Transcription

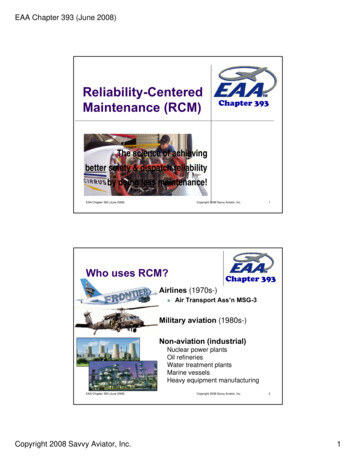

EAA Chapter 393 (June 2008)Reliability-CenteredMaintenance (RCM)Chapter 393The science of achievingbetter safety & dispatch reliabilityby doing less maintenance!EAA Chapter 393 (June 2008)Copyright 2008 Savvy Aviator, Inc.Who uses RCM?1Chapter 393Airlines (1970s-)zAir Transport Ass’n MSG-3Military aviation (1980s-)Non-aviation (industrial)Nuclear power plantsOil refineriesWater treatment plantsMarine vesselsHeavy equipment manufacturingEAA Chapter 393 (June 2008)Copyright 2008 Savvy Aviator, Inc.Copyright 2008 Savvy Aviator, Inc.21

EAA Chapter 393 (June 2008)Benefits of using RCMDCDC-8:TraditionalChapter 393350300250200DC-8: 339DC-10: 7150DCDC-10:RCM100500Components subject to scheduled overhaulor replacementEAA Chapter 393 (June 2008)Copyright 2008 Savvy Aviator, Inc.Benefits of using RCMDCDC-8:Traditional3Chapter 39340000003500000300000025000002000000DC-8: 4,000,000B-747: 66,0001500000B-747:RCM10000005000000Man-hours of structural inspections(first 20,000 hours TIS)EAA Chapter 393 (June 2008)Copyright 2008 Savvy Aviator, Inc.Copyright 2008 Savvy Aviator, Inc.42

EAA Chapter 393 (June 2008)Benefits of using RCMzChapter 393RCM has saved the airlines a fortune byzzSlashing the amount of scheduled PMEliminating most TBOszBig surprise: When PM was slashed andTBOs eliminated, aircraft safety and dispatchreliability improved dramatically!zQ: How can doing LESS maintenance result inMORE safety and reliability?z A: By reducing MIFs (Maintenance-induced failures)EAA Chapter 393 (June 2008)Copyright 2008 Savvy Aviator, Inc.5Maintenance has a dark side!Chapter 393zMaintenance is inherently invasive—it oftenbreaks things that were previously working finezzzPerforming unnecessary maintenancezzWe call this a maintenance-induced failure (MIF)The more invasive the task, the more likely a MIFWastes money and increases the risk of MIFEliminating unnecessary maintenancezSaves money and improves safety and reliabilityEAA Chapter 393 (June 2008)Copyright 2008 Savvy Aviator, Inc.Copyright 2008 Savvy Aviator, Inc.63

EAA Chapter 393 (June 2008)Traditional vs. RCMzTraditional view:zzzChapter 393Maintenance is a good thingThe more we do, the betterRCM view:zzzMaintenance is a necessary evil like surgeryThe less we do, the betterWe should do it only when absolutelynecessary, or when the benefits clearlyoutweigh the associated risks and costsEAA Chapter 393 (June 2008)Copyright 2008 Savvy Aviator, Inc.Key RCM questionszz7Chapter 393What are this component’s failure modes?For each failure mode:zHow likely is this failure to occur?zIs the probability of this failure:zzzHigher when component is old? (“age-related”)Higher when component is young? (“infant mortality”)Unrelated to component age? (“random”)zHow serious are the consequences of this failure?zCan we detect an incipient failure before it occurs?EAA Chapter 393 (June 2008)Copyright 2008 Savvy Aviator, Inc.Copyright 2008 Savvy Aviator, Inc.84

