![Hardness Tests [3]](/img/2/lmcm2-aula3.jpg)

Transcription

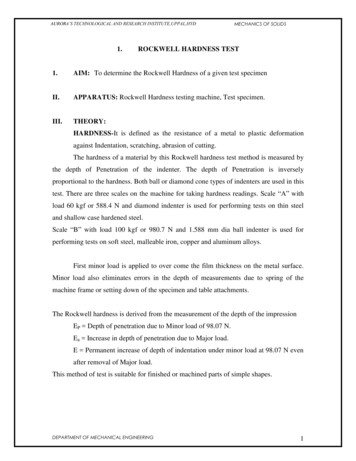

Hardness Tests [3]¾ HARDNESS: the resistance of a material to deformation,particularly permanent deformation, indentation, or scratching.¾ DISCUSSION: Different methods of evaluating hardness give differentratings because they are measuring somewhat different quantities andcharacteristics of the material. There is no absolute scale for hardness;therefore, to express hardness quantitatively, each type of test has itsown scale of arbitrarily defined hardness.(after ASTM E6).¾ Ranges of 2N F 30kN2N F, h 0.2μmh 0.2μmF – forceh – depthnon-destructive test (NDT)1

Mohs Hardness TestThe Mohs scale of mineral hardness is a qualitative ordinal scale thatcharacterizes the scratch resistance of various minerals through the ability ofa harder material to scratch a softer material. It was created in 1812 by theGerman geologist and mineralogist Friedrich Mohs (1773-1839).Mineral12after Wikipedia clasefeldsparKAlSi3O87QuartzSiO28TopazAl2SiO4(OH ,F CaCO34FluoriteCaF25ApatiteCa5(PO4)3(OH ,Cl ,F )2

Mohs Hardness Testafter Gilman (2009)3

Brinell Hardness Test¾ The Brinell Hardness characterizes the indentation hardness of materialsthrough the scale of penetration of an indenter, loaded on a material test-piece.It is one of several definitions of hardness in materials science. Proposed bySwedish engineer Johan August Brinell (1849-1925) in 1900, it was the firstwidely used and standardized hardness test in engineering and metallurgy.F 3000kgfD 10mmhardenedsteel ballsampleJ. A. Brinell4

Brinell Hardness Test¾ Brinell/Vickers durometer:¾ Selectable loadfrom 1 to 187,5kgf¾ hard metal / steel balls1; 2.5; 5 and 10mm diameter¾ optical micrometer¾ procedure: ASTM E105

Brinell Hardness Test¾ Calculation of Brinell Hardness HBW:HBW 2 Fπ D (D D d )22where:F test force in kgf,D diameter of the indenter ball in mm, andd measured mean diameter of the indentation in mm.¾ The Brinell hardness test is not recommended formaterials above 650 HBW.¾ Applied force dwell time: 10 to 15 seconds.after ASTM E10 (2015)6

Brinell Hardness Test¾ Applied force according to ASTM E10:Force-Diameter ratio (F/D2)D 5187.562.531.2515.6256.251301052,51ABCDEA: steels and iron alloys;B: heat treated Cu/Al light alloys;C: no heat treated Cu/Al light alloys;D-E: soft metallic materials.7

Brinell Hardness Test¾ Deformed zone near Brinell indentation:Top viewTransverse view¾ Indentation size: 0.24 D d 0.6 D¾ Sample thickness 10 times the depth of penetration, h.¾ Minimum distance between indentations must be 3 times d.after Herrman (2011)8

Brinell Hardness Test¾ Expressing results according to ASTM E10:220 HBW¾ Brinell hardness of 220 determined with a ball of 10 mm diameterand with a test force of 29.42 kN (3000 kgf) applied for 10 s to 15 s;350 HBW 5/750¾ Brinell hardness of 350 determined with a ball of 5 mm diameter andwith a test force of 7.355 kN (750 kgf) applied for 10 s to 15 s;600 HBW 1/30/20¾ Brinell hardness of 600 determined with a ball of 1 mm diameterand with a test force of 294.2 N (30 kgf) applied for 20 s;after ASTM E10 (2015)9

Rockwell Hardness Test¾ Hugh M. Rockwell (1890–1957) and Stanley P. Rockwell (1886–1940) coInvented in 1914 the "Rockwell hardness tester“, a differential-depth machine.Stanley contributed to develop and commercialize in 1924 his standardizedtesting machines manufactured by Wilson Mechanical Instrument Company.Hardness-testing machinePatent US 1516207 A(1924)H. M. RockwellS. P. Rockwellafter Wikipedia (2016)10

Rockwell Hardness Test¾ Principle:After ASTM E1811

Rockwell Hardness Test¾ Types of indenters:Hard metal ball indenters1/16”; 1/8”; 1/4” and 1/2”After ASTM E18diamond spheroconical indenter120 ; 0.2mm radius of curvature(Brale indenter)12

Rockwell Hardness Test¾ Rockwell Hardness Scales:¾ Brale indenter¾ Ball indenterAfter ASTM E18hRockwell Hardness 100 0.002hRockwell Hardness 130 0.002¾ Dwell time: 5-10 seconds13

Rockwell Hardness Testing Machine14

Rockwell Hardness Test¾ Deformed zone near Rockwell indentation (HRC):Top viewTransverse view¾ Sample thickness 10 times the depth of penetration, h.¾ Minimum distance between indentations must be 3 times d.after Herrman (2011)15

