Transcription

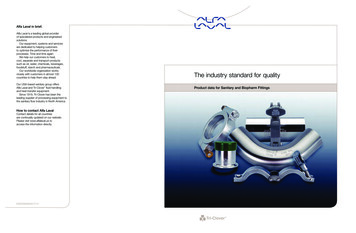

Alfa Laval in brief.Alfa Laval is a leading global providerof specialized products and engineeredsolutions.Our equipment, systems and servicesare dedicated to helping customersto optimize the performance of theirprocesses. Time and time again.We help our customers to heat,cool, separate and transport productssuch as oil, water, chemicals, beverages,foodstuff, starch and pharmaceuticals.Our worldwide organization worksclosely with customers in almost 100countries to help them stay ahead.Our USA-based sanitary group offersAlfa Laval and Tri-Clover fluid handlingand heat transfer equipment.Since 1919, Tri-Clover has been theleading supplier of processing equipment tothe sanitary flow industry in North America. The industry standard for qualityProduct data for Sanitary and Biopharm FittingsHow to contact Alfa LavalContact details for all countriesare continually updated on our website.Please visit www.alfalaval.us toaccess the information directly.ESE00584ENUS 071020852 Omslag 435x279.indd 103/10/07 11:39:32

The industry standardFor over 80 years, you’ve relied on Tri-Clover fittings, including theproven Tri-Clamp and Tri-Weld . Whether your application is in theFood, Beverage, Brewery, Dairy or Biopharm industry, the fittingsyou’ve come to know and trust meet today’s strict sanitary and qualitystandards and ensure increased productivity and controlled costs.Our 54,000 square-foot distribution center inIndianapolis, Indiana provides a centralizedsource for your fittings shipments and allowsfor efficiencies in picking, packing andshipping your order.Since 1919, Tri-Clover has beenNorth America’s leading source ofsanitary fluid handling equipment.Our Inside Sales Department iscomprised of talented individuals withyears of expertise. They will handleyour needs quickly and efficiently.Tri-Clover fittingscatalog circa 1947.20852 Omslag 435x279.indd 203/10/07 11:39:36

1. FittingsAlfa Laval constantly focuses on producing installation material with long durability,problem-free welding and assembly, and highest possible strength.Product Presentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1.0Sanitary Fittings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1.1BioPharm Fittings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1.2Bevel Seat Fittings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1.3Other Fittings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1.4Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1.5

Connection TypesClamp FittingsA Connection is made up of a plain ferrule, a clamp, anda gasket. Tees, elbows and reducers are available withTri-Clamp connections. All three styles are in compliancewith 3A standards for Clean In Place (CIP). The three typesof clamp fittings are designed for use in food, dairy,pharmaceutical and chemical Industries.Everything you need,everywhere you need itAlfa Laval is a world-leading supplier of fittings for a wide range of sanitary applicationswithin the food, dairy, beverage, bio-pharmand personal care industries. Our productsare developed not only to meet your exactingdemands for safety, reliability, efficiency andhygiene, but also to ensure the careful handlingof your products.One of the features that distinguishesus from our competitors is our breadth ofapplication. We can supply components forall stages of your process – besides fittings,our sanitary range includes pumps, valves, tankequipment and heat exchangers. As a worldwide supplier, Alfa Laval can accommodateyour ISO, SMS, SWG, DS, BS, DIN and JISinternational Fittings standards (upon request). Tri-Clamp connections are the industry standard, havingnueter-style ferrules to simplify design and installation. H-Line and HDI-Line male/female ferrules self-align duringtightening so joints are quick and easy to assemble ortake apart. H-Line uses the same series of clamps as the Tri-Clamp.Threaded FittingsA connection is made up of a plain ferrules, a threaded ferrule,a nut and a gasket. The faces on Bevel Seat fittings are angledto create a metal to metal sealing surface. A John Perry fittingconsistes of a flat-faced threaded ferrule, a flat-faced plainferrule and a profiled gasket. These joints are particularly usefulwith swing connections and flow diverter panels. A DC fittingutilizes the Bevel Seat plain ferrule and a threaded ferrule witha grooved face to retain a gasket. The three types of threadedfittings are designed for use in the food, dairy, and beverageprocessing industries. Bevel Seat Joints are in compliance with3A standards for manual cleaning. Both John Perry and DCfittings are in compliance with 3A standards for CIP.This brochure includes the following Alfa Lavalline of high-quality sanitary fittings: Unions, Tri-Clamp Fittings & Flanges Bends, Tees & Reducers Tubing Butterfly ValvesFor more detailed technical information andspecifications of our products, please refer tothe relevant product sheet provided by yourlocal Alfa Laval supplier, or to our website,www.alfalaval.usTri-Clamp - The industry standard.