EAA Chapter 393 (June 2008)TDM versus CDMzTime-directed maintenance (TDM)zzAttempts to avoid failures by retiring, replacing oroverhauling components at a specific age (TBO)Condition-directed maintenance (CDM)zzChapter 393Attempts to avoid failures by monitoring componentcondition to detect potential failures before theybecome functional failuresCDM is always more efficient than TDMzTDM should be used only when CDM is infeasibleEAA Chapter 393 (June 2008)Copyright 2008 Savvy Aviator, Inc.Hierarchy of consequenceszzzFailure invisible to crew, and might reduce safetyExample: failure of standby vacuum systemOperational consequenceszzzFailure might hurt or kill someoneExample: engine connecting rod failureHidden consequenceszzChapter 393Safety consequenceszz9Failure might make aircraft unflyable (AOG)Example: failure of a magnetoEconomic consequenceszzFailure has no significant operational impactExample: failure of #2 comm radioEAA Chapter 393 (June 2008)Copyright 2008 Savvy Aviator, Inc.Copyright 2008 Savvy Aviator, Inc.105

EAA Chapter 393 (June 2008)RCM decision treeImpacts safety?YesYesNoImpacts mission?YesIs CDM effective?YesChapter 393NoRisks damage?NoIs TDM effective?YesPerform CDMNoPerform TDMEAA Chapter 393 (June 2008)NoAccept failure,redesign system,or add redundancyRun tofailureCopyright 2008 Savvy Aviator, Inc.Age-related failuresChapter 393Do our pistonaircraft enginesexhibit thisfailure pattern?Traditional view Unacceptablerate of failureA few premature failuresSafe LifeEAA Chapter 393 (June 2008)Copyright 2008 Savvy Aviator, Inc.11TBOCopyright 2008 Savvy Aviator, Inc.126

EAA Chapter 393 (June 2008)Age-related failuresChapter 393Engine-failure accidents (2001-2005 small piston airplanes)EAA Chapter 393 (June 2008)Copyright 2008 Savvy Aviator, Inc.Age-related failures13Chapter 393Engine-failure accidents (2001-2005 small piston airplanes)!!Infant-mortality!Past TBO?EAA Chapter 393 (June 2008)Copyright 2008 Savvy Aviator, Inc.Copyright 2008 Savvy Aviator, Inc.147

EAA Chapter 393 (June 2008)Age-related failuresChapter 393Second-generation view “Bathtub curve”OVERHAUL AT TBO?EAA Chapter 393 (June 2008)Copyright 2008 Savvy Aviator, Inc.Age-related failures15TBO makes sense foronly 4%Chapterto 6% of the393components on civil A/CThird-generation view (RCM) Non-age-related77% to 92%EAA Chapter 393 (June 2008)Copyright 2008 Savvy Aviator, Inc.Age-related8% to 23%Copyright 2008 Savvy Aviator, Inc.168

EAA Chapter 393 (June 2008)Simple vs. complexzSimple itemszzzzChapter 393One dominant failure mode (e.g., metal fatigue)Failure probability often increases with ageAn age limit, safe-life limit, or TBO may be usefulComplex itemszzzMany different failure modesFailure probability usually doesn’t increase with ageAge limits, safe-life limits and TBOs are not effectiveEAA Chapter 393 (June 2008)Copyright 2008 Savvy Aviator, Inc.Condition monitoring17Chapter 393Scheduled inspection for potential failures (P)intended to prevent functional failures (F)Rule of thumb:For condition monitoring to detectpotential failures reliably andprevent functional failures, wemust inspect for potential failuresat approximately one-half of theP-F interval.EAA Chapter 393 (June 2008)Copyright 2008 Savvy Aviator, Inc.Copyright 2008 Savvy Aviator, Inc.189

EAA Chapter 393 (June 2008)Chapter 393Nowlan & Heap report: “Reliability Centered Maintenance”Dec. 1978, 520 pageshttp://www.savvyaviator.com/rcm nowlan heap.pdfEAA Chapter 393 (June 2008)Copyright 2008 Savvy Aviator, Inc.Let’s talk about TBO 19Chapter 393Overhauling an apparently healthy engine atTBO makes very little sensezComplex item, no single dominant failure modez so overhauling at TBO is not an effective methodof reducing failure riskzMost likely catastrophic failure is infant mortalityz so overhauling arbitrarily at TBO is more likely toincrease risk than decrease itzWhy throw away years of useful life?EAA Chapter 393 (June 2008)Copyright 2008 Savvy Aviator, Inc.Copyright 2008 Savvy Aviator, Inc.2010

