Transcription

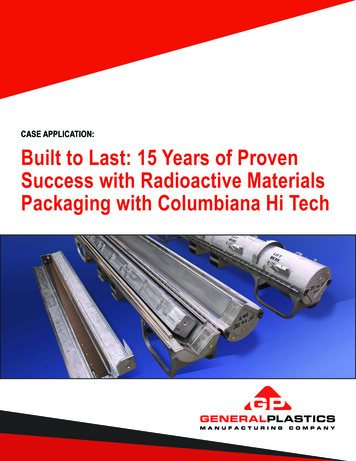

CASE APPLICATION:Built to Last: 15 Years of ProvenSuccess with Radioactive MaterialsPackaging with Columbiana Hi Tech

Radioactive Materials PackagingSuccess with Columbiana Hi TechTHE APPLICATION:For the past three decades, Columbiana Hi Tech (CHT) hassupported the full Nuclear Fuel Cycle, specializing in customfabrication and specialty products for the nuclear industry.Manufactured products range from front-end to backend transport and storage of nuclear materials, as well asequipment used for outage maintenance support. Additionalcapabilities include expert welding and machining services.CHT Supporting Nuclear Fuel Cycle: Front End Transport Reactor Services – Ancillary equipment Back End Transport/StorageNew UX-30 with SST plate.The company, founded by Don Olson in 1985, addressesa critical need to store and transport nuclear material thatmeets the arduous quality assurance requirements andregulations of the Nuclear Regulatory Commission (NRC). TheNRC mandates that any manufacturer intending to transportnuclear materials or produce transportation materials mustreceive a license or certification, respectively. NRC regulationsinclude “crash and fire protection” requiring radioactivematerials (RAM) packages to withstand 1,475 Fahrenheit,30-minute fire conditions, and 30-foot free drops.The products Columbiana Hi Tech manufactures are builtbased on customers’ design and requirements. Among theseare Traveler protective shipping containers and clamshellfor pressurized water reactor (PWR) fuel assemblies. Theseare fabricated with heavy gauge stainless steel, as well ashigh density polyurethane foam material. The stainless steelprovides structural strength, while the polyurethane foamacts as an impact absorber and thermal insulator for fireprotection.Small OP-TU.Every year, roughly three million packages ofradioactive materials are shipped within the UnitedStates from source to storage.

How CHT Meets Exacting Client Needs:Columbiana Hi Tech, the leader in radioactive materialspackaging, is required to adhere to stringent qualityassurance programs. Moreover, components used inmaterials packaging need to perform based on the strictestguidelines. Over the past 15 years, General Plastics’ LAST-AFOAM FR-3700 Performance Core Series has been spec’din to CHT’s clients’ projects. It is the only foam material thatmeets NRC requirements for Type A and Type B nuclearcontainers.The FR-3700 is a rigid, closed-cell polyurethane foam thatexhibits a high strength-to-weight ratio and boasts of afire-retardant mechanism that produces an intumescentchar when thermally attacked. It exhibits resistance tomost chemicals and solvents, and common petroleumproducts have proven to have negligible effect on it.The foam’s applications require that it retain its physicalproperties over the normal life span of the product. To thisend, tests have proven that compressive strength and charformation were not compromised despite long-term use,outperforming wood and other polymeric materials.Olson believes that one of the main reasons General Plasticsis chosen by his customers is due to their strong reputationfor quality and earned credibility through its long history inthe industry. Other companies have attempted to supplyfoam for front- and back-end nuclear transportation andstorage packages, but none were successful because theylack the certification and quality reputation that GeneralPlastics has with the NRC.“Having an FAA-certified testing lab works to theiradvantage,” Olson said, “I know that they’ve done extensivetesting on their foam, both for fire and compressionstrength. ” In addition, General Plastics meets the qualitystandards for NQA-1 and MIL-I-45208A.Contact us at 866-825-1378FR-3700 Benefits: Satisfies radioactive material (RAM)regulations Closed-cell foam with intumescentproperties High strength-to-weight ratio Proven long-term performance Biologically inert Does not swell, crack or split whenexposed to water Outperforms wood and other polymericmaterials Resistant to most chemicals and solventsContact us today to learn more about ourcomposite core foam series.The partnership between Columbiana Hi Tech and GeneralPlastics is a success story proven in almost two decadesof delivering quality products year after year. Every year,roughly three million packages of radioactive materials areshipped within the United States from source to storage.The NRC has a zero-tolerance policy for human contact withnuclear waste during transport, and has penned propertransportation procedures for RAM.Download FR-3700 Product Data Sheetwww.generalplastics.com

