Transcription

FMEA Dilemma andCountermeasuresGary Jing, PhDASQ World Conference – Session W06 – May 2, 2018

Learning Objectives This session is intended for experiencedpeople to discuss / exchange how to betterhandle the FMEA activities to get the bestout of it, by addressing challenges anddifficulties.– Interactions are encouraged & appreciated It’s not intended to teach basics tobeginners who have no experience.5/2/182018 WCQI W06 FMEA Gary Jing2

Agenda 5/2/18Speaker’s Connection to the TopicThe Challenges and DilemmaWhich Parts being DifficultTips to Deal With the DilemmaIntegration with Related ActivitiesAn Unique PracticeTakeawaysAppendix - More Discussions on Confusing Points2018 WCQI W06 FMEA Gary Jing3

Gary Jing’s BackgroundØ ASQ Fellow, MBA, PhD in IE, CQM / CQEØ Founding MBB @ Seagate TCO (1998 - 2005)Ø Sr. Mgr., Global LS / Founding MBB @ Entegris (2005 - 2009)Ø Global LSS Leader / MBB @ TE – ADC (2009 - 2015)Ø CI Director / MBB @ CommScope (2015 - Present)Ø US Delegation to ISO TC176 for ISO 9000 RevisionØ Editorial Review Board of Six Sigma Forum MagazineØ IQPC/PEX LSS Award Judge PanelØ Development of ASQ BB Certification Program (participant)Ø Delphi panel expert for SME/AME/Shingo Lean Certification ProgramØ Isixsigma DFSS Award (2011), Finalist of IQPC MBB of The Year (2008)Ø Two patents in disc drive modeling from his Sigma workØ Series publications on Lean SigmaØ More details on http://www.linkedin.com/in/ggaryjing.5/2/182018 WCQI W06 FMEA Gary Jing4

Foreword FMEA concept and practice can be appliedto almost anything. Most common ones are on design andproduction (process), which splits into:– Pre (production) release – easier to changedesign.– Post release – harder to change design.– Practice will be different b/w the 2 stages.– This session focuses on the Pre.5/2/182018 WCQI W06 FMEA Gary Jing5

Foreword The mechanism of FMEA is quitestraightforward, yet to do it well isn’t easy.So, what are the challenges?Gary Jing, FMEA Dilemma, Six Sigma Forum Magazine, May, 20145/2/182018 WCQI W06 FMEA Gary Jing6

What are the Biggest Challenges?Scenario 1: Cowboy under OSHA5/2/182018 WCQI W06 FMEA Gary Jing7

Example: Functions Identified for a Marker Cap20 “functions” identified.- Too much for FMEA.- Focus on NUD (new, unique,difficult) ones instead.5/2/182018 WCQI W06 FMEA Gary Jing8

A Fundamental Limitation of FMEA & RCAImpact / Return / RewardThe cost aspect needed for business decisionis usually not considered in FMEA (or lty / Effort / Cost5/2/182018 WCQI W06 FMEA Gary Jing9

What are the Biggest Challenges?Scenario 2: Everything is fine.5/2/182018 WCQI W06 FMEA Gary Jing10

So, What are the Biggest Challengesin doing FMEA?Effectiveness & Efficiency The quality of FMEA is hard to evaluate. No guaranty (or magic wand) 5/2/18With huge investment and no guaranty on results,people have the tendency to cut corner.2018 WCQI W06 FMEA Gary Jing11

Typical Ways to Boost FMEA Quality Experience- Ultimate pursuit Formality (& structure) - Less effective Right Focus- More effective Quantity- Trade efficiencyWill be elaborated in the remaining sections.5/2/182018 WCQI W06 FMEA Gary Jing12

Different Industries have Different Expectations onFMEA. More serious and formal in highly regulatedindustries– Medical Device, Aerospace, Automotive, etc.– Can be used as legal documents. Less formal in Telecom– Ad hoc in many cases. Less formal in Six Sigma activities– May be customized or use less formal form, e.g.Potential Problem Analysis (PPA).5/2/182018 WCQI W06 FMEA Gary Jing13

Agenda 5/2/18Speaker’s Connection to the TopicThe Challenges and DilemmaWhich Parts being DifficultTips to Deal With the DilemmaIntegration with Related ActivitiesAn Unique PracticeTakeawaysAppendix - More Discussions on Confusing Points2018 WCQI W06 FMEA Gary Jing14

Which Parts of FMEA are Difficult? Types of Failure Mode (FM) Types of Control– Prevention or Detection? Is it a Cause or Effect?– Cause – effect shifting Is it a process issue or design issue?– Some FMs may belong to both– Many process issues can be addressed by design Interaction between (sub-)structures (IBS)– IBS induced issues are hard to capture5/2/182018 WCQI W06 FMEA Gary Jing15

