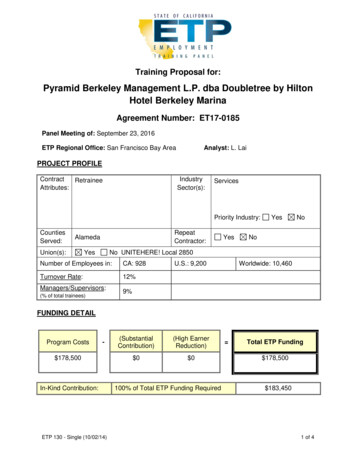

Transcription

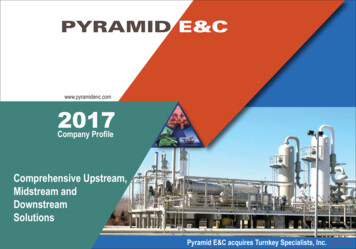

PYRAMID E&Cwww.pyramidenc.comCompany ProfileComprehensive Upstream,Midstream andDownstreamSolutionsPyramid E&C acquires Turnkey Specialists, Inc.More Inside

2017CONTENTSPyramid E&C acquires Turnkey Specialists Inc.TSI (www.turnkey-specialists.com) specializes in Oil & GasMidstream business and has a 20 year history of deliveringGas Plants, NGL Recovery units, Compression Stations andStorage facilities in North America. TSI has designed andengineered over 120 compression stations in 10 States i.e.Colorado, Florida, Louisiana, New Mexico, New York, Ohio,Oklahoma, Pennsylvania, Texas and West Virginia.This acquisition brings Pyramid E&C, a wealth of midstreamexpertise, proven track record and foothold in the US energyindustry, while for TSI this provides additional technicalcapabilities in Upstream and Downstream business,substantial financial and engineering resources, modularfabrication capabilities besides access to global markets.www.pyramidenc.com1.0Pyramid E&C1.1 Our Operations2.0Expertise2.1 Upstream: Oil & Gas Onshore2.2 Upstream: Oil & Gas Offshore2.3 Midstream2.4 Downstream: Refining & Petrochemicals2.5 Chemical & Industrial Facilities3.04.0Services3.1 Engineering3.2 Project Management3.3 Engineering, Procurement, Construction & OperationReferences4.1 Our Clients4.2 Case StudiesContacts

1Pyramid E&CPP ENGINEERINGPP PROCUREMENTPP CONSTRUCTIONPP OPERATIONPyramid E&C are a multicultural global company with our core competencein delivering Engineering, Procurement, Construction and Operationmanagement services for oil & gas production, storage, transportationand refining facilities.Founded in 1995, we have executed more than 500 projects in the Easternhemisphere and in 2016, with acquisition of TSI, we have now gained afoothold in the midsize EPC market in the US, substantially increasing ourglobal delivery capability.We have strong engineering capability, experienced project managementteams, modular fabrication facilities and reliable supply chain withoperations certified to global standards i.e. ISO 9001, 14001, 18001 and27001 as well as relevant US and European technical standards.Today, we are proud to serve the hydrocarbon industry in all geographicregions through all stages of project development, from feasibility studiesthrough engineering, project execution, delivery and operation of facilities.

1.1Pyramid E&C2017Our Operationswww.pyramidenc.comPyramid E&C Group key operations comprisesEngineering Centers of Excellence, ModularFabrication yards and Project Managementoffices strategically located to deliver projectsglobally.Houston, USAThe acquisition of Turnkey Specialists Inc. in2016 establishes our US operations and bringssignificant gas systems expertise to the Group.TSI has been operating since 1996, specializingin gas projects and has delivered more than270 projects in North America comprising gasplants, compression stations, NGL recovery,fractionation units, loading terminals andstorage facilities.Dubai, UAELondon, United KingdomDubai is our Middle East and Groupheadquarters and the financial center ofPyramid E&C Group. From here we provideservices for corporate management, sales,proposals, feasibility studies, front-endengineering, as well as project delivery intothe region.Established in 2006 as our European regionalheadquarters and specialist engineeringcenter for offshore oil & gas industry, ourLondon office provides technical expertise andspecialist services to handle fixed and floatingproduction systems, subsea engineering,human resources and strategic partnerships inEurope and Scandinavia.Mumbai, IndiaKuala Lumpur, MalaysiaEstablished in 1995, the past two decadeshave seen this center mature into a worldclass center for design and procurement witha capacity of more than a million man-hoursper annum. Here we have all the engineeringdisciplines and state-of-the-art detailingfacilities required for the hydrocarbonbusiness.Our subsidiary Pyramid Oil & Gas ConsultingSdn. Bhd. is a Petronas qualified engineeringand project management consultancy servicingthe oil & gas industry in Malaysia and the FarEast including production systems as well assubsea and marine systems.Lagos, NigeriaMundra, India - Modular FabricationIn joint venture with Westfield Energy, weoperate an engineering center to providelocal content and serve Nigerian oil & gasindustry. The center executes Master ServiceAgreements with international energy firmsoperating in Nigeria, delivering around 75,000engineering man-hours annually from localengineers.Located in a Special Economic Zone, ourMundra facility in Western India is spread overan area of 200,000 square feet. We can deliverlarge process packages of up to 800 tonnesin single modules of up to 10m x 10m x 30m.The facilities include modular assembly, pipefabrication, structural fabrication, electrical &instrument hook-up, blasting, painting, heattreatment, testing and shipping capabilities.