Creating a Legacy of Sucess:In January 2013, CHT was acquired by AREVA-TN, leadingprovider of total systems solutions for used fuel andradioactive waste management and nuclear transportationin the U.S. In 2015, Olson stepped down as President butremained as Vice President of Front End Business Lineand Fabrication, putting him in direct charge of all CHTmanufactured products using General Plastics foam. WhenCHT is awarded a contract from clients, they are providedall of the specifications and drawings, including the foammaterial. General Plastics may be the preferred producerof polyurethane foam for nuclear packaging in the UnitedStates due to its qualifications and certifications, but CHTenjoys working with General Plastics because of its highcaliber product and service.Traveller.“We’ve had absolutely no problems with them whatsoever,”Olson said, “Which is very unique when somebody has a solesource proprietary item. Usually they become lackadaisicaland you have to go to them, but General Plastics does notoperate that way.”For Olson, the road to getting CHT to where it is now may havespanned decades and different names (CHT was originallycalled Hi Tech Manufacturing) but Olson claims it was anexciting one.“It’s been good because of good customers and also becauseof good suppliers like General Plastics,” Olson said. “I lovehaving a vendor or supplier that I don’t have to worry about,but I can count those on probably one hand. General Plasticsis there.”General Plastics continues to work with Olson and his teamto deliver high-quality, successful products to Columbiana HiTech’s clients.Slide 13-RAJ ll.

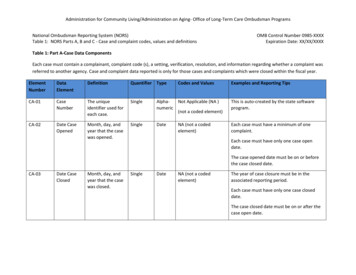

LAST-A-FOAM FR-3720 RIGID POLYURETHANE FOAM TDSLAST-A-FOAM FR-3720 RIGID POLYURETHANE FOAMPropertyEnglish320.0Density (pcf) (kg/m )MetricTest Method320ASTM D-1622ASTM D-1621Compressive Strength (psi) (kPa)Parallel to Rise-65 F75 F200 F250 FPerpendicular to Rise-65 F75 F200 F250 9885351713434ASTM D-1621Compressive Modulus (psi) (kPa)Parallel to Rise-65 F75 F200 F250 FPerpendicular to Rise-65 F75 F200 F250 516Flexural Strength (psi) (kPa)Rise Parallel to Test SpanRise Parallel to Beam Thickness1271125887648674Flexural Modulus (psi) (kPa)Rise Parallel to Test SpanRise Parallel to Beam Thickness4170742364287570292100Tensile Strength (psi) (kPa)Parallel to RisePerpendicular to RiseCoefficient of Thermal Expansion (in/in- F) (m/m- K)35 x 10-661 x 10-6ASTM D-1623 Type A SpecimensASTM D-790Method 1-AASTM D-790Method 1-AFrom -50 to 200 F, GP Method97.497.4Thermal Conductivity (BTU*in/ft2* F*h) (W/m* K)0.3580.052ASTM C-518 at 75 F (24 C) mean temp.Poisson's Ratio 0.3 0.3Literature (Gibson & Ashby)Hardness, Shore-D (cut foam surface)36.036.0Tumbling Friability: Weight Loss (%)1.01.00.009.045Closed Cell Content (%)Water Absorption (lbs/ft2) (kg/m2)ASTM D-6226ASTM D-2240ASTM C-421 (20 minutes @ 60 rpm)ASTM D-2842Specific Heat @25 C (BTU/lb- F) (J/g C)0.3531.477ASTM E-1269Heat of Combustion (BTU/lb) (MJ/kg)1170627.17ASTM D-240270132*S/E*S/EGlass Transition, Tg ( F) ( C)Fire SafetyASTM E-1824*Self-extinguishing via test method shown belowValues shown are average values determined from laboratory tests06/23/2015*FAR 25.853 (A) App. F (a)(1)(i) & (ii) tested vertically on 1/2" thick specimen using 12- and 60- second ignition with a Bunsen burnerGENERAL PLASTICS MANUFACTURING COMPANY4910 BURLINGTON WAYTACOMA, WA 98409phone (253) 473-5000fax (253) 473-5104e-mail: sales@generalplastics.comwebsite: www.generalplastics.comThis data is subject to revision and changes due to development of and changes to the material. The data is derived from tests and historical usage. The data isaveraged data and should be treated as such. Calculations should be verified by actual tests. The data is furnished without liability for the company and does notconstitute a warranty or representation in respect to the material or its use. The company reserves the right to release new data sheets in replacement.Contact us at 866-825-1378www.generalplastics.com

Where Great Ideas Take Shape4910 Burlington WayTacoma, WA 98409P: 253-473-5000 F: 253-473-5104www.generalplastics.com

Built to Last: 15 Years of Proven Success with Radioactive Materials Packaging with Columbiana Hi Tech. THE APPLICATION: Radioactive Materials Packaging Success with Columbiana Hi Tech For the past three decades, Columbiana Hi Tech (CHT) has supp