Alfa Laval’s program of bends,tees and reducers are available indiameters from 1" to 6" in size.Bends, Tees & ReducersAlfa Laval constantly focuses on producing fittings with longdurability, problem-free welding and assembly, and highestpossible strength. Key criteria in the manufacturing processinclude tight tolerances, a variety of finishes and uniform wallthickness.WeldingAlfa Laval is aware of the constantly increasing demandsplaced upon the quality of welding. In accordance with thesedemands, all our reducers meet the highest of standards.The reducers have cylindrical welding ends and are availablefor all tube combinations, ensuring that you will always get theright diameter and wall thickness for your process.TolerancesAlfa Laval ensures that all the angles are exact and that allthe tube, bend and tee connections are uniform. It is veryimportant that our customers do not have to compensate forany welding irregularities.FinishesAlfa Laval offers a range of mechanical polish as well aselectropolishing finishes. Mechanical polishing is achieved byusing a progressive series of abrasives, from low to high grit.This allows a consistent internal finish and both optimal andeconomical cleaning. Electropolishing is a further process thatpromotes a chromium-enriched surface layer that maximizescorrosion resistance as well as minimizing bacterial buildup onsurface cavities.In order to ensure that you are able to select a finish thatexactly matches your needs, Alfa Laval offers a wide rangeof surface finishes.The Right Partfor Your ApplicationAlfa Laval offers installation materialin different standards so you canalways find the right part, with theprocess quality you need, for yourspecific application.SanitaryManufactured to the 3A sanitarystandard, all product surfaces arepolished to 32 microinch Ra orbetter. Tri-Clover’s number 3 and 7finishes also meet 3A standards.Bio-PharmaceuticalBio-Pharmaceutical products aremanufactured to the BPE standard.Available in four finishes, PC and PLhave a contact surface finish of 20microinch Ra. PD and PM are electropolished finishes with a contactsurface finish of 15 microinch Ra.

TubingAlfa Laval offers a variety of tubing for all sanitary applications.It is available in a full line of sizes and finishes and ismanufactured to stringent specifications for perfectmatching with Tri-Weld fittings. Common source for fittings raw material and finishes tubing Compliant with ASME, BPE, ASTM A269/A270 and 3A,where applicable Sizes are available from stock are 1/2 inch to 6 inchWhatever your sanitary application,Alfa Laval is able to supply the right tube.

The industry standard for quality.Bio-Pharmaceutical FittingsAlfa Laval is proud to present their line of fittings designed foruse in the pharmaceutical and bio-technologies industries.This line consists of parts with either Tri-Weld ends suitable foruse with orbital welding equipment or self-aligning Tri-Clampend connections. Alfa Laval offers a full line of bio-pharmfittings that are manufactured in compliance with the ASMEBPE standards.MetallurgyIncoming raw material goes through a stringent inspectionprocess to ensure its chemistry will be ideal for both weldingand electropolishing.Quality Control MethodsOur manufacturing facilities operate under an ISO 9001approved quality standard. Wall thickness integrity ismaintained through the use of fabrication grade minimum walltubing for all cold-formed tubular products. Our BPE fittingsare designed for use with all current orbital welding equipment.After cold forming, our tube product is resized to ensurethat the ovality falls within the prescribed BPE tolerances.End facing is provided with a machined square-cut method.This allows for the most accurate and consistent orbital weldresult. All fittings are put through 100% visual inspectionand ovality and squareness tolerances are inspected withcalibrated equipment. Surface finish is inspected with acalibrated profilometer to ensure the Roughness average(Ra) maximum is not exceeded.Material Test ReportsEvery new bio-pharmaceutical Tri-Clover fitting will include aMaterial Test Report (MTR). As a new Alfa Laval standard,BPE fittings will be shipped with an MTR in the bag. This newMTR has a five letter Reference ID that takes traceability andvalidation to a new level. The Reference ID is stenciled onall fittings and together the heat numbers, part number,description, manufacturing reference number, and datemanufactured. This information along with the chemistry,mechanical properties, and raw material specification willbe listed on the MTR’s.As another key benefit, the Reference ID can be used to lookup fitting information on the internet. This new MTR webapplication will give 24/7 access to distributors and customersvia www.alfalaval.us