EAA Chapter 393 (June 2008)Let’s talk about TBO Chapter 393Operating an engine beyond TBO z is absolutely legalz won’t void your aircraft insurancez won’t make the overhaul more costlyz won’t make a catastrophic failure more likelyzIn fact, it will do exactly the opposite!EAA Chapter 393 (June 2008)Copyright 2008 Savvy Aviator, Inc.A tale of two engineszzzWhy? Because I chickened out! (Pretty dumb, huh?)At teardown, engines immaculatezzTCM’s published TBO is 1,400 hoursOn first run, these engines ran trouble-free for1,900 hours SNEW, then field overhauledzzChapter 393My 1979 Cessna T310R has two TSIO-520-BBszz21All 12 cylinders re-valved and continued in serviceAt TBO (1,400 SMOH), running greatAt 2,300 SMOH (164% of TBO), still running fineThis time, I’m in no hurry to overhaul!EAA Chapter 393 (June 2008)Copyright 2008 Savvy Aviator, Inc.Copyright 2008 Savvy Aviator, Inc.2211

EAA Chapter 393 (June 2008)TBO do’s and don’tszzChapter 393How we should use TBOzUse it to plan reserve for overhaulzUse it to adjust fair market valueHow we should not use TBOzDon’t euthanize an engine just because it hasattained some arbitrary agezzWhy throw away years of useful life?Monitor engine health using all available tools, andoverhaul strictly “on condition”EAA Chapter 393 (June 2008)Compression testEAA Chapter 393 (June 2008)Copyright 2008 Savvy Aviator, Inc.Copyright 2008 Savvy Aviator, Inc.23Chapter 393Copyright 2008 Savvy Aviator, Inc.2412

EAA Chapter 393 (June 2008)Compression testzMandated by FARs but problematic:zzzzzChapter 393Very unrealistic test conditionsPoor precision and reproducibilitySensitive to equipment, techniqueNumerous “false positives”—tens of thousandsof cylinders have been removed unnecessarilydue to “weak compression”Never pull a jug solely because ofa low compression reading!EAA Chapter 393 (June 2008)Compression testEAA Chapter 393 (June 2008)Copyright 2008 Savvy Aviator, Inc.Copyright 2008 Savvy Aviator, Inc.25Chapter 393Copyright 2008 Savvy Aviator, Inc.2613

EAA Chapter 393 (June 2008)Oil filter inspectionEAA Chapter 393 (June 2008)Oil filter inspectionzzChapter 393Copyright 2008 Savvy Aviator, Inc.27Chapter 393Mandated by FARsVery important test, but has limitations:zzWon’t detect microscopic wear metal particles 20 micronsMay not detect large chunks 1/16”EAA Chapter 393 (June 2008)Copyright 2008 Savvy Aviator, Inc.Copyright 2008 Savvy Aviator, Inc.2814

EAA Chapter 393 (June 2008)Oil filter inspectionWill detect this EAA Chapter 393 (June 2008)Chapter 393But may not detect this Copyright 2008 Savvy Aviator, Inc.Oil filter never saw this!EAA Chapter 393 (June 2008)Copyright 2008 Savvy Aviator, Inc.29Chapter 393Copyright 2008 Savvy Aviator, Inc.3015

EAA Chapter 393 (June 2008)Oil filter inspectionChapter 393How much metal is too much?zTCM does not offer guidancezLycoming says ground the aircraft iffilter is found to contain:zzzAny large pieces of metal(the size of broken pencil point)Numerous small particles totaling¼ teaspoon or moreAnything less, fly and re-evaluateEAA Chapter 393 (June 2008)Copyright 2008 Savvy Aviator, Inc.31 ¼ teaspoon of ferrous metalChapter 393¼”EAA Chapter 393 (June 2008)Copyright 2008 Savvy Aviator, Inc.On the tipof amechanic’smagneticpickup toolCopyright 2008 Savvy Aviator, Inc.3216

