Transcription

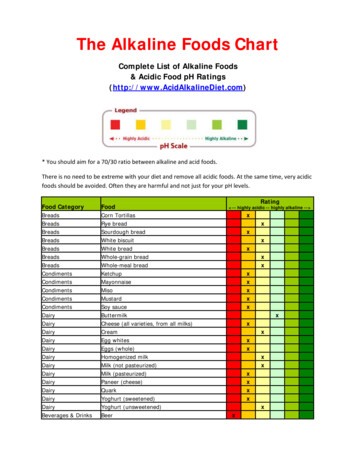

PROCESSING OF FOODSPROCESSINGRAW PRODUCTPROCESSPROCESSEDPRODUCTMichael Ngadi, PhD., P.Eng.Bioresource Engineering DepartmentMcGill UniversityFOOD PROCESSINGOPERATIONSPROCESSING OF FOODPRIMARY PROCESSING:Food Processing is the conversion ofagricultural product to consumablesubstances which have particulartextural, sensory and nutritionalproperties using commercially feasiblemethodsSECONDARY PROCESSING:- conversion of raw materialsto food commodities- conversion of ingredients intoedible productsEg: milling, chilling, drying,etc.- this involves combining foodsin a particular way to changeproperties.Eg: processed meats, dairyproducts, beverages andalcoholic drinks, food packaging,baking, freezing, dehydratingcanning and bottling.1

WHY PROCESS?FOOD PRODUCTSProducts may be made by several processes. Interactionsbetween product and processes differ. to convert to edible products to preserve to extend availability and provide accessibility to provide variety and choice to provide convenience to add valueTYPICAL FOOD PROCESSESSeveral steps are required to manufacture food products.The specific details of each may differ, but the basicprinciples are the same.Source ingredientsFillings addedDelivery of ingredientsFinish appliedStorage of ingredients(hoppers, bins, etc.)CookedStarch productsa. Breadb. Cakes and biscuitsc. Pastad. Rice productse. Corn productsOil productsa. Margarineb. low fat spreads)Mixture shaped orformed – extrusion,cutting, rolling, etc.StoredPackaged and labeledDistributionMeat productsa. Products from cattleb. Products from pigs Fish products Milk products Chocolate manufacture DrinksUNIT OPERATIONSUnique steps oroperations takento prepare foodproductsCooledWeigh and mixingredients - formulation These operationscan stand alone Material HandlingCleaningSeparatingSize reductionFluid FlowMixingHeat ling2

TERMS Process Design:the design of food processesand manufacturing methods, including processflowsheets, design of processing and controlequipment, and economic evaluation of theprocess. Plant Design:the design of whole processingplant, including the processing/control equipment,the utilities, the plant buildings, and the wastetreatment units.PROCESS FLOWSHEETSProcess flowsheets are graphicalrepresentations of the layout and flow ofequipment and materials in the plant.PBD: Process block diagramPFD: Process flowsheet diagramPCD: Process control diagramPID: Piping and instrumentation diagram3

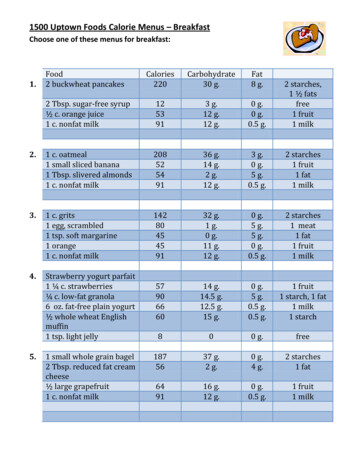

Energy accounting (processblock) diagram of tomatopaste manufacturing basedon an 8 hour shift4

GOOD MANUFACTURINGPRACTICES (GMPs)GMPs are a combination of manufacturing andmanagement practices aimed at ensuring that foodproducts are consistently produced to meet specificationsand customer expectations.GMPs requirements related to the design and layout offood plants include: Single-floor versus multistory buildings Land space for future expansion Waste disposal Building details (drainage, doors, lighting, ventilation,plumbing)FOOD SAFETY PROGRAMSAND HACCP Conduct a hazard analysis (biological, chemical, and physical) Determine the Critical Control Points (CCPs) Establish a critical limits for each CCP Establish a system to monitor each CCP Establish the corrective action to be taken when monitoring indicatesthat a particular CCP is not under control Establish procedures for verification to confirm that the HACCPsystem is working effectively Establish documentation concerning all procedures and recordappropriate to these principles and their application5

representations of the layout and flow of equipment and materials in the plant. PBD: Process block diagram PFD: Process flowsheet diagram PCD: Process control diagram PID: Piping and instrumentation diagram. 4 Energy accounting (p