Product PresentationFittings from Alfa Laval - Tri-Clover1.0.ky In all forms and shapeskyFittings from Alfa Laval - Tri-CloverApplicationAlfa Laval is your complete source for specialized fittings and tubingrequired in food, dairy, beverage, personal care, biotechnology andpharmaceutical process applications. Smooth, crevice-free interiorsand secure, self-aligning joints are characteristic of Alfa Laval Fittings.Each offers superior corrosion resistance and unmatched servicelife. Alfa Laval fittings are designed and manufactured to ensuredimensional accuracy and structural integrity, making them easy toinstall. Tri-Clover Tri-Clamp and Tri-Weld Fittings are part of AlfaLaval’s product line. Tubing is manufactured to Alfa Laval’s stringentspecifications, making it a perfect match for the Weld Fittings. Choosefrom a complete range of tube sizes, surface finishes and connectionoptions. All BPE items are individually capped and bagged in clear6 mil. Poly bags. All product is labeled with a bar code, productinformation and manufacturing date. This provides the optimumidentification and ensures that the product arrives to the job site in aclean orbital weld condition.BioPharm FittingsAlfa Laval is proud to present their line of Fittings designed for usein the Pharmaceutical and Bio-Technologies Industries. This lineconsists of Tri-Clover parts with either Tri-Weld ends suitable foruse with Orbital Welding Equipment or self-aligning Tri-Clamp endconnections. Alfa Laval offers a full line of BioPharm Fittings that aremanufactured in compliance with the current ASME BPE Standard.All BPE items are individually capped and bagged in clear 6 mil. Poly.bags. All product is labeled with a bar code, product informationand manufacturing date. This provides the optimum identificationand ensures that the product arrives to the job site in a clean orbitalweld condition.Technical DataWide Range of Surface Finish offering - Alfa Laval offers a rangeof Mechanical Polish as well as Electropolish finishes. Mechanicalpolishing is achieved by using a progressive series of abrasives, fromlow to high grit. This allows a consistent internal finish and both optimaland economical cleaning. Electropolishing is a further process thatpromotes a chromium-enriched surface layer that maximizes corrosionresistance as well as minimizing bacterial buildup on surface cavities.Metallurgy - Incoming raw material goes through a stringent inspectionprocess to ensure its chemistry will be ideal for both weldability andelectropolishingQuality Control Methods - Our manufacturing facilities operate underan approved ISO 9001 quality standard. Wall thickness integrity ismaintained through the use of fabrication grade minimum wall tubingfor all cold-formed tubular products. Our BPE fittings are designedfor use with all current orbital welding equipment. After cold forming,our tube product is resized to ensure that the ovality falls within theprescribed BPE tolerances. End facing is provided with a machinedsquare-cut method. This allows for the most accurate and consistentorbital weld result. All fittings are put through 100% visual inspectionand ovality and squareness tolerances are inspected with calibratedequipment. Surface finish is inspected with a calibrated profilometer toensure the Roughness average (Ra) maximum is not exceeded.Sanitary fittings identified with this symbol on the following pages areaccepted as meeting the 3A sanitary standards by the appropriatecommittees of the International Association of Milk, Food andEnvironmental Sanitarians, U.S. Public Health Service, and DairyIndustry Committee.1.0.9