Which Parts of FMEA are Difficult? Types of Failure Mode (FM)– Failing to meet the specification Complete failureToo little (partial, uneven or not complete)Too much (over)IntermittentFailure over time– Incorrect or inappropriate requirements Wrong, missing, hidden, unstated, assumed)– Unintended use, application, or environment– Does harm to others5/2/182018 WCQI W06 FMEA Gary Jing16

Which Parts of FMEA are Difficult? Is it a Cause or Effect?– Chain of Causation– Cause–effect shiftingIs Electrical Fault aCause, FM or Effect?- It depends, on whatlevel you are looking at:- At car level, it’s acause;- At sub-assembly levelis a FM;- At component level,it’s an effect.5/2/182018 WCQI W06 FMEA Gary Jing17

Which Parts of FMEA are Difficult? Types of Control– Prevention or Detection?– One of most confusing items, hard to do it right.– Prevention: Focus on preventing failure to occur,affect Occurrence (O).– Detection: Focus on preventing effect to occur,affect Detection (D).– Different sets for design and process, no overlap.5/2/182018 WCQI W06 FMEA Gary Jing18

Prevention vs. Detection ControlsDFMEA Prevention Controls typically occur prior tofinalizing the design and reduce the risk offailures during Product Validation Testing- Engineering analysis and evaluation: Antioverstress feature- Tolerance Stack-Up or Statistical Analysis,- Finite Element Analysis Detection Controls detect the failure mode,typically during Product Validation testing,prior to releasing design for customer orders- Examples include Reliability testing andPerformance testing conducted as part ofproduct validation testing5/2/18PFMEA Prevention Controls occurprior to manufacturing theproduct- Equipment setuprequirements- Poka-yoke Detection Controls occurafter manufacturing theproduct but prior toshipping product tocustomers2018 WCQI W06 FMEA Gary Jing- Product testing- Inspection19

Agenda 5/2/18Speaker’s Connection to the TopicThe Challenges and DilemmaWhich Parts being DifficultTips to Deal With the DilemmaIntegration with Related ActivitiesAn Unique PracticeTakeawaysAppendix - More Discussions on Confusing Points2018 WCQI W06 FMEA Gary Jing20

PollAre all of the FMEA columns equally important?Options: Yes / NoWhich ones are most important?Options: RPN Detection Function Failure mode Action Others5/2/182018 WCQI W06 FMEA Gary Jing21

Tips on FMEA Efficiency & EffectivenessAre all of the FMEA columns equally important?Which ones are most important?1. The most important column in FMEA ispotential failure mode (concerns)– To identify potential failures as thoroughly &completely as possible.2. The 2nd most important is thecountermeasures (actions) identified– To keep risk of FMs at acceptable level.– Be conscious on cost.5/2/182018 WCQI W06 FMEA Gary Jing22

Tips on FMEA Efficiency & Effectiveness3. The 3rd is the risk priority number (RPN)– To assess the risk, establish priorities and guideresponses.– Always highly subjective due to lack of data.– Frequently mistaken as most important in FMEA.– AIAG is moving away from using it.4. Everything else is in supporting functions– To help make better informed decisions in theprocess.5/2/182018 WCQI W06 FMEA Gary Jing23

Redirect Team’s Brain Power to Boost FMEAEfficiency & EffectivenessFocusing team resource on NUD and thetop 2 most important columns can boostefficiency & effectiveness of FMEA. The top 2 most important columns (failuremode & countermeasures) can benefit fromteam the most. An experienced lead person or a smallsubset group can handle the rest well.5/2/182018 WCQI W06 FMEA Gary Jing24

Redirect Team’s Brain Power to Boost FMEAEfficiency & Effectiveness We can let the whole group focus onbrainstorming for the top 2, and let anexperienced lead person take care of therest along with a small sub team. Focusing on NUD (new, unique, difficult),easing on ECO (easy, common, old) items,can gain efficiency.5/2/182018 WCQI W06 FMEA Gary Jing25

Agenda 5/2/18Speaker’s Connection to the TopicThe Challenges and DilemmaWhich Parts being DifficultTips to Deal With the DilemmaIntegration with Related ActivitiesAn Unique PracticeTakeawaysAppendix - More Discussions on Confusing Points2018 WCQI W06 FMEA Gary Jing26

Integration with Related Activities How is FMEA activity connected withothers that have similar intent? e.g.– Six Sigma– Product Development Process (PDP)– Dynamic Control Plan (DCP) It’ll be much more effective & efficient ifsystematically integrate FMEA withactivities with similar intent.5/2/182018 WCQI W06 FMEA Gary Jing27

Integration with Related Activities Six Sigma connection– Lean Design for Six Sigma (LDFSS), e.g.– VOC / requirement management, e.g. Failing to meet requirements is a/the primarymode of failure. How to make sure you identified hidden /latent / implied requirements?à LDFSS VOC section.5/2/182018 WCQI W06 FMEA Gary Jing28