2ExpertisePP UpstreamPP MidstreamPP DownstreamPP Chemical & Industrial FacilitiesThe solutions for upstream oil & gas operations we provide at Pyramid E&C covergas-oil separation plants, early production facilities (EPF) and central processingfacilities (CPF).In the midstream segment, we provide tank farms and pipelines for varioustypes of hydrocarbons ranging from heavy oils to volatile fluids. For downstreamprocessing, we offer solutions for production of fuels, e.g., gasoline, kerosene,jet fuel, diesel and fuel oil. Our portfolio also includes development of chemical &industrial facilities for producing chemicals and petrochemicals, bulk drugs, steel,cement, tyres etc.Our engineering teams have a capability of about a million man-hours annually,with seasoned project management teams and a modular fabrication facilitysuited for midsize to large projects. Our fabrication facility has access to port andprocess modules can be quickly shipped in sizes to suit site logistics.We also carry out financial engineering and offer equity participation for qualifiedenergy projects. To further support project development, we invest in genericprocess plants for oil & gas production and refining, which are pre-engineeredand pre-fabricated modular units, and can be deployed on a fast-track basis.

2.1Expertise2017Upstream: Oil & Gas OnshoreFor two decades, we have been servinghydrocarbon asset owners in all stagesof asset development, from feasibilitystudies through engineering, projectexecution, delivery and operation offacilities.www.pyramidenc.comWe can offer standard solutions which can be deployed on a fast-trackbasis to accelerate monetization of assets and avoid the expensive andtime consuming traditional route of developing the project by FEED andthen EPC tender.PP Early Production SystemsEarly Production Systems are the fastest way to monetize investment with an optimal solutionfor oil fields. We offer both pre-built and custom-built designs for fast-track delivery. With ourvast experience in designing crude oil treatment facilities, we have pre-engineered solutions fora wide range of crude oils, both heavy and light, sour (high sulphur) and sweet (low sulphur).With our ability to design and manufacture most equipment in-house, we can provide optimizedfacilities quickly.PP Gas PlantsOur solutions include standard pre-engineered as well as tailored systems for treating sweet aswell as sour gas. We offer plants for recovery of NGL and LPG together with acid gas treatmentusing Joule-Thomson refrigeration or turbo-expanders, and Claus or biological sulphur recoveryunits.PP Central Production FacilitiesWe offer complete Central Production Facilities comprising oil, gas and produced watertreatment trains as well as required infrastructure, storage, utilities and sophisticatedinstrumentation. These facilities are generally stick-built but we can also offer modularsolutions up to a certain size to reduce site engagement.

2.2Expertise2017Upstream: Oil & Gas OffshorePP FPSO Topsides & ConversionPP MOPU Topsides & ConversionPP Offshore PlatformsTo meet the challenge of ever rising energy demand, oil exploration andproduction companies are venturing into new geographies never exploredbefore. With discoveries of huge oil and gas reserves in deep sea andreasonable oil prices, extracting oil from these fields becomes a financiallylucrative proposition.With our rich experience in offshore oil and gas industry including floatingproduction systems combined with our fabrication and project managementstrength, we can offer a comprehensive EPC solution for fixed andfloating offshore units including FPSO, MOPU and NUI in association withour alliance partners for marine structures, hull conversion and sides for FPSO, MOPU and NUI can be delivered on an EPC or EPCM basis.With strong engineering capability combined with our fabrication partners or ourown facility, we are poised to deliver the topsides on a fast-track basis.PPMOPU ConversionTo tap marginal wells in shallow waters, we offer a unique fast-track solution withminimal investment. Process modules are installed on refurbished jack-up drillingrigs, minimizing project schedule and cost, making marginal field developmentseconomically viable. We also offer modular early production solutions, which canbe installed on offshore drilling rigs for production operations.PPFPSO ConversionWith our EPC strength combined with our modular fabrication facility, we can offercomprehensive conversion and installation solutions for FPSO topsides productionsystems, with a single point of project responsibility.Aoka Mizu FPSO operating in North Sea

