Transcription

Lean Daily Management SystemsSustained Improvement through Employee EngagementIowa Lean ConsortiumDes Moines, IowaPresenter: Brijesh (BK) MalhotraOctober 30th, 2019Session A4 11:00am – 12:15pmSession C93:00pm – 4:15pm375 Bridgeport Ave. Shelton Connecticut 06484 Tele 203.225.0451

Introduction Senior Consultant at Productivity Inc. – 4 Years Director, Continuous Improvement – Hershey Chocolate – 3 years Wm. Wrigley Jr. Co. – Total 18 years - (USA, EU, Asia)– 6 Years as a E2E Supply Chain Director– 2 Years Global CI– 10 years in Plant roles Merchant Marine Engineer – 10 years375 Bridgeport Ave. Shelton Connecticut 06484 Tele 203.225.0451

Objectives for today Session Objectives: Learning how to build an effective Daily Management Systems across yourplant/organization. Understanding the connection between Daily Management, employee engagement,and efficiency Understanding how “leaders as coaches” build capability at all levels of theorganization.The Problem Statement – The Why?Business NeedReflections / Questions in your mind?The What? Daily Management in a nutshellTacticsWhat do I need to do differently to be successful?How does DMS help us become successful?Leadership Responsibilities and BehaviorsHow can they best help add value?375 Bridgeport Ave. Shelton Connecticut 06484 Tele 203.225.0451

I am working hard to make this happen Are improvements being made only by experts?Are you unable to sustain gains beyond a few days?Are CI leaders unable to engage floor employees?Are your best resources busy fighting fires?Run, run, run . No time to make improvements !Low Productivity is chronic; inconsistent performance“Legacy” momentum, leadership credibility very low375 Bridgeport Ave. Shelton Connecticut 06484 Tele 203.225.0451

Setting the organization up for success First Step: Are there meaningfulgoals to driveimprovement? Is there a good line ofsight? How are we makingsure we will deliverconsistently?375 Bridgeport Ave. Shelton Connecticut 06484 Tele 203.225.0451

Strategy (Policy) DeploymentAligns the Organization on solving what matters mostProvides a Sense of Purpose for all375 Bridgeport Ave. Shelton Connecticut 06484 Tele 203.225.0451

Danaher Strategy Example 375 Bridgeport Ave. Shelton Connecticut 06484 Tele 203.225.0451

Integrated goals across the organization MarketingNew KPI’s: SalesNew KPI’s: CustomerServiceNew KPI’s: R&DNew KPI’s: QualityNew KPI’s: Supply ChainProductionNew KPI’s: New KPI’s: CustomerQCDObjectivesAll functions, departments, processes and people mustconstantly improve375 Bridgeport Ave. Shelton Connecticut 06484 Tele 203.225.0451

The Strategy Deployment CascadeCreate a Compelling Business Need (CBN)Business Model,Vision and StrategyStrategicActionsKVD(What)Target(How much)How much(Impact)Level 0Executive committeeInitiatives(How)AS(What)How much(Target)Howmuch(Impact)Level1:VP/Directorsand their teamsActions(How)How much(Target)Initiatives(What)How much(Impact)Level 2:Managers and team memberscatchball375 Bridgeport Ave. Shelton Connecticut 06484 Tele 203.225.0451

The Catchball – Employee Engagement 101 TOP DOWN– Proposed objectives andmilestones are presented– Employees: construct their owninitiatives and milestones give constructivefeedback present new facts andinformation BOTTOM UP– Proposed initiatives /plans & milestones arepresented– Managers give constructivefeedback present new facts andinformation revise their own Matrix10 The result of catchball is team alignment at the operational level through thechartering, linking, and networking of teams375 Bridgeport Ave. Shelton Connecticut 06484 Tele 203.225.0451

Create CBN goalsCBN* targets shoot for stretch improvementsacross all categoriesMetricBaseline3-yeargoalExample: Plant / Unit XYZRationale 25% reduction from Plant / Unit XYZ bestperformance (0.69 in 2012) 2nd best in network, Monterrey (0.11)SafetyDART rate3.520.52QualityConsumercomplaint ratio2.401.7Lbs / labor hr5.30%3.2%Waste &overweight124.93152.79 40% reduction in In- Process defects 25% reduction in Re-workCase fill rate97.3%98.5% Return to 2010 level sustained 98.5%case fill rate for the full yearCostDeliveryEngagement*CBN – Compelling Business NeedEngagementscore46.7%65% Surpass Plant / Unit ABC becomingnumber 4 in the network 50% YoY reduction in stops 30% reduction in breakdowns 50% reduction in changeover time 11% annual increase by focusing on lowperforming categories Surpass 2014 US manufacturing score of54.2%375 Bridgeport Ave. Shelton Connecticut 06484 Tele 203.225.0451

