Transcription

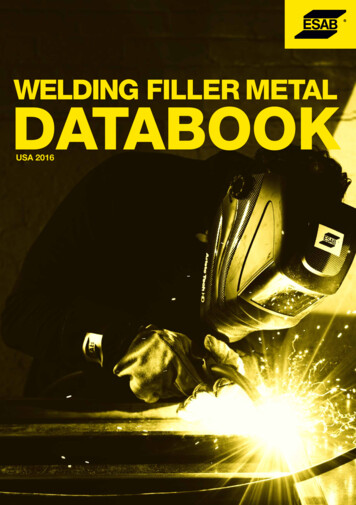

WELDING FILLER METALDATABOOKUSA 2016

WELDING FILLER METAL DATABOOKTABLE OF CONTENTSCOVERED (STICK) ELECTRODES (SMAW).1-1MIG/MAG WIRES (GMAW).2-1TIG RODS (GTAW).3-1CORED WIRE (FCAW) (MCAW).4-1SUBMERGED ARC WIRES AND FLUXES (SAW).5-1FILLER METAL CALCULATIONS.6-1FILLER METAL RECOMMENDATIONS FOR WELDING ASTM STEELS.7-1esab.comI

Covered (Stick) Electrodes (SMAW)

COVERED (STICK) ELECTRODES (SMAW)TABLE OF CONTENTSCOVERED (STICK) ELECTRODES (SMAW). 1-4MILD STEEL ELECTRODES. 1-4Sureweld 10P. 1-6Sureweld 10P Plus. 1-7Sureweld 710P. 1-8Sureweld 6010. 1-9Sureweld 6011. 1-10Sureweld 6013. 1-11Sureweld 7014. 1-12Sureweld 7024. 1-13LOW HYDROGEN ELECTRODES.1-16Atom Arc 7018. 1-17Atom Arc 7018 Acclaim. 1-18Atom Arc 7018-1. 1-19Atom Arc 7018-SR. 1-20Atom Arc 7018-B2L. 1-21Atom Arc 7018-Mo. 1-22Atom Arc 8018. 1-23Atom Arc 8018-B3L. 1-24Atom Arc 8018-B6. 1-25Atom Arc 8018-B6L. 1-26Atom Arc 8018-B8. 1-27Atom Arc 8018-CM. 1-28Atom Arc 8018-C1. 1-29Atom Arc 8018-SR. 1-30Atom Arc 8018-N . 1-31Atom Arc 9015-B9. 1-32Atom Arc 9018. 1-33Atom Arc 9018-B9. 1-34Atom Arc 9018-CM. 1-35Atom Arc 9018-SR. 1-36Atom Arc 10018. 1-37Atom Arc 10018-M1. 1-38Atom Arc 10018-MM. 1-39Atom Arc 12018. 1-40Atom Arc 12018-M2. 1-41Atom Arc 4340 . 1-42Atom Arc T. 1-431-2esab.com

COVERED (STICK) ELECTRODES (SMAW)TABLE OF CONTENTSSTAINLESS STEEL ELECTRODES.1-46Arcaloy 308L-15. 1-48Arcaloy 308L-16. 1-48Arcaloy 308/308H-16. 1-49Arcaloy 309L-15. 1-49Arcaloy 309L-16. 1-50Arcaloy 309/309H-16. 1-50Arcaloy 316LF5-15. 1-51Arcaloy 316LF5-16. 1-51Arcaloy 316/316H-16. 1-52Cryoarc 316L-15. 1-53OK 61.25. 1-54OK 61.81. 1-55OK 61.85. 1-56OK 67.13. 1-57OK 67.43. 1-58OK 67.45. 1-59OK 67.50. 1-60OK 67.55. 1-61OK 67.70. 1-62OK 68.17. 1-63OK 68.53. 1-64OK 68.81. 1-65NICKEL STEEL ELECTRODES.1-66OK Ni-1. 1-66OK NiCu 1. 1-67OK NiCu-7. 1-68OK NiCrFe-2. 1-69OK NiCrFe-3. 1-70OK NiCrMo-3. 1-71OK NiCrMo-5. 1-72OK NiCrMo-13. 1-73OK 92.55. 1-74HARDFACING ELECTRODES.1-75WEAR-ARC 4 IP. 1-75WEAR-ARC 6 IP. 1-75REPAIR AND MAINTENANCE.1-76CAST IRON ALLOYS.1-76OK Ni-CI. 1-76OK NiFe-CI-A. 1-77OK NiFe-CI. 1-78esab.com1-3