EAA Chapter 393 (June 2008)Dry particle analysisChapter 393When significant metal is found in filter:zUse magnet to identify if ferrous or non-ferrouszSend filter contents to labfor scanning electron microscopy (SEM)zCan often identify the exact source of the metalzTCM and Lycoming both do thiszAlso independent labsAviation Laboratories, http://www.avlab.com/EAA Chapter 393 (June 2008)Oil pressureCopyright 2008 Savvy Aviator, Inc.33Chapter 393Transient in-flight oil pressure fluctuationmay indicate chunks of metal (or other foreignmaterial) passing thru pressure relief valvezLand immediately!zCheck oil filter, pickup screen, governor gasketIn technically-advanced aircraft, might be anelectrical gremlin—but you must assumeit’s real unless proven otherwiseEAA Chapter 393 (June 2008)Copyright 2008 Savvy Aviator, Inc.Copyright 2008 Savvy Aviator, Inc.3417

EAA Chapter 393 (June 2008)Spectrographic oil analysiszComplements filter inspectionzzzChapter 393Detects microscopic wear metal particlesthat are too small to seeEstablishes a baseline “wear signature” forengine, then looks for departures from thatnormOil analysis excels at:zzDetecting very slow wear eventsEarly warning of accelerating wearEAA Chapter 393 (June 2008)Copyright 2008 Savvy Aviator, Inc.Spectrographic oil analysisSampleDateTotalHours35Chapter 393----- Parts Per Million ----CrFeNiCu 249227EAA Chapter 393 (June 2008)Copyright 2008 Savvy Aviator, Inc.Copyright 2008 Savvy Aviator, Inc.3618

EAA Chapter 393 (June 2008)Borescope inspectionChapter 39390-degreeviewing angleEAA Chapter 393 (June 2008)Copyright 2008 Savvy Aviator, Inc.Borescope inspectionzChapter 393Internal cylinder inspectionzz37Without cylinder removalNow “required” by TCM SB03-3at each compression test andannual/100-hour inspectionzzFAA says it’s not compulsory for Part91 but you’d be crazy not to!Eliminates most “false positives” ofcompression testsEAA Chapter 393 (June 2008)Copyright 2008 Savvy Aviator, Inc.Copyright 2008 Savvy Aviator, Inc.3819

EAA Chapter 393 (June 2008)Borescope inspectionChapter 393Best cylinderborescope I’vefound so far is adental intraoralcamera!EAA Chapter 393 (June 2008)Copyright 2008 Savvy Aviator, Inc.Borescope inspectionExhaustValveEAA Chapter 393 (June 2008)Copyright 2008 Savvy Aviator, Inc.39Chapter tricalexhaustdepositsCopyright 2008 Savvy Aviator, Inc.4020

EAA Chapter 393 (June 2008)Borescope inspectionChapter 393Thisexhaustvalvelooks fineNotereasonablysymmetricaldepositpatternEAA Chapter 393 (June 2008)Borescope inspectionCopyright 2008 Savvy Aviator, Inc.41Chapter 393Thisexhaustvalve isburned!!!Noteasymmetricaldeposits, andarea devoidof deposits(“hot spot”)EAA Chapter 393 (June 2008)Copyright 2008 Savvy Aviator, Inc.Copyright 2008 Savvy Aviator, Inc.4221

EAA Chapter 393 (June 2008)Chapter 393#3 Exhaust ValveEAA Chapter 393 (June 2008)Copyright 2008 Savvy Aviator, Inc.43Chapter 393EAA Chapter 393 (June 2008)Copyright 2008 Savvy Aviator, Inc.Copyright 2008 Savvy Aviator, Inc.4422

EAA Chapter 393 (June 2008)Chapter 393EAA Chapter 393 (June 2008)Copyright 2008 Savvy Aviator, Inc.45Chapter 393EAA Chapter 393 (June 2008)Copyright 2008 Savvy Aviator, Inc.Copyright 2008 Savvy Aviator, Inc.4623