Principles of Strategy DeploymentFrom vision to daily work Can every member of your organizationexplain the strategic objectives? Can they describe the link between theirdaily work and the strategic objectives? Does everyone understand the metricsthey are working to improve? How do we progress beyond our dailywork?A strong Daily Management System helps execute toachieve this “line of sight” 375 Bridgeport Ave. Shelton Connecticut 06484 Tele 203.225.0451

Strategy Deployment is great but .375 Bridgeport Ave. Shelton Connecticut 06484 Tele 203.225.0451

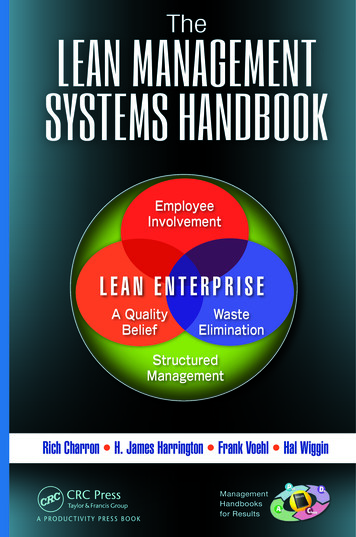

So let’s check a few “culture” boxes first .Lean is a culture, not a set of tools Serve value adding process owners – improve their work life Push decision making, ownership down to workplace Build capable, autonomous leaders in the organization Build a larger Problem Solving community through standards, tools Embed real time analytics into Daily Work flows Stay laser focused on measures that matter Communicate information in an easy, visual way Rewards and recognition375 Bridgeport Ave. Shelton Connecticut 06484 Tele 203.225.0451

DMS aligns to Change Management Process frameworkDaily DirectionResourcesTools / Methods375 Bridgeport Ave. Shelton Connecticut 06484 Tele 203.225.0451

Daily Management focuses teams on creating loss-focusedaction plansEnhances communication andleverages metrics.To create a daily plan toachieve performance targetsTight consistent agendaLoss-focused metricsPLANData driven prioritization& planningConsistently communicatedVisual boardsLoss focused and data drivenCreates accountabilityClear delineation ofresponsibilitiesAllocates resources effectively375 Bridgeport Ave. Shelton Connecticut 06484 Tele 203.225.0451

From Reactive to Proactive Lean is a 80% cultural, 20% tools Undefined goals Reacting / Fire fighting Problems are hidden, nodata Few experts solve problems Blame, disengagement Tribal knowledge No room for new ideas,change Measureable ObjectivesProactive managementManaging to standardsProblems are visibleData-based problem solvingLeaders on floor solvingproblems Everyone is engaged insolutions375 Bridgeport Ave. Shelton Connecticut 06484 Tele 203.225.0451

Leadership at all levels drives results by linking daily work“standards” to business imperatives .Important to connect and monitormeasureable metrics at all levels .ENTERPRISE LEVEL Customer Satisfaction Margin, Free-Up Cash Flow Preferred Employer of choiceMONTHLYMID MANAGEMENT Safety, QualityOn time Delivery, Project Mgmt.After sales serviceIntegrated LeadershipWEEKLYFIELD OPSShared StandardsFlexible Implementation Safety, QualityReduced downtime, reworkWorkplace organizationLean improvementsSkills, Employee engagementDAILY375 Bridgeport Ave. Shelton Connecticut 06484 Tele 203.225.0451

Huddles and Boards . General Principles:– Located where the work takes place– Organized into few macro topics with PDCA– Reviewed, information updated on each shift bythe employees– Review is led by Supervisor (good), Employee(better), Employee Rotation (best) Metrics must be relevant to the problems on the floor:––––Safety and Quality status & problemsProductivity constraints & problemsInventory ControlProcess Improvements19375 Bridgeport Ave. Shelton Connecticut 06484 Tele 203.225.0451

Daily Accountability DMB’s allow anyone to know how the team is doing & whatneeds to be worked on: what went right today, what went wrong? what did we learn today? what are we going to do tomorrow to make it better? what help do we need?20375 Bridgeport Ave. Shelton Connecticut 06484 Tele 203.225.0451