2.3Expertise2017MidstreamStorage and Transportation solutions for:PPPPPPPPPPNatural GasLiquefied ProductsCrude OilPetrochemicalsBunker Fuelswww.pyramidenc.comWe provide comprehensive EPC services for transportation and storage ofcomplete range of hydrocarbons, starting from the Methane to the heavyfuel oil and bitumen.PP Compression StationsCompression stations complete with NGL recovery units and fractionators for applicationsranging from well site to main gas transmission systems, and from high pressure turbinedriven systems to low pressure vapor recovery systems.PP Cryogenic StorageLow temperature cryogenic facilities for gaseous hydrocarbons, e.g., natural gas, propane,butane, LPG, ammonia and ethylene. We supply the facilities furnished with boil-offrefrigeration and regasification systems.PP Pressurized StorageHorton sphere or mounded bullet based plants for LPG, propylene and butylene forstorage of pressurized liquefied hydrocarbons at atmospheric temperatures.PP Atmospheric StorageFixed or floating roof installation for liquid hydrocarbon storage designed as per API 650or low pressure storage based on API 620. Our experience includes storage terminals forcrude oil, light petroleum products and heavy fuel oils.

2.4Expertise2017Downstream: Refining and Petrochemicalswww.pyramidenc.comPyramid E&C provides EPC delivery with performanceguarantees for the open-art units and works closelywith reputed technology partners for licensed units andprovides a single point solution for complete Refineryand Petrochemical facilities.For smaller installations, we have standard modulardesigns which reduce the project delivery time and cost.These units can be strategically deployed to fulfill localmarket needs and provide motor fuel security to smalland isolated populations.PP Field Diesel UnitsField Diesel Units are effective in areas where there is a ready supply of crudeoil but limited supply of diesel fuel such as sparsely populated areas, remote oilfields or drilling locations. A Field Diesel Unit can fulfill local fuel requirementsfor power generation and drilling operation. It can be started when needed andstopped once diesel storage is full and can be relocated easily.PP Diesel Topping UnitsWe supply topping units which are low investment and utilize light crude oiland condensate to produce diesel, kerosene, jet fuel, naphtha, LPG and fueloil. These refineries are pre-engineered and supplied complete with desalter,fired heater, atmospheric distillation units and all utilities required to obtain theproducts in desired specifications.PP Gasoline RefineriesWe provide complex refineries with treatment units to produce high octanegasoline along with other products obtained from diesel topping units. Theserefineries include additional units for naphtha reforming, light hydrocarbonisomerization, hydrogen purification, hydrotreating and sulphur removal. Wehave pre-engineered these plants for certain standard sizes and can deliver acombination of stick-built and modular packages to optimize time and cost.Ecomar Refinery, Fujairah

2.5Expertise2017Chemical & Industrial FacilitiesIn last two decades of operation,Pyramid E&C has gained expertisein development of several chemicalmanufacturing and industrialfacilities. With its internationalexperience and global operations,Pyramid E&C delivers facilities withstate-of-the-art technologies andbest-in-class sophistication backedby a certified quality and safetymanagement system.www.pyramidenc.comChemical and Industrial Facilities1.Petrochemicals2.Fine Chemicals3.Inorganic Chemicals4.Fertilizers5.Bulk Drugs6.Bio Ethanol and Bio Diesel7.Paints8.Tyres9.Steel Plants10. Cement Plants11. Waste to Energy Projects12. Factories and Assembly Lines

3ServicesPP 20 years of ExperiencePP 700 Projects DeliveredPP Modular Fabrication yard with port accessPP Global Delivery CapabilitiesPP Robust Quality ManagementPP 1000 000 Man-hours capacity for Engineeringand Project ManagementOur track record includes more than two decades of serving the energymarkets across the value chain at every stage of asset development.Our infrastructure and resources are aligned to deliver projects fromconcept stage to execution and operation. With our experience andextensive capabilities, we minimize external factors and mitigate projectuncertainties whilst improving delivery and quality. Our offerings includethe following services for the energy industry:PP EngineeringPP EPCMPP EPC TurnkeyPP Build Own Operate