COVERED (STICK) ELECTRODES (SMAW)MILD STEEL ELECTRODESELECTRODE SELECTIONThe following points should be considered when selecting the proper coated electrode:1.Match the mechanical properties of the base metal.2.Match the chemical composition of the base metal as closely as possible.3.Match electrode to available power supply — AC or DCEN (electrode negative) or DCEP(electrode positive).4.Match the electrode to the position of the weld.5.Observe joint design — use deep penetrating electrodes for tight fit-up and unbeveled joints.Use light penetration electrodes for poor fit-up and thin material.6.Observe service conditions and select electrode accordingly — high temperature, lowtemperature, corrosive atmosphere, impact loading. These conditions are best met by usinglow hydrogen electrodes.7.Consider welding costs — highest deposition rate is in the flat position. Use high iron powderelectrodes to further increase deposition. By far, the largest factor is labor and overhead.1-4esab.com

COVERED (STICK) ELECTRODES (SMAW)MILD STEEL ELECTRODESAWS CLASSIFICATION FOR STEEL COVERED ELECTRODESEXX YY - XX-H4-RElectrodeMinimum UTS in KSIor X 1000 for PSIMoisture resistant coatingWelding PositionmL H2/100 gms(1) All Position (F, V, OH)(2) Flat and Horizontal(3) Flat OnlyUsability of the electrode, typeof current and type of coveringChemical compositionof weld depositesab.com1-5

COVERED (STICK) ELECTRODES (SMAW)MILD STEEL ELECTRODESSureweld 10P The red coated Sureweld 10P is an all-position cellulosic electrode developed for the pipe welding industry in order toimprove ductility in the weld deposit while maintaining the standard welding characteristics needed for a pipe weldingelectrode. Sureweld 10P produces a steady, deep penetrating arc and maintains the proper keyhole in an open root.This electrode will produce X-ray quality joints in flat, horizontal, overhead, vertical-up, and vertical-down procedures.Sureweld 10P is recommended for welding API grades A25, A, B and X42 pipe and general structural, ship, barge andstorage tank fabrication. It may also be used for welding root passes in higher grade pipe in some circumstances.Classifications:AWS A5.1:E6010, ASME SFA 5.1Approvals:ABS AWS A5.1: E6010Industry or Segmentation:Pipeline, Industrial and General Fabrication, Civil ConstructionApprovals are based on factory location. Please contact ESAB for more information.Typical Tensile PropertiesConditionYield StrengthTensile StrengthElongationAs Welded465 MPa (67 ksi)550 MPa (79 ksi)29 %Typical Charpy V-Notch PropertiesConditionTesting TemperatureImpact ValueAs Welded-18 C (0 F)37 J (27 ft-lb)As Welded-29 C (-20 F)30 J (22 ft-lb)Typical Weld Metal Analysis %CMnSiSP0.120.300.200.020.01DiameterOptimal AmpsAmpsDeposition RateEfficiency (%)2.4 mm (3/32 in.)75 A40-75 A0.7 kg/h (1.5 lb/h)72 %3.2 mm (1/8 in.)100 A80-140 A0.9 kg/h (2.1 lb/h)76.3 %3.2 mm (1/8 in.)130 A80-140 A1 kg/h (2.3 lb/h)68.8 %4.0 mm (5/32 in.)140 A130-175 A1.3 kg/h (2.8 lb/h)73.6 %4.0 mm (5/32 in.)170 A130-175 A1.3 kg/h (2.9 lb/h)64.1 %4.8 mm (3/16 in.)160 A150-210 A1.5 kg/h (3.3 lb/h)74.9 %4.8 mm (3/16 in.)190 A150-210 A1.6 kg/h (3.5 lb/h)69.7 %Deposition Data1-6esab.com

