Transcription

PFEP – Plan for Every PartIntroductionMarek Piatkowski – April 2012Marek.Piatkowski@rogers.com1

Introduction - Marek Piatkowski Professional Background Toyota Motor Manufacturing Canada (TMMC) - Cambridge,Ontario from 1987-1994 TPS/Lean Transformation Consulting - since 1994Professional Affiliations TWI Network – John Shook, Founder Lean Enterprise Institute (LEI) – Jim Womack Lean Enterprise Academy (LEA) – Daniel Jones LEI Poland – Tomasz Koch, PresidentLean Transformation Solutions, Toronto, om2

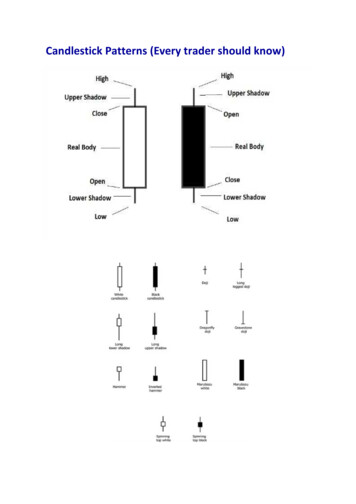

PN-150 PartNumberPart 04-220 BracketDescriptionFront End Sheet xt RidgeviewFront End Sheet MetalExt Ridgeview#1 Body BracketExt AcemcoPart's 1 Line #1 Used on # Parts / Kanban SystemWeight 2 Both Oper. # FrameRouting1.124x222201PN-150 Supplier1.1222201PN-150 Supplier1.422202PN-150 SupplierFU-31307BracketRHLower Control ArmExt Tecumseh4x43.112451PN-150 SupplierFU-31308BracketLHLower Control ArmExt Tecumseh4x43.112451PN-150 SupplierFU-31313*BracketRHFront ShockExt Metal Form N.4x42.912551PN-150 SupplierFU-31314*BracketLHFront ShockExt Metal Form N.4x42.912551PN-150 SupplierFU-31319-10* BracketRHFront Upper Control ArmExt Ridgeview4x41.312452PN-150 SupplierFU-31320*BracketLHRear Upper Control ArmExt Ridgeview4x41.112452PN-150 SupplierFU-31323-10 BracketRHFront Jounce BracketExt Tecumseh4x42.312801PN-150 SupplierFU-31324-10 BracketLHFront Jounce BracketExt Tecumseh4x42.312801PN-150 SupplierFU-31569*BracketRHEngine DifferentialExt Hamlin4x42.212551PN-150 SupplierFU-31570*BracketLHEngineExt Hamlin4x42.212551PN-150 SupplierFU-31595BracketRHT-Bar Sub-assemblyExt Tecumseh4x40.81201PN-150 SupplierFU-31596BracketFU-31599Reinforcement RHLHT-Bar Sub-assemblyExt Tecumseh4x40.81# 1 Cross BarExt Luitink4x40.91201PN-150 Supplier501PN-150 SupplierFU-31600Reinforcement LH# 1 Cross BarExt Luitink4x40.91501PN-150 SupplierFU-31601BracketRHLower Control ArmExt Tecumseh4x24.222401PN-150 SupplierFU-31602BracketLHLower Control ArmExt Tecumseh4x2FU-31603BracketCab Mounting RearExt Tower-UpperFU-31604BracketCab Mounting RearExt Tower-UpperFU-31605BracketUpper Control ArmExt Luitink4x2Ext Tecumseh4x2FU-31607Reinforcement RHLower Control Arm BracketFU-31608Reinforcement LHLower Control Arm BracketFU-31609BracketFU-316104.222401PN-150 SupplierSW & LW1.922202PN-150 SupplierSC1.922202PN-150 Supplier222404PN-150 Supplier1.5228514x2RHFront Jounce BracketExt Ridgeview4x2BracketLHFront JNCExt Ridgeview4x2FU-31639BracketRHTire StopExt RidgeviewFU-31640BracketLHTire StopExt RidgeviewFU-31641Reinforcement RHCenter Side Bar20.8820.8822501PN-150 Supplier2501PN-150 Supplier2301PN-150 Supplier2301PN-150 Supplier1.32Sub1PN-150 Supplier2Sub1PN-150 Supplier22551PN-150 SupplierCenter Side BarExt RidgeviewSWB1.3Center Side BarExt RidgeviewSC0.2PFEP is a data base created to gather and maintain information aboutall parts, components, supplies, WIP inventories, raw materials,finished goods and any other form of material used in your processes PFEP data base must have sorting capabilities.(Most common Excel and Access) It also can reside on your current ERP or MRP systemThis data base must be user friendly and accessible to read and abilityto print anywhere in your facilityPN-150 Supplier0.4SWBReinforcement LHReinforcement 10.4Ext RidgeviewFU-31642FU-31648What is Plan for Every Part (PFEP) ? Marek.Piatkowski@rogers.com3