3.1Services2017Engineeringwww.pyramidenc.comPP FEASIBILITY STUDIESOur business experts evaluate the strengths and weaknesses of the proposed project andprovide options to achieve optimal technical solution and profitability. We create bankabletechno-commercial feasibility reports covering the following aspects critical for investmentdecisions:Hydrocarbon processing is a highrisk business which needs a robustengineering capability to deliverperformance and operate safely.We have gained substantial experiencein our 20 years of operation and wehave an annual capacity of over onemillion high-quality engineering manhours covering all aspects of oil, gasand refining business.PP Development PlanningPP Technology SelectionPP Execution Model DevelopmentPP Economic ModelingPP Recommendations for Financial InvestmentPP Facility ConfigurationPP Environment Impact AssessmentPP CAPEX and OPEX BudgetingPP Risk AssessmentPP CONCEPTUAL STUDIESOur experience and extensive project database helps to make the right early decisions andmore quickly narrow down the viable concepts by referencing technical and commercialinformation from past projects without the need to conduct extensive engineering workor to scour the market for cost data. Our specialist engineers carry out developmentplanning, basic engineering, process simulation, infrastructure requirement assessment andpreliminary cost estimation to enable stakeholders choose the most suitable developmentoption.PP FRONT END ENGINEERING & DESIGN (FEED)Our multidiscipline engineering resources and experience allows us to develop conceptualstudies into front-end engineering and design (FEED) packages suitable for EPC or EPCMtendering. During the FEED phase, the project schedule, tendering philosophy, risk mitigationstrategy, work break down structure and detailed cost estimates are developed to plan theprocurement and construction phase.PP DETAILED ENGINEERINGWe have a strong team of engineers, capable of conducting detailed engineering jobfor several billion dollars worth of EPC projects. The detailed engineering facilities areequipped with state-of-the-art office infrastructure, design software, information systemsand communication facilities to seamlessly integrate with customer teams, vendors andconstruction sites.

3.2ServicesProject Management2017www.pyramidenc.comWe have domain specialists in upstream, midstream and downstream businesses and astructured project management organization comprising engineering, procurement, fabrication,health, safety, inspection, expediting, construction management, logistics departments forproject delivery assurance.Customers look toward the project managementskills of Pyramid E&C to deliver high-qualityprojects safely, within budget and on time.With our capability to offer different management models we can allow customers to choosebetween project management only or complete engineering, procurement and constructionmanagement (EPCM) models, where the group capabilities of detailed engineering, supplychain and material management can be harnessed to deliver projects more efficiently andcompetitively.To align and augment efforts, project management teams can draw from resources in thePyramid E&C Knowledge Management System, which contains a wealth of information,including technical and commercial data, archived from previous projects.Our state-of-the-art information system backbone supports the project teams, various offices,vendors and sites with necessary documents to conduct work. We use industry standard toolsfor document management, planning, scheduling and resource planning, e.g., Kronodoc ,Primavera and SAP with suitable customization.

3.3Services2017Engineering, Procurement, Construction & OperationPyramid E&C provides a single point Engineering,Procurement and Construction Solution forHydrocarbon Processing facilities with followingdelivery models as below:PPPPPPPPPPLump-sum TurnkeyCost PlusFEED to EPCReimbursableBuild, Own, OperateThe force behind Pyramid E&C comprises a very committed andcompetent team of engineers and managers producing about amillion hours of high quality work every year. With an extensive trackrecord of over two decades, we have a mature delivery capability formedium to large EPC projects. Our EPC system is technology drivenand all the operations are certified to ISO 9001, 14001, 18001 and27001 standards.www.pyramidenc.comPP Supply Chain ManagementOur strength is drawn from a reliable supply chain comprising competitive, high qualitysuppliers with proven track records in the oil & gas business. Due to our geographicalspread, we remain in close contact with qualified suppliers to keep them abreast of ourevolving needs and support them to prepare for the future.PP Modular FabricationSite work at many locations is expensive, lower in quality and creates a bottleneck in projectexecution. For such situations, we modularize the plant into smaller transportable skids andthus minimizing site work. Our module fabrication yard measuring 20,000 m² at Mundraport in Gujarat, Western India is located close to a jetty, making it possible to ship processequipment and modules weighing up to 800 tonnes in a single piece.PP Construction ManagementWe deploy our internationally certified Health, Safety and Quality management systems tothe construction sites along with a committed multidiscipline construction management team.The construction management team is supported by the information system connecting themto our specialist engineers, project, procurement and engineering offices to ensure seamlesscommunication, steady flow of construction documents and 24/7 access to executionresources.PP Build-Own-Operate-TransferOn several occasions, the hydrocarbon asset owners choose to lease assets for reasonsranging from well performance, risk mitigati

Pyramid E&C Group. From here we provide services for corporate management, sales, proposals, feasibility studies, front-end engineering, as well as project delivery into the region. Established in 20