COVERED (STICK) ELECTRODES (SMAW)MILD STEEL ELECTRODESSureweld 10P Plus Sureweld 10P Plus is a modified version of the standard 10P electrode and can be differentiated by its gray coating.It has also been developed for the pipe welding industry but has a more consistent burn-off and a more forgiving arcburn. This provides a better bead profile and sidewall fusion with lower spatter. Sureweld 10P Plus will maintain theproper keyhole in an open root and will produce X-ray quality joints in the flat, horizontal, overhead, vertical-up, andvertical-down procedures. Sureweld 10P Plus is recommended for welding API grades A25, A, B and X42 pipe andgeneral structural, ship, barge and storage tank fabrication. It may also be used for welding root passes in highergrade pipe in some circumstances.Classifications:AWS A5.1:E6010, ASME SFA 5.1Approvals:CWB CSA W48, ABS AWS A5.1: E6010Industry or Segmentation:Pipeline, Industrial and General Fabrication, Civil ConstructionApprovals are based on factory location. Please contact ESAB for more information.Typical Tensile PropertiesConditionYield StrengthTensile StrengthElongationAs Welded503 MPa (72.9 ksi)599 MPa (86.9 ksi)25 %Typical Charpy V-Notch PropertiesConditionTesting TemperatureImpact ValueAs Welded-29 C (-20 F)45 J (33 ft-lb)Typical Weld Metal Analysis %CMnSiSP0.150.600.200.010.01DiameterOptimal AmpsAmpsDeposition RateEfficiency (%)2.4 mm (3/32 in.)75 A40-75 A0.7 kg/h (1.5 lb/h)72 %3.2 mm (1/8 in.)100 A80-140 A0.9 kg/h (2.1 lb/h)76.3 %3.2 mm (1/8 in.)130 A80-140 A1 kg/h (2.3 lb/h)68.8 %4.0 mm (5/32 in.)140 A130-175 A1.3 kg/h (2.8 lb/h)73.6 %4.0 mm (5/32 in.)170 A130-175 A1.3 kg/h (2.9 lb/h)64.1 %4.8 mm (3/16 in.)160 A150-210 A1.5 kg/h (3.3 lb/h)74.9 %4.8 mm (3/16 in.)190 A150-210 A1.6 kg/h (3.5 lb/h)69.7 %Deposition Dataesab.com1-7

COVERED (STICK) ELECTRODES (SMAW)MILD STEEL ELECTRODESSureweld 710P Sureweld 710P is an all-position cellulosic electrode that is especially suited for welding high strength pipe. It producesthe consistent, deep penetration required to maintain a proper keyhole when vertical-down welding in open root pipejoints. X-ray quality joints can be produced with Sureweld 710P using flat, horizontal, overhead, vertical-up andvertical-down welding procedures. Sureweld 710P is recommended for welding API grades X46, X52, and X56 pipe.It may also be used for welding root passes in higher grade pipe in some circumstances.Classifications:AWS A5.5:E7010-P1, ASME SFA 5.5Approvals:Conforms to E7010-GIndustry or Segmentation:Industrial and General Fabrication, PipelineApprovals are based on factory location. Please contact ESAB for more information.Typical Tensile PropertiesConditionYield StrengthTensile StrengthElongationAs Welded480 MPa (69 ksi)560 MPa (81 ksi)22 %Typical Charpy V-Notch PropertiesConditionTesting TemperatureImpact ValueAs Welded-29 C (-20 F)39 J (29 ft-lb)As Welded-46 C (-50 F)35 J (26 ft-lb)Typical Weld Metal Analysis %CMnSiSPNiMo0.100.300.200.020.010.500.24Deposition DataDiameterOptimal AmpsAmpsDeposition RateEfficiency (%)2.4 mm (3/32 in.)75 A40-75 A0.7 kg/h (1.5 lb/h)72 %3.2 mm (1/8 in.)100 A80-140 A0.9 kg/h (2.1 lb/h)76.3 %3.2 mm (1/8 in.)130 A80-140 A1 kg/h (2.3 lb/h)68.8 %4.0 mm (5/32 in.)140 A130-175 A1.3 kg/h (2.8 lb/h)73.6 %4.0 mm (5/32 in.)170 A130-175 A1.3 kg/h (2.9 lb/h)64.1 %4.8 mm (3/16 in.)160 A150-210 A1.5 kg/h (3.3 lb/h)74.9 %4.8 mm (3/16 in.)190 A150-210 A1.6 kg/h (3.5 lb/h)69.7 %1-8esab.com

