Transcription

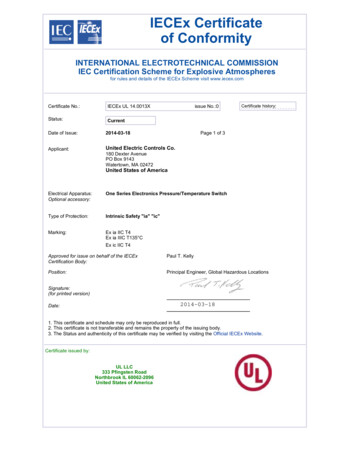

IECEx Certificateof ConformityINTERNATIONAL ELECTROTECHNICAL COMMISSIONIEC Certification Scheme for Explosive Atmospheresfor rules and details of the IECEx Scheme visit www.iecex.comCertificate No.:IECEx UL 14.0013XStatus:Currentissue No.:0Date of Issue:2014-03-18Applicant:United Electric Controls Co.Certificate history:Page 1 of 3180 Dexter AvenuePO Box 9143Watertown, MA 02472United States of AmericaElectrical Apparatus:Optional accessory:One Series Electronics Pressure/Temperature SwitchType of Protection:Intrinsic Safety "ia" "ic"Marking:Ex ia IIC T4Ex ia IIIC T135 CEx ic IIC T4Approved for issue on behalf of the IECExCertification Body:Paul T. KellyPosition:Principal Engineer, Global Hazardous LocationsSignature:(for printed version)2014-03-18Date:1. This certificate and schedule may only be reproduced in full.2. This certificate is not transferable and remains the property of the issuing body.3. The Status and authenticity of this certificate may be verified by visiting the Official IECEx Website.Certificate issued by:UL LLC333 Pfingsten RoadNorthbrook IL 60062-2096United States of America

IECEx Certificateof ConformityCertificate No.:IECEx UL 14.0013XDate of Issue:2014-03-18Issue No.: 0Page 2 of 3United Electric Controls Co.Manufacturer:180 Dexter AvenuePO Box 9143Watertown, MA 02472United States of AmericaAdditional Manufacturing location(s):This certificate is issued as verification that a sample(s), representative of production, was assessed and tested andfound to comply with the IEC Standard list below and that the manufacturer's quality system, relating to the Ex productscovered by this certificate, was assessed and found to comply with the IECEx Quality system requirements. Thiscertificate is granted subject to the conditions as set out in IECEx Scheme Rules, IECEx 02 and Operational Documentsas amended.STANDARDS:The electrical apparatus and any acceptable variations to it specified in the schedule of this certificate and the identifieddocuments, was found to comply with the following standards:IEC 60079-0 : 2011Explosive atmospheres - Part 0: General requirementsEdition: 6.0IEC 60079-11 : 2011Explosive atmospheres - Part 11: Equipment protection by intrinsic safety "i"IEC 60079-26 : 2006Explosive atmospheres - Part 26: Equipment with equipment protection level (EPL) GaEdition: 6.0Edition: 2This Certificate does not indicate compliance with electrical safety and performance requirements other than thoseexpressly included in the Standards listed above.TEST & ASSESSMENT REPORTS:A sample(s) of the equipment listed has successfully met the examination and test requirements as recorded inTest Report:US/UL/ExTR14.0022/00Quality Assessment Report:US/UL/QAR07.0002/06