Operational Area review board displaystrends for key metricsDefect handlingRCOBU MeetingHealth CheckCheckHealth# Defectsfoundvs.%DefectsCIL taskscompleted%differenceof actualvs. #foundvs.# Defectsfixed for C/Os # Defects fixedtargetduration1-Dec8-Dec15-Dec22-DecBU Meeting Health Check1Did the meeting start on time?111123Was the entire team present and engaged?Was all information recorded before the meeting?011110114Did the team cover all information? in order?10015Did the team create a plan for the day?11106Did the team create a plan for planned maintenanceto address top losses?Were action items from the previous day sDDSTeam Lead MeetingHealth Check1-Dec8-Dec15-Dec22-DecTeam Lead Meeting HealthCheck1Did the meeting start on time?11112Was the entire team present and engaged?01113Were all metrics recorded?1014Did the team cover all information? in order?10015Did the team create a plan for the shift?11106Were all action items recorded?11117Were action items from previous shift completed?C/LCILRCOC/LC/Lstaskscheckedvs.% CILcompleted% C/Ls on targetdifferenceof vs.actual vs.% C/Lscheckedtarget%C/Lsdurationon targetfor C/OsFollow ups:ups:FollowFollow ups:ups:FollowFollow ups:ups:FollowFollow ups:ups:FollowMTBF# BreakdownsWasteOverweightFollow ups:Follow ups:Follow ups:Follow ups:Unplanned DT as % ofscheduled timePlanned DT as % ofscheduled timeC/O as % ofscheduled timeOEEFollow ups:Follow ups:Follow ups:Follow ups:1111186%71%86%86%1-Dec8-Dec15-Dec22-Dec1Did the meeting start on time?11112Were all operators present and engaged?11013Did the shift supervisor cover all information?10114Did the shift supervisor cover the plan for the shiftfor the entire line? for each line area?11115Were action items assigned to operators to own?1111100%80%80% 100%OutputOperator HuddleHealth CheckOperator Huddle Health CheckCILDefectHandling

Dashboard records historical data for key metrics and tracksprogress toward meeting targetsLine 1 Metric DashboardWeekWeek EndingIn Process MeasuresTime Spent on ChangeoversTime Scheduled for Changeovers(Standard Hours)Time Scheduled for Changeovers(Using 2014 Avg durations)Defects FoundDefects Fixed% of Defects that were Fixed1234561/4/2015 1/11/2015 1/18/2015 1/25/2015 2/1/2015 2/8/2015UnitsTarget:hours Standard Hours3825424Comments:44 Completed 5 changeovers and an allergen 1311624%68%65%50%67%count Defects Found%100%9 Notifications entered for fixing remaining defects.100% CILs scheduled at standard times on each shift.84% Scheduling huddles to discuss CL completion in the firsthour of production. This will help avoid misses on short88% runs.Comments:% CILs Completed%100%69%89%81%90%% Centerlines Checked%100%60%97%100%85%92%% Centerlines on 903.083.512.62MTBF MoldinghoursTBD2.602.003.362.72# Breakdownscount021748OEE 2%62%65.8%54.7%48.9%48.5%66.4%Line Efficiency% 100%86.5%112.0%94.0%107.2%94.4%111.2%Output MeasuresMTBF WrappingTraining Progression - % Complete2.46 MTBF was driven down by the large number ofchangeovers and start-ups.1.095 Top breakdown was wrapper #3 date coder.34.5% Lower OEE driven by weather related downtime andchangeovers.Comments:UnitsTarget:Defect .0%ChangeoversBusiness ImpactComments:UnitsWasteUSD 195 4,978 2,496OverweightUSD 583 1,031 2,982Direct Labor Efficiency VarianceUSD( 1,569)Changeover Time Reduced vs. StandardChangeover Time Reduced vs. 2014Average1TotalUSDCumulative Total YTD 3,448 3,109 2,591 2,323 ( 1,803)( 1,515) ( 1,176) ( 1,325)USDUSD 1,442 ( 1,140) 112 ( 19,331) 2,300 4,117 12,260 Large waste positivity due to running Canadian items. Wecontinue to trend very well on OW%. 1,572 1,393 0 ( 1,416) 220 4,824( 791) 5,936 3,162 3,410( 18,543) 13,809( 791) 5,145 8,307 11,717( 6,826) 6,983

Safety PDCA Near misses, Unsafe observations23375 Bridgeport Ave. Shelton Connecticut 06484 Tele 203.225.0451Daily Management

375 Bridgeport Ave. Shelton Connecticut 06484 Tele 203.225.0451

375 Bridgeport Ave. Shelton Connecticut 06484 Tele 203.225.0451

How do I audit the DMB? Do actions specifically close the gap between actual & plan? Are metrics presented in a visual way & can be understood bysomeone outside the department? Are the metrics relevant to the problems and aligned through to allthe process owners? Do employees from upstream/downstream attend the DMB check? Does peer coaching or teaching occur? Are countermeasures included in standards and communicated?26375 Bridgeport Ave. Shelton Connecticut 06484 Tele 203.225.0451

Quality - Right First Time PDCA Defects, Yield, Scrap, ErrorsPlanLess than5443322110DoCheckAct4Stopper Rod DDR's per weekF day F nt S day S nt S day S nt M day M nt T day T nt W day W nt T day T ionOwnerCheck stopper rods setupsJ.FTAKE BOX 93 & 96 TO MACHINE SHOP TO CHECK CYLINDERSDS427375 Bridgeport Ave. Shelton Connecticut 06484 Tele 203.225.0451Daily Management