COVERED (STICK) ELECTRODES (SMAW)MILD STEEL ELECTRODESSureweld 6010 Sureweld 6010 is an all-position, quick solidifying cellulosic type electrode with minimal spatter and excellent arc control.It offers deep penetration and easy removal of slag which allows single and multiple pass welds of x-ray quality.Sureweld 6010 adapts exceptionally well to vertical and overhead projects on all mild steels. It can also be used to weldlow alloy and high resistance steels where the thickness of the sections is 1/4” or less. Sureweld 6010 is used extensivelyin the welding of holding tanks, freight cars, and truck chassis.Classifications:AWS A5.1:E6010Industry or Segmentation:Industrial and General Fabrication, Mobile Equipment, Ship/Barge BuildingTypical Tensile PropertiesConditionYield StrengthTensile StrengthReduction in AreaElongation427 MPa (62 ksi)490 MPa (71 ksi)65 %28 %100% CO2As WeldedTypical Weld Metal Analysis %CMnSiSP0.100.360.200.010.01Deposition DataDiameterAmpsDeposition RateEfficiency (%)2.4 mm (3/32 in.)60-80 A0.9 kg/h (2 lb/h)60 %3.2 mm (1/8 in.)85-120 A1.1 kg/h (2.4 lb/h)63.9 %4.0 mm (5/32 in.)140-175 A1.4 kg/h (3 lb/h)71.9 %5.0 mm (3/16 in.)170-210 A1.7 kg/h (3.7 lb/h)67 %esab.com1-9

COVERED (STICK) ELECTRODES (SMAW)MILD STEEL ELECTRODESSureweld 6011 Sureweld 6011 is an all-position, cellulosic type electrode designed for AC. It produces an easily controlled forcefularc with deep penetration and a high quality weld metal which will pass specification requirements for radiography.Sureweld 6011 is used primarily for welding mild steels such as ASTM A-36, A-283, A-284, A-285, A-515, A516and ABS hull and boiler steel. Typical applications include welding of buildings, piping, shipbuilding, pressure vesselsand tanks. AC-DCEP (Electrode Positive).Classifications:AWS A5.1:E6011Industry or Segmentation:Industrial and General Fabrication, Mobile Equipment, Ship/Barge BuildingTypical Tensile PropertiesConditionYield StrengthTensile StrengthReduction in AreaElongationAs Welded462 MPa (67 ksi)524 MPa (76 ksi)56 %22 %Typical Weld Metal Analysis %CMnSiSP0.100.360.150.0120.012DiameterOptimal AmpsAmpsDeposition RateEfficiency (%)2.4 mm (3/32 in.)70 A60-80 A0.9 kg/h (2 lb/h)60 %3.2 mm (1/8 in.)100 A85-120 A1.1 kg/h (2.4 lb/h)70 %4.0 mm (5/32 in.)140 A140-175 A1.7 kg/h (3.7 lb/h)77 %5.0 mm (3/16 in.)180 A170-210 A1.8 kg/h (4.1 lb/h)73 %Deposition Data1-10esab.com