EAA Chapter 393 (June 2008)Chapter 393EAA Chapter 393 (June 2008)Copyright 2008 Savvy Aviator, Inc.Digital engine monitorsJPI EDM-760JPI EDM-700EAA Chapter 393 (June 2008)Copyright 2008 Savvy Aviator, Inc.47Chapter 393Insight Gemini 1200E.I. UBG-16 Insight GEM-610Copyright 2008 Savvy Aviator, Inc.4824

EAA Chapter 393 (June 2008)Digital engine monitorsChapter 393E.I. MVP-50JPI EDM-930XerionAuRACLEEAA Chapter 393 (June 2008)Copyright 2008 Savvy Aviator, Inc.Digital engine monitorsEAA Chapter 393 (June 2008)Copyright 2008 Savvy Aviator, Inc.49Chapter 393Copyright 2008 Savvy Aviator, Inc.5025

EAA Chapter 393 (June 2008)Digital engine monitorsChapter 393Absolutely indispensable for real-timemonitoring and diagnosis of:zzzzzzzBurned exhaust valvesMisfiring spark plugsFaulty ignition leadsImproper magneto timingClogged fuel injectorsInduction leaksCooling baffle problemsEAA Chapter 393 (June 2008)Copyright 2008 Savvy Aviator, Inc.51Chapter 393EGTCHT4 HoursEAA Chapter 393 (June 2008)Copyright 2008 Savvy Aviator, Inc.Copyright 2008 Savvy Aviator, Inc.5226

EAA Chapter 393 (June 2008)Chapter 393EGTCHTWhat’s wrong with this engine? 30 F4 Hours20 cycles in 30 minutesEAA Chapter 393 (June 2008)Copyright 2008 Savvy Aviator, Inc.53Chapter 393#3 Exhaust ValveEAA Chapter 393 (June 2008)Copyright 2008 Savvy Aviator, Inc.Copyright 2008 Savvy Aviator, Inc.5427

EAA Chapter 393 (June 2008)Burned exhaust valvezSignature is “dancing EGT”zzzChapter 393EGT variation 30-50 F, often 1 cycle/minuteIf your analyzer isn’t in “normalize” mode,you’ll never notice it!Distinguishing from a failing probeor loose connectionzzUsually rapid and random,not slow and rhythmicUsually spikes DOWN (not UP)EAA Chapter 393 (June 2008)Copyright 2008 Savvy Aviator, Inc.55#2 EGTApr 9, 2005Chapter 393Jun 5, 2005Jul 28, 2005Aug 7, 2005EAA Chapter 393 (June 2008)Copyright 2008 Savvy Aviator, Inc.Aug 21, 2005Copyright 2008 Savvy Aviator, Inc.5628

EAA Chapter 393 (June 2008)Chapter 393EGTROP LOPRough EngineEnrich a bit“Big Mixture Pull”#2 & #4 go cold#2 & #4 come backbut EGT erraticCHTTCM IO-520One MinuteEAA Chapter 393 (June 2008)Copyright 2008 Savvy Aviator, Inc.57Chapter 393EGT#5 EGT and TITare now stableROP LOPPilot goes full-rich,#5Pull”EGT and TITthen leans a bit“Big Mixturedrift up; otherless aggressivelyEGTs stableCHTTCMTSIO-52010 MinutesEAA Chapter 393 (June 2008)Copyright 2008 Savvy Aviator, Inc.Copyright 2008 Savvy Aviator, Inc.5829

EAA Chapter 393 (June 2008)Is it fuel or spark?Chapter 393zFuel-related problems usually cause CHTand EGT to move in the same directionzIgnition-related problems usually causeCHT and EGT to move in the oppositedirectionEAA Chapter 393 (June 2008)Copyright 2008 Savvy Aviator, Inc.59Chapter 393EGTCHTTCMTSIO-520EAA Chapter 393 (June 2008)Copyright 2008 Savvy Aviator, Inc.Copyright 2008 Savvy Aviator, Inc.6030