Customer Service PDCAProductivity, Changeovers, Schedule Adherence Connects status of product throughput vs. planNon-Ops Examples: Finance – Good management of cash Human Resources – Open positions filled tomeet staffing requirements Engineering – Capital projects closed on timeto budget28375 Bridgeport Ave. Shelton Connecticut 06484 Tele 203.225.0451

Lean Improvements in Marketing Streamline the promotional events process Improve export campaign’s efficiency and ime reduction from 3weeks to 4 days for simplepromotional packs 2 major marketingcampaigns/yearA new annual Marketing /Sales Calendar375 Bridgeport Ave. Shelton Connecticut 06484 Tele 203.225.0451

Daily Management can be implemented in eachDepartment: Customer Service – Laboratory – Marketingand Sales – HR – Finance

Lean Daily Management in Laboratory Improve our Service to direct customers:– Improve overall efficiency in Chemical and MicrobiologicallabsLeadtime reduction from 20/30days to 7-daysReleased extra capacity in Labeliminating outsourcingReduction of personnel turnoverPositive environment375 Bridgeport Ave. Shelton Connecticut 06484 Tele 203.225.0451

Operational Excellence in Sales Review the Tender Process (Sales, Marketing,Finance, Quality) for Private LabelsLeadtime reductionfrom 4-weeks to 2weeks Optimize Product Development for Private Labelproducts (R&D, Quality, Marketing and Sales)Conversion Rate: 40%– Ongoing project375 Bridgeport Ave. Shelton Connecticut 06484 Tele 203.225.0451

Lean in HR The Challenge: reduce time spent inadministrative activities (from beginning to the endof employee contract) to increase time availablefor Business and managers support.Creation of shared standardsReduction of anomalies and leadtimeon payrollsIntroduction of new softwareFull compliance to legislation for allcontractsHR backup teams between sites 375 Bridgeport Ave. Shelton Connecticut 06484 Tele 203.225.0451

Role of Leadership . Understand the customer, their needs for the foreseeable future Declare a “Compelling Business Need” with aggressive 2-3 year goals forimprovement (Safety, Quality, Service, Cost, Employee Engagement) Cascade these goals as the only goals with which to measure organizationalperformance “Front load” top talent, , capital at every site to assist / deploy themethodologies Be accountable to the results, metrics directly linked to Lean results Institutionalize tools and terminology and apply them in daily work375 Bridgeport Ave. Shelton Connecticut 06484 Tele 203.225.0451

Leadership behaviors .Build a Problem Solving culture of process excellenceThe “right thing” to do?Leadership in the fieldLeaders as coaches, Servant LeadershipGrowing and developing peopleKnow / understand the issuesBuild standardized processesDedicate resources to problem solvingFocus on standard workLinkage of all work to chronic losses375 Bridgeport Ave. Shelton Connecticut 06484 Tele 203.225.0451

Leadership Behaviors - Servant LeadershipInvert the Org Chart, Build a Problem Solving culture375 Bridgeport Ave. Shelton Connecticut 06484 Tele 203.225.0451

Leadership Behaviors - Daily ManagementLeadership must show daily routines that take care of the people whotake care of the customersLeaders as teachers, going into the workplace with purposeDaily rigor, structured communication, and ever evolving standard workEnsure that leadership aspirations are directly aligned with daily work375 Bridgeport Ave. Shelton Connecticut 06484 Tele 203.225.0451

Title of Presentation375 Bridgeport Ave. Shelton Connecticut 06484 Tele 203.225.04513

Process Excellence & Importance of StandardsWhy improvements don’t stick?What is a Standard? (or lack thereof)A current best way to perform a task or deliver a service“Without standards, there can be noimprovement”“Standards should not be forced down fromabove but rather set by working with theproduction workers themselves.”-Taiichi Ohno(founding father of the Toyota ProductionSystem)375 Bridgeport Ave. Shelton Connecticut 06484 Tele 203.225.0451

Employee EngagementThere is a near perfectcorrelation between theperformance of anorganization and thedemonstrated competenceof the people in theroles to which they areassignedPut your best people incharge of leading yourtransformation processCarefully manage buildingcapabilities in thischanging environment375 Bridgeport Ave. Shelton Connecticut 06484 Tele 203.225.0451

Q&A375 Bridgeport Ave. Shelton Connecticut 06484 Tele 203.225.0451

Lean Daily Management Systems Sustained Improvement through Employee Engagement Iowa Lean Consortium Des Moines, Iowa. Presenter: Brijesh (BK) Malhotra. October 30. th, 2019.