Plan forEvery PartStep 1Establish a position of an Inventory Analyst Responsible for the PFEPThe only person that can modify PFEP systemMust be notified of any and all changes that are made to any partNeeds to maintain the PFEP on a common drive so that anyonethroughout the company can view the informationIf this position cannot be created assign this responsibility to anindividual in your Production Control departmentInventory Analyst must drive Inventory Policy Creates less inventory! ( purchased and finished goods)Produce what you need when you need it!Marek.Piatkowski@rogers.com4

Plan forEvery PartStep 1Inventory AnalystKey Points - ResponsibilitiesReasons1. Maintenance and control of max/minlevels, lead times, order quantities, reorder points, etc in SAP/MRP system1. To maintain and to keep all informationin the system up to date and to providefeedback to management2. Maintenance of BOM and Pick Lists2. Update information at least monthly3. Management of new and obsolete partsand components3. Add new parts and remove obsoleteonce from the system4. Plan-for-Every-Part (PFEP)4. Single source of information5. Introduction and maintenance of aKanban cards and system5. Kanban cars get lost and Kanban cardsmust be updated on regularr basis6. Inventory policies (levels, controls andmanagement)6. To review inventory information atmonthly Sales and Operations meetingsMarek.Piatkowski@rogers.com5

Plan forEvery PartStep 2Identify the Type of Parts in your PFEP Data Base Purchased Parts Finished GoodsMarek.Piatkowski@rogers.com6

Plan forEvery PartStep 3Start collecting Information for (PFEP) For every part, gather information related to: Part identification – part #, description, unique features Storage information – container type, pieces/container Transportation - what equipment needed to move partsDelivery – how frequently do we ship and deliverProduction capabilities – daily or hourly production ratesCustomer Requirements – forecast and actual shipmentsGroup every part into one of the three categories: Runners (A), Repeaters (B), or Strangers (C)Marek.Piatkowski@rogers.com7

Plan forEvery PartStep 3Establishing PFEP – How much detail? Part number Container type Description Length Daily usage Width Point of use location Height Storage location Weight Order frequency Standard pack quantity Supplier name Delivery frequency Supplier city CarrierSupplier country Transit time Marek.Piatkowski@rogers.com8

Plan forEvery PartStep 4PFEP – Information about the Part Purchased Parts12 345Finished Goods1Information about the PartPartDescription2345Part NameModel /ColorInformation about the Part Part numberPart NumberSupplier PartNumber Customer PartNumber17227751722775ValveFLAT VALVELHFU-31301*1722775BracketLower Control ArmGray1710786917107869ClipSILVER CLIPSRHPart NameModel /ColorPart NumberCustomerPart NumberPartDescriptionFU-31302*17107869BracketLower Control ArmBlue Part Description1710950317109503SpringCPC SPRINGSLHFU-31304-22017109503ReinforcementFront ShockGray Part Name1712407517124075AssemblySRHVL AssyRHFU-3130717124075ReinforcementFront ShockBlack Model/Color2410000524100005BodySRHVL BODYLHFU-3130824100005BracketFront Upper Control Blue2512351825123518PlungerSRHVL PlungerRHFU-31313*25123518BracketRear Upper Control 71BracketFront BracketGray2517623525176235ValveFLAT VALVERHFU-31319-10*25176235BracketFront BracketBlack2517623525176235ClipSILVER CLIPSLHFU-31320*25176235BracketEngine DifferentialBlue2517623525176235ClipGOLD 25176236SpringSAT. SPRINGLHFU-31324-1025176236BracketUpper Control ArmGrayMarek.Piatkowski@rogers.com9

