Transcription

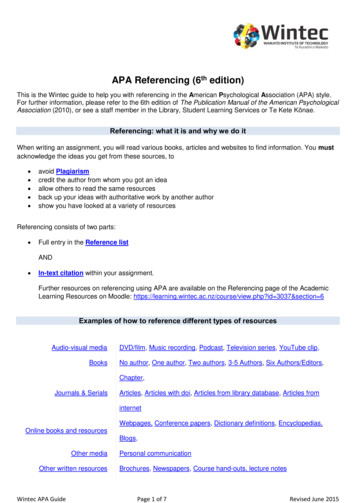

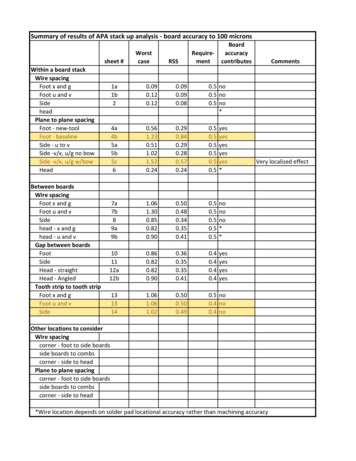

Summary of results of APA stack up analysis ‐ board accuracy to 100 micronssheet #Within a board stackWire spacingFoot x and gFoot u and vSideheadPlane to plane spacingFoot ‐ new‐toolFoot ‐ baselineSide ‐ u to vSide ‐v/x, u/g no bowSide ‐v/x, u/g w/bowHeadBetween boardsWire spacingFoot x and gFoot u and vSidehead ‐ x and ghead ‐ u and vGap between boardsFootSideHead ‐ straightHead ‐ AngledTooth strip to tooth stripFoot x and gFoot u and butes1a1b20.090.120.120.090.090.080.5 no0.5 no0.5 020.500.500.490.5 no0.4 no0.4 noCommentsVery localized effectOther locations to considerWire spacingcorner ‐ foot to side boardsside boards to combscorner ‐ side to headPlane to plane spacingcorner ‐ foot to side boardsside boards to combscorner ‐ side to head*Wire location depends on solder pad locational accuracy rather than machining accuracy

x and g wire spacing within a foot boardx and g wire spacingContributions to stack up in yDescriptionTooth strip groove to grooveTooth strip groove to grooveWorst Case wire to wireRSS wire to wireDWGtolerance Effect onor specposition /‐0.09 t0.0900.0900.090Effect onStack‐up wireTolerance spacing( /‐)( /‐)0.0900.053

u and v wire spacing within a foot boardu wire spacingContributions to stack up in yDescriptionTooth strip tooth to toothTotal y cont for one boardDWGtolerance Effect onor specposition /‐0.09 tEffect onStack‐up wireTolerance spacing( /‐)( /‐)0.0900.0730.073Contributions to stack up in xTooth strip tooth to toothTotal x cont for one boardTotal wire to wireRSS wire to wire /‐0.08 t0.0800.0470.0470.1200.087

u and v wire spacing within a side boardu wire spacingContributions to stack up in xDescriptionTooth strip tooth to toothTotal y cont for one boardDWGtolerance Effect onor specposition /‐0.09 tEffect onStack‐up wireTolerance spacing( /‐)( /‐)0.0900.0530.053Contributions to stack up in zTooth strip tooth to toothTotal x cont for one boardTotal wire to wireRSS wire to wire /‐0.08 t0.0800.0650.0650.1170.084

x,v,u,g foot board plane to plane spacing ‐ with proposed toolContributions to stack up in zDescriptionConcentricity of toolTool ODMin. clearancehole IDLocation of "shoulder"Height of tooth stripTotal for one boardWorst Case Plane to PlaneRSS Plane to PlaneDWGtolerance Effect onor specposition0.050 t/2 /‐0.025 t/20.000 c/4 /‐0.100 t/2 /‐0.1 t /‐0.09 tStack‐upTolerance( /‐)0.0250.0130.0000.0500.1000.0900.2780.560.292

x,v,u,g foot board plane to plane spacingContributions to stack up in zDWGStack‐uptolerance Effect on Toleranceor specposition ( /‐)Description*Hole position in tube0.250 t/20.13Tapped Hole pitch diameter /‐0.059 t/20.03Min screw radial clearance0.022 t/40.01Screw pitch diameter /‐0.045 t/20.02**Concentricity screw head (3%)0.240 t0.24Location of "shoulder" /‐0.100 t0.10Height of tooth strip /‐0.090 t0.09Total for one board0.61Worst Case Plane to Plane1.23RSS Plane to Plane0.836*Verified with TradeTech (frame vendor) via email**Screw thread standards for Federal services, 1944."heads shall be concentric within 3% of axis of body"