Product PresentationFittings from Alfa Laval - Tri-Clover1.0.ID or Product Contact SurfaceMaximum Surface Roughness (Ra)Finish code Microinches Micrometers ASME BPEPolishing Method(µ-inch)(µm)Finish Code#1Unpolished#3320.8----Mechanical polished#7320.8----Mechanical polishedPC200.5SFF1Mechanical polishedPD150.4SFF4Mechanical polished and electropolishedPL200.5SFF1Mechanical polishedPM150.4SFF4Mechanical polished and electropolishedOD or Product Non-contact SurfaceUnpolishedUnpolishedPolished to Ra, 32 µ-inch/0.8 µmUnpolishedUnpolishedPolished to Ra, 32 µ-inch/0.8 µmPolished to Ra, 32 µ-inch/0.8 µmService Rating of Tri-Clamp ConnectionsSize Tube OD13MHLAat 70 Fat 250 F13MHHMat 70 Fat 250 F13MHHSat 70 Fat 250 F13MHPat 70 Fat 250 FA13MOat 70 Fat 250 FA13MHMat 70 Fat 250 FService Ratings* (PSI)2 inch2½ inch3 inch(Screw tightened to maximum)150150150150125125125125(Wing nut tightened to 25 in. lb. of torque)500450400350300300200195(Wing nut tightened to 25 in. lb. of torque)600550450350300275225175(Bolts tightened to 20 ft. lb. of torque)15001000100010001200800800800(1-3" nuts tightened to 20 in. lb., 4" to 30 in. lb.)500350300200250200150100(Wing nut tightened to 25 in. lb. of torque)500450400350300250200175½ & ¾ inch1 & 1½ inch----22001200-------4 inch6 755030015015075* Service ratings are based on hydrostatic tests using standard-molded Buna-N material gaskets, with proper installation of ferrules, assembly of jointsand absence of shock pressure. Contact Tri-Clover for service of other type and material gaskets, and for ratings at higher temperatures.All ratings shown are dependent upon related components within the systems and proper installation. For temperatures above 250 F, we recommendusing only 13MHP clamps. This information is only valid if Tri-Clover clamps, ferrules, and gaskets are used.Tri-Clamp Gasket MaterialsCharacteristicOriginal Physical PropertiesHardness, Shore ATensile Strength, psiElongation, %Temperature RangeResistanceAcid ResistanceAlkali ResistanceResistance to Fats/OilsAbrasion ResistanceCompression Set ResistanceBuna-N (U)EPDM (E)Fluoro- elastomer (SFY)Silicone (X)PTFE (G)701875340701650317701212272701340260--------65 to 200 F-60 to 300 F-20 to 350 F-40 to 400 F-40 to 200 F *GoodFair to GoodGood to Excel.ExcellentGoodGood to Excel.Good to Excel.PoorGoodFairGood to Excel.Poor to GoodGood to Excel.Good to Excel.Good to Excel.Poor to GoodPoor to FairPoor to GoodPoorGood to Excel.Good to Excel.ExcellentExcellentFairCold Flows* Note: PTFE materials tendency to "cold flow" and incompressibility, limit its max. temperature to 200 F due to possible leaking problems.1.0.10

Fittings from Alfa Laval - Tri-CloverProduct Presentation1.0Basic Dimensions of Tri-Clamp OD Outer Diameter (Inches)½¾11½22½34Connection for Sanitary OD-TubingWall Thickness (Inches/Gauge)ID Inner Diameter (Inches)0.065 / 16 ga.0.370.065 / 16 ga.0.620.065 / 16 ga.0.870.065 / 16 ga.1.370.065 / 16 ga.1.870.065 / 16 ga.2.370.065 / 16 ga.2.870.083 / 14 ga.3.87A Ferrule Face nitary Tube InformationTube ODTube ight DryGal/100 bs/100 eight withWaterLbs/100 1Flow (GPM) at a Mean Velocity5 fps1.74.79.32343691011804097417 fps2.36.613326096141252573103810 fps3.49.41946861382023608181482Technical InformationPipe Schedule and Chemical edule 5 PipeOD InchesID 56.4078.6258.407Wall l Composition 14.02.0-3.0* The sulfur content for 316L ASME BPE fittings is 0.005-0.017% forall weld ends.1.0.11

