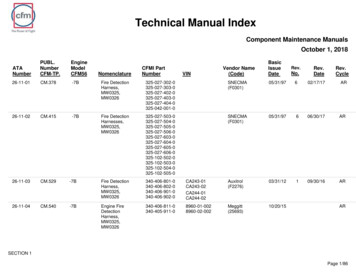

Transcription

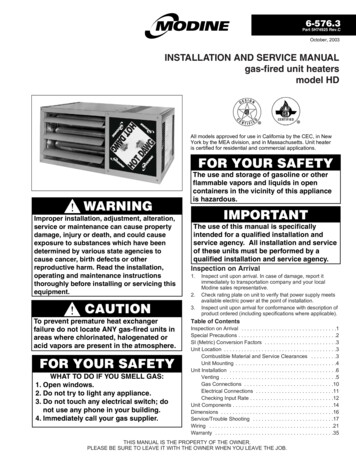

6-576.3Part 5H74925 Rev.COctober, 2003INSTALLATION AND SERVICE MANUALgas-fired unit heatersmodel HDAll models approved for use in California by the CEC, in NewYork by the MEA division, and in Massachusetts. Unit heateris certified for residential and commercial applications.FOR YOUR SAFETYWARNINGImproper installation, adjustment, alteration,service or maintenance can cause propertydamage, injury or death, and could causeexposure to substances which have beendetermined by various state agencies tocause cancer, birth defects or otherreproductive harm. Read the installation,operating and maintenance instructionsthoroughly before installing or servicing thisequipment.CAUTIONTo prevent premature heat exchangerfailure do not locate ANY gas-fired units inareas where chlorinated, halogenated oracid vapors are present in the atmosphere.FOR YOUR SAFETYWHAT TO DO IF YOU SMELL GAS:1. Open windows.2. Do not try to light any appliance.3. Do not touch any electrical switch; donot use any phone in your building.4. Immediately call your gas supplier.The use and storage of gasoline or otherflammable vapors and liquids in opencontainers in the vicinity of this applianceis hazardous.IMPORTANTThe use of this manual is specificallyintended for a qualified installation andservice agency. All installation and serviceof these units must be performed by aqualified installation and service agency.Inspection on Arrival1.2.3.Inspect unit upon arrival. In case of damage, report itimmediately to transportation company and your localModine sales representative.Check rating plate on unit to verify that power supply meetsavailable electric power at the point of installation.Inspect unit upon arrival for conformance with description ofproduct ordered (including specifications where applicable).Table of ContentsInspection on Arrival . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1Special Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2SI (Metric) Conversion Factors . . . . . . . . . . . . . . . . . . . . . . . . .3Unit Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3Combustible Material and Service Clearances . . . . . . . . .3Unit Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4Unit Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6Venting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5Gas Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10Electrical Connections . . . . . . . . . . . . . . . . . . . . . . . . . . .11Checking Input Rate . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12Unit Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16Service/Trouble Shooting . . . . . . . . . . . . . . . . . . . . . . . . . . . .17Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35THIS MANUAL IS THE PROPERTY OF THE OWNER.PLEASE BE SURE TO LEAVE IT WITH THE OWNER WHEN YOU LEAVE THE JOB.