v,u side board plane to plane spacing ‐ does not include x to v or u to gContributions to stack up in zDescriptionPin ODMin clearanceHole IDLocation of "shoulder"Height of tooth stripTotal for one boardWorst Case Plane to PlaneRSS Plane to PlaneDWGtolerance Effect onor specposition /‐0.025 t/20.000 c/4 /‐0.100 t/2 /‐0.100 t /‐0.090 tStack‐upTolerance( /‐)0.0130.0000.0500.1000.0900.2530.5050.288

v to x and u to g plane to plane spacing ‐ this is a local effectContributions to stack up in z from u or v boardStack‐upDWGtolerance Effect on Toleranceor specposition ( /‐)Description*Hole position in tube0.250 t/20.125Tapped Hole pitch diameter /‐0.059 t/20.030Min screw radial clearance0.022 t/40.006Screw pitch diameter /‐0.045 t/20.023Screw major diameter tolerance /‐0.070 t/20.035Sleeve ID tolerance /‐.025 t/20.013Min screw radial clearance0.020 t/40.005sleeve concentricity0.025 t/20.013Pin OD /‐0.025 t/20.013Min clearance0.000 c/40.000Hole ID /‐0.100 t/20.050Location of "shoulder" /‐0.100 t0.100Height of tooth strip /‐0.090 t0.090Total for one board0.500Contributions to stack up in z from x or g foot board*Hole position in tube0.250 t/2Tapped Hole pitch diameter tol. /‐0.059 t/2Min screw radial clearance0.022 t/4Screw pitch diameter tol /‐0.045 t/2Tapped Hole pitch diameter tol. /‐0.059 t/2Min screw radial clearance0.022 t/4Screw pitch diameter tol /‐0.045 t/2Concentricity of tool0.050 t/2Tool OD /‐0.025 t/2Min. clearance0.000 c/4hole ID /‐0.100 t/2Location of "shoulder" /‐0.1 tHeight of tooth strip /‐0.09 tTotal for one boardWorst case for plane to plane for both boardsRSS Plane to Plane*Verified with TradeTech (frame vendor) via 0.0000.0500.1000.0900.5181.0180.281

v to x and u to g plane to plane spacing Including frame bow‐ very local effectBow tolerance is 11mm which translates to 0.5mm over one cell.Contributions to stack up in z from u or v boardDWGtolerance Effect onor specpositionDescription tBow in frame limit for one cell /‐0.5*Hole position in tube0.250 t/2Tapped Hole pitch diameter /‐0.059 t/2Min screw radial clearance0.022 t/4Screw pitch diameter /‐0.045 t/2Screw major diameter tolerance /‐0.070 t/2Sleeve ID tolerance /‐.025 t/2Min screw radial clearance0.020 t/4sleeve concentricity0.025 t/2Pin OD /‐0.025 t/2Min clearance0.000 c/4Hole ID /‐0.100 t/2Location of "shoulder" /‐0.100 tHeight of tooth strip /‐0.090 tTotal for one boardContributions to stack up in z from x or g foot board*Hole position in tube0.250 t/2Tapped Hole pitch diameter tol. /‐0.059 t/2Min screw radial clearance0.022 t/4Screw pitch diameter tol /‐0.045 t/2Tapped Hole pitch diameter tol. /‐0.059 t/2Min screw radial clearance0.022 t/4Screw pitch diameter tol /‐0.045 t/2Concentricity of tool0.050 t/2Tool OD /‐0.025 t/2Min. clearance0.000 c/4hole ID /‐0.100 t/2Location of "shoulder" /‐0.1 tHeight of tooth strip /‐0.09 tTotal for one boardWorst case for plane to plane for both boardsRSS Plane to Plane*Verified with TradeTech (frame vendor) via emailStack‐upTolerance( 020.0250.0130.0000.0500.1000.0900.5181.5180.574

Plane spacing between head boardsv wire spacingContributions to stack up in zDescriptionz board thicknessWorst case plane to planeRSS Plane to PlaneDWGtolerance Effect onor specposition0.240 tStack‐upTolerance( /‐)0.2400.2400.240