COVERED (STICK) ELECTRODES (SMAW)MILD STEEL ELECTRODESSureweld 6013 Sureweld 6013 is an all-position electrode. The arc is very stable even when low-voltage open circuit transformers areused. The power of its arc allows depositing quick welds, medium penetration, and good appearance. Sureweld 6013eliminates the risk of trapping the slag due to its special characteristics and mineral coating. Sureweld 6013 is usedon a wide array of mild steel fabrication where ease of operation and good appearance is required. Sureweld 6013 isrecommended for welding vehicle bodies, profiles, tanks, ducts chassis, freight cars, ornamental jobs and thin-sheetstructures.Classifications:AWS A5.1:E6013Approvals:CWB CSA W48: E4913Industry or Segmentation:Industrial and General Fabrication, Mobile Equipment, Ship/Barge BuildingTypical Tensile PropertiesConditionYield StrengthTensile StrengthReduction in AreaElongationAs Welded482 MPa (70 ksi)558 MPa (81 ksi)55 %27 %Typical Charpy V-Notch PropertiesConditionTesting TemperatureImpact ValueAs Welded0 C (32 F)47 J (35 ft-lb)Typical Weld Metal Analysis .05Deposition DataDiameterAmpsDeposition RateEfficiency (%)2.4 mm (3/32 in.)60-90 A0.7 kg/h (1.6 lb/h)73 %3.2 mm (1/8 in.)120-135 A1 kg/h (2.1 lb/h)73 %4.0 mm (5/32 in.)145-190 A1.2 kg/h (2.6 lb/h)75 %4.0 mm (5/32 in.)145-190 A1.45 kg/h (3 lb/h)74 %esab.com1-11

COVERED (STICK) ELECTRODES (SMAW)MILD STEEL ELECTRODESSureweld 7014 Sureweld 7014 is an iron powder coated electrode permitting the use of higher welding currents while improving thedeposition rate. The use of an iron powder coating also improves deposition efficiency. High speeds and high heats canbe used without undercut. Slag removal is excellent. Sureweld 7014 is widely used for welding mild steels such as ASTMA-36, A-113, A-283, A-284, A-285, A-306, A-515 and A-516. Typical applications include construction equipment, metalfixtures, automotive parts, barges and farm machinery.Classifications:AWS A5.1:E7014Industry or Segmentation:Industrial and General Fabrication, Mobile Equipment, Ship/Barge BuildingTypical Tensile PropertiesConditionYield StrengthTensile StrengthReduction in AreaElongationAs Welded420 MPa (61 ksi)490 MPa (71 ksi)64 %28 %Typical Weld Metal Analysis %CMnSiSP0.040.300.140.020.02Deposition DataDiameterAmpsDeposition RateEfficiency (%)2.4 mm (3/32 in.)70-100 A0.9 kg/h (2 lb/h)60 %3.2 mm (1/8 in.)100-150 A1.1 kg/h (2.4 lb/h)63.9 %3.2 mm (1/8 in.)100-150 A1.4 kg/h (3.1 lb/h)61.1 %4.0 mm (5/32 in.)160-200 A1.4 kg/h (3 lb/h)71.9 %4.0 mm (5/32 in.)160-200 A1.7 kg/h (3.7 lb/h)67 %1-12esab.com