SPECIAL PRECAUTIONS/TABLE OF CONTENTSSPECIAL PRECAUTIONSTHE INSTALLATION AND MAINTENANCE INSTRUCTIONS IN THISMANUAL MUST BE FOLLOWED TO PROVIDE SAFE, EFFICIENTAND TROUBLE-FREE OPERATION. IN ADDITION, PARTICULARCARE MUST BE EXERCISED REGARDING THE SPECIALPRECAUTIONS LISTED BELOW. FAILURE TO PROPERLYADDRESS THESE CRITICAL AREAS COULD RESULT IN PROPERTYDAMAGE OR LOSS, PERSONAL INJURY, OR DEATH. THESEINSTRUCTIONS SUBJECT TO ANY MORE RESTRICTIVE LOCAL ORNATIONAL CODES.HAZARD INTENSITY LEVELS1.2.3.4.DANGER: Indicates an imminently hazardous situationwhich, if not avoided, WILL result in death or serious injury.WARNING: Indicates a potentially hazardous situationwhich, if not avoided, COULD result in death or serious injury.CAUTION: Indicates a potentially hazardous situation which,if not avoided, MAY result in minor or moderate injury.IMPORTANT: Indicates a situation which, if not avoided,MAY result in a potential safety concern.DANGERAppliances must not be installed where they may be exposedto a potentially explosive or flammable atmosphere.WARNING1. Gas fired heating equipment must be vented - do notoperate unvented.2. A built-in power exhauster is provided - additional externalpower exhausters are not required or permitted.3. All field gas piping must be pressure/leak tested prior tooperation. Never use an open flame. Use a soap solution orequivalent for testing.4. Gas pressure to appliance controls must never exceed 14"W.C. (1/2 psi).5. Disconnect power supply before making wiring connectionsto prevent electrical shock and equipment damage.6. All appliances must be wired strictly in accordance withwiring diagram furnished with the appliance. Any wiringdifferent from the wiring diagram could result in a hazard topersons and property.7. Any original factory wiring that requires replacement mustbe replaced with wiring material having a temperaturerating of at least 105 C.8. When servicing or repairing this equipment, use onlyfactory-approved service replacement parts. A completereplacements parts list may be obtained by contactingthe factory. Refer to the rating plate on the appliance forcomplete appliance model number, serial number, andcompany address. Any substitution of parts or controls notapproved by the factory will be at the owners risk.9. If you are replacing an existing heater, it may be necessaryto resize the venting systems. Improperly sized ventingsystems can result in vent gas leakage or the formation ofcondensate. Refer to the National Fuel Gas Code ANSIZ223.1 or CAN/CGA B149.1 or .2 latest edition. Failure tofollow these instructions can result in injury or death.10. To reduce the opportunity for condensation, the minimumsea level input to the appliance, as indicated on the serialplate, must not be less than 5% below the rated input, or5% below the minimum rated input of duel rated units.11. Ensure that the supply voltage to the appliance, asindicated on the serial plate, is not 5% greater than therated voltage.2CAUTION1. Installation must conform with local building codes or in theabsence of local codes, with Part 7, Venting of Equipment,of the National Fuel Gas Code, ANSI Z223.1 (NFPA 54) latest edition. In Canada installation must be in accordancewith CAN/CGA-B149.1 for natural gas units, andCAN/CGA-B149.2 for propane units.2. Consult piping, electrical, and venting instructions in thismanual before final installation.3. Turn off all gas before installing appliance.4. Do not locate units in tightly sealed rooms or smallcompartments (commonly referred to as confined spaces)without provisions for adequate combustion air and venting.Combustion air must have access to the confined spacethrough a minimum of two permanent openings in theenclosure, at least one near the bottom. They shouldprovide a free area of one square inch per 10,000 BTU/Hrinput rating of the unit with a minimum of 100 square inchesfor each opening, whichever is greater.5. When leak testing the gas supply piping system, theappliance and its combination gas control must be isolatedduring any pressure testing in excess of 14" W.C. (1/2 psi).6. Check the gas inlet pressure at the unit upstream of thecombination gas control. The inlet pressure should be 6-7"W.C. on natural gas or 12-14" W.C. on propane. If inletpressure is too high, install an additional pressure regulatorupstream of the combination gas control.7. Purging of air from gas supply line should be performed asdescribed in ANSI Z223.1 - latest edition “National FuelGas Code”, or in Canada in CAN/CGA-B149 codes.8. The minimum distance from combustible material is basedon the combustible material surface not exceeding 160 F.Clearance from the top of the unit may be required to begreater then the minimum specified if heat damage, otherthan fire, may occur to materials above the unit heater atthe temperature described.9. Do not attempt to reuse any mechanical or electronicignition controllers which has been wet. Replace defectivecontroller.10. Do not install unit outdoors.11. Servicing or repairing of this equipment must be performedby a qualified service agency.12. Do not install units below 7' measured from the bottom ofthe unit to the floor in commercial applications and 5'measured from the bottom of the unit to the floor inresidential applications.13. Be sure no obstructions block air intake and discharge ofunit heaters.14. Allow 18" of clearance at rear (or 6" beyond end of motor atrear of unit, whichever is greater) and access side toprovide ample air for combustion and proper operation of fan.15. Installation of units in high humidity or salt wateratmospheres will cause accelerated corrosion resulting in areduction of the normal life of the units.16. The unit should be isolated from the gas supply pipingsystem by closing its field installed manual shut-off valve.This manual shut-off valve should be located within 6' ofthe heater.17. In aircraft hangars, keep the bottom of the unit at least 10'from the highest surface of the wings of engine enclosureof the highest aircraft housed in the hangars and inaccordance with the requirements of the enforcing authorityand/or NFPA 409-latest edition.