Wire spacing for x and g teeth across the gap on foot boardsx and g wire spacingContributions to stack up in yDWGtolerance Effect onor specpositionDescription*Hole position in tube0.250 t/2Tapped Hole pitch diameter tol. /‐0.059 t/2Min screw radial clearance0.022 t/4Screw pitch diameter tol /‐0.045 t/2Tapped Hole pitch diameter tol. /‐0.059 t/2Min screw radial clearance0.022 t/4Screw pitch diameter tol /‐0.045 t/2Concentricity of tool0.050 t/2Tool OD /‐0.025 t/2Min. clearance0.000 c/4hole ID /‐0.100 t/2Location of tooth /‐0.2 tTotal for one boardWorst case for tooth to tooth across gapRSS Plane to Plane*Verified with TradeTech (frame vendor) via emailStack‐upTolerance( 0.0000.0500.2000.5281.0550.497

Wire spacing between u and v teeth across the gap on foot boardsv wire spacingContributions to stack up in xDescriptionx board thicknessv board thicknessStrip datum to pinTotal x cont for one boardDWGtolerance Effect onor specposition0.150 t0.150 t0.080 tContributions to stack up in y*Hole position in tube0.250 t/2Tapped Hole pitch diameter tol. /‐0.059 t/2Min screw radial clearance0.022 t/4Screw pitch diameter tol /‐0.045 t/2Tapped Hole pitch diameter tol. /‐0.059 t/2Min screw radial clearance0.022 t/4Screw pitch diameter tol /‐0.045 t/2Concentricity of tool0.050 t/2Tool OD /‐0.025 t/2Min. clearance0.000 c/4hole ID /‐0.100 t/2Location of tooth /‐0.2 tTotal for one boardWorst case for tooth to tooth across gapRSS Plane to Plane*Verified with TradeTech (frame vendor) via emailEffect onStack‐up wireTolerance spacing( /‐)( 0.0410.1620.4281.3010.483

Wire spacing between u teeth across the gap on side boardsContributions to stack up in z from u or v boardDescriptionv board thicknessStrip datum to pinTotal x cont for one boardDWGtolerance Effect onor specposition0.150 t0.080 tContributions to stack up in x from u or v board*Hole position in tube0.250Tapped Hole pitch diameter /‐0.059Min screw radial clearance0.022Screw pitch diameter /‐0.045Screw major diameter tolerance /‐0.070Sleeve ID tolerance /‐.025Min screw radial clearance0.020sleeve concentricity0.025Pin OD /‐0.025Min clearance0.000Hole ID /‐0.100Location of "edge" /‐0.100Total for one boardTotal for two boardsRSS board to board t/2 t/2 t/4 t/2 t/2 t/2 t/4 t/2 t/2 c/4 t/2 tStack‐up Effect onTolerance wire( 0580.2390.8530.345

Solder pad spacing between x and g solder pads across the gap on head boardsContributions to stack up in y from g boardDWGtolerance Effect onor specpositionDescription*Hole position in tube0.250 t/2Tapped Hole pitch diameter /‐0.059 t/2Min screw radial clearance0.022 t/4Screw pitch diameter /‐0.045 t/2Screw major diameter tolerance /‐0.070 t/2Sleeve ID tolerance /‐.025 t/2Min screw radial clearance0.020 t/4sleeve concentricity0.025 t/2Pin OD /‐0.025 t/2Min clearance0.000 c/4Hole ID /‐0.100 t/2Location of "solder pad" /‐0.100 tTotal for one boardTotal for two boardsRSS board to boardStack‐upTolerance( 00.0500.1000.4100.8200.354

Solder pad spacing between u and v solder pads across the gap on head boardsContributions to stack up to perpendicular distance between solder padsDWGStack‐uptolerance Effect on Toleranceor specposition ( /‐)Description*Hole position in tube0.250 t/20.13Tapped Hole pitch diameter /‐0.059 t/20.03Min screw radial clearance0.022 t/40.01Screw pitch diameter /‐0.045 t/20.02Screw major diameter tolerance /‐0.070 t/20.035Sleeve ID tolerance /‐.025 t/20.013Min screw radial clearance0.020 t/40.005sleeve concentricity0.025 t/20.013Pin OD /‐0.025 t/20.013Min clearance0.000 c/40.000Hole ID /‐0.100 t/20.050Location of "pad" /‐0.141 t0.141Total for one board0.451Total for two boards0.9020.406

Gap between foot boardsContributions to stack up in yDWGtolerance Effect onor specpositionDescription*Hole position in tube0.250 t/2Tapped Hole pitch diameter tol. /‐0.059 t/2Min screw radial clearance0.022 t/4Screw pitch diameter tol /‐0.045 t/2Tapped Hole pitch diameter tol. /‐0.059 t/2Min screw radial clearance0.022 t/4Screw pitch diameter tol /‐0.045 t/2Concentricity of tool0.050 t/2Tool OD /‐0.025 t/2Min. clearance0.000 c/4hole ID /‐0.100 t/2Location of board edge /‐0.100 tTotal for one boardWorst case for tooth to tooth across gapRSS Plane to Plane*Verified with TradeTech (frame vendor) via emailStack‐upTolerance( 0.0000.0500.1000.4280.8550.356