EAA Chapter 393 (June 2008)Chapter 393EGTCHTTCMTSIO-520EAA Chapter 393 (June 2008)Copyright 2008 Savvy Aviator, Inc.Troubleshooting high CHTzzToo leanPoor coolingIf cylinder is running too lean:zzzChapter 393Two possibilities:zz61Hot when ROPCool when LOPIf cylinder has inadequate cooling air (dueto problems with baffles and/or baffle seals):zzHot when ROPHot when LOPEAA Chapter 393 (June 2008)Copyright 2008 Savvy Aviator, Inc.Copyright 2008 Savvy Aviator, Inc.6231

EAA Chapter 393 (June 2008)Using these tools togetherChapter 393Never remove a cylinder or tear down anengine based on any one test:zIf there’s a real problem, it will almost alwaysreveal itself in several wayszIf the preponderance of the evidence allpoints in the same direction, you can beconfident of the diagnosisEAA Chapter 393 (June 2008)Copyright 2008 Savvy Aviator, Inc.Using these tools togetherzz63Chapter 393Example:zFeb. 2006, oil analysis shows elevated nickel.zApr. 2006, RE #3 compression is “funky”but exhaust valve looks fine under borescope.zMar. 2007 (11 months and 150 hours later),engine monitor shows RE #3 EGT jitters.Borescope clearly shows two hot spots on valve.Compression test shows RE #3 at 0/80.Verdict: Replace RE #3 exhaust valve & guideEAA Chapter 393 (June 2008)Copyright 2008 Savvy Aviator, Inc.Copyright 2008 Savvy Aviator, Inc.6432

EAA Chapter 393 (June 2008)A 21st century engine conditionmonitoring program includes:zzzzzzzzChapter 393Oil filter inspectionSEM analysis of filter contentsSpectrographic oil analysisOil temperature & pressure trend analysisCompression testBorescope inspectionSpark plug inspectionDigital engine monitor data analysisEAA Chapter 393 (June 2008)Copyright 2008 Savvy Aviator, Inc.Secrets ofCost-EffectiveMaintenance65Chapter 393Five simple rules that candramatically reduce yourmaintenance expenditures,year after yearEAA Chapter 393 (June 2008)Copyright 2008 Savvy Aviator, Inc.Copyright 2008 Savvy Aviator, Inc.6633

EAA Chapter 393 (June 2008)Maintenance is a team sport!zCertificated mechanic (A&P)zzzzPerforms repairs and alterationsAnalogy: “licensed electrician, plumber, roofer”Inspects and approves (annuals, 337s)Analogy: “licensed building inspector”Aircraft owner/operatorzzPrimary responsibility for maintenanceAnalogy: “general contractor”EAA Chapter 393 (June 2008)Copyright 2008 Savvy Aviator, Inc.Why this teamwork breaks downz67Chapter 393Asymmetric knowledgezzzzFAAAuthorized inspector (IA)zzChapter 393Owner is theoretically in chargeA&Ps and IAs are theoretically “hired help”In GA, owner usually has no maintenancetraining and minimal maintenance knowledgeConflicts of interestzzzIA determines what work must be doneA&P income derives from work performedIn GA, IA and A&P are usually the same person!EAA Chapter 393 (June 2008)Copyright 2008 Savvy Aviator, Inc.Copyright 2008 Savvy Aviator, Inc.6834

EAA Chapter 393 (June 2008)Why this teamwork breaks downzChapter 393Lack of “informed consent”Aircraft owners routinely approve maintenancewithout knowing:zzzzzzzWhat it is going to costWhy it is being performedWhether it is really necessary for safetyWhether it is required by regulationHow invasive it isWhat the risks areWhether the benefits outweigh the risks and costEAA Chapter 393 (June 2008)Copyright 2008 Savvy Aviator, Inc.Why this teamwork breaks downz69Chapter 393Defensive maintenancezExplosion in litigation since 1994 (GARA)zzPrior to GARA, A&Ps worried about two things:zzz18-year limit on manufacturer’s product liabilityIt it safe?Is it legal? (i.e., does it comply with FAA regulations?)Since GARA, A&Ps have to worry about a third:zHow will it look to a jury of citizens (who have noknowledge about aviation or maintenance) when spun inthe most unfavorable possible light by a skilled plaintiff’sattorney?EAA Chapter 393 (June 2008)Copyright 2008 Savvy Aviator, Inc.Copyright 2008 Savvy Aviator, Inc.7035