SPECIAL PRECAUTIONS / SI (METRIC) CONVERSION FACTORS / UNIT LOCATIONCAUTION18. In commercial garages or other sections of aircraft hangarssuch as offices and shops which communicate with areasused for servicing or storage, keep the bottom of the unitat least 7' above the floor. In public garages, the unit mustbe installed in accordance with the Standard for ParkingStructures NFPA 88A and the Standard for Repair GaragesNFPA 88B. In Canada, installation of unit heater in airplanehangars must be in accordance with the requirements ofthe enforcing authority, and in public garages inaccordance with the current CAN/CGA-B149 codes.19. Low profile heaters are designed for use in heatingapplications with ambient temperatures between -40 Fand 90 F.20. All literature shipped with this unit should be kept forfuture use for servicing or service diagnostics. Do notdiscard any literature shipped with this unit.21. Ensure that the supply voltage to the appliance, asindicated on the serial plate, is not 5% less than the ratedvoltage.IMPORTANT1. To prevent premature heat exchanger failure, do not locateANY gas-fired appliances in areas where corrosive vapors(i.e. chlorinated, halogenated or acid) are present in theatmosphere.2. To prevent premature heat exchanger failure, the input tothe appliance as indicated on the serial plate, must notexceed the rated input by more then 5%.SI (METRIC) CONVERSION FACTORSTable 3.1To Convert Multiply By To Obtain"W.C.0.24kPapsig6.893kPa F( F-32) x 0.555 Cinches25.4mmfeet0.305metersCFM0.028m3/minTo Convert Multiply By To GENERALCAUTION1. All literature shipped with this unit should be kept for futureuse for servicing or service diagnostics. Do not discardany literature shipped with this unit.2. Consult piping, electrical, and venting instructions in thismanual before final installation.3. Do not attach ductwork, air filters, or polytubes to anypropeller unit heater.In the U.S., the installation of these units must comply with the“National Fuel Gas Code,” ANSI Z223.1, latest edition (alsoknown as NFPA 54) and other applicable local building codes.In Canada, the installation of these units must comply with localplumbing or waste water codes and other applicable codes andwith the current code CAN/CGA-B149.1 “Installation Code forNatural Gas Burning Appliances and Equipment” or CAN/CGAB149.2, “Installation Code for Propane Burning Appliances andEquipment.”1.All installation and service of these units must beperformed by a qualified installation and service agencyonly as defined in ANSI Z223.1, latest edition or in Canadaby a licensed gas fitter.2.3.4.5.This unit is certified with the controls furnished. Forreplacements parts, please order according to thereplacement parts list on serial plate. Always know yourmodel and serial numbers. The right is reserved tosubstitute other authorized controls as replacements.Unit is balanced for correct performance. Do not alter fanor operate motors at reduced speed.Information on controls is supplied separately.The same burner is used for natural and propane gas.UNIT LOCATIONDANGERAppliances must not be installed where they may be exposedto a potentially explosive or flammable atmosphere.CAUTION1. Do not locate units in tightly sealed rooms or smallcompartments (commonly referred to as confined spaces)without provisions for adequate combustion air andventing. Combustion air must have access to the confinedspace through a minimum of two permanent openings inthe enclosure, at least one near the bottom. They shouldprovide a free area of one square inch per 10,000 BTU/Hrinput rating of the unit with a minimum of 100 squareinches for each opening, whichever is greater.2. Low profile heaters are designed for use in heatingapplications with ambient temperatures between -40 Fand 90 F.3. Do not install unit outdoors.4. In commercial garages or other sections of aircraft hangarssuch as offices and shops which communicate with areasused for servicing or storage, keep the bottom of the unitat least 7' above the floor. In public garages, the unit mustbe installed in accordance with the Standard for ParkingStructures NFPA 88A and the Standard for Repair GaragesNFPA 88B. In Canada, installation of unit heater in airplanehangars must be in accordance with the requirements of theenforcing authority, and in public garages in accordance withthe current CAN/CGA-B149. codes.5. In aircraft hangars, keep the bottom of the unit at least 10'from the highest surface of the wings or engine enclosureof the highest aircraft housed in the hangars and inaccordance with the requirements of the enforcing authorityand/or NFPA 409-latest edition.6. Installation of units in high humidity or salt water atmosphereswill cause accelerated corrosion resulting in a reduction ofthe normal life of the units.IMPORTANTTo prevent premature heat exchanger failure, do not locateANY gas-fired appliances in areas where corrosive vapors(i.e. chlorinated, halogenated or acid) are present in theatmosphere.Location Recommendations1. When locating the furnace, consider general space andheating requirements, availability of gas and electricalsupply, and proximity to vent locations.2. When locating units, it is important to consider that theexhaust vent piping must be connected to the outsideatmosphere.3