Gap between side boardsContributions to stack up in z from u or v boardDWGtolerance Effect onor specpositionDescriptionContributions to stack up in x from u or v board*Hole position in tube0.250 t/2Tapped Hole pitch diameter /‐0.059 t/2Min screw radial clearance0.022 t/4Screw pitch diameter /‐0.045 t/2Screw major diameter tolerance /‐0.070 t/2Sleeve ID tolerance /‐.025 t/2Min screw radial clearance0.020 t/4sleeve concentricity0.025 t/2Pin OD /‐0.025 t/2Min clearance0.000 c/4Hole ID /‐0.100 t/2Location of "edge" /‐0.100 tTotal for one boardTotal for two boardsRSS board to boardStack‐upTolerance( 00.0500.1000.4100.8200.354

Gap between u and v head boardsContributions to stack up in y from v boardDWGtolerance Effect onor specpositionDescription*Hole position in tube0.250 t/2Tapped Hole pitch diameter /‐0.059 t/2Min screw radial clearance0.022 t/4Screw pitch diameter /‐0.045 t/2Screw major diameter tolerance /‐0.070 t/2Sleeve ID tolerance /‐.025 t/2Min screw radial clearance0.020 t/4sleeve concentricity0.025 t/2Pin OD /‐0.025 t/2Min clearance0.000 c/4Hole ID /‐0.100 t/2Location of "straight" edge /‐0.100 tTotal for one boardTotal for two boardsRSS board to boardStack‐upTolerance( 0.0000.0500.1000.4100.8200.354

Gap between angled surface of u and v head boardsContributions to stack up perpendicular to angled gapDWGtolerance Effect onor specpositionDescription*Hole position in tube0.250 t/2Tapped Hole pitch diameter /‐0.059 t/2Min screw radial clearance0.022 t/4Screw pitch diameter /‐0.045 t/2Screw major diameter tolerance /‐0.070 t/2Sleeve ID tolerance /‐.025 t/2Min screw radial clearance0.020 t/4sleeve concentricity0.025 t/2Pin OD /‐0.025 t/2Min clearance0.000 c/4Hole ID /‐0.100 t/2Location of "angled" edge /‐0.141 tTotal for one boardStack‐upTolerance( 00.0500.1410.4510.9020.406

Gap between foot tooth stripsContributions to stack up in yDWGtolerance Effect onor specpositionDescription*Hole position in tube0.250 t/2Tapped Hole pitch diameter tol. /‐0.059 t/2Min screw radial clearance0.022 t/4Screw pitch diameter tol /‐0.045 t/2Tapped Hole pitch diameter tol. /‐0.059 t/2Min screw radial clearance0.022 t/4Screw pitch diameter tol /‐0.045 t/2Concentricity of tool0.050 t/2Tool OD /‐0.025 t/2Min. clearance0.000 c/4hole ID /‐0.100 t/2Location of tooth edge /‐0.200 tTotal for one boardWorst case for tooth to tooth across gapRSS Plane to Plane*Verified with TradeTech (frame vendor) via emailStack‐upTolerance( 0.0000.0500.2000.5281.0550.497 Nominal gap is 0.5

Gap between side tooth stripsContributions to stack up in xDWGtolerance Effect onor specpositionDescription*Hole position in tube0.250 t/2Tapped Hole pitch diameter /‐0.059 t/2Min screw radial clearance0.022 t/4Screw pitch diameter /‐0.045 t/2Screw major diameter tolerance /‐0.070 t/2Sleeve ID tolerance /‐.025 t/2Min screw radial clearance0.020 t/4sleeve concentricity0.025 t/2Pin OD /‐0.025 t/2Min clearance0.000 c/4Hole ID /‐0.100 t/2Location of "edge" /‐0.200 tTotal for one stripTotal for two stripRSS strip to stripStack‐upTolerance( 00.0500.2000.5101.0200.495

Contributions to stack up in x Description DWG tolerance or spec Effect on position Stack‐up Tolerance ( /‐) Effect on wire spacing ( /‐) x board thickness 0.150 t 0.150 0.088 v board thickness 0.150 t 0.150 0.088 Strip datum to pin 0.080 t 0.080 0.047 Total x cont for one bo