How is FMEA Integrated with Relevant Activities- Product Development Ws: Measurable Technical ique FeaturesWSVEasy to useSSWHATs for One-Time-Use Camera (VOC Input Data)VRegular 35 mm Camera performanceWWV11.05.0Can't mis-fire when Iput it away in mypocket or purse4.0Has to be durable ifI drop it12.0Low purchase price15.0Must fit in my shirtpocket2.0Want to takepictures in any light6.0Has to be reallyeasy to use14.0Easy to wind1.0Large view finderthat helps me getpictures centeredeasily10.0KKJKKFFFFFHFFHHHFFFFFHFFGF35A QXYHFFFGProcess orProduct Name:Prepared by:Responsible:FMEA Date (Orig) (Rev)A QXYGFGFFFXQ YAQXYHHHFFFFFFFFHHI don't want it tolook cheap7.0FFFFGFSpin DrawProcessA YXQFHHProcessStep/PartNumberAX Q YAG3.0FAG9.0FQ XYGH8.0FYX QHH13.0HHGGHas to take aminimum of 27H4A Q XYHas to be close tomy 35mm in picturequalityG2FHas to be light &easy to carryHStore BrandsFPrefer 35 mm formatG1Our Camera Co.AGGFGFuji0GHFHKonicaQXYAProcess/ProductFailure Modes and Effects Analysis(FMEA)A QXYHFIFFFKHHHHigh appearance ratingSimilar to 35Imin. of 27 picturesKCarrying mechanismKViewfinding indicator graphicsKCamera weightKLabel clarityKViewfinder AreaJ35 mm filmFEase of UseKBody contouringFKFlash powerFIFlash forceFKSnap forceIWinding forceKFlash re-charge timeJExternal dimensionsKSurface roughnessKUMCImpact force resistanceKMaximize part re-useSnap load resistanceCustomer ImportanceLow GraininessPictures can't be"washed out"Color Saturation16.0DensityClear PicturesLow GrainGood Image QualityVGeneral FeaturesImage QualityContrastOTU Camera ExampleDirection of ImprovementCustomerAssessmentAIAG is movingto this directionin joint effortwith VDA.AXFAY QPotential Failure EffectsSEVUndersized package, High SDpanel-hours lost2Potential Failure ModeFiber BreakoutsPotential CausesDirty SpinneretX YQQAYXFilament motion5OCCCurrent ControlsDETRPN9144Visual Detection of Wraps and8 broken Filaments2Visual Sight-glass8809144A XYQFFAFPolymer defectsYXQAX8QY2Fuzzball LightHow MuchTechnicalAssessmentOrganizational DifficultyQYAXKonicaFujiStore BrandsOur Camera .362929290Weighted ImportanceRelative ImportanceDFMEAConceptGenerationVOC /RequirementsPrototypeFunctional Architectural SchematicReam ofPaperLoad / StorePaperDesign Review(The important functions and flows)Increment andHold PaperDeliver andStore PaperJettedInkProcessDataInput DataInk LevelIndicationPick PaperDesign for Display InkLevelProcess/ProductFailure Modes and Effects Analysis(FMEA)Material flowJet InkPower flowInkStore InkSignal flowProcess orProduct Name:Vapors110/220V ACSupplyPowerRemove HeatHeatCaptureVaporFilter FlowHotGasesProcessStep/PartNumberFrom Dave Cutherall, Design Edge,Kristin Wood, Univ. of Texas,Kevin Otto, PDSS ConsultingSpin DrawProcessProcess MapCool airFunctional Analysis/ NUD-New,Unique, Difficult5/2/18Prepared by:Responsible:FMEA Date (Orig) (Rev)Potential Failure ModeFiber BreakoutsPotential Failure EffectsSEVUndersized package, High SDpanel-hours lost258Potential CausesDirty SpinneretFilament motionPolymer defectsOCCCurrent ControlsVisual Detection of Wraps and8 broken Filaments22Visual Sight-glassFuzzball LightDETRPN914488091440Pugh Analysis2018 WCQI W06 FMEA Gary JingPFMEA29

How is PFMEA Integrated with Relevant Activities- Post Production Release 5/2/182018 WCQI W06 FMEA Gary Jing30

Agenda 5/2/18Speaker’s Connection to the TopicThe Challenges and DilemmaWhich Parts being DifficultTips to Deal With the DilemmaIntegration with Related ActivitiesAn Unique PracticeTakeawaysAppendix - More Discussions on Confusing Points2018 WCQI W06 FMEA Gary Jing31