Fittings from Alfa Laval - Tri-CloverProduct Presentation1.0Material Test Reports (MTRs)Easy Online Access to Comprehensive Fittings InformationGo to www.alfalaval.us and follow these simple steps to access MTRs:Step 1. Once at our website, click on the MTR linkA 5-alpha character serial ID is stenciled on to each new 316SS fittingAs one of the most comprehensive and technologically advancedreports in the market, our new Material Test Reports (MTRs) providedetailed information that takes traceability and validation to a new level.Alfa Laval has established a new standard as all MTRs are available 24hours a day, 7 days a week online at www.alfalaval.us.Step 2. On the MTR page, click "View Material Test ReportsSimply type a 5-alpha character code (e.g. AAABC) called the serialID, which you can find stenciled on each new 316SS fitting, to accessthe following information: All heat certification numbers used to manufacture the fittingDate the fitting was manufacturedThe fitting’s part number and descriptionView and print any MTR and the above informationThis web site will even allow you to print the MTR or original heatcertification from the raw material supplier. If you do not know theactual number, MTRs can be searched by either MTR serial ID or heatcertification number.Step 3. Enter or search for the Serial ID1.0.12

Fittings from Alfa Laval - Tri-CloverProduct Presentation1.0Connection TypesClamp FittingsTri-ClampHDI-LineH-LineA connection is made up of a plain ferrule, a clamp, and a gasket. Tees, elbows and reducers are available with Tri-Clamp connections. All three stylesare in compliance with 3A standards for C.I.P. (clean in place). The three types of clamp fittings are designed for use in Food, Dairy, Pharmaceuticaland Chemical Industries. Tri-Clamp connections are the industry standard, having nueter-style ferrules to simplify design and installation.H-Line and HDI-Line male/female ferrules self-align during tightening so joints are quick and easy to assemble or take apart.H-Line uses the same series of clamps as the Tri-Clamp.Threaded FittingsBevel SeatJohn PerryDCA connection is made up of a plain ferrules, a threaded ferrule, a nut and a gasket. The faces on Bevel Seat fittings are angled to create a metal to metalsealing surface. A John Perry fitting consistes of a flat-faced threaded ferrule, a flat-faced plain ferrule and a profiled gasket. These joints are particularlyuseful with swing connections and flow diverter panels. A DC fitting utilizes the Bevel Seat plain ferrule and a threaded ferrule with a grooved face toretain a gasket. The three types of threaded fittings are designed for use in the Food, Dairy, and Beverage processing industries. Bevel Seat Joints are incompliance with 3A standards for manual cleaning. Both John Perry and DC fittings are in compliance with 3A standards for C.I.P. (clean-in-place). Bevel Seat John Perry DC1.0.13

Product PresentationFittings from Alfa Laval - Tri-Clover1.0Loss of head pressure due to friction. Loss is shownin feet of head. Loss through tubing is for 1ft.of tubeCapacityin .1050.1350.170.210.250.340.570.851.18NOTES: 1. For elbows - R/D 1.53. Test medium - water at 70 20.420.540.670.810.951.102. Flow thru teesFlow A to BPort C capped offPrepared by members of the sanitary pump subgroupof the natl. assn. of dairy equipment " I.D.1.402" I.D.1.870" I.D.2.370" I.D.2.870" I.D.3.834"Tubing Elbow Tee Tubing Elbow Tee Tubing Elbow Tee Tubing Elbow Tee Tubing Elbow Tee Tubing Elbow 84.45.05.76.37.08.6

1.1 Sanitary FittingsThe Tri-Clover sanitary installation material in this section is with dimensions accordingto ASME BPE.Price SheetsSanitary Tri-Clamp Elbows . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Sanitary Tri-Clamp Tees . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Sanitary Tri-Clamp Reducing Tees . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Sanitary Tri-Clamp Crosses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Sanitary Tri-Clamp Clamp Ferrule . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Sanitary Tri-Clamps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Sanitary Tri-Clamp Gaskets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Sanitary Tri-Clamp Adapters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Sanitary Tri-Clamp Thermometer Caps and Solid End Caps . . . . . . . . . . . .Sanitary Tri-Clamp Reducers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Sanitary Tri-Weld Bends . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Sanitary Tri-Weld Tees . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Sanitary Tri-Weld Reducing Tees . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Sanitary Tri-Weld Crosses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Sanitary Tri-Weld Adapters and End Caps . . . . . . . . . . . . . . . . . . . . . . . . . .Sanitary Tri-Weld Reducers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1.301.1.311.1.321.1.351.1.361.1.391.1.401.1.41