EAA Chapter 393 (June 2008)Chapter 393The bottom line:Most aircraft ownersdo a terrible jobof managing theirmaintenance!EAA Chapter 393 (June 2008)Copyright 2008 Savvy Aviator, Inc.71Chapter 393www.savvyaviator.comEAA Chapter 393 (June 2008)Copyright 2008 Savvy Aviator, Inc.Copyright 2008 Savvy Aviator, Inc.7236

EAA Chapter 393 (June 2008)Training may not be enough!Chapter 393Managing maintenance properly requires amajor investment in time, effort and studyzSome owners can’t do this because they’re toobusy running a business or raising a family.zSome owners feel they bought an airplane tosave them time, not cost them time.zMany owners are not comfortable telling theirA&Ps what to do (instead of the other way around)EAA Chapter 393 (June 2008)Copyright 2008 Savvy Aviator, Inc.73Chapter 393EAA Chapter 393 (June 2008)Copyright 2008 Savvy Aviator, Inc.Copyright 2008 Savvy Aviator, Inc.7437

EAA Chapter 393 (June 2008)Rule #1:Chapter 393Choose the rightservice facilityand/or technicianfor the job.EAA Chapter 393 (June 2008)An owner’s job #1z75Chapter 393As “general contractor” an owner’s job is to:zzzzCopyright 2008 Savvy Aviator, Inc.Hire skilled tradesman (IAs, A&Ps, other technicians)Manage them to ensure they perform as desired andget the job done within schedule and budgetFire them if they do not perform to expectationsThe most important of these is the first!zzIf you hire the right person for the job, the resttends to work out well most of the timeIf you hire the wrong person for the job, the bestmanagement skills in the world may not be enoughto rescue the situationEAA Chapter 393 (June 2008)Copyright 2008 Savvy Aviator, Inc.Copyright 2008 Savvy Aviator, Inc.7638

EAA Chapter 393 (June 2008)Hiring the right shopzMost owners do it the wrong way:zzzzChapter 393The shop is at or near the aircraft’s home baseThe mechanic or DOM seems friendlyAn aircraft-owner friend recommends itMuch more “due diligence” is requiredzzInterview the shop as you would an employeeLook for the three C’s:zzzCompetentCommunicativeCooperativeEAA Chapter 393 (June 2008)The three C’sCopyright 2008 Savvy Aviator, Inc.77Chapter 393zCompetent means the shop has extensiveexperience with your make and modelzCommunicative means the shop is committedto keeping you continually “in the loop”zCooperative means the DOM is customeroriented and willing to do things your wayEAA Chapter 393 (June 2008)Copyright 2008 Savvy Aviator, Inc.Copyright 2008 Savvy Aviator, Inc.7839

EAA Chapter 393 (June 2008)Rule #2:Chapter 393Insist on a writtendiscrepancy listand cost estimatebefore approvingany work or parts.EAA Chapter 393 (June 2008)Copyright 2008 Savvy Aviator, Inc.Avoiding “sticker shock”79Chapter 393Never approve maintenance until you knowwhat it’s going to costzGet it in writing!zInstruct the shop that they are not authorized toexceed their written estimate unless they give youan amended estimate and obtain your explicitapprovalzIf you first learn the cost at invoice time, it’s toolate to affect the outcome!EAA Chapter 393 (June 2008)Copyright 2008 Savvy Aviator, Inc.Copyright 2008 Savvy Aviator, Inc.8040

EAA Chapter 393 (June 2008)What about inspections?Chapter 393Require a three-phase protocol:zzzShop inspects aircraft (for a flat-rate charge) andpresents owner with a written discrepancy list, withspecific repair recommendations and detailed costestimates for parts, labor, and outside workOwner reviews discrepancy list and estimates,asks questions, seeks second opinions, doeshomework to ensure informed consentOwner gives shop specific written directionand authorization to proceedEAA Chapter 393 (June 2008)Copyright 2008 Savvy Aviator, Inc.Rule #3:81Chapter 393If it ain’t broke,don’t let them fix it!EAA Chapter 393 (June 2008)Copyright 2008 Savvy Aviator, Inc.Copyright 2008 Savvy Aviator, Inc.8241