Rockwell Hardness Test¾ Expressing results according to ASTM E18:64 HRC¾ Rockwell hardness number of 64 on Rockwell C scale using aBrale indenter with a total force test of 150 kgf.72 HRBW¾ Rockwell hardness number of 72 on the Rockwell B scaleusing a 1/16” tungsten carbide ball indenter (1.588-mm) with atotal force test of 100 kgf.53 HRFS¾ Rockwell hardness number of 53 on the Rockwell F scaleusing a 1/16” hardened steel ball indenter (1.588-mm) with atotal force test of 60 kgf.after ASTM E18 (2015)16

Vickers Hardness Test¾ The Vickers hardness test was developed in 1921 by Robert L. Smith andGeorge E. Sandland at Vickers Ltd as an alternative to the Brinell method tomeasure the hardness of materials. The Vickers test has a great advantageof using one hardness scale to test all materials.after Wikipedia (2016)17

Vickers Hardness Test¾ Brinell/Vickers durometer:¾ Selectable loadfrom 1 to 187,5kgf¾ pyramidal indenter¾ optical micrometer¾ procedure: ASTM E38418

Vickers Hardness Test¾ Calculation of Vickers Hardness HV:FHV 1.8544 2dwhere:F test force in kgf,d measured mean diagonal of the indentation in mm.¾ Vickers hardness testing is divided into 2 ranges:microhardness: 1 F 1000 gfmacrohardness: 1 F 120 kgf¾ Applied force dwell time: 10 to 15 seconds.after ASTM E384 (2011)19

Vickers Hardness Test¾ Deformed zone near Vickers indentation:Top viewTransverse view¾ Sample thickness 10 times the depth of penetration, h.¾ Minimum distance between indentations must be 3 times d.after Herrman (2011)20

Vickers Hardness Test¾ Expressing HV results according to ASTM E384:250 HV 1¾ Vickers hardness number of 250 kgf/mm2 using a force test of 1 kgfduring 10 to 15 seconds.510 HV 10/30¾ Vickers hardness number of 510 kgf/mm2 using a force test of 10 kgfduring 30 seconds.after ASTM E384 (2011)21

Knoop Hardness Test¾ The test was developed by Frederick Knoop and colleagues at theNational Bureau of Standards (now NIST) of the USA in 1939.¾ Calculation of Knoop Hardness HK:FHK 14.229 2dwhere:F test force in kgf,d length of long diagonal of the indentation in mm.¾ Knoop hardness testing is usually applied in microhardness range: 1 F 1000 gf¾ Applied force dwell time: 10 to 15 seconds.after ASTM E384 (2011)22

Knoop Hardness Test¾ Expressing HK results according to ASTM E384:250 HK 0.1¾ Knoop hardness number of 250 kgf/mm2 using a force test of 0.1 kgf(100 gf) during 10 to 15 seconds.510 HK 0.5/30¾ Knoop hardness number of 510 kgf/mm2 using a force test of 0.5 kgf(500 gf) during 30 seconds.after ASTM E384 (2011)23

Examples of IndentationHBWHVHRCHK24

Standard Hardness Conversion Tables for Metals¾ ASTM E140: Approximate hardness conversionafter ASTM E140 (2012)25

Standard Hardness Conversion Tables for Metals¾ ASTM E140: Approximate hardness conversionafter ASTM E140 (2012)26

Standard Hardness Conversion Tables for Metals¾ ASTM E140: HARDNESS CONVERSION EQUATIONS FORNON-AUSTENITIC STEELS there are similar equations for austenitic steels, Ni alloys, Cu alloys, and Al alloys.after ASTM E140 (2012)27

References¾ https://en.wikipedia.org/wiki/Mohs scale of mineral hardness¾ Gilman, J. J. Chemistry and Physics of Mechanical Hardness. John Wiley & Sons,Inc., New Jersey, 2009. (ISBN 978-0-470-22652-0)¾ Herrman, K. Hardness Testing: Principles and Applications. ASM International,Materials Park, 2011. (ISBN 0-61503-832-9)¾ ASTM International. ASTM E10: Standard Test Method for Brinell Hardness ofMetallic Materials. West Conshohocken, 2015.¾ https://en.wikipedia.org/wiki/Rockwell scale¾ ASTM International. ASTM E18: Standard Test Methods for RockwellHardness ofMetallic Materials. West Conshohocken, 2015.¾ Chinn, R. E. Hardness, Bearings, and The Rockwells. Advanced Materials &Processes, October, pp. 29-31, 2009.¾ https://en.wikipedia.org/wiki/Vickers hardness test¾ ASTM International. ASTM E384: Standard Test Method for Knoop and VickersHardness of Materials. West Conshohocken, 2011.¾ http://www.buehler.com/China/eClub/vol1 issue6.pdf¾ ASTM International. ASTM E140: ASTM E140 - Standard Hardness ConversionTables for Metals Relationship Among Brinell Hardness, Vickers Hardness, RockwellHardness, Superficial Hardness, Knoop Hardness, Scleroscope Hardness, and LeebHardness. West Conshohocken, 2012.¾ Metals Handbook, ASM. Mechanical Testing and Evaluation, volume 8.ASM, 9th edition, 1981.Notas de aula preparadas pelo Prof. Juno Gallego para a disciplina Lab. Materiais de Construção Mecânica II. 2016. Permitida a impressão e al/28

Knoop Hardness Test after ASTM E384 (2011) 22 ¾The test was developed by Frederick Knoop and colleagues at the National Bureau of Standards (now NIST) of the USA in 1939. ¾Calculation of Knoop Hardness HK: 2 14.229 d F HK where: F test force in kgf, d length of long diagonal of the indentation in mm. ¾Knoop hardness testing is usually applied in micro-