COVERED (STICK) ELECTRODES (SMAW)MILD STEEL ELECTRODESSureweld 7024 Sureweld 7024 is a high speed, heavy-coated, iron powder electrode for high deposition rates on horizontaland downhand welding. Excellent operator appeal, produces equal 45 fillets, thereby eliminating over welding.Excellent bead appearance and self-cleaning slag. This electrode has good weldability and superior mechanicalproperties. It is particularly useful in obtaining increased penetration with little or no root porosity in horizontal orpositioned fillets. Sureweld 7024 is ideal for making high speed horizontal fillet and lap welds on mild and some alloysteels, such as earthmoving and construction equipment, truck bodies, ships, barges and railcars. Sureweld 7024exceeds the AWS A5.1 elongation% and Charpy V-Notch requirements for 7024-1.Classifications:AWS A5.1:E7024, ASME SFA 5.1Approvals:CWB CSA W48: E4924Industry or Segmentation:Industrial and General Fabrication, Barges, Mobile Equipment, RailcarsApprovals are based on factory location. Please contact ESAB for more information.Typical Tensile PropertiesConditionYield StrengthTensile StrengthReduction in AreaElongationAs Welded490 MPa (71 ksi)550 MPa (81 ksi)63 %26 %Typical Charpy V-Notch PropertiesConditionTesting TemperatureImpact ValueAs Welded-18 C (0 F)34 J (25 ft-lb)Typical Weld Metal Analysis %CMnSiSP0.060.800.300.0180.01DiameterOptimal AmpsAmpsDeposition RateEfficiency (%)4.0 mm (5/32 in.)180 A180-240 A2.4 kg/h (5.3 lb/h)71.3 %4.0 mm (5/32 in.)210 A180-240 A2.9 kg/h (6.3 lb/h)72.5 %4.0 mm (5/32 in.)240 A180-240 A3.3 kg/h (7.2 lb/h)69.4 %4.8 mm (3/16 in.)245 A250-290 A3.4 kg/h (7.5 lb/h)69.2 %4.8 mm (3/16 in.)270 A250-290 A3.8 kg/h (8.3 lb/h)70.5 %4.8 mm (3/16 in.)290 A250-290 A4.1 kg/h (9.1 lb/h)68 %5.6 mm (7/32 in.)320 A300-340 A4.3 kg/h (9.4 lb/h)72.4 %5.6 mm (7/32 in.)360 A300-340 A5.3 kg/h (11.6 lb/h)69.1 %6.4 mm (1/4 in.)400 A350-400 A5.7 kg/h (12.6 lb/h)71.7 %Deposition Dataesab.com1-13

COVERED (STICK) ELECTRODES (SMAW)MILD STEEL ELECTRODESELECTRODE DIMENSION CONVERSION CHARTDiameterLength1/6 in.3.2 mm14 in.350 mm5/32 in.4.0 mm14 in.350 mm3/16 in.4.8 mm14 in.350 mm7/32 in.5.6 mm18 in.450 mm1/4 in.6.4 mm18 in.450 mmSUREWELD COATED ELECTRODE DEPOSITION DATA AND CURRENT RANGES*Electrode DiameterCurrent Range AmpsOptimum Current AmpsDeposition RateEfficiency75 A0.7 kg/hr (1.5 lb/hr)72.0 %E6010/E7010-A1/E7010-P1/E8010-P12.4 mm (3/32 in.)40-75 A3.2 mm (1/8 in.)80-140 A100 A0.9 kg/hr (2.1 lb/hr)76.3 %3.2 mm (1/8 in.)80-140 A130 A1.0 kg/hr (2.3 lb/hr)68.8 %4.0 mm (5/32 in.)130-175 A140 A1.3 kg/hr (2.8 lb/hr)73.6 %4.0 mm (5/32 in.)130-175 A170 A1.3 kg/hr (2.8 lb/hr)64.1 %4.8 mm (3/16 in.)150-210 A160 A1.5 kg/hr (3.3 lb/hr)74.9 %4.8 mm (3/16 in.)150-210 A190 A1.6 kg/hr (3.5 lb/hr)69.7 %5.6 mm (7/32 in.)180-275 A190 A2.0 kg/hr (4.5 lb/hr)76.9 %5.6 mm (7/32 in.)180-275 A230 A2.3 kg/hr (5.1 lb/hr)73.1 %E60112.4 mm (3/32 in.)60-80 A75 A0.6 kg/hr (1.3 lb/hr)61.0 %3.2 mm (1/8 in.)90-130 A120 A1.0 kg/hr (2.3 lb/hr)70.7 %4.0 mm (5/32 in.)130-160 A150 A1.7 kg/hr (3.7 lb/hr)77.0 %4.8 mm (3/16 in.)155-190 A180 A1.9 kg/hr (4.1 lb/

This electrode will produce X-ray quality joints in flat, horizontal, overhead, vertical-up, and vertical-down procedures. Sureweld 10P is recommended for welding API grades A25, A, B and X42 pipe and general structural, ship, barge and storage tank fabrication. It may also be used for welding