IECEx Certificateof ConformityCertificate No.:IECEx UL 14.0013XDate of Issue:2014-03-18Issue No.: 0Page 3 of 3ScheduleEQUIPMENT:Equipment and systems covered by this certificate are as follows:These devices are pressure or temperature operated switches which may contain an industrial control, solidstate switch mechanism. The device consists of a single metal enclosure with a plastic cover and includes amembrane switch panel. These devices include a LCD (Liquid Crystal Display) that is protected by a Lexancover. These devices are provided with a terminal block for field installation. The metal enclosure is providedwith a conduit opening and a pressure/temperature sensor port for measuring various ranges ofpressure/temperature. The pressure sensor has a maximum rated pressure of 4,500 psi. The connections areintended to be attached to the input of a PLC (Programmable Logic Controller), DCS (Distributed ControlSystem) or in series with a load. The device derives its operating power from the leakage current associatedwith the PLC, DCS or the load that it is switching.Please see Annex for more details.CONDITIONS OF CERTIFICATION: YES as shown below: The One Series 2-Wire Electronic Pressure or Temperature Switch must be installed in accordance withControl Drawing No. 62174-20. The metallic part of the enclosure is epoxy powder coated. Cleaning of the surface should be performedwith a damp cloth only. Should the surface exhibit signs of flaking or wear, the product should beremoved from the service in hazardous locations where IECEx approvals are required. A urethane based conductive coating is applied to the faceplate perimeter. Cleaning of the surface shouldbe performed with a damp cloth only. Should the surface exhibit signs of flaking or wear, the productshould be removed from the service in hazardous locations where IECEx approvals are required. For installations in which both the Ci and Li of the connected apparatus exceeds 1% of the Co and Loparameters (excluding the cable), then 50% of Co and Lo parameters are applicable and shall not beexceeded.Annex: Annex to IECEx UL 14.0013X.pdf

Annex to IECEx UL IIII – Series Designation2W – 2-Wire SwitchII – Switch Power Designation2D – 24 VDCIII – Analog Output Type0- NoneIV – Switch Output TypeN – None (No Switch Provided0 – 2 Wire Switch (Switch/Power combined – Reference Switch Power Designation (II) foroperating voltage)V – Sensor TypeP – Type 316 Stainless Steel, Hastealloy or equivalent, piezoresistive 1/2in. NPT FemalePressure Connection.T – 2 Wire Temperature Sensor. Operating Ambient Temperature range of -40 C to 85 C.K – Differential Pressure Sensor, Type 303/316 Stainless Steel, Hastealloy or equivalent,piezoresistive ¼ in. NPT male or female pressure connection.VI – Pressure Sensor Probe Model10 – 0 to 5 psi (0 to 0.35 bar) pressure sensor11 - 0 to 15 psi (0 to 1.03 bar) pressure sensor12 - 0 to 30 psi (0 to 2.07 bar) pressure sensor13 - 0 to 50 psi (0 to 3.45 bar) pressure sensor14 - 0 to 100 psi (0 to 6.9 bar) pressure sensor15 - 0 to 300 psi (0 to 20.7 bar) pressure sensor16 - 0 to 500 psi (0 to 34.5 bar) pressure sensor17 - 0 to 1000 psi (0 to 70.0 bar) pressure sensor18 - 0 to 3000 psi (0 to 206.8 bar) pressure sensor19 - 0 to 4500 psi (0 to 315.0 bar) pressure sensorTemperature Sensor Probe ModelL1 – 4 in. (102 mm) ProbeL2 – 6 in. (102 mm) ProbeL3 – 10 in. (102 mm) Probe

R1 – 6 ft. Remote ProbeRC – Custom Length Remote ProbeH1 – 6 ft. High Temperature Remote ProbeHC – Custom Length High Temperature Remote ProbeDifferential Pressure Sensor Probe Model10 - 0 to 5 psi (0 to 0.35 bar) differential pressure sensor11 - 0 to 50 psi (0 to 3.45 bar) differential pressure sensor12 - 0 to 100 psi (0 to 6.90 bar) differential pressure sensor13 - 0 to 200 psi (0 to 13.8 bar) differential pressure sensorVII – Internal Pressure Port Material0 – Stainless Steel (360 degree welded)VIII – Miscellaneous OptionsFour character/digit alphanumeric code not affecting electrical ratings or pressure ratings of thedevice.

Certification Body: Paul T. Kelly Position: Principal Engineer, Global Hazardous Locations Signature: (for printed version) Date: 1. This certificate and schedule may only be reproduced in full. 2. This certificate is not transferable and remains the property of the issuing body. 3.