Sanitary Tri-Clamp ElbowsSanitary Fittings1.1Tri-Clover SanitaryFinish: OD/ID Ra 0.8Product code: 5010/AAMaterialMaterialItem 9634-0029199634-002920Not availableItem 127.0168.32FMP-14 Plain Bevel Seat 90 Elbow- #7 FMP-15 Threaded Bevel Seat 90 Elbow - #7 ableavailable2x2x2½ .0127.0Not availableNot 6ABInchmmB2CMP - #7 (3A)2CMP-31MP - #7 (3A)11½222½350.8 x50.8 x63.5 x76.2 x76.2 x101.6 0.869.988.988.9108.0130.2B2KMP - #7 (3A)Not availableNot 1189634-0031199634-003120Not 425.428.636.544.552.460.379.4133.4* Not AvailableNote: 3A approved for finish #7Fittings part number starting with "B" are produced according to ASME BPE dimensions.1.1.16

Sanitary FittingsSanitary Tri-Clamp Tees1.1Tri-Clover SanitaryFinish: OD/ID Ra 0.8Product code: 5030/AAMaterialMaterialSizeItem 9634-0033199634-003320Not availableItem 181.0181.0B7MP - #7 (3A)Note: 3A approved for finish #7Fittings part number starting with "B" are produced according to ASME BPE dimensions.1.1.17

Sanitary Tri-Clamp Reducing TeesSanitary Fittings1.1Tri-Clover SanitaryFinish: OD/ID Ra 0.8Product code: 5030/AAMaterialMaterialSizeItem 038469634-003847Item 0038949634-003895DN/ODNot availableNot 6340500529634050055Inch2x12 x 1½2½ x 23x23 x 2½4x14 x 1½4x24 x 8 x 25.450.8 x 38.163.5 x 50.876.2 x 50.876.2 x 63.5101.6 x 25.4101.6 x 38.1101.6 x 50.8101.6 x 63.5101.6 x 76.2152.4 x 12.7152.4 x 19.0152.4 x 25.4152.4 x 38.1152.4 x 50.8152.4 x 63.5152.4 x 76.2152.4 x 81.0181.0181.0181.0Note: 3A approved for finish #7Fittings part number starting with "B" are produced according to ASME BPE dimensions.1.1.18BB7RMP - #7 S Short Outlet Reducing Tee - #7 .33.7595.33.7595.3

Sanitary FittingsSanitary Tri-Clamp Crosses1.1Tri-Clover SanitaryFinish: OD/ID Ra 0.8Product code: 5030/AAMaterialMaterialSizeItem 9634-0035199634-003520Item .884.75mm66.773.085.792.198.4120.7B9MP - #7 (3A)Note: 3A approved for finish #7Fittings part number starting with "B" are produced according to ASME BPE dimensions.1.1.19

Sanitary Tri-Clamp Clamp FerruleSanitary Fittings1.1Tri-Clover SanitaryFinish: OD/ID Ra 0.8Product code: 5058/AAMaterialMaterialItem No.304240606241605242605243605244606245596Item ODInchmm125.41½38.1250.82½63.5376.24101.6Not availableNot 628.628.628.628.628.6DimensionBInchmmCInchmmL14AM - #7 (3A)14WMPS - #7 .43.5890.04.69 119.16.58 167.16.58 538.138.138.144.514WMO - #114WLMP - #7 (3A)3.0076.23.0076.23.0076.23.0076.24.00 101.64.00 101.6Note: 3A approved for finish #71 3A approved for modify

manufactured in compliance with the current ASME BPE Standard. All BPE items are individually capped and bagged in clear 6 mil. Poly bags. All product is labeled with a bar code, product information and manufacturing date. This provides the optimum identification and ensures that the pr