Plan forEvery PartStep 5PFEP – Information about the ContainerPurchased Parts and/or Finished Goods 7891011121314151617Information about the Packaging Container Container TypeContainer TypeStandardContainerQuantityUnit ofMeasure Standard ContainerQuantityCradboard BoxYESPieces Unit of MeasureQuantity ns andweightQuantity per rtFullContainerWeight in ContainerWeight in KGKGWeight in KGContainerLength inCmContainerContainerWidth in Cm Height in 444434.4010066141.5Cradboard erMarek.Piatkowski@rogers.com10

Plan forEvery PartStep 6PFEP – Shipping Information Purchased Parts and/or Finished Goods19202122232425MinShipmentSizeNumber ofPieces per MinShipmentInspectionRequired?Shipping Information Order Frequency Lead Times Carrier Shipment Frequency Min Shipment Size Number of piecesper Shipment Is InspectionRequired ?DeliveryOrderTransportation ShipmentLead Time FrequencyCarrierFrequencyDaysBradley ExpressWeeklyBox50NO7FedEx2 / WeekPallet2,880NO1Bradley ExpressWeeklyBox400NODaily12 / WeekDailyDaily1Bradley ExpressWeeklyBox25NO1 / ool500YESDaily1Bradley ExpressWeeklyBox300NODaily1Bradley ExpressWeeklyBox50NO2 / Week5UPS2 / WeekPallet2,000NO2 / Week5UPS2 / WeekPallet2,000NODaily1Bradley ExpressBox200NODailyMarek.Piatkowski@rogers.com11

Plan forEvery PartStep 7Developing the PFEP PlanOnce you populate the data base you can start planning Develop delivery plans or production plans based on standardContainer sizes Identify inventory re-order points and quantities Identify re-order frequencies Implement standardized parts and components delivery methods Identify inventory levels required at each machine and work station Identify inventory levels at each storage location and Supermarket Define and minimize Standard Pack QuantitiesMarek.Piatkowski@rogers.com12

Plan forEvery PartStep 7Size of ContainersIdentify if each container is “Line Ready” – YES or NO Small box, easy to liftLess than 12 KG (30 lbs)Marek.Piatkowski@rogers.com13

Plan forEvery PartStep 7 Does the part needrepacking? Or the container isLine Ready?Marek.Piatkowski@rogers.com14

Plan forEvery PartStep 7 Should we starttalking to ourSupplier aboutdelivering parts inLine Readycontainers?Marek.Piatkowski@rogers.com15

Plan forEvery PartStep 7 Why do wespending so muchmoney on packagingby Suppliers whenwe do not use it anddo not need it?Marek.Piatkowski@rogers.com16

Plan forEvery PartStep 8A B C – Analysis of all Current Parts Are all current parts in the Data Base active? When was the last time some of these parts were used? Which ones are obsolete or not-active?Number of CodesNumber of CodesNumber of ActiveCodes – 35%Number ofNot-Active Codes – 65%Number of Codesused in last 4 Months– 20%Number of Codes NOTused in last 4 Months– 80%Marek.Piatkowski@rogers.com17

Plan forEvery PartStep 10PFEP - Keys to Success Controlled maintenance of a single databaseEstablished system to provide data for updatesUse database that has sorting capabilitiesLoad data in smallest element possible (container size should be threedifferent entries-length, width and height)Marek.Piatkowski@rogers.com18

Lean Transformation SolutionsThis presentation is an intellectual property of F.S.P. Consulting Inc.No parts of this presentation can be copied or reproducedwithout a written permission from:Marek PiatkowskiF.S.P. Consulting Inc.iPhone: 416-235-2631Cell: work.comMarek.Piatkowski@rogers.com19

01.09.2012 · (Most common Excel and Access) . Maintenance of BOM and Pick Lists 3. Management of new and obsolete parts and components 4. Plan-for-Every-Part (PFEP) 5. Introduction and maintenance of a Kanban cards and system 6. Inventory policies (levels, controls and management) Inventory Analyst . 6 Marek.Piatkowski@rogers.com Identify the Type of Parts in your PFEP Data Base Finished Goods