-Mat .A remote control valve is typically used to automaticallyactivate inline drip systems. Alternatively, a manual valveor even hose bib may be used for non-automatic systems.Each hydrozone should be irrigated by a separate valve.Hydrozones are areas with specific conditions that affectirrigation, including plant type, spacing, density, microclimate, exposure, and slope. Follow all local requirements to prevent backflow andback siphonage.ET-SensorET-based controllers optimizescheduling based on real-timeweather conditions to minimize water waste due tomanagement factors. Hunter’s Solar Sync ET sensor addseven more efficiency to inline drip project by automatically adjusting irrigation scheduling for changing weatherand site-specific climate conditions. The Solar Sync iscompatible with all AC operated Hunter controllers. Bothinstallation and operation are simple processes.Zone Control KitEvery successful inline drip irrigation zone starts withthree items: zone control, filtration, and pressure regulation. Hunter’s Drip Zone Control Kit combine all three intoone factory-assembled, water-tested kit, which speeds upspecification and installation. For moreoptions, each component can be individually specified.10FilterFiltration must be provided for all inline drip systems,regardless of water supply type. Even potable watercontains suspended particulates which may clog inlineemitters. Filters also help reduce biological contaminants.For large or distributed systems, consider a disk filternear the point of connection. This provides a single, easilymaintained item in an accessible location. Use screen filters at each drip valve as a secondary level of protection incase any debris enters the irrigation system downstreamof the primary filter.Use a filter with a minimum filtration level of 120 microns(approximately 120 mesh, or 0.125 mm).Inline Drip TubingInline drip tubing consists of tubing laid in parallel rows.This creates a grid of emitters evenly spaced throughoutthe entire irrigated area.Website hunterindustries.com Customer Support 760-744-5240 Technical Service 760-591-7383

Pressure RegulationBarbed FittingsAll Hunter inline drip products feature built-in pressurecompensation, allowing an inlet pressure of 15-50 PSI.For mainline pressures exceeding 50 PSI, use a pressureregulator downstream of the valve and filter.Barbed insert fittings provide a positive connection to inline drip tubing.Hunter 17 mm insert fittings are colormatched with PLD, are UV resistant,handle pressures up to 200 PSI, andprovide a positive, easy-to-install,watertight connection without using tools, clamps, orglue.LateralsLaterals moving water from the valve to the header(s)must be sized to accommodate the full flow of eacharea they serve. Industry standards are not to exceed avelocity of 5 FPS. Laterals are typically PE or PVC pipe.The may also be constructed of blank inline drip tubingfor smaller areas.Air/Vacuum Relief (AVR) ValveWhile Hunter inline drip emitters are designed torelease air from the system and block back siphonage,AVR valves speed the process and provide an immediatepath for large volumes of air to escape. They should beinstalled on the highest position of the each contiguousarea of inline drip tubing. AVR valves must be usedwhen automatic flush valves are specified to preventback-siphonage throughemitters duringthe initialAIR/VACUUMRELIEF VALVEInstall at highest point of each areaflush cycle.INLINE DRIP TUBINGPLD, Eco-Wrap, or Eco-MatExhaust HeaderSUPPLY HEADERSizing laterals and headersPVC, PE, or blank PLD tubingSizing supply headers and laterals is crucial to the properoperation of all inline drip systems. Perform a pressure losscalculation from the point of connection to the farthest endLATERALof each supply header. Size the headerto provide the flowSize sizedas requiredfor andtotalneeded for the entire zone. Improperlyheaderszone flowlaterals may not allow proper emitter function.Supply HeaderWATER SUPPLYRemote control valve, filter,and pressure regulatorEach supply header must be sized to accommodate thefull flow of the entire area it serves. Headers may beeither end-feed or center-feed configurations.The exhaust header serves to equalize pressure andflow between runs of inline drip tubing and provide anoutlet path for flushing. The exhaust header does notneed to be sized to equal the supply header, but mustbe able to accommodate the flow rate of the flush valve,without exceeding 5 FPS.FLUSH VALVEManualor automaticFlushValves and PLD CapEXHAUSTHEADERFlush valvesare required on every inlinePVC, PE, or blankdrip systemandPLD tubing must be located to provide anoutlet from every point in each zone. Regularflushing not only removes debris and particles from the tubing, but the high volumeof turbulent water during flushing also helpsdislodge biological growth. Flush valvescan be either automatic or manual. The Hunter PLDbarbed valve is an affordable option to flush the system.Learn more. Visit hunterindustries.com or contact your local sales manager.11

LAYOUT Maximum length: To adequately supply all emitters,do not exceed the maximum run shown in the tablesbelow. Remember to add the length of all branchedruns.Typical zone layout consists of supply header(s) andexhaust header(s) with parallel lines of inline drip tubingbetween. These may be either center-feed or end-feedconfigurations. Line spacing: Spacing should not be greater thanshown in the tables below, but may be reduced asrequired to equally space lines within a zone or provideadditional coverage. (Note: Increased spacing on theZone design and line layout follow these basic principles:PLD APPLICATION RATES Layout: Start with the longest side. Create parallel rowsto fill the area. Identify supply and exhaust header locaEMITTERFLOW RATE– 1.0 GPHEMITTERFLOWtoRATE – 0.6lowerGPH thirdEMITTERRATE – 0.4toGPHof slopesFLOWis an exceptionthis guideline.)tions,and connectthe lines.Use returnsor branchesfollowcurvededges.RowRowRowEmitter Spacing (in.)Emitter Spacing (in.)Emitter Spacing (in.)SpacingLaySpacing(in.) inline12 tubing18 perpendicular24 Slopes:to the (in.)slope 12121.601.070.80 lay tubing120.96(parallelto contours).Inflat areas,in straight14 accommodating1.380.920.69 by14returning or0.83lines,curved edges161.200.800.60160.72branching lines.181.070.710.53180.64 Edges:Hardscapeare 0.58200.96 edges0.64and limits0.48 of planting20240.80240.480.530.40subjectto wind,radiantheat, reflectedsunlight, andotherNotesfactors that increase evaporation and plant waterneeds.Placeratesperimeterclose to edges, typically ¼Applicationin inches linesper hourof the regular on center spacing, but not greaterthan 90.24Spacing 30.370.320.290.260.210.320.280.240.210.190.16PLD EMITTER LINE MAXIMUM LENGTH CHARTSEMITTER LINE LENGTH –0.4 GPHEMITTER LINE LENGTH –0.6

TABLE OF CONTENTS Introduction 1 About This Technical Guide 1 About Hunter Industries 2 PLD 3 Eco-Wrap 4 Eco-Mat 5 About Inline and Subsurface Drip 6 Applications 7 Limitations Design 8 Water Quality 8 Soil Type and Water Movement 10 Components of an Inline Drip System 20 Calculations Installatio