EAA Chapter 393 (June 2008)If it ain’t broke, don’t fix it!Chapter 393zEvery service manual contains hundreds ofscheduled preventive maintenance taskszSuch one-size-fits-all recommendationsmake no sense!zzzzIs aircraft based in Tampa or Tucson?Does aircraft fly 30 hours/year, or 300 hours/year?Is aircraft hangared, or tied down outdoors?Compliance is usually not required,and often is a huge waste of moneyEAA Chapter 393 (June 2008)Copyright 2008 Savvy Aviator, Inc.Don’t do it “by the book”!83Chapter 393It never makes sense to maintain anycomponent on a fixed timetable if it isfeasible to monitor condition and determinewhen maintenance is actually requiredzCDM is always more cost-efficient than TDMzTCM should be used only if CDM is infeasiblezNumerous studies show that CDM is feasible forabout 95% of the components on civil aircraftEAA Chapter 393 (June 2008)Copyright 2008 Savvy Aviator, Inc.Copyright 2008 Savvy Aviator, Inc.8442

EAA Chapter 393 (June 2008)Rule #4:Chapter 393Don’t let them fix ituntil you’re surewhat’s wrong with it!(Complete the diagnosisbefore starting therapy.)EAA Chapter 393 (June 2008)Copyright 2008 Savvy Aviator, Inc.Troubleshooting failuresz85Chapter 393Have you ever had this experience?zYou put your aircraft in the shop to have a squawk fixed;zYou received an invoice for parts and labor;zYou discovered that the squawk wasn’t fixed?zIf so, you were victim ofa troubleshooting failure!zIncorrect/inadequate troubleshooting is the#1 cause of wasted maintenance dollars!EAA Chapter 393 (June 2008)Copyright 2008 Savvy Aviator, Inc.Copyright 2008 Savvy Aviator, Inc.8643

EAA Chapter 393 (June 2008)Troubleshooting failureszzChapter 393A&Ps are often poor troubleshooterszThey are trained as therapists, not diagnosticianszMany aircraft problems cannot be reproduced in themaintenance hangarzIf a mechanic can’t reproduce a problem, he can’ttroubleshoot it systematically (so he has to guess)What’s the solution?zTroubleshoot the problem yourselfzConsult with an expert on the system in questionEAA Chapter 393 (June 2008)Copyright 2008 Savvy Aviator, Inc.Rule #5:87Chapter 393Don’t let your shopoverkill the problem!EAA Chapter 393 (June 2008)Copyright 2008 Savvy Aviator, Inc.Copyright 2008 Savvy Aviator, Inc.8844

EAA Chapter 393 (June 2008)Don’t overkill the problem!zChapter 393When your airplane has a problem and you’vediagnosed it properly, get it fixed but don’t gooverboard!zIf you have a cylinder with a burned exhaust valve,repair the valve, don’t replace the jugzIf you have one or two weak cylinders, don’t gettalked into doing a top overhaulzNo matter how many cylinders are bad, don’t eventhink about overhauling the engineEAA Chapter 393 (June 2008)Copyright 2008 Savvy Aviator, Inc.Review: The five rules89Chapter 3931.Choose the right shop and/or technician2.Require a written discrepancy list & estimate3.If it ain’t broke, don’t let them fix it4.Don’t fix it until you’re sure what’s wrong5.Don’t overkill the problemEAA Chapter 393 (June 2008)Copyright 2008 Savvy Aviator, Inc.Copyright 2008 Savvy Aviator, Inc.9045

EAA Chapter 393 (June 2008)Does this stuffreally work?Chapter 393You bet it does!Lots of good info atwww.savvymx.comEAA Chapter 393 (June 2008)Copyright 2008 Savvy Aviator, Inc.Copyright 2008 Savvy Aviator, Inc.9146

zWe call this a maintenance-induced failure (MIF) zThe more invasive the task, the more likely a MIF zPerforming unnecessary maintenance zWastes money and increases the risk of MIF zEliminating unnecessary maintenance zSaves money and improves safety and reliability Maintenance has