UNIT LOCATION / UNIT MOUNTING3. Be sure the structural support at the unit location site isadequate to support the weight of the unit. For properoperation the unit must be installed in a level horizontalposition.4. Do not install units in locations where the flue products canbe drawn into the adjacent building openings such aswindows, fresh air intakes, etc.5. Be sure that the minimum clearances to combustiblematerials and recommended service clearances aremaintained. Units are designed for installation with theminimum clearances below:Top and bottom 1"Non-Access Side 1"Vent Connector 4"Rear 18"Access Side 18"6. Do not install units in locations where gas ignition system isexposed to water spray, rain, or dripping water.7. Mounting Height (measured from bottom of unit) at which unitheaters are installed is critical. Refer to mounting heightinformation and heat throw data on page 16 of this manual.The maximum mounting height for any unit is that heightabove which the unit will not deliver heated air to the floor.Combustion Air RequirementsThe National Fuel Gas Code defines an “unconfined space” asa space whose volume is greater than 50 cubic feet per 1,000Btu/Hr input of the installed appliance(s). A confined space is 50cubic feet or less per 1,000 Btu/Hr input of the installedappliance(s).It is not recommended to install these unit heaters into residentialconfined spaces. This recommendation is due to the concernthat at some point in time, the combustion air openings providedby the installer may become blocked or eliminated by the owner,either intentionally or unintentionally. Despite this commendation,if these units are installed into a residential confined space, seeNational Fuel Gas Code ANSI Z223.1 or CAN/CGA B149.1 or .2Installation Code, latest edition, for detailed combustion airprovisions. These requirements must be adheard to.Units installed into confined spaces in industrial/commercialinstallations, must be provided with two permanent openings,one near the top of the confined space and one near the bottomof the confined space. Each opening should have a free area ofnot less than one square inch per 1,000 BTU per hour of the totalinput rating of all units in the confined space, freelycommunicating with interior areas having, in turn, adequateinfiltration from the outside.For further details on supplying combustion or to a confined(tightly sealed) space or unconfined space, see the National FuelGas Code ANSI Z223.1 or CAN/CGA B149.1 or .2 InstallationCode, latest edition.Turning The Unit 180 All units are produced at the factory with left-side controls, whenlooking at the unit. If the installation requires that the controls beon the right side, the unit heater can be “turned over”. In addition,the following instructions must be followed: By turning the unit 180 from the way it was received fromthe factory, the sides become opposite but the front andback remain in the same relative position. The bottom panelnow becomes the top panel and vice-versa. Remove the access panel, turn it 180 , and re-attach it tothe unit. This is important so that all the information labelscan be read. Remove the spring loaded deflector blades, turn them over,replace, and adjust so they are open and in a position todirect the heated air down to the floor.4UNIT SUSPENSIONCAUTION1. Do not install units below 7' measured from the bottom ofthe unit to the floor in commercial applications and 5'measured from the bottom of the unit to the floor inresidential applications.2. Be sure no obstructions block air intake and dischargeof unit heaters.3. The minimum distance from combustible material isbased on the combustible material surface notexceeding 160 F. Clearance from the top of the unitmay be requited to be greater than the minimumspecified if heat damage, other than fire, may occur tomaterials above the unit heater at the temperaturedescribed.4. Allow 18" clearance at rear (or 6" beyond end of motorat rear of unit, whichever is greater) and access side toprovide ample air for combustion and proper operationof fan.1.Be sure the means of suspension is adequate to supportthe weight of the unit (see page 16 for unit weights).2. For proper operation, the unit must be installed in a levelhorizontal position.3. Clearances to combustibles as previously specified must bestrictly maintained.4. Mounting bracket installation:Before lifting the heater for suspension, the mountingbrackets must be installed. Decide if the unit will beinstalled as standard; that is with left-side controls whenlooking at the front of the unit or with right-side controls.For standard (left side)remove brackets from shippingposition and remove the (3) screws along the top edge ofboth the front and back of unit. Align screw holes onmounting bracket with holes along front and back topedges. Secure (1) mounting bracket to front of unit withretained screws. Secure the other mounting bracket to backof unit in a similar way.For right-hand, the mounting brackets are attached in asimilar manner after the unit is turned over.5a. Suspension by screws/lag bolts:Secure the mounting brackets to the ceiling joists or truss,using 1/4" screws with

9. If you are replacing an existing heater, it may be necessary to resize the venting systems. Improperly sized venting systems can result in vent gas leakage or the formation of condensate. Refer to the National Fuel Gas Code ANSI Z223.1 or CAN/CGA B149.1 or .2 latest edition. Failure to fol