3-Day DFMA / FMEA Joint Event- An Unique Practice Addresses a host of manufacturing relatedconcerns together, including:Many of them––––––have similarDesign reviewintent in differentangles, to identifyDesign for “X”and eliminateModularity / part reuseproblems in thefuture, thus it’sLean manufacturing & assemblybetter to joinField installation & maintenanceforce.FMEA (Design, Process, Application) Typically done right after the 1st majorprototype acquired.5/2/182018 WCQI W06 FMEA Gary Jing32

Activities & Schedule of Joint EventPreEventStage 0Prep &Kick-offStage 1ReviewCurrentDesignStage 2Brainstorm /DocumentConcernsStage 3GenerateBetterSolutionDay 1MorningDay 1AfternoonDay 2MorningDay 2AfternoonDay 3MorningBreakout toConsolidateideas & reviewcountermeasuresBreakout aftQFD &FMEAVOCupdates,Teardownprototype,touch & feel.Whole teambrainstorm,prioritizeconcerns,Breakout todocumentconcerns onFMEA,quicklyassess risk.Multiplerounds ofideations ontop concernsBreakout toreview QFDStage 4Finalizing5/2/18Day 3Afternoon2018 WCQI W06 FMEA Gary JingFinalizeimprovements &FMEA33

Take-aways What are the constant struggles with FMEA?– Efficiency and effectiveness. The most important columns in FMEA are?– Failure Mode & Countermeasures (Actions). Everything else is in?– Secondary supporting role, to help making betterinformed decisions. Focusing the group resource on the?– Most important items can significantly improve theefficiency and effectiveness of FMEA.

Questions?Gary Jing - http://www.linkedin.com/in/ggaryjing

AppendixMore Discussions on Confusing Points

More Discussions on Confusing Points What’s the primary intent / ultimate goal ofFMEA?– To prevent future problems. Choices of actions should build around this goal.– Not for investigation / problem solving. FMEA format isn’t suited to show complicatedcause-effect relationships.– Additional or variation on goals are possible.5/2/182018 WCQI W06 FMEA Gary Jing37

More Discussions on Confusing Points What’s in the Scope– ASQ critical assumption for PFMEA All components coming into the process step aredefect-free. – Defective part out of scope.– My view Anything that may jeopardize your goal is inscope, incl. defective incoming material. Failures & solutions not limited to current design.– May lead to new design, components or process. If FMEA doesn’t lead to design change duringdevelopment stage, it’s not as effective as it can.5/2/182018 WCQI W06 FMEA Gary Jing38

More Discussions on Confusing Points Expectation / “standard” on outputs– There is no perfect FMEA or outputs for anysubjective analyses– Different people doing the same subjectiveanalysis will get different results Which is ok à Delphi Theory – Things willconverge through iterations.àUse your judgment to decide the best practicefor you.5/2/182018 WCQI W06 FMEA Gary Jing39

More Discussions on Confusing Points Could same FM have multiple effects withdifferent Severity (S), O and/or D?– Possible to any of them. A FM may have multiple causes and/or effects. A cause or effect may associate to multiple FMs.– To simplify the analysis, a popular practice is tofocus on the most server effect per FM. There is a chance to miss an effect with lowerseverity yet higher RPN. That’s a risk to take to trade for efficiency.5/2/182018 WCQI W06 FMEA Gary Jing40

More Discussions on Confusing Points Can recommended actions lower Severity?––––5/2/18A frequently debated item.Two schools of thought w/ opposite views.Ultimately what’s affected is Criticality SxO.More common to keep S unchanged, onlychange O, to keep things simple and avoidconfusing debate.2018 WCQI W06 FMEA Gary Jing41

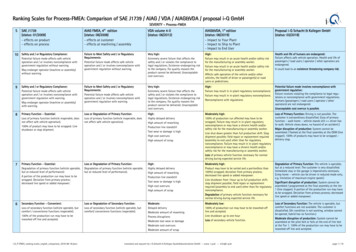

More Discussions on Confusing Points What training style / format is more effective– Standalone training w/ hypothetical example /exercise (e.g. ASQ)?– Learn through doing real projects? FMEA is evolving– AIAG joining VDA* is proposing dramatic changes Emphasize structural analysis (similar to LDFSS) Eliminate RPN– Industries will follow suit in the near future.* VDA - German Association of the Automotive Industry5/2/182018 WCQI W06 FMEA Gary Jing42

AIAG/VDA to Emphasize Structural AnalysisAIAG moving toward VDA practice.5/2/182018 WCQI W06 FMEA Gary Jing43

AIAG/VDA to Replace RPN by Action Priority (AP)Using more sophisticated Guidance Table to guide AP,replacing single threshold for RPN.5/2/182018 WCQI W06 FMEA Gary Jing44

FMEA Dilemma and Countermeasures Gary Jing, PhD ASQ World Conference –Session W06 –May 2, 2018. Learning Objectives This session is intended for experienced people to discuss / exchange how to b